Pro-Weld ARC 1850 User manual

OPERATION/MAINTENANCE

MANUAL

ARC 1850

PRO WELD

PAGE

1.0

INTRODUCTION.......................................................

1

2.0

WARRANTY............................

...................................

1

3.0

UNPACKING YOUR UNIT.......................................

1

4.0

SUGGESTED SAFETY PREC

AUTIONS.......….......

1

4.1

PERSONAL SAFETY PRECAUTIONS…………….

1

4.2

POWER SUPPLY SAFETY PRECAUTIONS……..

2

5.0

GENERAL DESCRIPTI

ON..........................…...........

2

6.0

ELECTRICAL INPUT REQUIREMENT.......…........

2

7.0

CONTROL PANEL DESCRIPTION.....

........…........

4

8.0

WELD GUN SETUP.........................................…........

5

8.1

PLUNGE LENGTH....................

.................................

5

8.2

CHECKING GUN LIFT....................................….......

6

9.0

PARTS LIST..........

..........................................…........

7thru13

10.0

TROUBLE SHOOTING...................................….......

15

LIST OF FIGURES

1

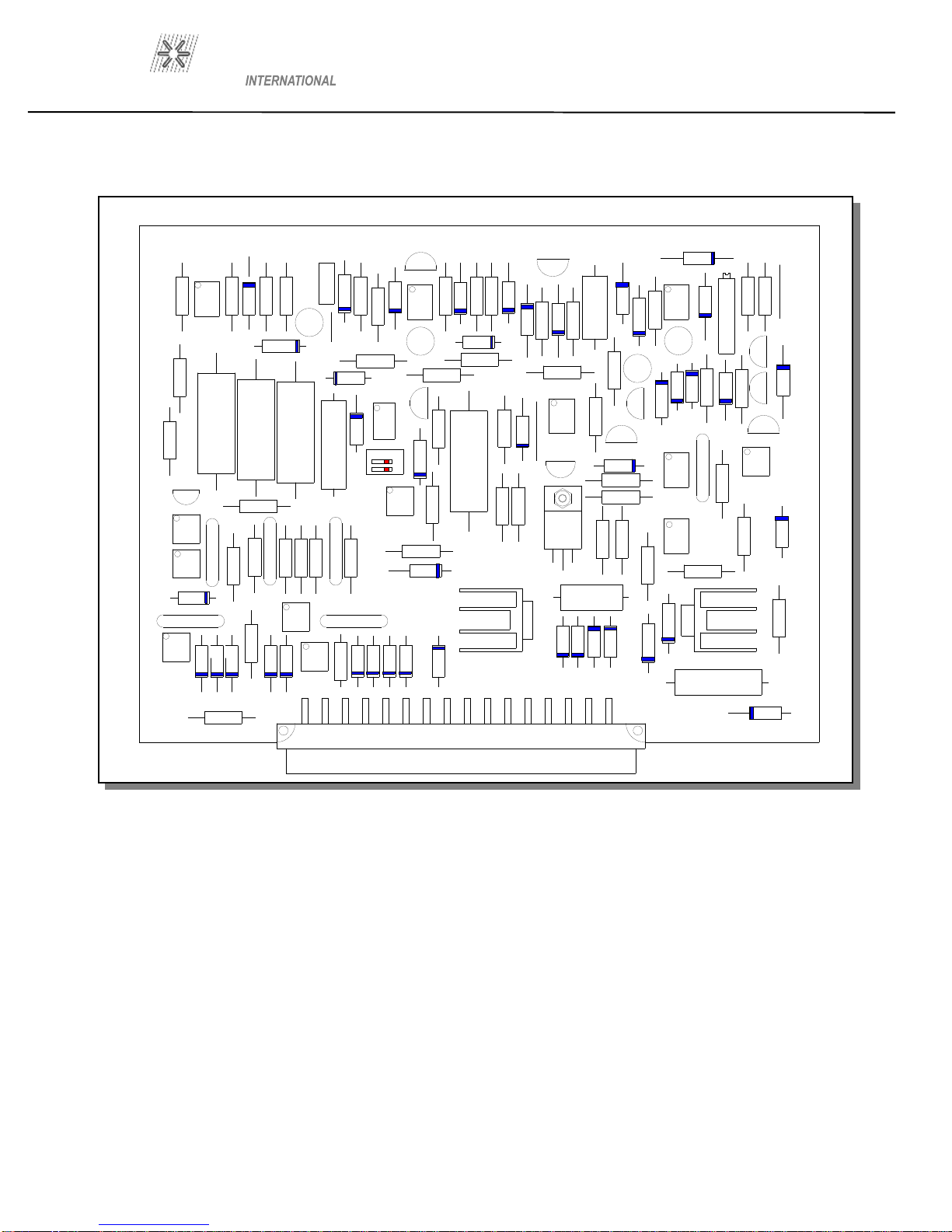

JUMPER LINK ARRANGEMENT...................…......

3

2

CONTROL PANEL FRONT.........................…........

..

4

3

STANDARD GUN SET

-

UP..........................…............

5

4

FUSE BLOCK.................................................

..............

6

5

CONTROL UNIT

-

FRONT.........................................

7

6

CONTROL UNIT

-

REAR..........................

.................

8

7

CONTROL UNIT

-

SIDE VIEW................................

9

8

RECTIFIER, WELD BRIDGE ASSY................…...

...

10

9

PRINTED CIRCUIT BOARD ENCLOSURE.…......

11

10

GUN TIMER CONTROL PCB...................................

12

11

MONITOR PCB..

.........................................................

13

12

CURRENT CONTROL PCB..............................….....

14

TABLE OF CONTENTS

ARC 1850

PRO WELD

ARC 1850

PRO WELD

ARC 1850

PRO WELD

ARC 1850

PRO WELD

ARC 1850

PRO WELD

PAGE 1

1

.0 INTRODUCTION

Your new stud welding equipment has been carefully co

n-

structed using the finest components and material available.

Used properly, this equipment will give you many years of

profitabl

e, efficient service.

