PRO SHOT AS2 MAGNUM User manual

Operations Guide

PRO SHOT

PRO SHOT

TM

TM

Slope Lasers

Slope Lasers

AS2 \ AS2

AS2 \ AS2

MAGNUM

MAGNUM

Introduction

Thank you for purchasing a Pro ShotTM AS2 or AS2 MAGNUM laser system.

You now have superior laser accuracy and productivity available for all your

projects.

Both Pro ShotTM AS2 laser models are rugged, reliable, high quality products,

backed by the industry leading Guardian 36 month warranty. Warranty

details are printed in the back of this manual.

Please take the time to thoroughly read this manual. It contains vital

information on how to safely get the most from your investment in high

performance laser technology.

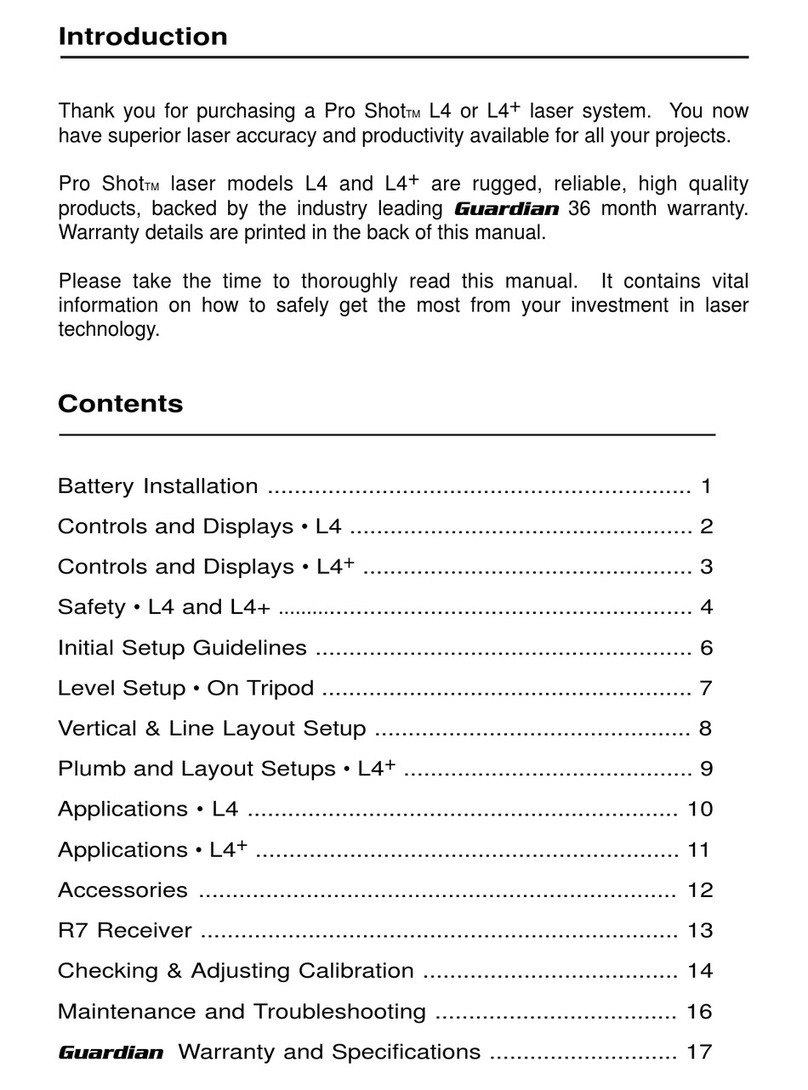

Contents

Battery Installation ............................................................... 1

Controls and Displays .......................................................... 2

Safety ........

.........

................................................................... 4

Initial Setup Guidelines ........................................................ 6

Level Setup .......................................................................... 7

Slope setup .......................................................................... 8

