PRO TUNE PR-4 User manual

0

Document Revision: (2)

0

0

Product Manual

PR-4

t

1

Document Revision: (2)

1

1

Product Manual

PR-4

Disclaimer

Printed copies of this manual are not controlled.

This document is intellectual property of Pro Tune Electronic Systems. This manual cannot be reproduced,

distributed or transmitted by any means, electronic or printed, without the proper authorization of Pro Tune

Electronic Systems.

The company, its employees and resellers are not responsible for the incorrect use of the information,

inaccuracies or omissions in this document.

Pro Tune reserves the right to make changes to this document without prior notice.

2

Document Revision: (2)

2

2

Product Manual

PR-4

Congratulations!

You just bought a product from Pro Tune. We thank you for your trust in our products, which are produced

following stringent international standards together with highly rigorous quality control, so that you receive a

superior product in performance, finish and functionality.

Our products are 100% manufactured in Brazil, from the assembly of the electronic components, through

programming and finishing with the case machined in aluminum, which gives a durable and professional look to the

products.

We hope you have a great experience with Pro Tune products, and we are available to answer any questions

and supply any technical support you might have in installing or operating our products.

3

Document Revision: (2)

3

3

Product Manual

PR-4

Glossary of terms and abbreviations

CAN –Controller Area Network .

CKP –Crankshaft Position Sensor.

CMP –Camshaft Position Sensor.

DATALOG –Sample set of readings from a group of sensors, saved on a device with memory.

ECU –Engine Control Unit.

ET –Engine Temperature.

GPS –Global Position System.

IAT –Intake Air Temperature.

MAF –Mass Air Flow.

MAP –Manifold Absolute Pressure.

NTC –Negative Temperature Coefficient.

OBD II –On-Board Diagnostic II.

PEAK & HOLD –Activation strategy for low impedance fuel injectors.

PINOUT –Diagram, or pin configuration of a device.

TDC –Top Dead Center –Highest position of the piston inside the cylinder.

PP –Pedal Position Sensor.

PWM –Pulse Width Modulation.

RGB –Red Green Blue

SHIFT LIGHTS –Progressive lights with activation linked to engine speed.

TDL –Touch Dash Logger.

TP –Throttle Position.

TPS –Throttle Position Sensor.

USB - UNIVERSAL SERIAL BUS.

4

Document Revision: (2)

4

4

Product Manual

PR-4

Summary

1. Overview 6

Harness Reference Table 7

2. Read Before Installing 9

3. Instalation Diagram 10

3.1 –Basic Wiring: 10

4.1 –Inputs 11

Crank and Camshaft Possiton Sensors 11

Manifold Absolute Pressure (MAP) 12

Throttle Position (TP) 12

Engine and Intake Air Temperatures Sensors 13

Lambda Sensor NTK UEGO 14

Mass Air Flow–MAF 14

Pedal Position Sensor 15

Vehicle Speed Sensor 15

Generic Potentiometer (Gear Position, Steering Angle, etc) 16

Load on Shift Lever 17

Oil / Fuel Pressure 18

Injectors –Sequential 18

Injectors –8 Cilinders Semi-Sequential 19

Injectors –Secondary Injector Rail 19

Injectors –Secondary Injector Rail Semi-Sequential 20

Ignition Coils without Integrated Driver 20

Dual Ignition Coils without Integrated Driver Semi-Sequential 21

Triple Ignition Coils without Integrated Driver Semi-Sequential 21

Ignition Coils with Integrated Driver 22

Electric Fan 22

Electronic Throttle Control 23

Switch 24

Solenoid Valve 24

Tachometer Output 25

4. Sync 26

5

Document Revision: (2)

5

5

Product Manual

PR-4

Trigger Wheel for Crank Position and Engine Speed: 26

Distributor for Rotation and Phase Reading: 28

Distributor only for phase reading: 28

Camshaft Position Sensor for Phase Reading: 28

6

Document Revision: (2)

6

6

Product Manual

PR-4

1.Overview

The PR-4 ECU features a 48-pin waterproof connector. Its image can be seen in the figure below.

