PRO SHOT L4 User manual

Introduction

Thank you for purchasing a Pro ShotTM L4 or L4+laser system. You now

have superior laser accuracy and productivity available for all your projects.

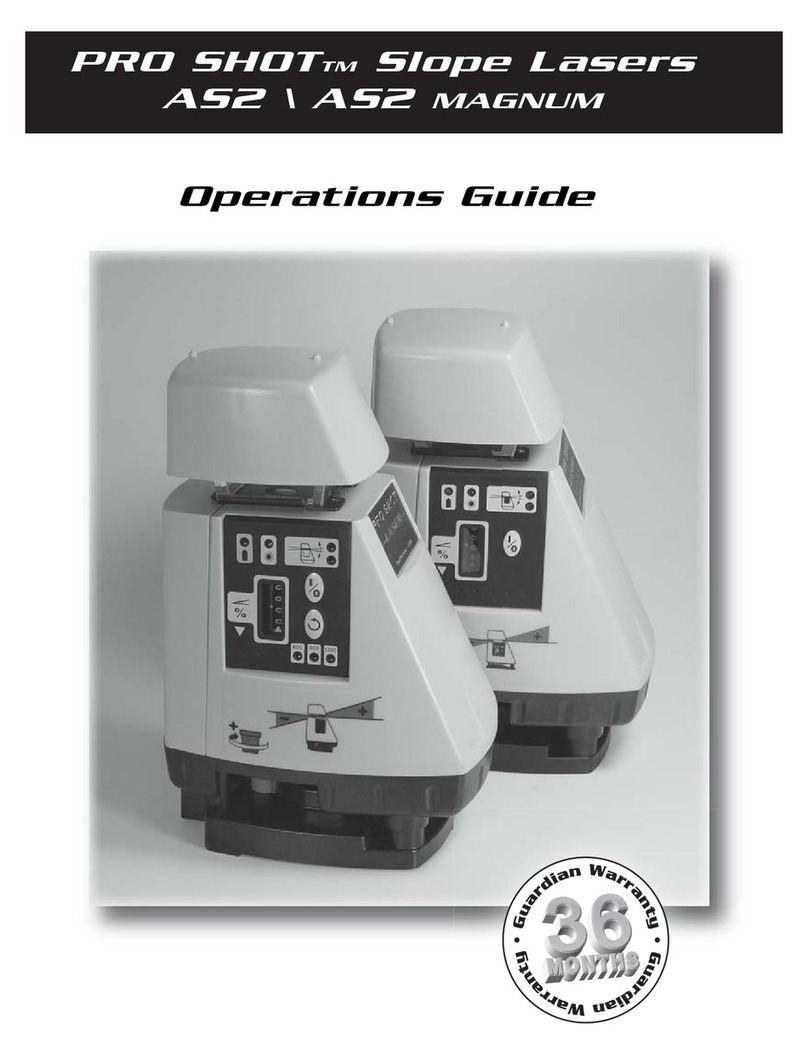

Pro ShotTM laser models L4 and L4+are rugged, reliable, high quality

products, backed by the industry leading Guardian 36 month warranty.

Warranty details are printed in the back of this manual.

Please take the time to thoroughly read this manual. It contains vital

information on how to safely get the most from your investment in laser

technology.

Contents

Battery Installation ............................................................... 1

Controls and Displays

•

L4 ................................................... 2

Controls and Displays

•

L4

+

................................................. 3

Safety

•

L4 and L4+

.........

...................................................... 4

Initial Setup Guidelines ........................................................ 6

Level Setup

•

On Tripod ....................................................... 7

Vertical & Line Layout Setup ............................................... 8

Plumb and Layout Setups

•

L4

+

........................................... 9

Applications

•

L4 ................................................................ 10

Applications

•

L4

+

............................................................... 11

Accessories ....................................................................... 12