Compound Slope Setup ..................................................... 10

Checking & Adjusting Calibration ...................................... 12

R7 • AS2 System Receiver ................................................ 14

R8 • AS2 MAGNUM System Receiver .................................. 15

Maintenance and Troubleshooting ..................................... 16

Guardian Warranty and Specifications ............................. 17

1

Getting Started

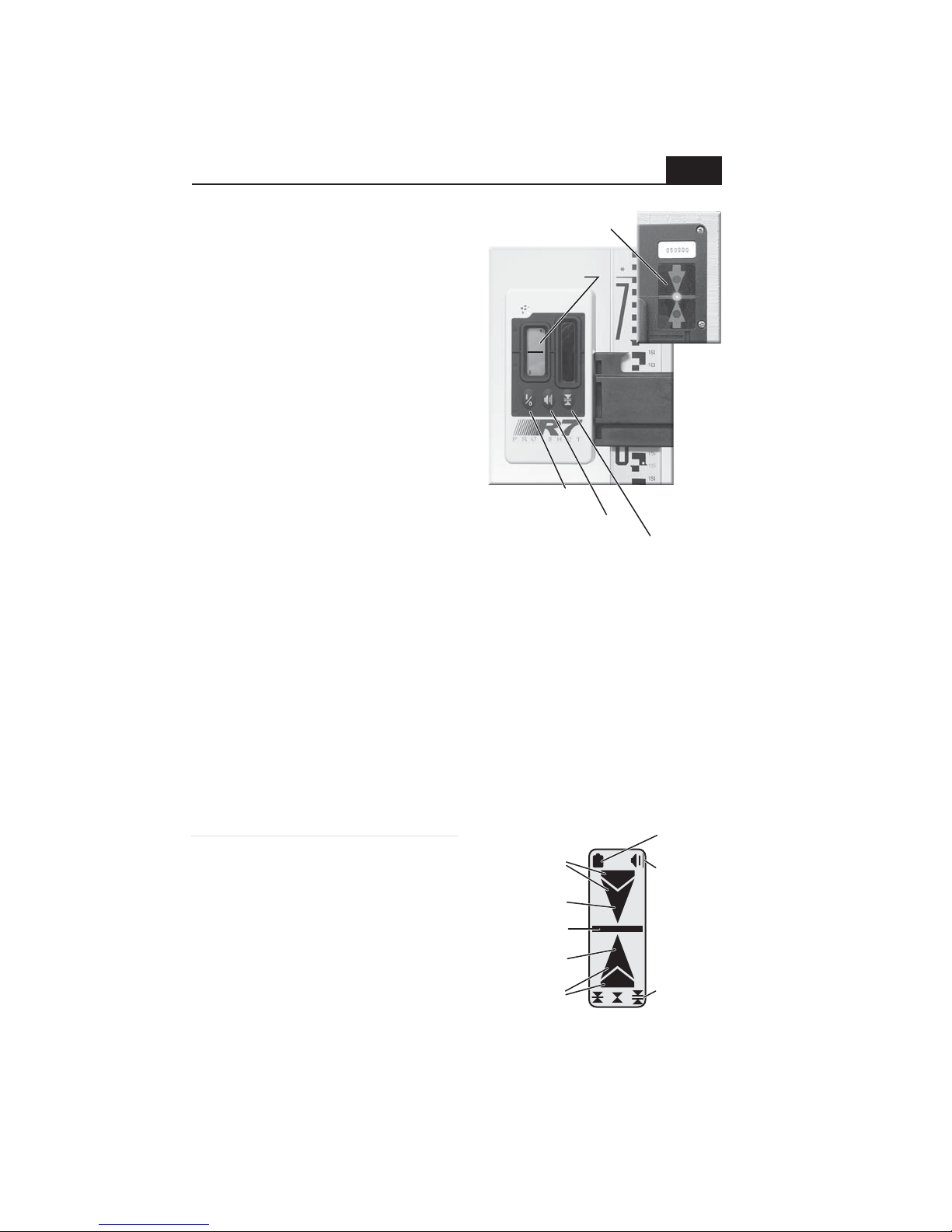

Case contents (will vary - may be ordered with different accessories)

Receiver

Battery charger

Manual package

Laser transmitter

C-cell batteries

Battery installation

1 Pull on tab at base

Pull on tab at base

of door to remove

of door to remove

1Pull on tab at base

of door to remove

3 Hook battery door under

Hook battery door under

metal plate below lighthouse

metal plate below lighthouse

and push at base of door to latch

and push at base of door to latch

3Hook battery door under

metal plate below lighthouse

and push at base of door to latch

2 I nstall batteries according

I nstall batteries according

to the instructions molded on

to the instructions molded on

the battery holder

the battery holder

2Install batteries according

to the instructions molded on

the battery holder

!