This connector uses a letter and number system to identify each pin, with the columns being identified by

letters A to M and lines identified by numbers 1 to 4. In addition to this alphanumeric label, all Pro Tunes pre-wired

harness has cables with identification printed on its cover.

The PR-4 ECU has an integrated USB port on the top where an A-B USB cable can be plugged into the ECU for

configuration. In addition, the ECU has CAN communication used to communicate with various CAN devices.

Pro Tune ECU has several functions, for example, Lambda Control, Boost Control, and others. Therefore, the

factory-enabled functions on the ECU depends on whether a package (Advanced or Plus) is chosen at the purchase

moment. If there is an interest in using new functions, the user can contact Pro Tune to purchase only the activation

code needed, not requiring the exchange of the product or the installation of extra modules.

Before proceeding to the electrical installation, it is essential to choose the inputs to which the sensors will

be connected to the ECU. On the inputs equipped with pull-up resistors, it is possible to operate in Temperature

Mode to connect temperature sensors and buttons with ground-based operation.

The fast inputs are suitable for reading signals of sensors that have a high rate of variation, such as throttle

position, pedal position, intake pressure sensor and mass flow sensor. Inputs up to 15 V are suitable for sensors with

signal amplitude greater than 5V. These inputs can be used to, for example, read the trigger status of a 12V switch.

The digital inputs are those that support frequency signals. At these inputs, for example, wheel speed sensors can be

connected.

7

Document Revision: (2)

7

7

Product Manual

PR-4

Harness Reference Table

The Functions of each wire and its respective pin in the connector can be seen in the following table.

PR-4 - Power

Pin

Function

Label

L2

Sensor Ground

No Label

K3

Sensor 5V

SENSOR 5V

L3

Power Ground

No Label

L4

Power Ground

No Label

M4

12V Power

+12V_SWITCH

PR-4 –Crank Position Sensor

Pin

Function

Label

F4

Positive Input - Crank Position Sensor (CKP+)

No Label

G4

Negative Input –Crank Position Sensor (CKP-)

No Label

*The cables described above are part of a triple shielded black cable with the label CKP.

PR-4 –Camshaft Position Sensor

Pin

Function

Label

H4

Positive Input –Camshaft Position Sensor (CMP+)

No Label

J4

Negative Input –Camshaft Position Sensor (CMP-)

No Label

* The cables described above are part of a triple shielded black cable with the label CMP.

PR-4 –Injectors

Pin

Function

Label

A1

Injector 1 Output

INJ_1

B1

Injector 2 Output

INJ_2

C1

Injector 3 Output

INJ_3

D1

Injector 4 Output

INJ_4

PR-4 –Ignition

Pin

Function

Label

H1

Ignition 1 Output

IGN_1

J1

Ignition 2 Output

IGN_2

K1

Ignition 3 Output

IGN_3

H2

Ignition 4 Output

IGN_4

8

Document Revision: (2)

8

8

Product Manual

PR-4

PR-4 –Auxiliaries Inputs

Pin

Function

Label

C2

Auxiliary Input 1

IN_1

D2

Auxiliary Input 2

IN_2

E2

Auxiliary Input 3

IN_3

F2

Auxiliary Input 4

IN_4

G2

Auxiliary Input 5

IN_5

G3

Auxiliary Input 6

IN_6

F3

Auxiliary Input 7

IN_7

H3

Auxiliary Input 8

IN_8

J3

Auxiliary Input 9

IN_9

E4

Digital Input 2

DIG_IN2

PR-4 - Auxiliaries Outputs

Pin

Function

Label

G1

Auxiliary Output 1

OUT_1

F1

Auxiliary Output 2

OUT_2

E1

Auxiliary Output 3

OUT_3

L1

Electronic Throttle Control Output (positive)

ETC+

M1

Electronic Throttle Control Output (negative)

