1. MACHINE DESCRIPTION

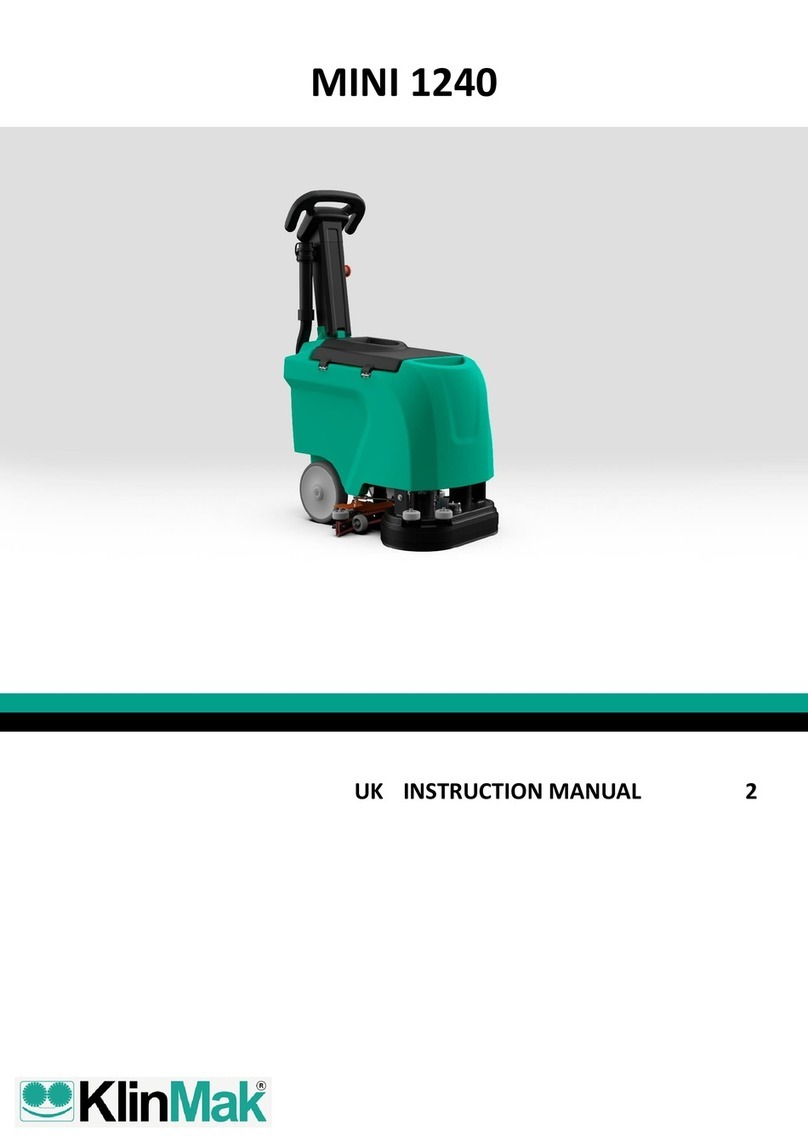

Trion is a Walk-behind Scrubber-Dryer machine, to wash and dry hard floors, battery powered and

with cable, intended for retail use.

The main systems of the machine are as follows:

▪The detergent solution tank and relevant circuit,

▪The washing brushes plate

▪The dirty water recovery tank and relevant circuit

▪The electrical system and relevant control panel, the steering and speed device.

The function of the detergent solution tank is to store water (with dilution of any detergent), supplying it

to the washing system.

The relevant system includes the tank, filter, proportional valve to adjust flow rate and controls.

The tank contains the detergent solution (water and detergent) and supplies it to the washing system when

required. The filter protects the solenoid valve from debris contained in the water. The proportional

solenoid valve controls detergent solution supply to the washing system. The valve automatically

prevents the flow of the detergent solution. The control selector of the solution flow - by controlling

opening duration and section of the solenoid valve - regulates the amount of detergent solution conveyed

to the washing system.

The disc washing device includes: two counter-rotating disc brushes, the electric motor that rotates 2

brushes and a turbine for liquid extraction. The brushes wash the floor while the motor and the pair of

gears, solidly attached to the brushes, actuate their motion. The side band, in bristles, lets the detergent

solution remain in the brushes' working area.

The wiper (or squeegee) is the water collecting device. It can be lifted manually: when it is lifted towards

the machine’s belly, it attaches firmly to the belly by means of 2 magnets.

The water flow is regulated by a proportional solenoid valve (from 0 to 2.0 litres/minute), there is also the

option of mixing the water with the chemical detergent, contained in the specific bottle. The mixture

percentage is set by a peristaltic pump which regulates the detergent flow, conveying it and mixing it

downstream of the proportional solenoid valve (in the version with Ki-Do device).

The function of the recovery device (wiper or squeegee) is to suck the dirty water and convey it to the

recovery tank.

The recovery system includes: the wiper, the vacuum turbine, the filter, the recovery tank and the

controls. The wiper collects the dirty detergent solution from the floor as the machine moves forward.

The vacuum turbine assures the necessary vacuum to suck the dirty detergent solution from the floor and

convey it to the recovery tank. The recovery tank stores the dirty detergent solution.

The maximum recovery water level is controlled by a level sensor connected to the control unit and acting

on the motor; therefore the turbine and the brushes will stop operating as soon as the recovery water

reaches the maximum level.