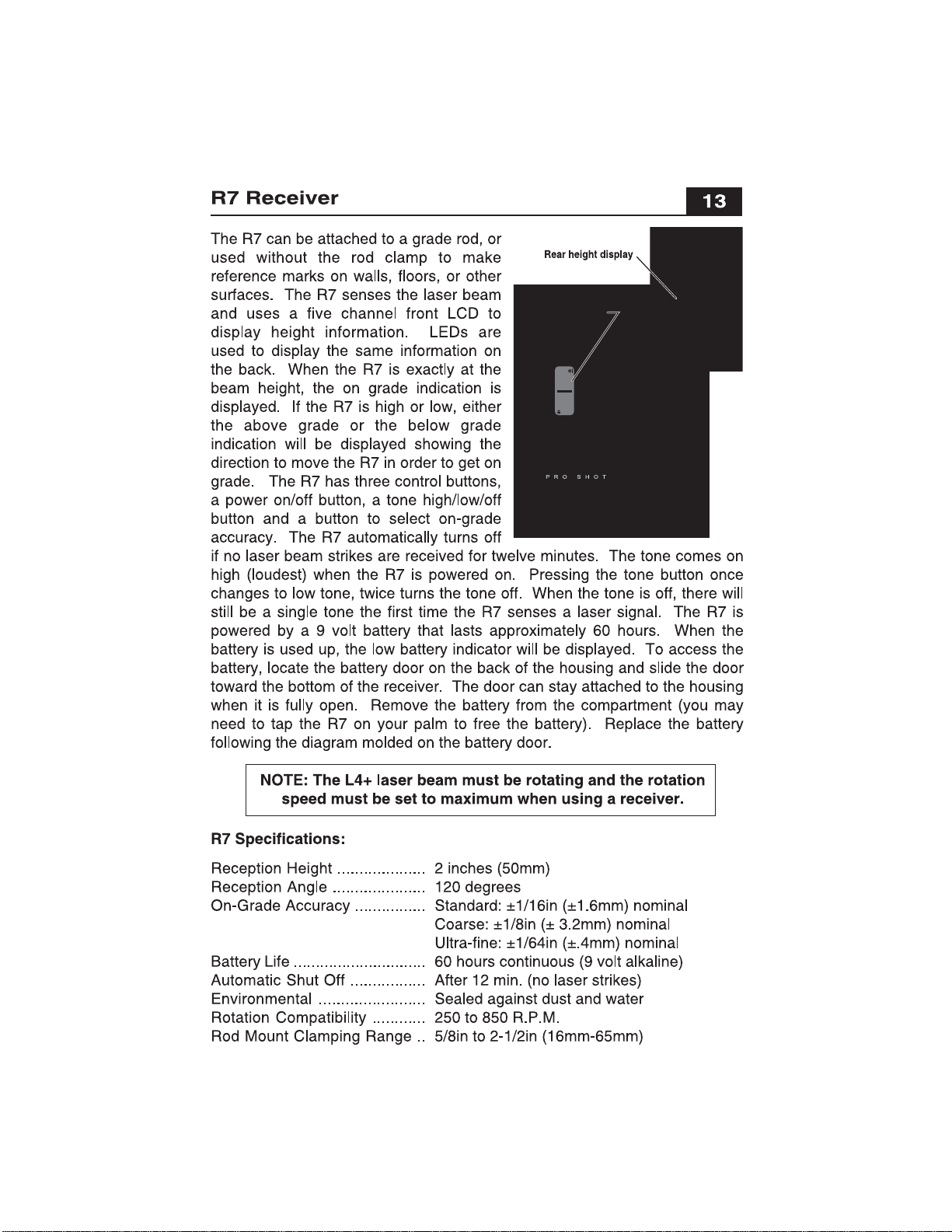

R7 Receiver ....................................................................... 13

Checking & Adjusting Calibration ...................................... 14

Maintenance and Troubleshooting .................................... 16

Guardian

Warranty and Specifications ............................ 17

1

Battery Installation

Battery charging jack

For connecting battery charger

when using rechargeable batteries.

(see pg. 12 for accessory info.)

Battery door release screw

Releases with 1/4 turn counter-

clockwise.

Battery installation

Install batteries as shown here.

For reference, a diagram is

molded onto the battery holder.

!