The system incorporates the latest in engineering advances

for complete, reliable end welding of mild ste

el, stainless

steel and aluminum fasteners.

A careful study of this manual will enable you to understand

how the welder operate

s to insure proper performance under

all conditions.

2.0 WARRANTY

The electrical and mechanical components of the stud

welder are thoroughly performance inspected prior to asse

m-

bly in the welder. The assembled welder is completely pe

r-

formance checked. The welder is delivered to you in fun

c-

tional electro

-mechanical condition.

All parts used in the assembly of the welder and its

accessories are fully warranted for

a period of 1 YEAR from

the date of delivery. In addition, the welding capacitors are

warranted for a period of 1 YEAR from the

date of delivery.

The printed circuit boards used in all proweld equipment are

warranted for a period of 3 years.

Under the wa

rranty, the manufacturer reserves the

right to repair or replace, at their option, defective parts

which fail during the guarant

ee period. Notice of any claim

for warranty repair or replacement must be furnished to the

manufacturer by the purchaser within

ten (10) days after the

defect is first discovered. The manufacturer does not assume

any liability for paying shipping cost or any labor or mater

i-

als furnished where such cost are not expressly authorized in

writing.

The manufacturer does not warrant any parts or acce

s-

sories against failures resulting from misuse, abuse, improper

installation, maladjustment, or use not in accordance with the

op

erating instructions furnished by the manufacturer. The

warranty is valid only when studs are purchased from sources

approved by the manufacturer or are of identical specific

a-

tions to the manufacturer’s

3.0 UNPACKING YOUR UNIT

Upon receipt of your unit, place it as close as possible to the

point of installation before unpacking it. Once the unit is u

n-

packed, it is recommended that you inspect it for any phys

i-

cal damage that may have occurred in shipping.

Y

our unit has been completely assembled and inspected at

the factory. Upon receipt, the unit must be hooked up to the

recommended

incoming power before welding.

Place the unit in a large enough area to provide adequate

ve

n

tilation. Do not restrict the air flow around the front lou-

vers or from the fan at the rear of the unit. Do not allow w

a-

ter to enter the unit in any way.