CHARGE ONLY

RECHARGEABLE

BATTERIES

Always follow recycling

directives for electronic waste

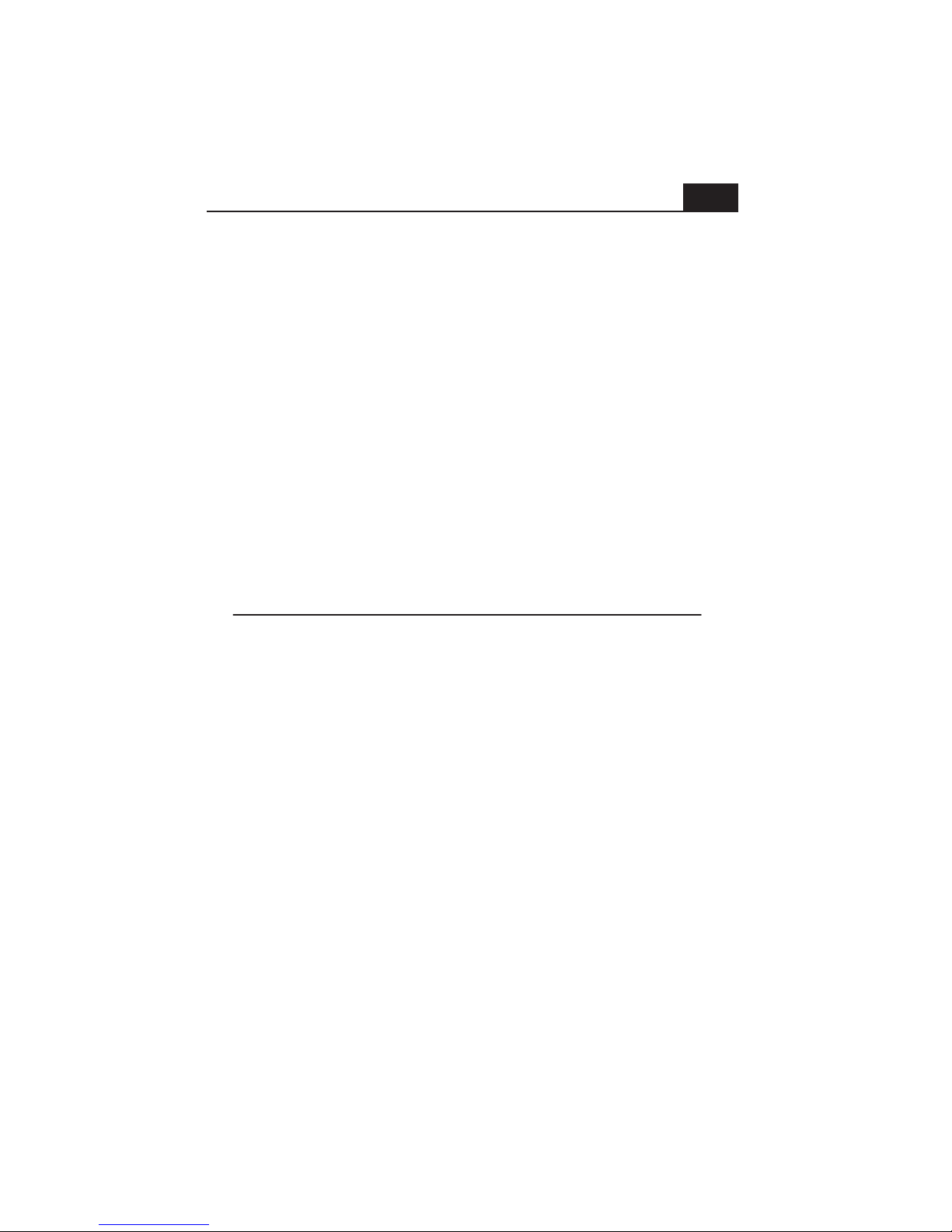

Controls and Displays

Low Battery

Indicator

Laser Power

Indicator

2

Slope

Alignment

Sights

Leveling

Indicators

Slope

Adjustment

Knob

Slope

Display

Note: Controls and displays are the same for both models

except that the AS2 MAGNUM has a rotation speed selection

button and speed indicator LEDs.

Rotation Speed

Selector

(MAGNUM)

Power

Switch

Rotation Speed

Indicators

(MAGNUM)

-Y

+Y

Charging

Jack

Controls And Displays

• Slope alignment sights

These sights are used to align the slope axis of the laser for excavating and

grading when there is a slope required.

• Laser Power indicator

The green L.E.D. indicates the laser beam is on.

• Low battery indicator

The yellow L.E.D. indicates the batteries need to be replaced or charged.

• Leveling indicators / H.I. alert

A green L.E.D. in the upper leveling indicator control panel window turns on

when the leveling system is active. A constant light indicates the laser is

leveling. A flashing light indicates the laser is nearly level. When the laser is

fully level, the rotating mirror begins to spin, the green power indicator L.E.D.

comes on and the leveling L.E.D. turns off. If the laser cannot level, a red

L.E.D. in the lower leveling indicator control panel window will flash. This

indicates the tripod or surface the laser is on must be more level or closer to

the slope that is dialed in.

When the laser finishes leveling and has been running for about five

seconds, a feature called H.I. alert activates. When the laser enters this

mode, the upper leveling indicator green L.E.D. will flash slowly five times.

With H.I. alert active, if the laser is moved or bumped, or the grade knob is

moved, the laser beam will shut-off, the rotor will stop spinning and the red

and green leveling L.E.D.s will flash alternately. Any grade adjustments

should be made before H.I. alert activates. To clear the H.I. alert, simply turn

the laser off, then on again. You must recheck your setup before continuing

your work to avoid errors.

• Slope display

The counter displays the amount of slope set into the plane of laser light.

The display has a resolution of .01% and can be set from 0 to 25%.

• Slope adjustment knob (see H.I. alert above)

The slope adjustment knob is used to set slope into the laser, or to set the

laser to level (00.00 slope).

• Power switch

The power switch turns the laser on or off.

• Rotation speed selector (MAGNUM only)

The rotation speed switch changes the rotation speed between 600, 900 and

1200rpm. The speed will stay at the last setting when the laser is shut down.

• Rotation speed indicators (MAGNUM only)

One of these indiactors will be on whenever the laser is powered-up to

indicate the selected rotation speed.

3

4

Safety

Precautions to follow when using any laser.

• Don't stare into the laser beam or view it directly with optical instruments.

• Don't disassemble the laser or attempt to service it.

• Don't use the laser until you have read the instruction manual and you are

familiar with how to operate the laser properly.

U.S. OSHA requirements for operating visible lasers.

• Only qualified, trained employees may install, adjust and operate the laser.

• Laser operators must carry proof of qualification.

• The area of a job site where a laser is being used must be posted with a

laser warning placard.

• The laser should be set up above or below eye level and never intentionally

aimed at anyone.

• Turn the laser off when it is not being used, such as during lunch hour, at

the end of the day, or during other long breaks in the work.

Note: The L1-AS is a CDRH class II laser and an IEC 60825 class 2 laser.

The L1-ASM MAGNUM is a CDRH class IIIa laser and an IEC 60825 class 3R

laser. Both models conform to applicable EC directives regarding RFI and

EMI and to FDA performance standards 21 CFR subchapter J.

Laser

Light is emitted

from this aperture

AVOID EXPOSURE

Serial / CDRH / EC compliance

Serial No.

Manufactured by: Laser Reference, Inc.