ETC-

M3

Auxiliary Output 6

OUT_6

K4

Main Relay Output

OUT_MAIN_RELAY

PR-4 –Lambda Sensor

Pin

Function

Label

A3

Lambda –Heater Ground

LAMBDA1_HT-

B3

Lambda –Reference

LAMBDA1_SENSOR

REF

C3

Lambda –Calibration

LAMBDA1_RCAL

D3

Lambda –Ipump

LAMBDA1_IP

E3

Lambda –Nernst Cell

No Label

PR-4 –Communication

Pin

Function

Label

A2

Pro Tune CAN Low

CAN_LOW

B2

Pro Tune CAN High

CAN_HIGH

9

Document Revision: (2)

9

9

Product Manual

PR-4

2.Read Before Installing

Pro Tune products are developed with attention to robustness and reliability. However, some care is

required when installing the product

1 –Internal combustion engines are very sensible devices and in case of accidents present lethal risks. It is

very important that all care is taken, such as individual operator protection, fire prevention and fire fighting,

prior checking of fuels and lubricants, as well as the installation, maintenance and operation done only by

qualified people.

2 –Place the wiring harness as far as possible from the ignition circuit.

3 –Avoid installing the ECU in the engine compartment.

4 –Place the product in an accessible location for the USB cable, preferably with the main connector facing

down.

5 –When the wiring is done, keep unused (White) cables intact and connect them ti the negative battery

terminal.

6 –Make sure the intake pressure measurement hose attachment is securely fastened. Poorly fixed or

leaking hoses result in incorrect reading of intake pressure, which can cause serious engine damage.

7 –The intake hose must always be connected between the throttle body and the engine.

8 –If the triple cable named CMP is not used, do not cut it and isolate its wires individually.

9- Always check the wiring diagram of each sensor or actuator before finishing the harness and turning on

the ECU.

10- Pay attention to the safe grounding of the engine block and the vehicle chassis.

11-Pay attention to the sensors ground (Pin L2), with black cable, which should not be connected to the

battery or to the chassis of the vehicle. It is a ground wire for sensors, which must be used exclusively to

connect the negative terminal of the sensors.

12- Use suitable fuses in the power circuit.

13- Use suppressive spark plug cables and resistive type spark plugs.

14- Use shielded USB communication cables.

10

Document Revision: (2)

10

10

Product Manual

PR-4

3.Installation Diagram

3.1 –Basic Wiring:

Special Case:

When the user wishes that an auxiliary output to remain triggered after switching off the engine (electric

water pump, electric fan, etc), the ECU (pin 87 of the relay) and the main relay power must be apart from each other

in separated switches.

11

Document Revision: (2)

11

11

Product Manual

PR-4

4.1 –Inputs

Crank and Camshaft Position Sensors

1 –Inductive type:

*PS: The mesh must be grounded either on the Power GND pin of the ECU or through the sensor. If the mesh is

not grounded or grounded in the both sides, sync problems may occur.

2 –Hall effect type:

12

Document Revision: (2)

12

12

Product Manual

PR-4

Manifold Absolute Pressure (MAP)

Pro Tune ECUs have an internal MAP sensor, all you have to do is install a hose connecting the intake

manifold to the ECU. External MAP sensors can be used as well by following the diagram below.

Throttle Position (TP)

13

Document Revision: (2)

13

13

Product Manual

PR-4

Engine and Intake Air Temperatures Sensors

Lambda Sensor LSU 4.2 / 4.9

CAUTION: LSU 4.2 and LSU 4.9 have different pinout. This scheme doesn’t illustrates sensor pinout.

14

Document Revision: (2)

14

14

Product Manual

PR-4

Lambda Sensor NTK UEGO

Mass Air Flow–MAF

15

Document Revision: (2)

15

15

Product Manual

PR-4

Pedal Position Sensor

Vehicle Speed Sensor

16

Document Revision: (2)

16

16

Product Manual

PR-4

Generic Potentiometer (Gear Position, Steering Angle, etc)

17

Document Revision: (2)

17

17

Product Manual

PR-4

Load on Shift Lever

In order to use the Quick-Shift function, a load cell sensor must be applied to the vehicle shift lever. This

sensor is installed in Pro Tune’s factory, by sending the lever. For further information, contact technical support.

Alternatively, an activation signal switch can be used, the connection description is located on page 24.