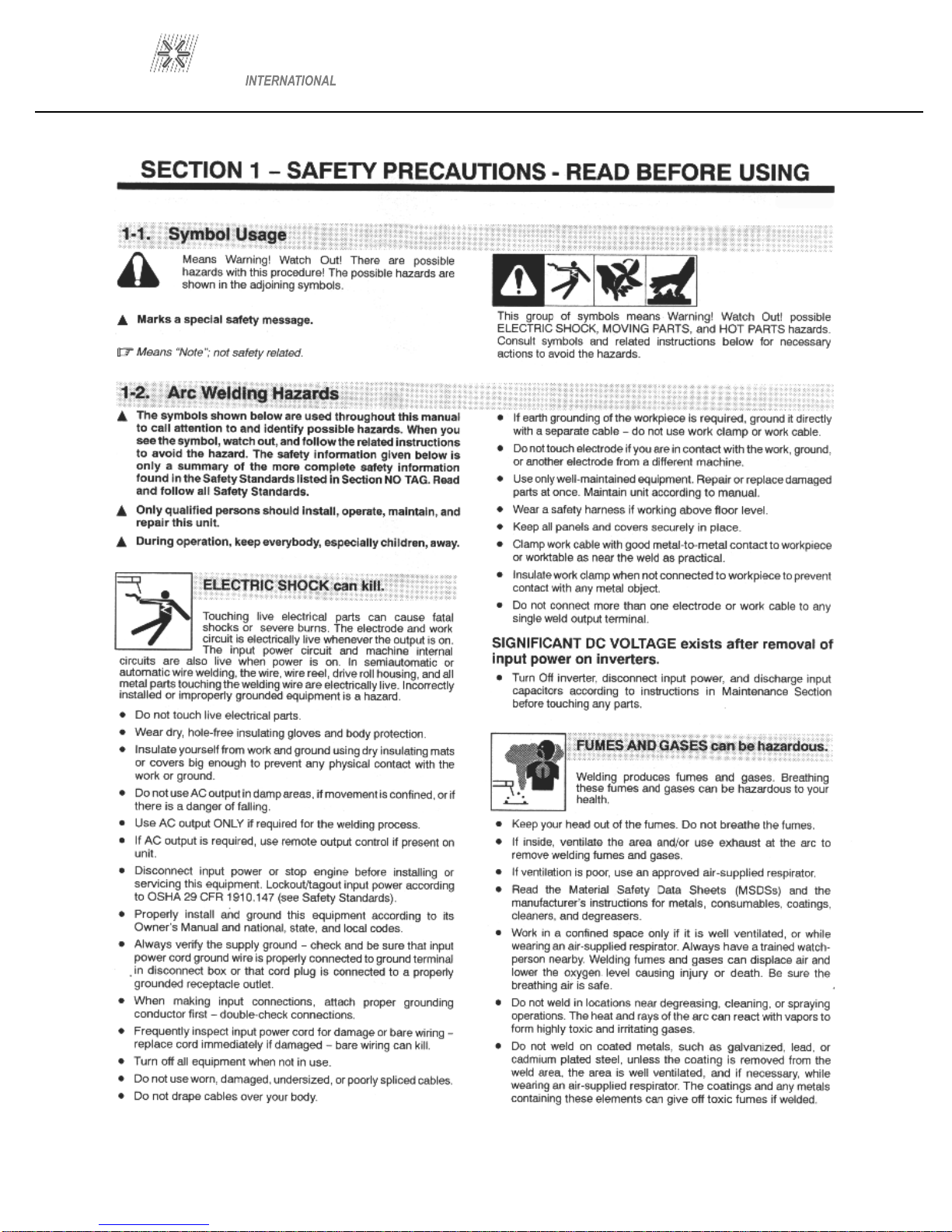

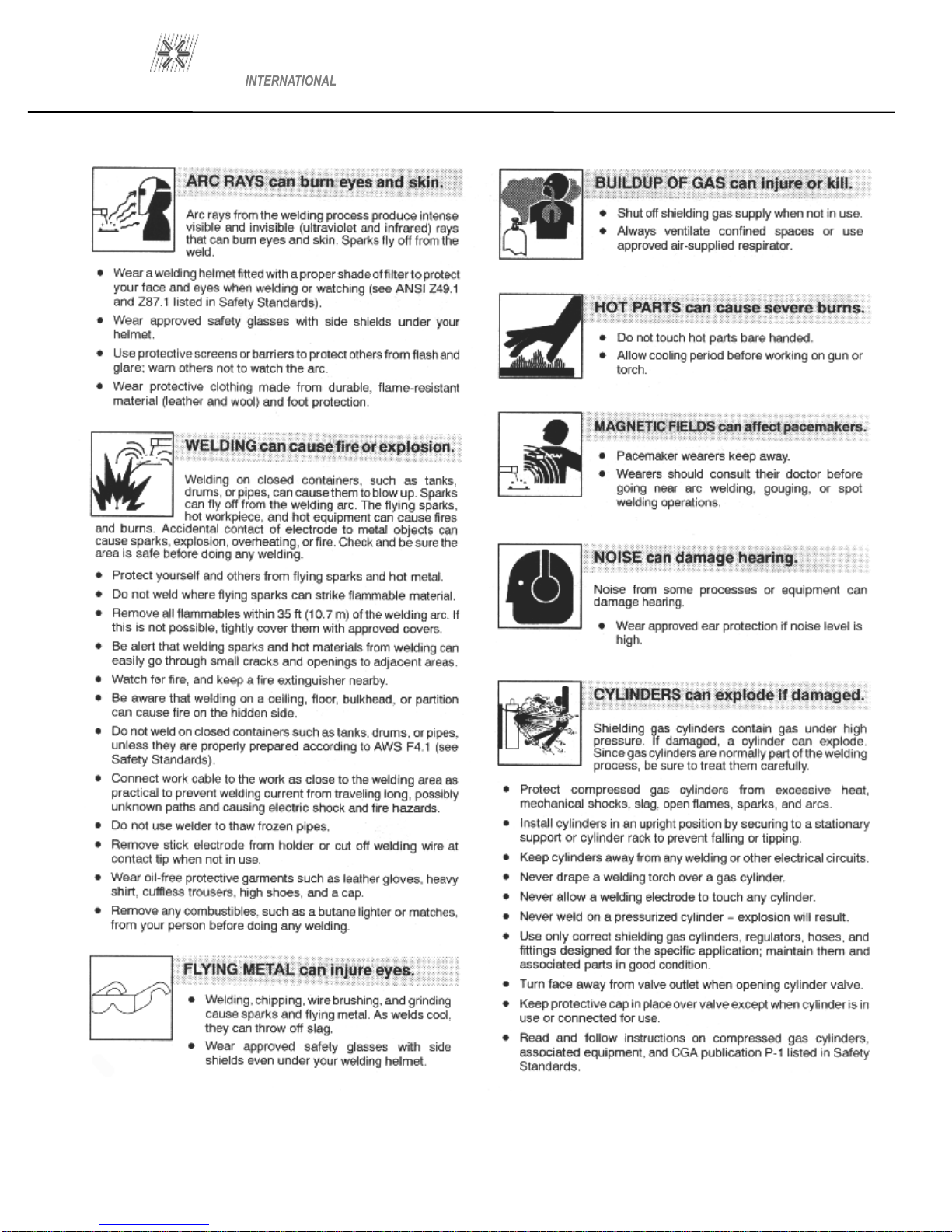

4.0 SUGGESTED SAFETY PRECAUTIONS

In any welding operation, it is the responsibility of the

welder

to observe all safety rules to insure his or her personal safety

and to protect those working in the area.

Reference is directed without endorsement or recommend

a-

tion to ANSI Z49.1, Safety in Welding and Cutting, and to

AWG Publication A6,1

-

66, Recommended Safe Practices for

Gas

-

Shielded A

rc Welding.

4.1 Personal Safety Precautions

1. Always treat electricity with respect. Under open circuit

conditions, the welding machines output voltage may be da

n-

gerous.

2. Don’t work on live circuits or conductors. Disconnect the

main power before checking the machine or performing any

maintenance or repair operations.

3. Be sure the welding machine cabinet is properly grounded

to a good electrical ground. Con

sult local electrical codes.

4. Never operate a welder in the rain, or operate a welder

while standing in water. Avoid wearing

wet or sweaty clothes

when welding.

5. Don’t operate with worn or poorly connected cables, and

don’t operate the weld gun with loose cable connections. I

n-

spect all cables frequently for insulation failures, exposed

wires, loose connections and repair as needed.

6. Don’t overload w

elding cables or continue to operate with

over heated cables.

7. Don’t weld near flammable materials or liquids in or near

the

area, or on ducts or pipes carrying explosive gases.

8. Don’t weld on containers which have held combustible or

flammable materials, or on materials which give off flamm

a-

ble or toxic vapors when heated.

ARC 1850

PRO WELD

PAGE 2

9

. Be sure to provide proper ventilation when welding in a co

n-

fined area.

10. Never look at the electric arc without wearing protective

eye shields.

11. Always use the proper protective cl

othing, gloves, etc.

12. Never strike an arc when near a bystander who is unaware

of the dangers of ultraviolet light to their

eyes.

4.2 Power Supply Safety Precautions

1.

Always connect the frame to the power supply to ground in

accordance with the National Electric Code and the manufa

c-

turer’s recommendation.

2.

Installation, servicing or trouble shooting should be done by

qualified personnel trained to work on

this type of equipment.

3.

Before servicing this piece of equipment, turn off the disco

n-

nect switch at the fuse box.

4.

When in operation, all the covers must be on the equipment.