CHARGE ONLY

RECHARGEABLE

BATTERIES

5

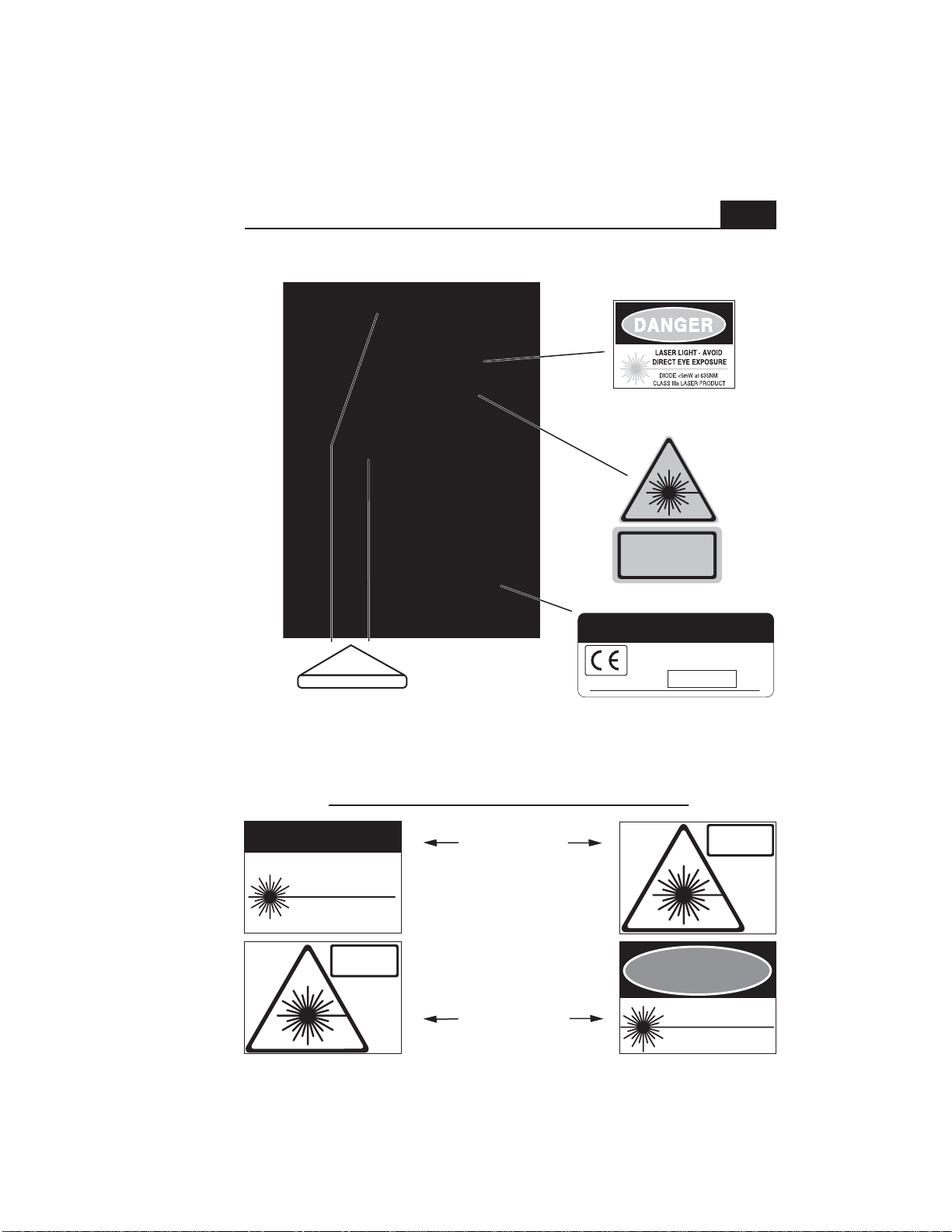

Warning, Class IIIa label for lasers

sold in the U.S. and Canada

LASER LIGHT

LASER LIGHT

DO NOT STARE INTO BEAM

OR VIEW DIRECTLY WITH

OPTICAL INSTRUMENTS

CLASS 3R LASER PRODUCT

Warning, Class 3R labels for lasers

sold where IEC standards apply

Laser

Light is emitted

from this aperture

AVOID EXPOSURE

Serial / CDRH / EC compliance

Serial No.

Manufactured by: Laser Reference, Inc.

151 Martinvale Lane •San Jose, CA 95119

This product complies with FDA

standards 21 CFR subchapter J

X 000000

Aperture

warning

Safety

•

L4 and L4+

Caution and certification label locations - L4+

Note: The L4+transmitter is a class 3R laser under the 1993 IEC 825-1 laser

safety standard and revised edition of the European Norm EN60825. The

L4+laser conforms to applicable EC directives regarding RFI and EMI.

The L4+ complies with FDA performance standards 21 CFR sub-chapter J.

