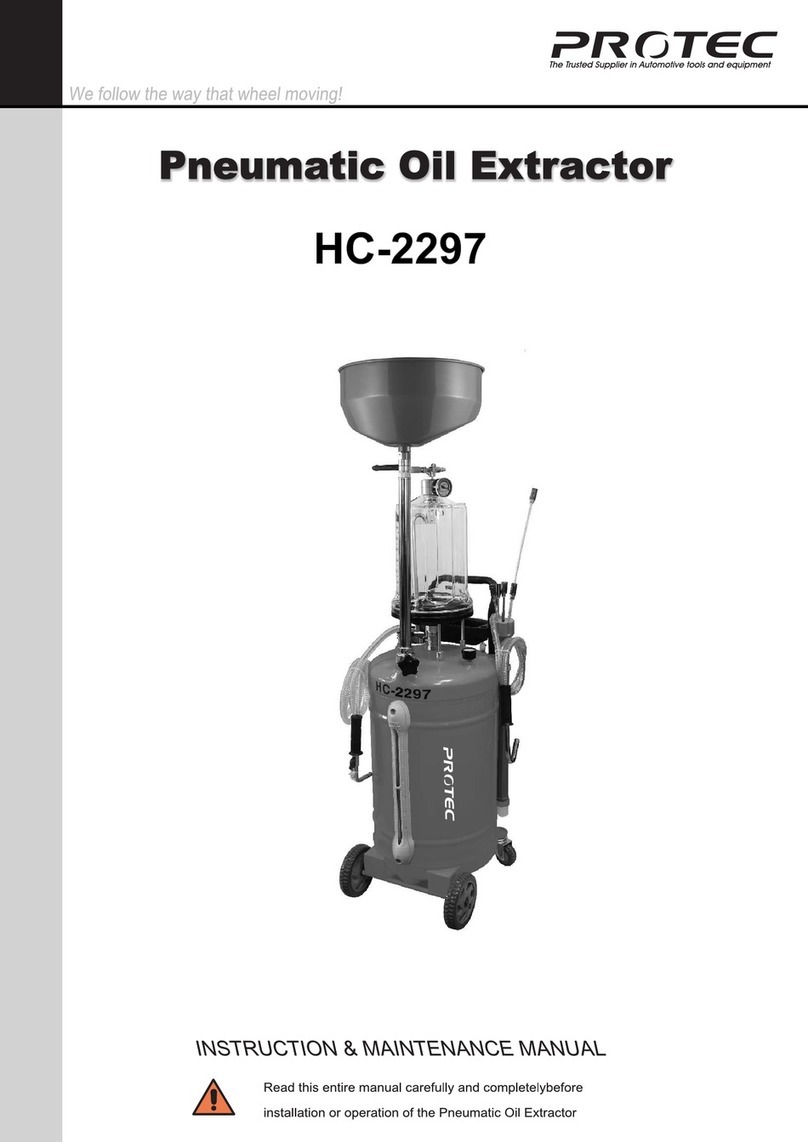

Pro-tec HC-2285 Instructions for use

INSTRUCTION & MAINTENANCE MANUAL

We follow the way that wheel moving!

Read this entire manual carefully and completelybefore

installation or operation of the Pneumatic Oil Extractor

Pneumatic Oil Extractor

HC-2285

2

Safety Warnings and Precautions

WARNING: When using tool, basic safety precautions should always be followed to reduce the risk of

personal injury and damage to equipment.

1. Keep work area clean. Cluttered areas invite injuries.

2. Observe work area conditions. Do not use machines or power tools in damp or wet locations. Don’t expose

to rain. Keep work area well lighted. Do not use electrically powered tools in the presence of flammable gases

or liquids.

3. Keep children away. Children must never be allowed in the work area. Do not let them handle machines,

tools or extension cords.

4. Store idle equipment. When not in use, tools must be stored in a dry location to inhibit rust. Always lock up

tools and keep out of reach of children.

5. Avoid Unintentional Starting. Be sure the air pressure is in the off position when not in use and before

making hose connection.

6. Stay alert. Watch what you are doing, use common sense. Do not operate any tool when you are tired.

7. Check for damaged parts. Before using any tool, any part that appears damaged should be carefully checked

to determine that it would operate properly and perform its intended function. Check for alignment and

binding of moving parts; any broken parts or mounting fixtures; and any other condition that may affect

proper operation. Any part that is damaged should be properly repaired or replaced by a qualified technician.

Do not use the tool if any control or switch does not operate properly.

8. Replacement parts and accessories. When servicing, use only identical replacement parts. Use of any other

parts will void the warranty. Only use accessories intended for use with this tool.