5.0 GENERAL DESCRIPTION

THE

PROCESS

Stud welding is a time saving tool which semi

-

automatically

arc welds the FULL CROSS

-

SECTION of a weld stud to the

base

material in a fraction of a second and develops superior

strength over normal arc welding procedures.

Since the ARC

-

1850 stud

welding system provides the proper

arc length and allows you to select the proper arc time and

wel

d

ing current, the variables that affect weld quality are min

i-

mized.

THE UNIT

The ARC

-

1850 is a fully regulated stud welding power supply

that is available in a single or dual gun version

. Both versions

have the constant output feature that allows the unit to be used

as a power source that can operate external stud welding co

n-

trol units. An added feature in the ARC

-

1850 is the ability to

dial in the desired weld time and weld current before even

ma

k

ing a weld. By selecting the setup mode, the weld time and

current can be adjusted and displayed on the front panel’s dig

i-

tal meters.

.

A

specially designed electronic gun control circuit has been

incorporated in this system. If a fault condition occurs due to a

shorted gun solenoid or a faulty control cable, the circuit will

prevent gun triggering and eliminate damage to printed circuit

boards. The ARC

-

1850 system is capable of welding studs

from 12ga. to 3/4” diameter with precision and repeatability.

6.0 ELEC

TRICAL INPUT REQUIREMENT

This welding power source is designed to be operated from

three

-

phase, 60 Hertz, AC power supply which has a line vol

t-

age rating that corresponds with one of the electrical input vol

t-

age shown on the nameplate or input data label. Consult the

local electric utility if there is any question about the type of

electrical system available at the installation site or how proper

connections to the welding power source are to be made.

The

ARC

-

1850

should be operated from a separate fused or

circuit breaker protected circuit. Install three primary leads plus

one gr

ound wire (see tables for proper wire and fuse sizes)

through the inlet hole in the rear of the unit, using proper strain

relief

. The primary cables connect to the terminals L or line.

The fourth lead (ground connection) should be fastened to the

welder fr

om the ground bolt. The other end of the ground lead

or cable should be attached to a suitable ground such as a water

pipe, gro

und rod, etc.

This unit is equipped with input voltage jumper links either

installed or in a bag on the jumper link board to allow oper

a-

tion from different line voltages. If installed, the jumper links

are positioned for the highest voltage stated on the nameplate

or on the input data label. In either case the jumper links should

always be checked to see if they are properly positioned for

the

voltage being used.

Open the access door located on the lower portion of the rear

panel to expose the jumper link board. I

f necessary, reposition

the jumper links to match the line voltage being used. (see Fi

g-

ure 6.1)

ARC 1850

PRO WELD

PRIMARY WIRE

DELAY TYPE FUSE

SIZE

-

AWG

GND

SIZE IN AMPS

230V

NO.1(2)

NO.2

200

460V

NO.4(6)

NO.6

100

575V

NO.4(6)