151 Martinvale Lane •San Jose, CA 95119

This product complies with FDA

standards 21 CFR subchapter J

X 000000

Aperture warning

CDRH / IEC

warnings

CHARGE ONLY

RECHARGEABLE

BATTERIES

CAUTION

CAUTION

LASER LIGHT

DO NOT STARE

INTO BEAM

CLASS II LASER PRODUCT

LASER LIGHT

LASER LIGHT

DO NOT STARE INTO BEAM

CLASS 2 LASER PRODUCT

635nm - 670nm

Safety label locations • AS2

5

Safety

L1-AS (IEC)

LASER LIGHT

LASER LIGHT

DO NOT STARE INTO BEAM

CLASS 2 LASER PRODUCT

A warning placard is included with each laser and can be attached to the outside

of the carrying case. The case can then be placed in a visible location near where

the laser is being used in order to meet jobsite posting requirements.

L1-AS (CDRH)

CAUTION

CAUTION

LASER LIGHT

DO NOT STARE

INTO BEAM

635nm - 670nm

CLASS II LASER PRODUCT

Laser

Light is emitted

from this aperture

AVOID EXPOSURE

Serial / CDRH / EC compliance

Serial No.

Manufactured by: Laser Reference, Inc.

151 Martinvale Lane •San Jose, CA 95119

This product complies with FDA

standards 21 CFR subchapter J

X 000000

Aperture warning

CDRH / IEC

warnings

CHARGE ONLY

RECHARGEABLE

BATTERIES

LASER LIGHT

LASER LIGHT

DO NOT STARE INTO BEAM

OR VIEW DIRECTLY WITH

OPTICAL INSTRUMENTS

CLASS 3R LASER PRODUCT

CAUTION

CAUTION

LASER LIGHT - DO NOT STARE

INTO BEAM OR VIEW DIRECTLY

WITH OPTICAL INSTRUMENTS

CLASS IIIa LASER PRODUCT

MAXIMUM POWER < 2.5mw

AT 635nm

P/N 010-9023

L1-ASM MAGNUM (IEC) L1-ASM MAGNUM (CDRH)

CAUTION

CAUTION

LASER LIGHT - DO NOT STARE

INTO BEAM OR VIEW DIRECTLY

WITH OPTICAL INSTRUMENTS

CLASS IIIa LASER PRODUCT

MAXIMUM POWER < 2.5mW

AT 635nm - 670nm

LASER LIGHT

LASER LIGHT

DO NOT STARE INTO BEAM

OR VIEW DIRECTLY WITH

OPTICAL INSTRUMENTS

CLASS 3R LASER PRODUCT

Safety label locations • AS2 MAGNUM

6

Initial Setup Guidelines

Calibration should be checked from time to time.

Although both AS2 models are calibrated at the factory and are

exceptionally rugged lasers, it is well worth the effort to check calibration

before you first use your laser (after shipping) and then from time to time

to ensure that you are doing the highest quality work possible. Always

check calibration if the laser has been handled roughly.

Check your setup.

Although not required, it is good jobsite practice when using any laser or

optical instrument to check your setup from time to time. Use

engineered benchmarks on the jobsite to assure that your setup is

correct and matches the design of the job. Particularily on very large

sites, or where accuracy is critical, taking a few minutes to verify the

elevation marks you have been given to work from makes sense.

Realize that even engineered benchmarks may not be perfect and

enough verification must be done to be confident you are properly set up.

If there are not suitable benchmarks on the site, you can set your own by

driving stakes and recording their elevations, or by marking the laser

beam height on stable objects such as telephone poles, concrete walls,

etc. The benchmarks should be 900apart for greatest accuracy. Having

benchmarks to check is of great value for jobs where setups need to

match day after day. If you will only be using the setup for a brief time,

this may not be needed.

Work as close to the laser as possible.

You can work up to 1000 feet (305M) from the AS2 with the R7 receiver

and 1650 feet (500M) from the AS2 MAGNUM using the R8 receiver or

most brands/models of machine control receivers. As with all

instruments, the farther you go, the more any error can add up. Set the

laser in a safe place, as close as possible to your work

Maintain your equipment.

Keeping tripod and mounting hardware tight, and being sure grade rods

are in good condition, can prevent errors and performance problems.

Level Setup

Follow the instructions in the "initial

setup guidelines" section (page 6).

Zero the grade display precisely.

Turn the laser on and allow it to

level.

The aiming of the laser when

working dead-level is not

important.

In the event that a very long distance is required, the AS2 can be set-up in

the middle of the site, covering a total diameter of 2000 feet (610 meters)

using the R7 receiver. The AS2 MAGNUM can cover a 3300 foot (1000M)

diameter using the R8 receiver, or most brands/models of machine control

receivers.

Periodically check your setup against existing benchmarks or set and check

benchmarks of your own.

7

Slope Setup

Follow the suggestions in the "initial setup guidelines" section (page 6).

Carefully aim the laser using the sights on the top cap. These sights indicate

the direction of slope. The front sloped face of the laser should be aimed

uphill (as shown on the graphic just above the slope knob).

Using the red slope adjustment knob, adjust the slope display to your

required slope. Note that if the laser has finished leveling and H.I. Alert has

become active (see initial controls and displays pg. 2/3) you will need to turn

the laser off, then on again to clear H.I. Alert.