9. Do not operate tool if under the influence of alcohol or drugs. Read warning labels if taking prescription

medicine to determine if your judgment or reflexes are impaired while taking drugs. If there is any doubt, do

not operate the tool.

10. Maintenance. For your safety, service and maintenance should be performed regularly by a qualified

technician.

Note: Performance of this tool may vary depending on variations in air pressure and compressor

capacity.

Product specific safety precautions

This equipment is designed be operated by qualified personnel. It should only be operated after reading

and understanding the safety warnings and operating procedures in this instruction manual.

3

1. Do not smoke near this equipment.

2. Firework is strictly prohibited during operation, keep away from heat, high voltage, flammable and

explosive place

3. Use in a well ventilated area.

4. When leaks are found in the equipment or hoses, immediately turn the air pressure off and repair the

leaks.

5. Once leakage is found in the hose or other components during operation, turn off air compressor

immediately, conduct a detailed inspection and proceed with troubleshooting.

6. Do not exceed the recommended operating air pressure. This could damage equipment.

7. Keep a type ABC fire extinguisher nearby in case of fires.

8. Always protect your skin and eyes from contact with oil and solvents.

9. Do not start engine during the time of oil extraction. Otherwise it will cause the damage of extraction

probes and injuries of people.

10. Be careful for the oil extracted out from the vehicle, as temperature of oil is high, always between

40~60℃

11. Used oil should be properly disposed or recycled. Please contact with your local waste liquid/solid

authority for information on recycling.

Product description:

1.Fast vaccum speed, capable of high negative pressure, multi-purpose equipment.

2.High quality cylinder, higher intensity, high grade of transparency as well as high temperature resistance (able to

withstand 80℃& negative pressure without deforming). Transparent cylinder allows oil observation and

measurement.

3. Use compressed air as power source; guarantee the safety in use, Eco friendly and low power consumption

4. Vacuum cylinder and oil tank at a same time, increase oil extraction speed

5. Different diameter of oil suction probes to meet the need of different type of cars

6. Can be used with other mechanical engine oil, lubricants as well as temporary storage. Brake fluid, gasoline,

diesel and other liquid contains methanol and ketones or flammable is strictly prohibited.

4

Specification:

Functions: Remove and extract waste fluids or oil out from engine and etc. with flexible PVC tube and robust CU

probe. Power from compressed air

Air Inlet Pressure::

6~8bar/ 87~116PSI

Ejection pressure:

0.7~1 bar/ 10~15PSI

Air consumption:

150L/MIN

Vacuum Degree:

0~-1 bar/-15PSI

Tank Capacity:

80L(21.1Gallon)

Oil tray volume:

15L

Working Temperature:

40~60℃

Package:

Oil tank/box

Carton size:

550*430*980mm

Oil extraction probe:

Φ5*L800mm,(Cu,1 PCS)

1.9 L/Min.

Φ6*L800mm,(Cu,1 PCS)

3.7 L/Min.

Φ5*L800mm,(PVC,1PCS)

1.0 L/Min.

Φ6*L800mm,(PVC,1PCS)

2.0L/Min.

Φ8*L800mm,(PVC,1PCS)

6.5 L/Min.

Φ7*L1000mm,(PVC,1PCS)

3.7 L/Min.

Package Contents

Please inspect and look for damages from shipping when package is first received. If the unit is damaged in any

way, please contact customer service and include pictures if possible.

In the package, you will find:

a) English manual

b) One Complete Oil Tank/Reservoir

c) One Oil Collecting Bowl/tray

d) One Strain

e) Extension funnel 3pc/set

f) Probes 6 pcs with sleeve

g) BMW, Mercedes, Volkswagen connector

5

Operation Instruction

1. Vacuum Generation

Turn off all valves BEFORE use. Connect the air compressor to

the air inlet(Part No.32HC-0801), gradually turn on the air inlet ball valve

(Part No.32HC-0803)for vacuumization. When finger reaching to the MAX.

area on the vacuum gauge, turn off the air inlet valve for completion

of vacuum extraction.

2. Extraction

Ensure the oil tank is under negative pressure, FIG.2 remove engine oil case, Choose suitable probe (which is the

largest diameter one can be inserted into the engine) and tightly connect it to the extraction pipe connector, Insert

the end of the probe into the engine oil inlet hole. FIG.4 Turn on the ball valve (Part No. 32HC-1703) for oil

extraction.

NOTICE:

Do not exceed maximum oil extraction temperature 60℃.

Hold the hose protection sheath during extraction to avoid scald

Place the machine in a flat ground to avoid sliding under working condition

Oil temperature higher than 80 ° C will cause seriously damage to the components, in worst case it could lead to

machine failure.

FIG.1

Fig.2

Fig.