NO.6

9

0

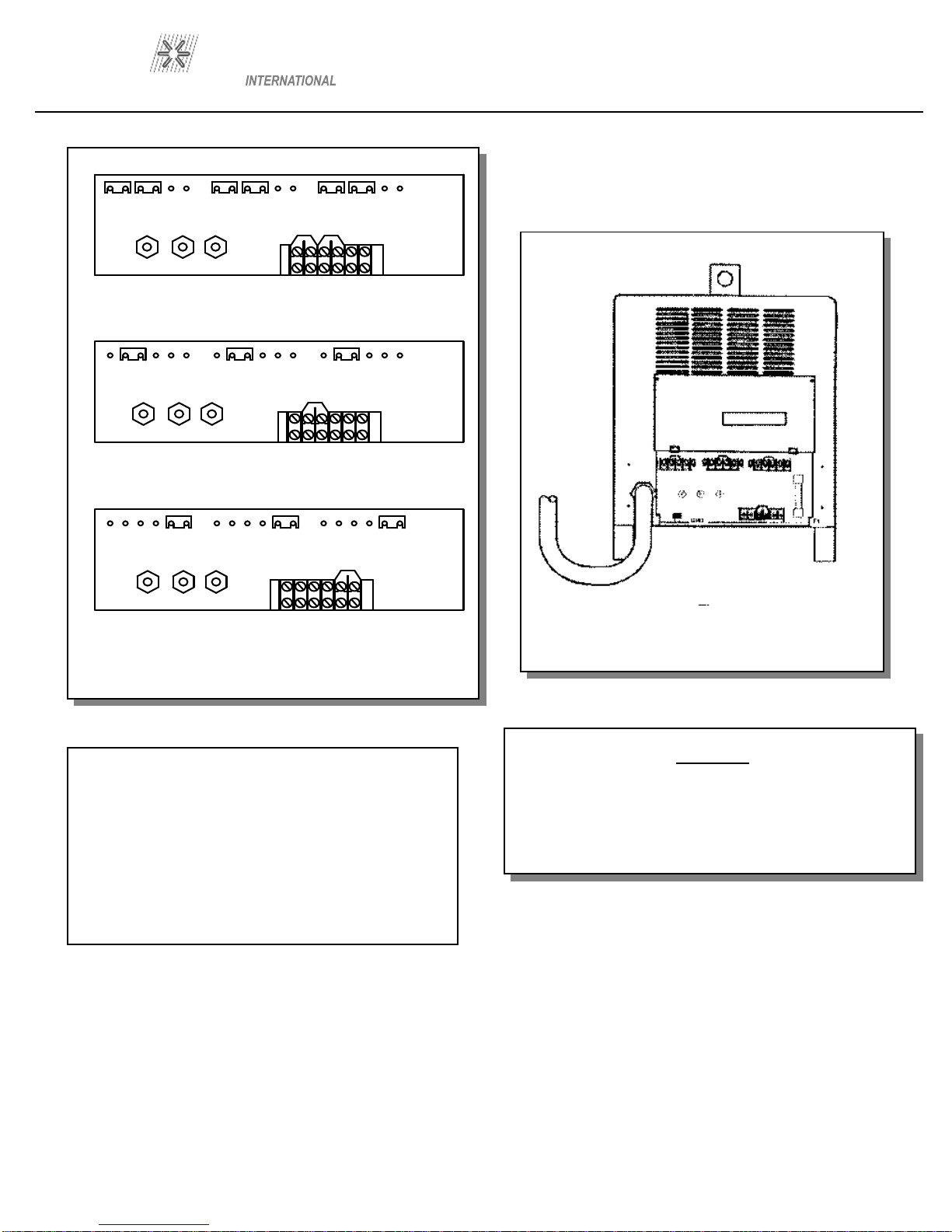

Figure 1

Jumper Link Arrangement

230V

L3L2L1

654321

1 654321 65432654321

L3L2L1

654321

1 654321 65432654321

L3L2L1

654321

1 654321 65432654321

460V

575V

Jumper Link connections

CAUTION

The stud labeled GND is connected to the unit chassis and

is for grounding purposes only. Do not connect a wire

from th

e terminal labeled GND to one of the three

-

phase

line terminals as this may result in “hot” power unit cha

s-

PAGE 3

ARC 1850

PRO WELD

Figure 2 CONTROL PANEL FRONT

(DUAL GUN SYSTEM)

7

.0 CONTROL PANEL DESCRIPTION

START/STOP PUSH BUTTON

Momentarily depressing the START button will energize the

main contactor inside the unit allowing all circuits to be act

i-

vated and the the cooling fan to run. Momentarily depressing

the STOP button will deactivate the entire machine.

STUD/CONSTANT

OUTPUT SWITCH

When this switch is in the stud position, the unit is a ded

i-

cated stud welding power supply with built in time and cu

r-

rent controls. When in the constant output position the unit

becomes a welding power supply that can operate an external

control

box.

WELD/SETUP SWITCH

This switch directs the digital panel meter to display either

the setup parameters or the actual weld p

arameters. This

switch

must be in the weld position for the unit to weld.

TIME/CURRENT SWITCH

This switch selects either the

weld time or weld current that

is to be displayed on the digital meter.

WELD TIME ADJUSTMENT

Select: SETUP, TIME and adjust th

e time control knob until

the digital meter displays the desired time. Return setup

switch to WELD before attempting to weld. Th

e weld time is

adjustable from .1 to 1.6 seconds.

W

ELD/CURRENT ADJUSTMENT

Select: SETUP, CURRENT and adjust the current control

knob until the digital meter displays the desired current. R

e-

turn setup switch to WELD, before attempting to weld. Weld

current is adjustable from 100 to 1900 amps.

DIGITAL PANEL METERS

D

isplays weld time or weld current.

After a stud weld, the digital meter will automatically display

the actual weld parameters. The meter will automatically r

e-

set and display the time or current for each weld.

TRIGGER LED INDICATOR

The trigger LED “on” indicates a complete circuit to

the unit

through the gun control cables and gun switch. This LED

will turn “on” when the gun trigger is pressed.

GUN FAULT LED INDICATOR

The gun fault LED “on” indicates a shorted gun solenoid or a

shorted control cable. The LED will stay “on” and lock

out

the gun from triggering.

THERMAL LED INDICATOR

The thermal LED “on” indicates the internal temperature has

reached the max

imum rated temperature in either the weld

bridge or the main transformer. LED “on” will prevent the

gun from being triggered.

PAGE 4

ARC 1850

PRO WELD

8

.0 WELD GUN SET

-

UP

8.1 Plunge Length

1. A different and correctly sized chuck and ferrule grip are

needed for each different

stud diameter and style that will be

welded (see PRO WELD Accessories catalog for help in this

area). The appropriate chuck, or

stud holder, is inserted into

the tapered chuck adapter and tapped lightly to insure a tight

fit. The ferrule grip is inserted in the hole in the foot and s

e-

cured with the locking screws to hold it in place.

2. Studs must NOT bind or hang up on the foot, ferrule grip,

or ferrule duri

ng the entire stud welding process. To assure

this, the foot/ferrule arrangement must be centered in relation

to the stud to be

welded. To assure centering, loosen the leg

screws that hold the foot to the legs. Place a stud in the

chuck and a ferrule in th

e ferrule grip. With the leg screws

loosened, the foot will move freely in all directions. Adjust

the foot so that the stud is centered in the ferrule and no co

n-

tact occurs between the stud and the ferrule during retraction

or forward plunge of the stud.

3. The “plunge length” is the amount of the stud exposed b

e-

yond the ferrule during initial set

-

up. Set the plunge by loo

s-

ening the leg adjusting screws and moving the foot until the

stud extends 1/8” to 3/16” past the end of the ferrule. Tighten

the

leg adjusting screws after setting the plunge and recheck

centering to be sure the stud is aligned properly in the fe

r-

rule.

4. The lift height, which determines the arc length, has been

preset at the factory and will automatically lift and plung

e the

stud during the welding process. “Lift”, is the distance the

gun will raise the stud above the welding surface during the

weld. This distance governs the voltage and the arc. I

m-

proper lift will cause unsatisfactory welds. Refer to par

a-

graph 8

-

1 if it becomes necessary to a

d-

5

. Make sure that the cables are connected to the power

source (standard set

-

up is straight polarity

-

Negative to co

n-

troller (or gun) and Positive (ground cable) to the work su

r-

face).

6. Turn on the power supply and adjust the current and time

for the weld base diameter of the fastener to be welded.

7.

Place the gun, loaded with the stud and ferrule, squarely

against the grounded work surface. The main spring in the

gun will ta

ke up the “plunge length” and the ferrule will seat

against the base plate.

DO NOT MOVE THE GUN DURING THE WELD

CYCLE

8. Pull

the trigger holding the gun completely still as above.

The gun will lift the stud from the base plate and draw an

arc. The end

of the stud and the adjacent material of the base

plate, will be melted by the weld arc.

The gun will then

plunge the stud into the molten pool, exti

n-

guishing the arc, to end the controlled portion of the weld

cycle.