Pinout

Pin

Function (4-way connector )

Function (5-way connector)

1

GND(-)

+ 12V

2

Sensor -

3

Sensor +

GND(-)

4

+ 5V

5

Signal (Vout)

18

Document Revision: (2)

18

18

Product Manual

PR-4

Oil / Fuel Pressure

Injectors –Sequential

Ps: Up to two low impedance (Peak and Hold) injectors can be used per output with 2A/0,5A drive.

19

Document Revision: (2)

19

19

Product Manual

PR-4

Injectors –8 Cylinders Semi-Sequential

Injectors –Secondary Injector Rail

Table of contents

Other PRO TUNE Control Unit manuals

Popular Control Unit manuals by other brands

Bosch

Bosch Rexroth R-IB IL 24 PSDO 8-PAC manual

Johnson Controls

Johnson Controls TrueRH Series Care, use and installation instructions

Asco

Asco 8316 Series Installation & maintenance instructions

GREE ELECTRIC

GREE ELECTRIC GRJWB04-J manual

Mikroe

Mikroe FM click quick guide

Monmouth Scientific

Monmouth Scientific CAM-F 1500 operating & maintenance manual

Kollmorgen

Kollmorgen MKD Series installation manual

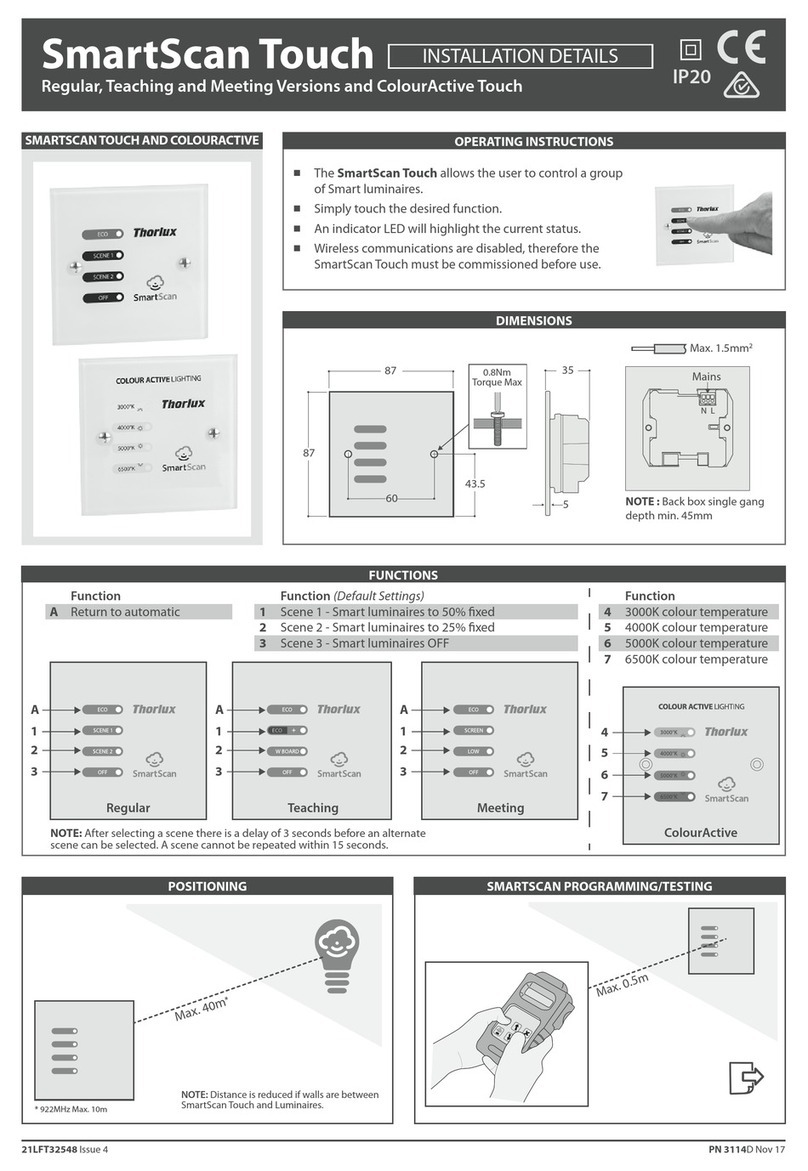

Thorlux Lighting

Thorlux Lighting SmartScan Touch Installation details

ZyXEL Communications

ZyXEL Communications N-611 user manual

Conrad

Conrad BRC34M operating instructions

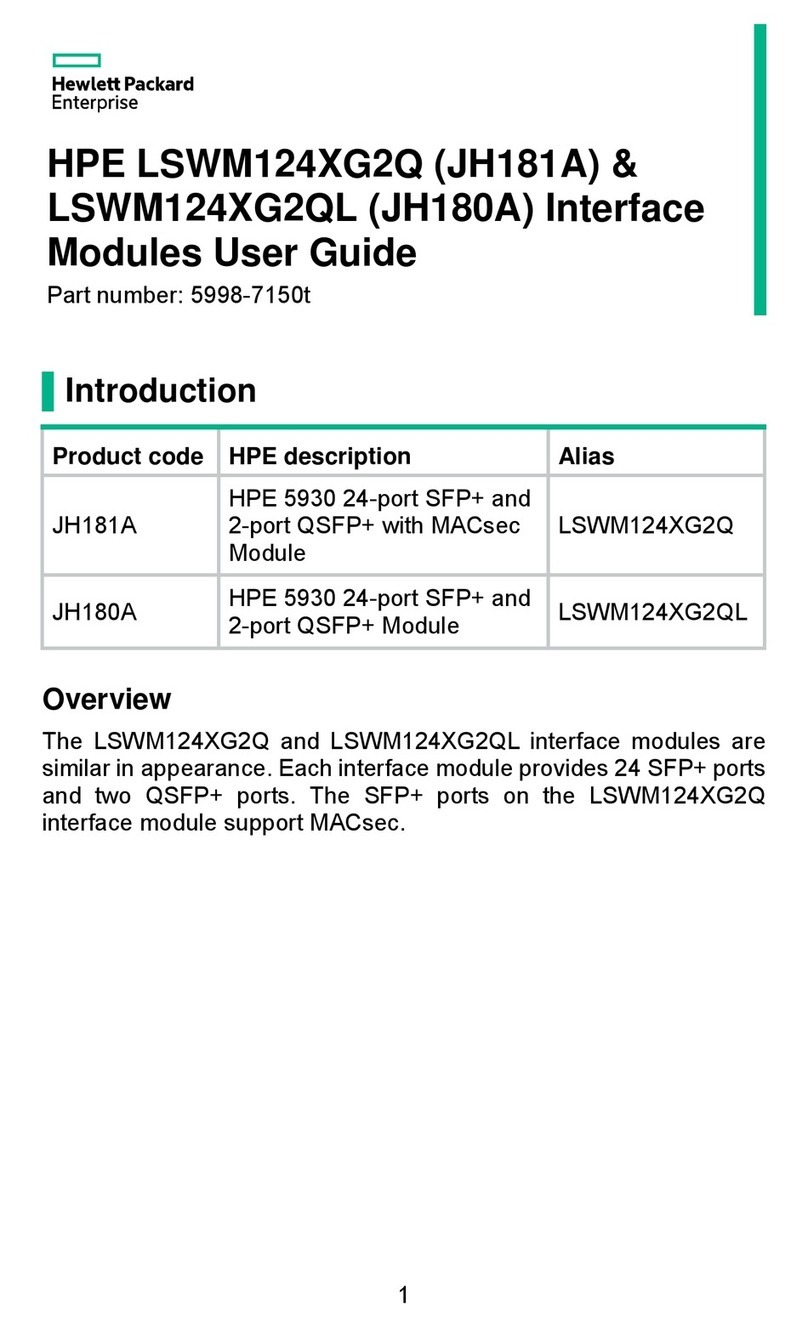

HPE

HPE LSWM124XG2Q user guide

UTC Fire and Security

UTC Fire and Security interlogix VT7820 Installation & operation instructions