8

Slope

alignment

sights

Slope

adjustment

knob

Note: When using either AS2 model at slope settings over 14%, you will

need to tilt the tripod to allow the laser to reach the desired slope. By

aligning the laser so that one tripod leg is to the rear (down slope side), you

can shorten that leg to tilt the tripod head and the setup will remain stable.

Slope

display

counter

Slope Setup

The display reads in percent of grade (the number displayed is the units of

rise or fall per 100 units of run). A 2-1/2% slope (projecting upward from the

front of the laser) shows as 2.50 on the display. If a down slope is needed,

the display is set to the required slope and the rear of the laser is aimed in

the direction of slope. The graphic label just above the slope knob shows the

direction that upward or downward slopes are projected and the proper

direction to turn the knob to increase or decrease the slope.

In order to be able to set an accurate zero percent slope (dead level), the

counter can be turned below zero. When the counter on either model is

turned to below zero, the upper counter digit will display a 9. This makes it

obvious that the slope is set incorrectly and should be changed to zero

(level), or to a positive slope setting. (see photo below)

Regularly check your setup against benchmarks. If none are present, set at

least two benchmarks of your own to monitor the accuracy of your setup.

The laser can be set at an offset to a ditch or excavation. Just be sure to

point the sights on the top cap parallel to the direction of the slope.

9

This counter digit

displays a 9 when

the slope setting

goes below zero.

Re-set the slope to

zero (level), or to

a positive slope

setting when you see

a 9 displayed here.

10

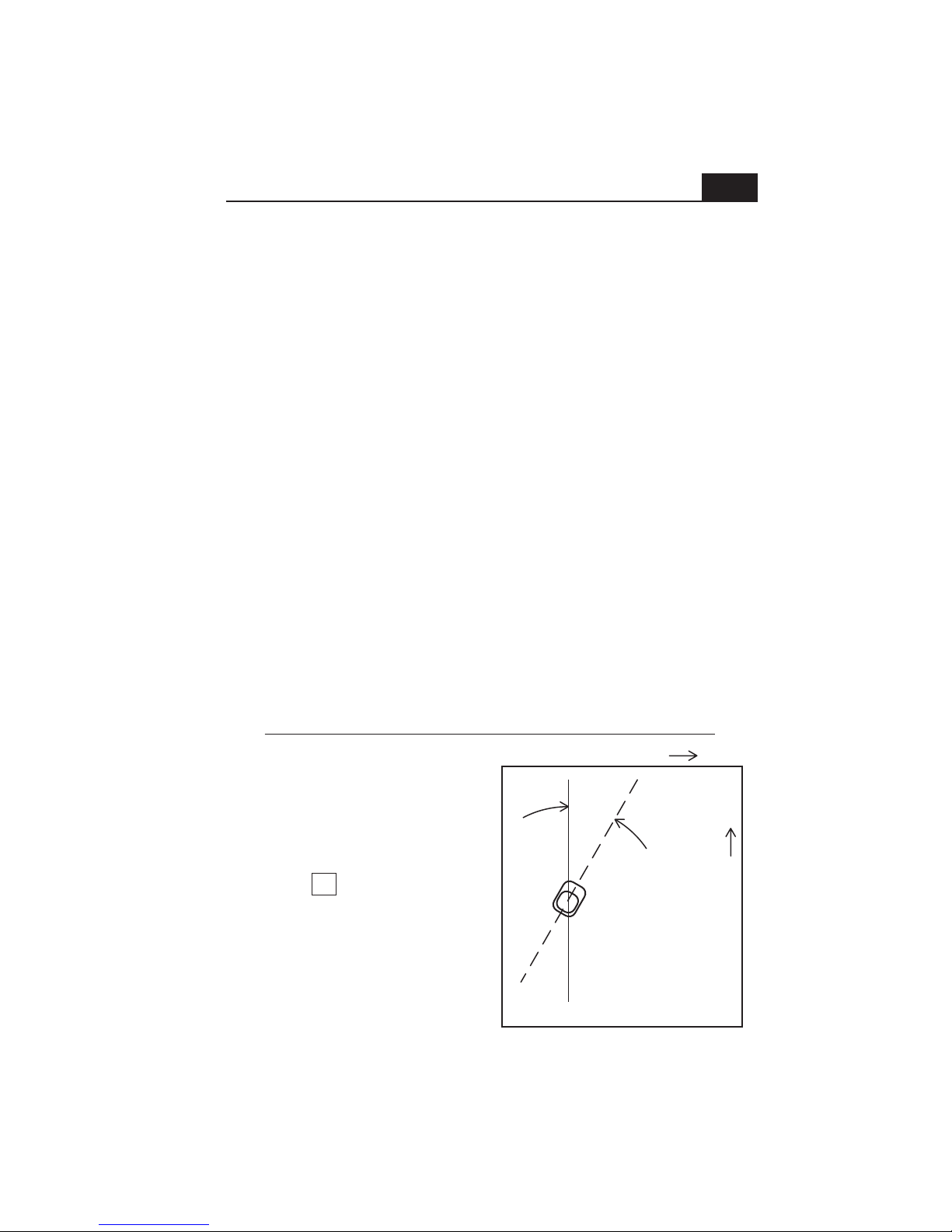

Compound Slope Setup

Sites designed with compound slope

actually have just a single resultant

slope. When a site design has slope

in two directions, 90 degrees apart,

the optional model S2 Compound

Slope Adapter Kit can be used to

calculate and set the AS2 to the

proper angle and resultant slope.