9. After the controlled weld cycle, allow the molten metal to

solidify briefly with the work surface to assure completion

of the cycle (about an extra second holding "still" after the

weld

is usually sufficient).

10. Remove the gun from the work by lifting straight away

from the welded stud (this will assure better

life to the gun's

expendable accessories). The ferrule may now be removed

by breaking it away from the welded stud to allow ins

pect

-

tion of the weld results. After inspection of sample welds the

gun can be adjusted, as per the step in this procedure,

for

optimum results.

PAGE 5

ARC 1850

PRO WELD

Figure 4

FUSE BLOCK

(Dual gun version shown)

F12

F11

F10

F9

F8

F7

F6

F5

F4

F3

F2

25 AMP

SLO BLO

5 AMP

CERAMIC

1 AMP

1 AMP

1 AMP

1 AMP

1 AMP

25 AMP

SLO BLO

25 AMP

SLO BLO

1 AMP

1 AMP

8

.2 Checking Gun Lift

To measure lift, turn the stud welding unit on and set the timer to

maximum time. (On certain units there

may be a Lift

Check switch available, and in these cases this switch can be used

to check lift.) Trigger the gun in the air, or

on a

non-

grounded or insulated surface, to observe the lift cycle. Mea

s-

ur

ing the distance the stud or gun mechanism

moves equals lift

-

usually this can be easily done by visual obse

r-

vation or simple measurement against a static ref-

erence point (i.e. the ferrule properly seated in the ferrule grip).

Recommen

ded Lift Settings.

Stud Base Dia.

Lift Setting

Less than 1/2”

1/16”

1/2” through 3/4”

3/32”

Greater than 3/4”

7/64”

When it does become necessary to adjust lift, you do so by r

e-

moving the rear cap from the gun. This will expose the

rear coil yoke assembly, the set screw and the lift adjusting screw

(Loos

en the set screw to avoid damaging the threads

of the lift adjusting screw).

To increase lift: turn the lift adjusting screw out (counter cloc

k-

wise).

To decrease lift: turn the lift adjusting screw in (clockwise).

Once the lift has been set, tighten the set screw and r

eplace the rear

cap.

PAGE 6

ARC 1850

PRO WELD

1

Figure 5 Control Unit (Front View)

9.0 PARTS LIST

ITEM

DESCRIPTION

PART NUMBER

1

Switch

104

-

0014

2

On/Off Operator

104

-

0016

2

N.O. Contact

104

-

0017

2

N.C.

Contact

104

-

0018

3

Power Light (Green Neon)