3

Fig.4

6

3. Oil collection from oil tray

FIG.5 lift the vehicle up with workshop lift, move the oil extractor below car

engine, oil tray position right under the vehicle oil drain hole. Release plum knob

to adjust lifting pole , tighten plum knob (to fix its height, open ball valve under

the oil tray ,release oil drain bolt for oil collection from vehicle.

4. Tank Emptying

As FIG.8 shows oil level reached STOP sign, stop oil extraction

Immediate, turn off all valves for tank emptying. FIG..8 insert ejection

Hook into the external disposal tank, connect air compressor with

Air inlet (Part No.32HC-0801).Turn on air inlet valve (Part No.

32HC-0803) slowly, Adding tank pressure, turn off air inlet valve

(Part No.32HC-0803).(The valve will automatically release pressure

when the tank pressure reach 1.0 bar/14PSI, turn off the air compressor

immediately and quickly drop the tank pressure below 0.7bar/10PSI,

otherwise it could lead to serious incident. Turn on wing valve (Part No.

32HC-0402) for oil draining. Cut off air source.Empty tank pressure and

close all valve for completion.

As FIG. 7 shows, discharge Residual oil from Residual oil cup when it reach STOP sign

FIG.7 FIG.8

FIG.5

FIG.6

7

8

BOM Part List

No.

name

qty

unit

22HC-0101

tank

1

pcs

21HC-0201

directional wheel

2

pcs

21HC-0202

snap ring

2

pcs

21HC-0301

universal wheel

2

pcs

21HC-0302

nut

2

pcs

21HC-0501

level pipe

0.4

m

21HC-0502

elbow connector

2

pcs

21HC-0503

level pipe protector

1

pcs

21HC-0504

hexagonal screw

2

pcs

21HC-0701

pressure gauge

1

pcs

21HC-0804

straight connector

1

pcs

21HC-1104

straight connector

1

pcs

21HC-1105

vacuum generator protector

1

pcs

21HC-1801

oil drain hose

2

m

21HC-1802

oil drain hook

1

pcs

21HC-1902

screw

2

pcs

21HC-2003

screw

2

pcs

21HC-2101

fixing seat

1

pcs

21HC-2102

seal ring

2

pcs

21HC-2105

lift pole

1

pcs

22HC-2501

oil tray

1

pcs

21HC-2502

strainer

1

pcs

21HC-2704

connector

1

pcs

21HC-2801

handrail

1

pcs

21HC-3802

gasket

2

pcs

32HC-0303

gasket

4

pcs

32HC-0304

thread rod

2

pcs

32HC-0401

cast-iron bend

3

pcs

32HC-0402

butterfly valve

1

pcs

32HC-0601

safe valve

1

pcs

32HC-0801

wind nozzle

2

pcs

21HC-0805

T connector

1

pcs

32HC-0803

mini ball valve

1

pcs

32HC-1101

Bolt

1

pcs

32HC-1102

vacuum generator

1

pcs

32HC-1103

silencer

1

pcs

32HC-1107

seal ring

1

pcs

32HC-1201

bead valve

1

set

9

32HC-1701

extraction oil hose

2

m

32HC-1702

oil extraction hook

1

pcs

32HC-1703

mini ball valve

1

pcs

32HC-1704

seal ring

2

pcs

32HC-1901

tool box

1

pcs

32HC-1903

nut

2

pcs

32HC-2103

seal ring

2

pcs

32HC-2104

brake sleeve

1

pcs

32HC-2107

knob

1

pcs

32HC-2201

probe sleeve

1

pcs

32HC-2202

oil cup

1

pcs

32HC-2301

oil extraction probe

1

pcs

32HC-2302

oil extraction probe

1

pcs

32HC-2303

oil extraction probe

1

pcs

32HC-2304

oil extraction probe

1

pcs

32HC-2305

oil extraction probe

1

pcs

32HC-2306

oil extraction probe

1

pcs

32HC-2703

handle sleeve

2

pcs

22HC-4301

hex nut

1

pcs

22HC-4302

gasket

1

pcs

22HC-4303

locating sleeve

1

pcs

22HC-4304

hex socket set screw

1

pcs

22HC-4307

lift

1

pcs

21HC-3805

seal ring

1

pcs

21HC-3806

screw

1

pcs

21HC-3807

ball valve

1

pcs

Table of contents

Other Pro-tec Scrubber manuals

Popular Scrubber manuals by other brands

Pacific

Pacific Z210T parts manual

Clarke

Clarke Vantage 17 Battery Service manual

Nilfisk-Advance

Nilfisk-Advance 48 LPG instruction manual

Sealed Air

Sealed Air TASKI swingo XP-M Technical manual

Plymovent

Plymovent MOBILEPRO Installation and user manual

Amperes Electronics

Amperes Electronics iPX5455 instruction manual