NOTE: The S2 kit is standard with

the AS2 MAGNUM system.

In order to begin a compound slope

setup, the S1 Compound Slope

Adapter Kit must be installed on the

laser, following the instructions

included with the kit.

Next, follow the steps below

and on page 11:

1. Determine the two slopes

for the site and the direction

of each slope. Set the

compound slope adapter

angle to zero (0) degrees

and aim the laser parallel to

the main slope on the site

(the main slope is the

steeper of the two slopes).

Be certain that the up-slope

direction of the laser is

aimed uphill on the main

slope. If there is any

question which is the

up-slope direction for the

laser, you can refer to the

label on the side of the laser

just above the slope knob.

S2 Compound slope adapter kit

+Y Axis

-Y Axis

Compound Slope Setup

2. Using the compound slope chart supplied with the S2 kit, find the two

slopes for the site on the chart and follow their row and column until they

intersect. Remember that the main slope is the steeper of the two slopes.

The upper number in the box where the two slopes intersect is the angle to

set into the S2 adapter. The lower number is the resultant slope to dial into

the laser's slope counter. Note: The slope number is displayed with greater

precision than the slope counter increments.

3. Rotate the S2 adapter until it matches the angle determined with the slope

chart. Note: if, when standing behind the laser, the highest corner on the

site is to the right of the grade sight, you must rotate the adapter counter

clock-wise until you reach the proper reading. If the high corner is to the left,

you must rotate the adapter clock wise.

4. Turn the entire laser toward the uphill direction of the cross slope (toward

the highest corner on the site) until the slope alignment sight is once again

aligned parallel to the main slope. The laser is now at the proper angle.

5. To finish the setup, dial in the resultant slope determined from the chart

and go to work. Note: you can re-check the setup at any time by doing the

following: A. Verify the slope counter setting. B. Verify that the proper angle

is set into the compound slope adapter. C. Verify that the slope sighting slot

is parallel with the main slope direction. D. Verify that the uphill direction of

the laser is aimed toward the high corner of the site.

Always set at least two grade checking stakes that are 90 degrees apart so

that you can verify the laser setup from day to day on the site.

Low corner

High corner

Main slope= .25% up

Compound slope example

31°

Resultant

slope .29%

1. Zero the compound slope adapter ring and

aim the laser parallel to the main slope, with

the up-slope direction of the laser aimed

up-hill on the site.

2. Look-up the intersection of the main slope

(.25) and the cross slope (.15) using the

slope chart. The box at the intersection.

looks like this:

3. Turn the adapter sighting slot 31° counter

clock-wise.

4. Turn the entire laser to re-align the sighting

slot parallel with the main slope. (the laser is

now aimed 31° toward the high corner).

5. Dial the resultant slope of .29% into the

slope counter. Setup is complete.

Cross slope= .15% up

31

0.292

11

Checking and Adjusting Calibration

Calibration is your responsibility, check it often.

Although both AS2 models are calibrated at the factory and are exceptionally

rugged lasers, it is well worth the effort to check calibration before you first

use your laser (after shipping) and then from time to time to ensure that you

are doing the highest quality work possible. Always check calibration if the

laser has been handled roughly.

Follow the steps below to check the calibration of the laser and make

necessary adjustments.

1. Attach the laser to a flat head tripod approximately 100 feet from a wall or

other stable vertical surface (a telephone pole or concrete building will work

well). We will call the vertical surface the target. The tripod head must be

level enough to allow you to turn the laser 360 degrees with minimal

re-leveling needed. Use the tripod leg adjustments to get the tripod head

level.

2. Rotate the entire

laser so that either

direction of the cross (X)

axis (see picture) is

aimed at the target.

3. Carefully set the

slope display counter to

00.00 (The red stripe on

the last counter digit

should be aligned with

the pointer). Turn the

laser on and allow it to

level.

4. Take the receiver to

the target and find the

height of the laser beam

by moving the receiver

up or down until you get

a display and/or tone.

Now, find the center of

the display and mark the

target, using the

receiver's beam center

notch as a guide.

12

-Y

+Y

Checking and Adjusting Calibration

5. Return to the laser and rotate it 180 degrees. Allow the laser to re-level.

The opposite cross axis (X) direction is now aimed at the target. Find and

mark the laser beam height (see step 4).

6. The difference between the two marks (if any) is double the difference

between how the laser is calibrated and true level for the cross axis. Half

way between these two marks is true level. Make a long mark at true level.

If the difference between either outer mark and true level is within your

working tolerance, go on to step 10. If not, continue with the next step.

7. Remove the battery door and the rubber plug on the lower left side of the

battery holder. The four button switches inside control the calibration of the

laser. Each push of a button moves the calibration by approximately 3 arc

seconds (approx. 1/64” @100’ / .4mm @30m). A small screwdriver, allen

wrench or even a dull pencil can be used to press the buttons. The label

below the opening shows which direction each button will move each axis.

Press the + or - button corresponding to the X axis the number of times

estimated to bring the beam to the true level mark. Go to the target surface

and check the beam elevation. If the elevation is correct, go on to step 8. If

not, continue to press the button until the beam comes to level.

8. Check the cross axis adjustment by rotating the laser back to the first

direction and letting the laser re-level. Check that the reading is within the

needed tolerance of the true level mark.