102-

0087

4

Knob

102

-

0060

4

20k Potentiometer

111

-

0012

5

Red LED

108

-

0028

6

Pan

el Meter

103

-

0004

7

Green LED

108

-

0029

8

Amber LED

108

-

0030

9

Positive Output Terminal

102

-

0058

10

4 Pole Panel Mounted Conn

ector

107

-

0001

9

10

11

1 6 7 5 2 3

4 8

PAGE 7

ARC 1850

PRO WELD

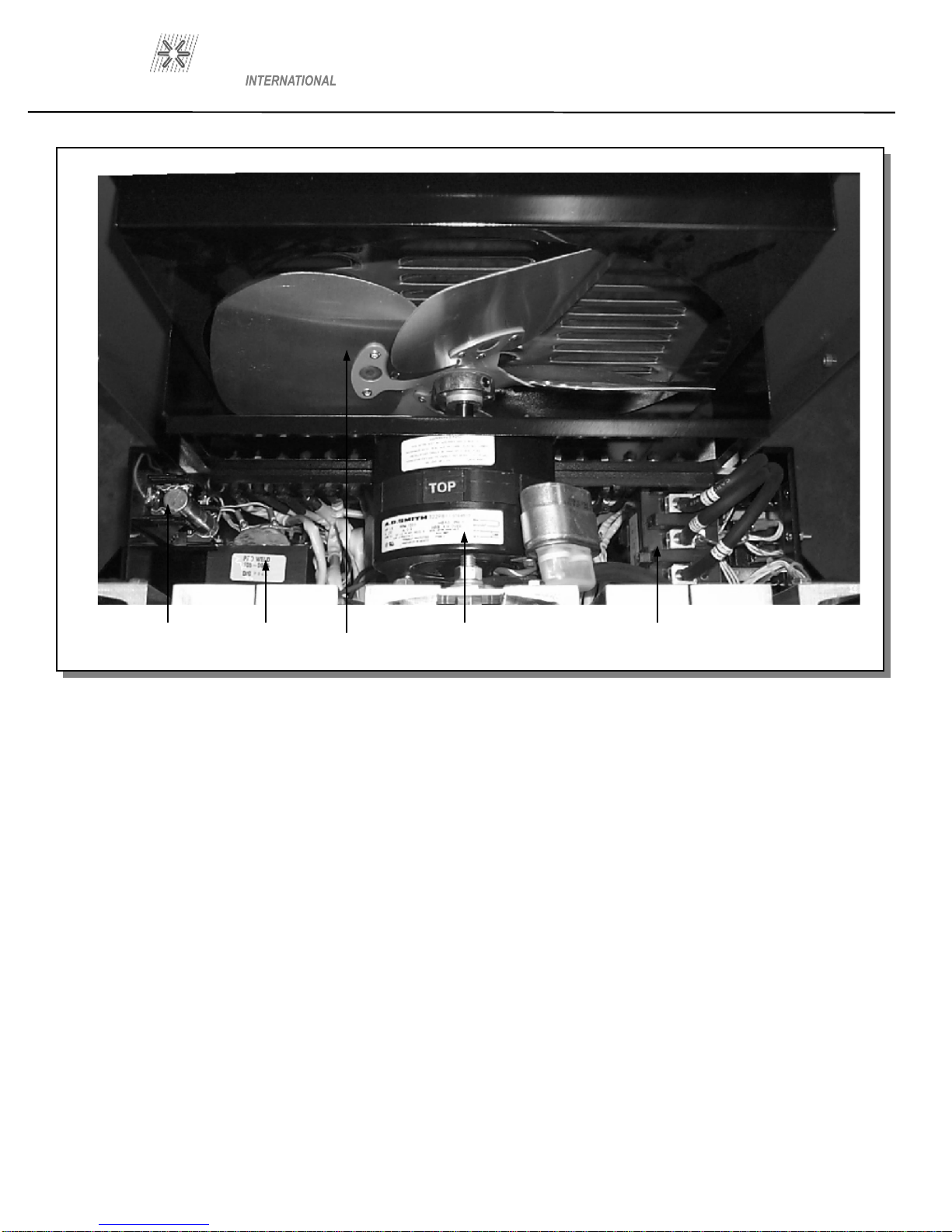

Figure 6 Control Unit

Rear

12

13

14

15

16

9.0 PARTS LIST

ITEM

DESCRIPTION

PART NUMBER

12

Fuse 6 amp 600 volt

102

-

0007

13

Control Transformer

105

-

0015

14

Fan Blade

14”