L4+

(IEC)

L4

(IEC)

LASER LIGHT

LASER LIGHT

DO NOT STARE INTO BEAM

CLASS 2 LASER PRODUCT

LASER LIGHT

LASER LIGHT

DO NOT STARE INTO BEAM

OR VIEW DIRECTLY WITH

OPTICAL INSTRUMENTS

CLASS 3R LASER PRODUCT

LASER LIGHT - AVOID

DIRECT EYE EXPOSURE

DIODE <5mW at 635nm

CLASS IIIa LASER PRODUCT

DANGER

DANGER

A warning placard is included

with each laser and it can be

attached to the carrying case

and the case placed in a visible

location near where the laser

is being used to meet job site

posting requirements.

L4+

(U.S./CAN)

L4

(U.S./CAN)

CAUTION

CAUTION

LASER LIGHT

DO NOT STARE

INTO BEAM

635nm - 670nm

CLASS II LASER PRODUCT

6

Initial Setup Guidelines

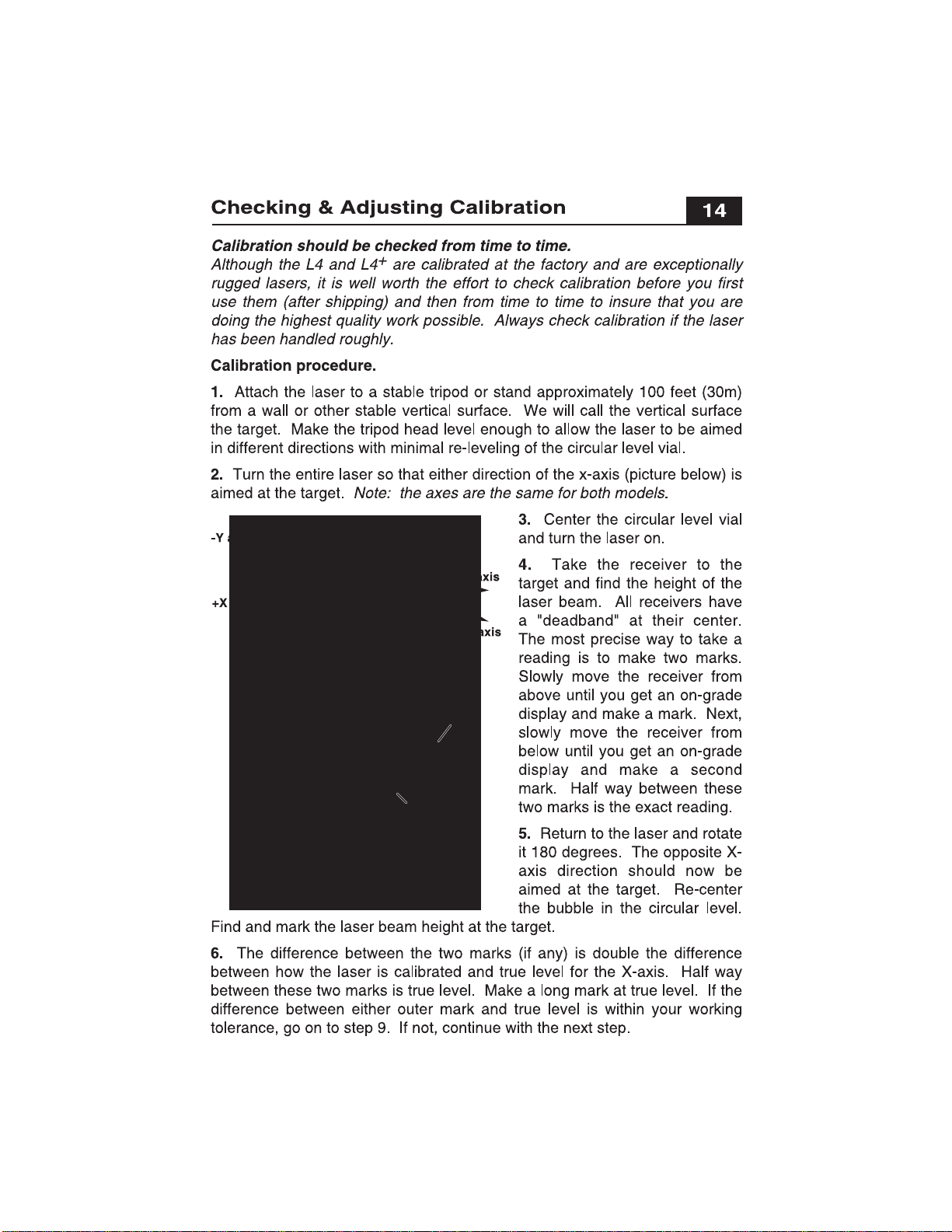

Calibration should be checked from time to time.