9. Rotate the laser 90 degrees to aim the front of the slope axis at the target

(+Y axis). Allow the laser to re-level and check the reading at the target. If

the reading is on, or within tolerance of the true level mark, calibration is

complete. If not, continue on.

10. Verify the counter is set to exactly 00.00. Remove the battery door and

the rubber plug on the lower left side of the battery holder. The four button

switches inside control the calibration of the laser. Each push of a button

moves the calibration by approximately 3 arc seconds (approx. 1/64” @100’ /

.4mm @30m). A small screwdriver, allen wrench or even a dull pencil can be

used to press the buttons. The label below the opening shows which

direction each button will move each axis. Press the + or - button

corresponding to the Y axis the number of times estimated to bring the beam

to the true level mark. Go to the target surface and check the beam

elevation. If the elevation is correct, put the rubber plug back in. If not,

continue to press the button until the beam comes to level.

Calibration is now complete.

13

R7

•

AS2 System Receiver

The R7 senses the plane of laser light

projected by the AS2 and indicates a

height position relative to the plane (high,

low, or on grade). The R7 uses a five

channel front LCD to display height

information and a three channel rear LED

display. Along with the visual displays,

an audio tone also indicates when the

receiver is high, low, or on grade. When

the R7 is exactly centered at the beam

height, an on grade "bar" indication is

displayed. If the R7 is high or low, an

"arrow" shows the direction to move the

R7 in order to get an on grade indication.

The R7 has three control switches, power

on/off, tone high/low/off and on-grade

accuracy select. Pressing the power

switch activates the R7. The audio tone

will sound and the LCD display will show the tone and accuracy icons. The

R7 is ready to operate in standard accuracy with loud tone. Pressing the

volume switch once changes to low volume, twice turns the volume off.

When the volume is off, there will still be a single tone the first time the R7

senses a laser signal. Pressing the accuracy switch once changes to the

coarse setting, twice changes to fine. The R7 automatically turns off if no

laser beam strikes are received for twelve minutes. The R7 is powered by a

9 volt battery that lasts approximately 60 hours. When the battery is nearly

used up, the low battery indicator will be displayed. To replace the battery,

locate the battery door on the back of the housing and slide the door toward

the bottom of the receiver. Remove the battery from the compartment (you

may need to tap the R7 on your palm to free the battery). Replace the

battery following the diagram molded on the battery door.

14

Five channel

front display

Rear display

Volume switch

Accuracy switch

Power switch

Tone

volume

Accuracy

L - R: std.,

fine, coarse

High fine

Low coarse

(both)

On Grade bar

Low batt.

Low fine

High coarse

(both)

2 inches (50mm)

120 degrees

±1/16 in. (±1.6mm) nominal

±1/8 in. (±3.2mm) nominal

±1/64 in. (±.4mm) nominal

9 volt battery

60 hours continuous

After 12 min. (no laser strikes)

Sealed against dust and water

250 to 850 R.P.M.

5/8in to 2-1/2in (16mm-65mm)

Reception Height ............

Reception Angle ..............

Standard mode accuracy

Coarse mode accuracy ...

Ultra-fine mode accuracy

Power Supply ..................

Battery life (alkaline) .......

Automatic Shut Off ........

Environmental ...............

Rotation Compatibility ...

Mount Clamping Range

Specifications and display icons

R8

•

AS2 MAGNUM System Receiver

15

Volume

Accuracy

Power

R8 shown on optional cut/fill rod

Rear display

Rear display

Rear display

The R8 senses the plane of laser light

projected by the AS2 MAGNUM and

indicates a height position relative to

the plane (high, low, or on grade).

The R8 uses five channel front and

rear LCDs to display height

information. Along with the visual

displays, an audio tone also indicates

when the receiver is high, low, or on

grade. When the R8 is exactly

centered at the beam height, an on

grade "bar" indication is displayed. If

the R8 is high or low, an "arrow"

shows the direction to move the R8 in

order to get an on grade indication.

The R8 has three control switches,

power on/off, tone high/low/off and

on-grade accuracy select. Pressing

the power switch activates the R8. The audio tone will sound and the LCD

display will show the power, tone and accuracy icons. The R8 is ready to

operate in standard accuracy with loud tone. Pressing the volume switch

once turns the volume off, twice changes to low volume. When the volume is

off, there will still be a single tone the first time the R8 senses a laser signal.

Pressing the accuracy switch once changes to the coarse setting (note:

display is 3 channels in coarse), twice changes to fine. The R8 automatically

turns off if no laser beam strikes are received for 30 minutes. The R8 is

powered by two AA cell batteries that last approximately 70 hours. When the

battery is nearly used up, the low battery indicator will be displayed. To

replace the batteries, locate the battery door on the lower back of the

housing and open the latch using a coin. Replace batteries following the +

diagram on the housing.

Five channel

front display

Tone volume

Accuracy

High fine

(both)

Low coarse

On Grade bar

Low batt.

Low fine

(both)

High coarse

2 inches (50mm)

90 degrees

±1/16 in. (±1.6mm) nominal

±1/8 in. (±3.2mm) nominal

±1/32 in. (±.8mm) nominal

2 AA cell batteries

70 hours continuous

After 30 min. (no laser strikes)

Sealed against dust and water

Reception Height ............

Reception Angle ..............

Standard mode accuracy

Coarse mode accuracy ...

Ultra-fine mode accuracy

Power Supply ..................