102

-

0083

15

Fan Motor

102

-

0085

16

Start Contactor

113

-

0017

PAGE 8

ARC 1850

PRO WELD

Figure 7 Control Unit

Side View

18

17

FRONT OF UNIT

9.0 PARTS LIST

ITEM

DESCRIPTION

PART NUMBER

17

Main Transformer

105

-

0023

18

Shunt

102

-

0107

PAGE 9

ARC 1850

PRO WELD

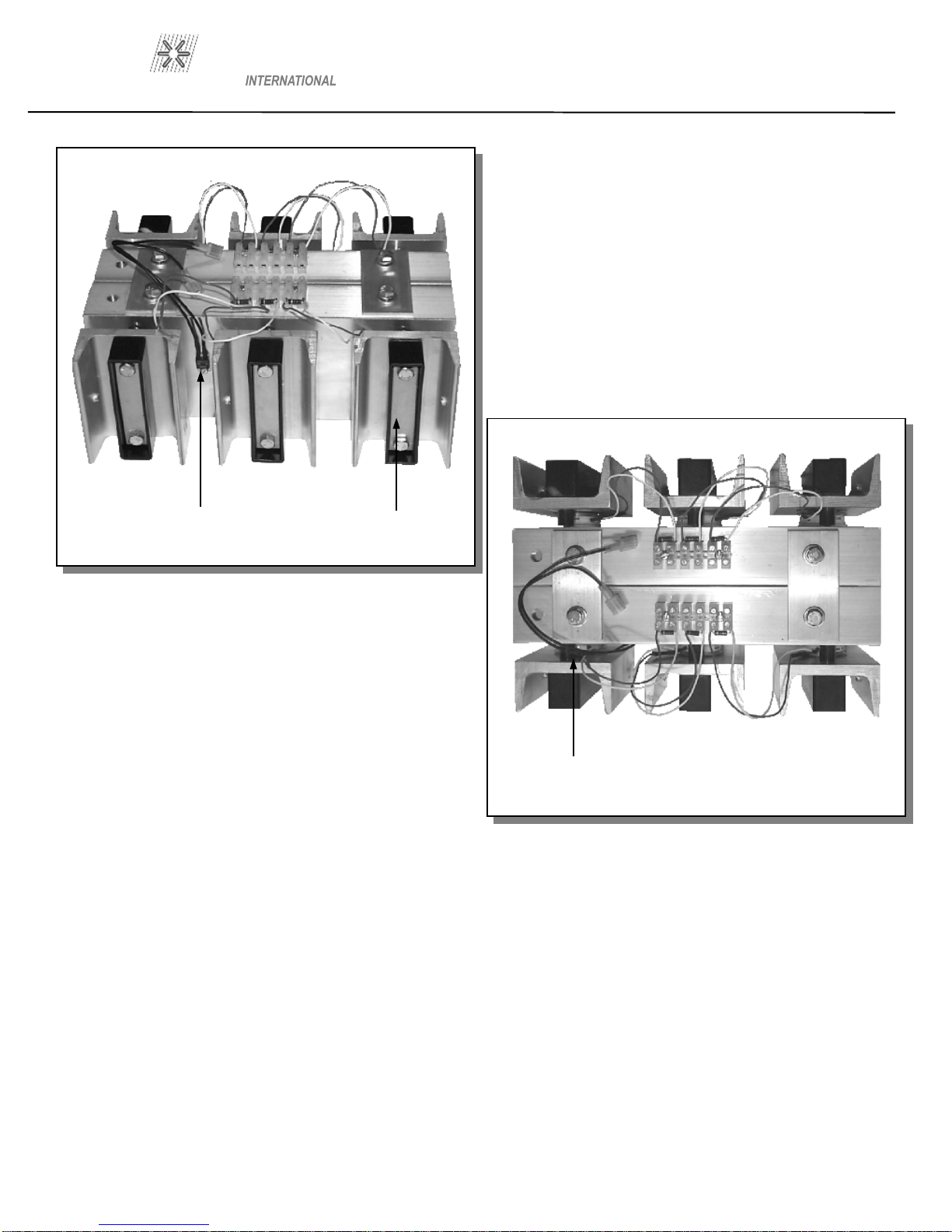

Figure 8

RECTIFIER, SCR ASSEMBLY

SIDE AND TOP VIEW

9.0 PARTS LIST

ITEM

DESCRIPTION

PART NUMBER

19

Weld SCR Thermostat

102

-

0032

20

Weld SCR Clamp

102

-

0109

21

Weld SCR

108

-

0058

19

20

21

PAGE 10

ARC 1850

PRO WELD

9.0 PARTS LIST

ITEM

DESCRIPTION

PART NUMBER

22

Choke Coil

105

-

0004

23

Time Control P.C.Board

600

-

0010

24

Current Control

P.C.Board

600

-

0012

25

Monitor Control P.C.Board

600

-

0011

26

Time Control P.C.Board

600

-

0010

27

Fuse Block

104

-

0015

28

Sustai

ning arc SCR

108

-

0042

29

Gun Discharge Capacitor

106

-

0024

Front of Unit

Figure 9

Printed Circuit Board Enclosure

Top and Side View

22

23

24

25

26

27

28

29

PAGE 11

ARC 1850

PRO WELD

PAGE 12

Figure 10

GUN TIME CONTROL P.C. BOARD

P/N 600

-

0010

21

ON

OFF

IC104

V112

C104

+

+

R122

IC103

R121

D122

R123

R124

C106

C107

D118

R130

R128

D125

V106

D126

R144

R131

R132

D119

D116

R145

D103

R114

C102 +

D117

ZD102

R119

IC102

D114

R118

R112

R125

C105

V109

V110

D113

R117

D115

R116

D112

D104

V108

R115

+

R141

R142

OP101

V103

D102

R103

R155

V111

D111

D139

OP104

R126

R127

R153

D124

ZD105

D127

C108

+

R139

R138

C110 +

R104

C109 +

R129 R120

V105

R137

OP

109

OP

105

C111

R149

R143

C103

R136

R135

R150

R134

C112

D140

OP

102

R102

R101

R110

R109

R108

R140

C101

+

D101

D133

D132

D135

D134

D138

R151

Q101

D107

D108

D106

D105

ZD103

ZD104

V102

R107

D121

R113

R105

IC101

R146

D109

VR101

R111

R154

OP

103

OP110

C115

R147

D110

C114

OP

106

C113

OP

107

OP

108

R133

D131

D130

D129

D136

D137

R152

D120

V104

V107

ZD101

R148

ARC 1850

PRO WELD

Figure 11

MONITOR P.C. BOARD

P/N 600

-

0011

PAGE 13

IC201

R231

V201

R226

R202

C202

R203

D201

C201 +

R206

OP203

C209

+

IC203 R211

R212

R213

R210

IC202

R207

R208

R209

R204

OP201

OP202

C204

C203

R215

OP205

OP207

OP213 OP209

C205

OP204

C206

+

D204

V202

R217

R216

D202

D203

R218

D207

OP208

R221

R220

V204

V203

R219

R234

OP210

ZD202

D209

OP206

R223

D205

D206

R225

V205

R224

D207

C208

+

R227

V206

V207

OP212

OP211

C207

R222

R235

D210

ZD203

D208

R228

R229

R230

VR201

ZD201

R232

R233

R201

R205

R214

Table of contents

Other Pro-Weld Welding System manuals

Popular Welding System manuals by other brands

Telwin

Telwin 954374 instruction manual

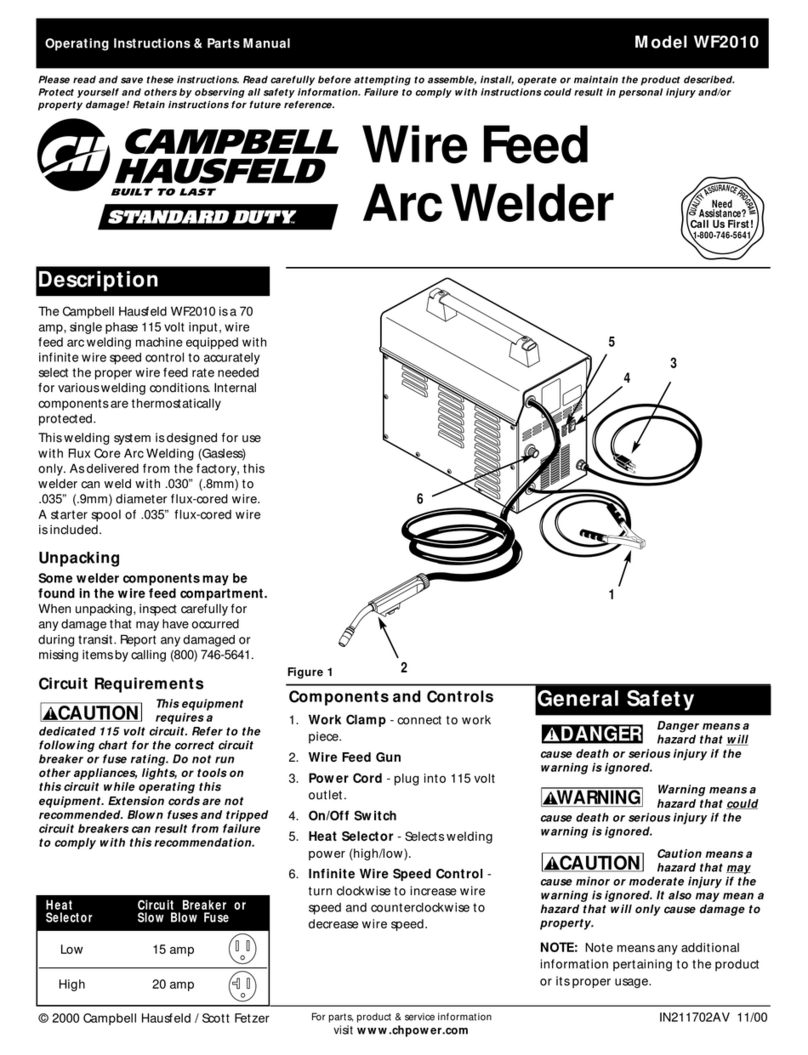

Campbell Hausfeld

Campbell Hausfeld WF2010 Operating instructions & parts manual

Kemppi

Kemppi A5 MIG Rail System 2500 operating manual

Telwin

Telwin 954426 instruction manual

Magmaweld

Magmaweld Monotig 160ip user manual

MEGAPOWER

MEGAPOWER MP-13030HWG Operator's manual

GYS

GYS EASYMIG 110 manual

ESAB

ESAB Aristo Mig C3000i instruction manual

Lincoln Electric

Lincoln Electric AC-225 Technical specifications

Praxair

Praxair PROSTAR manual

Lincoln Electric

Lincoln Electric LINC FEED 37 Operator's manual

Chicago Electric

Chicago Electric 55167 Assembly and operating instructions