Although the L4 and L4+are calibrated at the factory and are exceptionally

rugged lasers, it is well worth the effort to check calibration before you first

use them (after shipping) and then from time to time to insure that you are

doing the highest quality work possible. Always check calibration if the laser

has been handled roughly. See "checking / adjusting calibration" page 14.

Check your setup.

Outdoors: Although not required, it is good jobsite practice when using any

laser or optical instrument to check your setup from time to time. Use

engineered benchmarks on the jobsite to assure that your setup is correct

and matches the design of the job. On very large sites, or where accuracy is

critical, taking a few minutes to verify the elevation marks you have been

given to work from makes sense. Even engineered benchmarks may not be

perfect and enough verification must be done to be confident you are

properly set up. If there are not suitable benchmarks on the site, you can set

your own by driving stakes and recording their elevations, or by marking the

laser beam height on stable objects such as telephone poles, concrete walls,

etc. The benchmarks should be 900apart for greatest accuracy. Having

benchmarks to check is of great value for jobs where setups need to match

day after day. If you will only be using the setup for a brief time, this may not

be needed.

Indoors: The same logic applies, if you will need to setup the laser more

than once for a particular operation, make reference marks, preferably 900

apart, along the plane of beam travel once you have set the laser up either

horizontally or vertically. Check your setup from time to time using the marks

as a guide. Use the marks as a guide for later setups.

Work as close to the laser as possible.

You can work up to 750 feet (230 meters) away from the L4, or 1000 feet

(305 meters) away from the L4+ with the R7 receiver, or with the MC-1

machine control receiver. As with all instruments, however, the further away

you work, the more any error can add up. Set the laser in a safe place, as

close to your work as possible for best results.

Maintain your equipment.

Keeping tripod and mount hardware tight, and being sure grade rods are in

good condition, can prevent errors and performance problems.

Applications

•

L4

+

11

Ceilings

Plumb Walls

Layout

Transferring points from floor to ceiling or

maintaining alignment on high-rise structures

can be accomplished very accurately with the

L4+. The low cost accessory P1 plumb plate is

used to precisely locate the L4+ over a point for

this type of work.

The W1 mount, makes vertical setups for steel

wall alignment easy. Setting the W1 mount to

the "vert" mark aligns the rotating beam with

the edge of the mount to align top, bottom

channels. The mount can then be moved to a

2" (50mm) offset to allow the magnetic targets

to be used for checking stud placement.

With its 90º fixed spot, the L4+eliminates the

need to use 3-4-5 calculations or other difficult

methods to align right-angle intersections. One

person can easily accomplish layout tasks,

even on large commercial sites.

The W1 wall and vertical mount, provided in the

system, allow the L4+to be attached to T-bar

wall angle. A "0" height mark on the W1 sets

the beam at finished ceiling elevation for

installing wall angle. A -2" (-50mm) mark sets

the beam at the center of the system magnetic

targets for installing the grid.

In addition to the outdoor capabilities of the L4, the L4+ has been designed to

perform many additional functions for interior work:

12

W1 Wall and Vertical mount

The W1 is part of the basic package for the L4+

and is an available option for the L4 to allow

vertical setups for layout work or plumbing walls

or posts in a plane.

P1 Plumb Plate

The P1 allows quick and easy setups

for getting the L4+ over a point to transfer

points from floor to ceiling.

MT1 Magnetic Target

Two Mt1 targets are included in the basic

package for the L4+. MT1 targets are available

as replacements or to allow additional workers

to use the laser on larger jobs.

B40 Rechargeable Battery Kit

The B40 kit provides four industrial

grade Ni-Mh rechargeable batteries and

a charger that plugs into the charging jack

at the rear of the laser. The batteries will

run for 50-55 hours and a full recharge

takes about 20 hours

!

CHARGE ONLY

RECHARGEABLE

BATTERIES

16

Maintenance And Troubleshooting

Calibration • There is no set interval for calibrating the L4 or L4+, but

calibration should be checked from time to time in order to ensure that the

highest possible quality of work is being done. Calibration should always be

checked if the laser has been handled roughly or shipped.