Battery life (alkaline) .......

Automatic Shut Off ..........

Environmental .................

Specifications and display icons

Power

16

Maintenance And Troubleshooting

Calibration • There is no set interval for calibrating either AS2 model, but

calibration should be checked from time to time in order to ensure that the

highest possible quality of work is being done. Calibration should always be

checked if the laser has been handled roughly or shipped.

Batteries • Occasionally remove the batteries and check the contacts for

corrosion. Alkaline batteries will last far longer than carbon batteries. If you

use rechargeable batteries, be careful to never charge alkaline or carbon

batteries. Never run the laser from the charger unless there are

rechargeable batteries installed. Keep a spare set of batteries in the carrying

case to avoid down time.

Laser output windows • Regularly check the output windows for dust and

dirt. Dust can be removed with a camera brush or clean compressed air.

Control panel and exterior • Clean the control panel and the other exterior

surfaces of the laser with a soft damp cloth.

Caution! • Never store the laser in a carrying case that is wet inside.

Moisture can get inside the laser this way. Should this happen, remove the

battery cover and place the laser in a warm area until it is completely dry.

Troubleshooting

The laser will not operate, there is no obvious damage • If the low battery

indicator is on, or you suspect the batteries may be dead, replace the

batteries. Check the battery contacts to be sure that they are clean.

The receiver shows an on-grade at two different heights • Check the jobsite

for windows or mirrored surfaces that might be reflecting the laser and

causing the other reading. Check for others on the site using a rotary laser.

The laser was knocked over • Visually check the optics for damage. Inspect

the laser for any other physical damage. Use the receiver to check that the

laser is transmitting. Check the calibration and adjust as needed.

The laser only works at short distances • Check the output windows for

heavy dust or moisture. Remove dust with a camera brush or blow off gently

with clean compressed air. Allow moisture to dry.

The receiver does not indicate "on grade" at long distance • Be sure you are

within the max distance specification from the laser. Check the windows that

surround the rotating mirror on the laser for dust or moisture. Remove dust

with a camera brush or blow off gently with clean compressed air. Allow

moisture to dry.

Warranty

Guardian

36 month warranty coverage

The AS2 and AS2 MAGNUM laser transmitters, along with the R7 receiver, are

warranted for thirty-six (36) months from the date of new equipment purchase from an

authorized dealer. The R8 receiver is warranted for twenty-four (24) months. During

the warranty period, Laser Reference, or its authorized service center, will repair or

replace, at Laser Reference's sole discretion, laser transmitters or receivers, free of

charge, (except for transportation costs) if the products are found by Laser

Reference, or its authorized service center, to be defective in either materials or

workmanship. The Guardian 36 month warranty also covers the internal leveling

mechanism and internal optics (parts only, not labor) against damage from any cause.

Maintaining the calibration of the product is not the responsibility of Laser Reference

or its authorized service centers. If service is needed, the product(s) must be sent

FREIGHT PREPAID to the nearest authorized service center or to Laser Reference.

17

Specifications

1000' rad., 2000' dia. (305m/610m)

1650' rad., 3300' dia. (500m/1000m)

±14 arc seconds (2.0mm per 30m)

(.080" per 100')

±10 arc seconds (1.5mm per 30m)

(.060" per 100')

0

-

25%, single axis, .01% increments

S2 compound slope kit optional

S2 compound slope kit included

±4 Degrees

600rpm

600, 900, 1200rpm (selectable)

Four C-cell batteries (alkaline std.)

Available option (NiMh)

115 hrs. (alkaline) / 95 hrs. (NiMh)

70 hrs. (alkaline) / 55 hrs. (NiMh)

If off-level for more than 3 min.

Dust and water resistant (IP55)

14ºf to +122ºf (-10ºc to +50ºc)

14ºf to +140ºf (-10ºc to +60ºc)

-40ºf to +140ºf (-40ºc to +60ºc)

CDRH Class 2 • IEC 825-1 Class 2

CDRH Class 3A • IEC 825-1 Class 3R

9.7in (24.5cm) / 4.4lbs (2.0kg)

Range with receiver • AS

2

.....

AS

2

MAGNUM .......

Leveling accuracy • AS

2

........

AS

2

MAGNUM .......

Slope Capability ....................

Compound slope capability ...

AS

2

MAGNUM .......

Self-Leveling Range ..............

Rotation speed • AS

2

.............

AS

2

MAGNUM .......

Power Supply ........................

Rechargeable Batteries .........

Run Time (continuous) • AS

2

.

AS

2

MAGNUM .......

Automatic Shut-off .................

Environmental .......................

Operating Temp. • AS

2

..........

AS

2

MAGNUM .......

Storage Temperature ............

AS

2

Laser rating ....................

AS

2

MAGNUM Laser rating ..

Height / Weight ......................

Customer information

Laser Serial number _____________________________

Receiver S/N __________________________________

Date of purchase _______________________________

Part No. 010-6065 Version 2.0

Laser Reference, Inc.

151 Martinvale Lane

San Jose, CA 95119 •USA

Toll Free (USA)

Telephone

Fax

Web

Email

• +

1.800.238.0685

• +

1.408.361.0220

• +

1.408.361.3180

•

www.pro

pro

shotlaser

laser

.com

•

sales@pro

pro

shotlaser

laser

.com

California

•

USA

California

•

USA

Table of contents

Other PRO SHOT Measuring Instrument manuals