Batteries • Occasionally remove the batteries and check the contacts for

corrosion. Alkaline batteries will last far longer than carbon batteries. If you

use rechargeable batteries, be careful to never charge alkaline or carbon

batteries. The Ni-Mh batteries in the optional factory kit will need to be

charged after about 50 to 55 hours of operation. Never run the laser from

the charger unless there are rechargeable batteries installed. Keep a spare

set of batteries in the carrying case to avoid down time.

Laser output windows • Regularly check the output windows for dust and dirt.

Dust can be removed with a camera brush or clean compressed air.

Control panel and exterior • Clean the control panel and the other exterior

surfaces of the laser with a soft damp cloth.

Caution • Never store the laser in a carrying case that is wet inside. Moisture

can get inside the laser this way. Should this happen, remove the battery

cover and place the laser in a warm area until it is completely dry.

Troubleshooting

The laser will not operate, there is no obvious damage • If the low battery

indicator is on, or you suspect the batteries may be dead, replace the

batteries. Check the battery contacts to be sure that they are clean.

The receiver shows an on-grade at two different heights • Check the jobsite

for windows or mirrored surfaces that might be reflecting the laser and

causing the other reading. Check for others on the site using a rotary laser.

The laser was knocked over • Visually check the optics for damage. Inspect

the laser for any other physical damage. Use the receiver to check that the

laser is transmitting. Check the calibration and adjust as needed. Check to

see that the laser displays the "limit" light when the circular level vial bubble

moves approximately half way outside the circle.

The laser only works at short distances • Check the output windows for

heavy dust or moisture. Remove dust with a camera brush or blow off gently

with clean compressed air. Allow moisture to dry.

The receiver does not indicate "on grade" at long distance • Be sure you are

within the max distance specification from the laser. Check the windows that

surround the rotating mirror on the laser for dust or moisture. Remove dust

with a camera brush or blow off gently with clean compressed air. Allow

moisture to dry.

Warranty

Guardian

36 month warranty coverage

The L4 and L4+laser transmitters, and the R7 receiver, are warranted for

thirty-six (36) months from the date of new equipment purchase from an

authorized dealer. During the warranty period, Laser Reference, or its

authorized service center, will repair or replace, at Laser Reference's sole

discretion, laser transmitters or receivers, free of charge, (except for

transportation costs) if the products are found by Laser Reference, or its

authorized service center, to be defective in either materials or workmanship.

The Guardian 36 month warranty also covers the internal leveling

mechanism and internal optics against damage from any cause. Maintaining

the calibration of the product is not the responsibility of Laser Reference or

its authorized service centers. If service is needed, the product(s) must be

sent FREIGHT PREPAID to the nearest authorized service center or to

Laser Reference.

17

750' rad., 1500' dia. (230m/460m)

1000' rad., 2000' dia. (305m/610m)

360 degrees

±10 arc seconds (1/16" per 100')

(1.6mm per 30m)

±10 arc minutes

Built-in vial, optional mount

(L4+system includes mount)

Four C-Cell batteries

L4: 70 hours (alkaline)

L4+: 60 hours (alkaline)

If off-level for more than 3 min.

Optional kit (NiMh) 50-55 hrs. run time

Dust and water resistant

L4: 600rpm / L4+: 0 to 450rpm

-14ºf to +122ºf (-10ºc to +50ºc)

-40ºf to +140ºf (-40ºc to +60ºc)

CDRH Class II • IEC 825-1 Class 2

CDRH Class IIIa • IEC 825-1 Class 3R

9in (23cm)

4.1lbs (1.86kg)

L4 Range (with receiver) .......

L4+ Range (with receiver) .....

Rotational Coverage .............

Accuracy ...............................

Self-Leveling Range ..............

Vertical Capability .................

Power Supply ........................

Run Time on New Batteries ..

Automatic Shut-off ..............

Rechargeable Batteries .......

Environmental .......................

Rotation Speed .....................

Operating Temp. (ambient) ...

Storage Temperature ............

Safety - L4 .............................

Safety - L4+...........................

Height ....................................

Weight ...................................

Specifications

This manual suits for next models

1

Table of contents

Other PRO SHOT Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

LOVATO ELECTRIC

LOVATO ELECTRIC DME D112 installation manual

LaserLiner

LaserLiner RangeXtender 40 quick start guide

GeoMax

GeoMax Zenith35 Pro Series installation guide

Meriam

Meriam MPG2000BBL Series operating instructions

Agilent Technologies

Agilent Technologies 53147A Assembly Level Service Guide

FISCHER

FISCHER FERITSCOPE FMP30 Operator's manual