Pro-Weld AG-805 User manual

OPERATION/MAINTENANCE

MANUAL

300-0805

PRO WELD

TABLE OF CONTENTS

1.0 INTRODUCTION........................................................................................ 1

2.0 WARRANTY..........................................................................................…... 1

3.0

SUGGESTED SAFETY

PRECAUTION...................................................

1

4.0 GENERAL DESCRIPTION........................................................................ 2

5.0

UNPACKING................................................................................................

2

6.0

GUN SET

-UP................................................................................................. 3

7.0

WELD TEST AND INSPECTION.............................................................

5

7.1

WELD TEST.................................................................................................

5

7.2 WELD INSPECTION.................................................................................. 5

7.3

CAUSES OF POOR OR ERRATIC WELDS...............…...............…….

5

7.4

TROUBLE SHOOTING POOR WELDS..................................................

7

8.0

MAINTENANCE..........................................................................................

7

8.1

DISASSEMBLY..........................................................……………………..

7

8.2

RE

-

ASSEMBLY…………………………..............................................…..

7

8.3 WELD CABLE REPLACEMENT..……………....................................... 8

8.4 CONTROL CABLE REPLACEMENT..................................................… 8

8.5 GUN MAINTENANCE................................................................................. 8

PARTS LIST GUN ASSEMB

LY ARC STD. LD................…......………. 9,10

9.0 TROUBLE SHOOTING GUIDE............................................................... 11

PRO WELD 300-0805

300-0805

PRO WELD

PRO WELD 300-0805

300-0805

PRO WELD

PRO WELD 300-0805

1

.0 INTRODUCTION

Your new stud welding equipment is constructed

of the finest components and material available.

Used properly

, this equipment will give you years

of profitable, efficient service.

The system incorporates the latest in engineering

advanc

es, for complete reliable welding of mild

steel, stainless steel, and aluminum.

2.0 WARRANTY

The electrical and mechanical co

mponents of the

stud welder are thoroughly performance inspected prior

to assembly in the welder. The assembled welder is

completely performance checked. The welder is d

e

li

v-

ered to you in functional electro

-

mechanical cond

i

tion.

All parts used in the assembly of the welder and

its accessories are fully warranted for a period of 1

YEAR from the date of delivery. In addition, the wel

d-

ing capacitors are warranted for a period of 1 YEAR

from the date of delivery. The printed circuit boards

used in all proweld equipment are warranted for a p

e-

riod of 3 years.

Under the warranty, the manufacturer reserves

the right to repair or replace, at their option, defective

part

s which fail during the guarantee period. Notice of

any claim for warranty repair or replacement must be

furnished to the manufa

cturer by the purchaser within

ten (10) days after the defect is first discovered. The

manufacturer does not assume any liabilit

y for paying

shipping cost or any labor or materials furnished where

such cost are not expressly authorized in writing.

The ma

nufacturer does not warrant any parts or

accessories against failures resulting from misuse,

abuse, improper installation, malad

justment, or use not

in accordance with the operating instructions furnished

by the manufacturer. The warranty is valid only whe

n

studs are purchased from sources approved by the

manufacturer or are of identical specifications to the

manufacturer’s

3

.0 SUGGESTED SAFETY PRECAUTIONS

In any welding operation, it is the responsibility of the

welder to observe all safety rules to insure his or her pe

r-

sonal safety and to protect those working in the area.

Reference is directed, without endorsement or recomme

n-

dation, to ANSI Z49.1, Safety in Welding and Cutting, and

to AWG Publication A6

-

66, Recommended Safe Practices

for Gas

-Shielded

Arc Welding.

1. Always treat electricity with respect. Under open ci

r-

cuit conditions, the welding machines output voltage may

be dangerous.

2. Don’t work on live circuits or conductors. Disconne

ct

the main power before checking the machine or perfor

m-

ing any maintenance.

3. Be sure the welding machine cabinet is properly

grounded to a good electrical ground. Consult local ele

c-

tr

i

cal codes.

4. Never operate a welder in the rain, or operate a welder

while standing in water. Avoid wearing wet or sweaty

clothes when welding.

5. Don’t operate with worn or poorly connected cables,

and don’t operate the weld gun with loose cable conne

c-

tions. Inspect all cables frequently for insulation failures,

exposed wires, loose connections and repair as needed.

6. Don’t

overload welding cables or continue to operate

with over heated cables.

7. Don’t weld near flammable materials or liquids in

or

near the area, or on ducts or pipes carrying explosive

gases.

PAGE 1

300-0805

PRO WELD

8

. Don’t weld on containers which have held

combustible or flammable materials, or on m

a-

terials which give off flammable or toxic v

a-

pors when heated.

9. Be sure to provide for proper ventilation

when welding in a confined area.

10. Never look at the electr

ic arc without

wea

r

ing protective eye shields.

11. Always use the proper protective clothing,

gloves, etc.

12. Never strike an arc when near a

bystander

who is unaware of the danger of ultraviolet

light to their eyes.

4

.0 GENERAL DESCRIPTION

AG

-

805 LIGHT DUTY ARC GUN W/DAMPER

(Part No. 300

-

0805)

A shaped to the hand, semi automatic stud welding

tool. Welds any length stud with a diameter range of

12 gauge through 5/8 inches. Refer to figure 4

-

1 for

weight and size s

pecifications.

5.0 UNPACKING

There is very little to do when unpacking your ARC

Stud Welding gun. Your Stud Welder comes co

m-

plete with all the accessories and tool required for

set

-

up, adjustment, and maintenance. Aside from the

correct chuck, ferrule grip, and any special access

o-

ries required for your application your ARC weld

gun is ready for hook

-

up to a Pro Weld power

source.

PAGE 2

Typical working weight gun plus

4 feet of unsupported 1/0 cables ..7 pounds

Shipping weight of gun plus

approximately 8 fee

t of

1/0 cable and connectors....... 11 pounds

Note: Chuck and ferrule grip are not standard

and must be ordered separately.

Figure 4

-

1 Standard AG

-

805 M.D. ARC Gun

1.0

10

6.1

6.6

PRO WELD 300-0805

6

.0 GUN SET

-

UP

The standard gun set

-

up is used for welding the m

a-

jority of applications. It consists of the standard a

d-

justable face plate, two legs, a foot, chuck adapter,

chuck, and spring for your specific stud size.

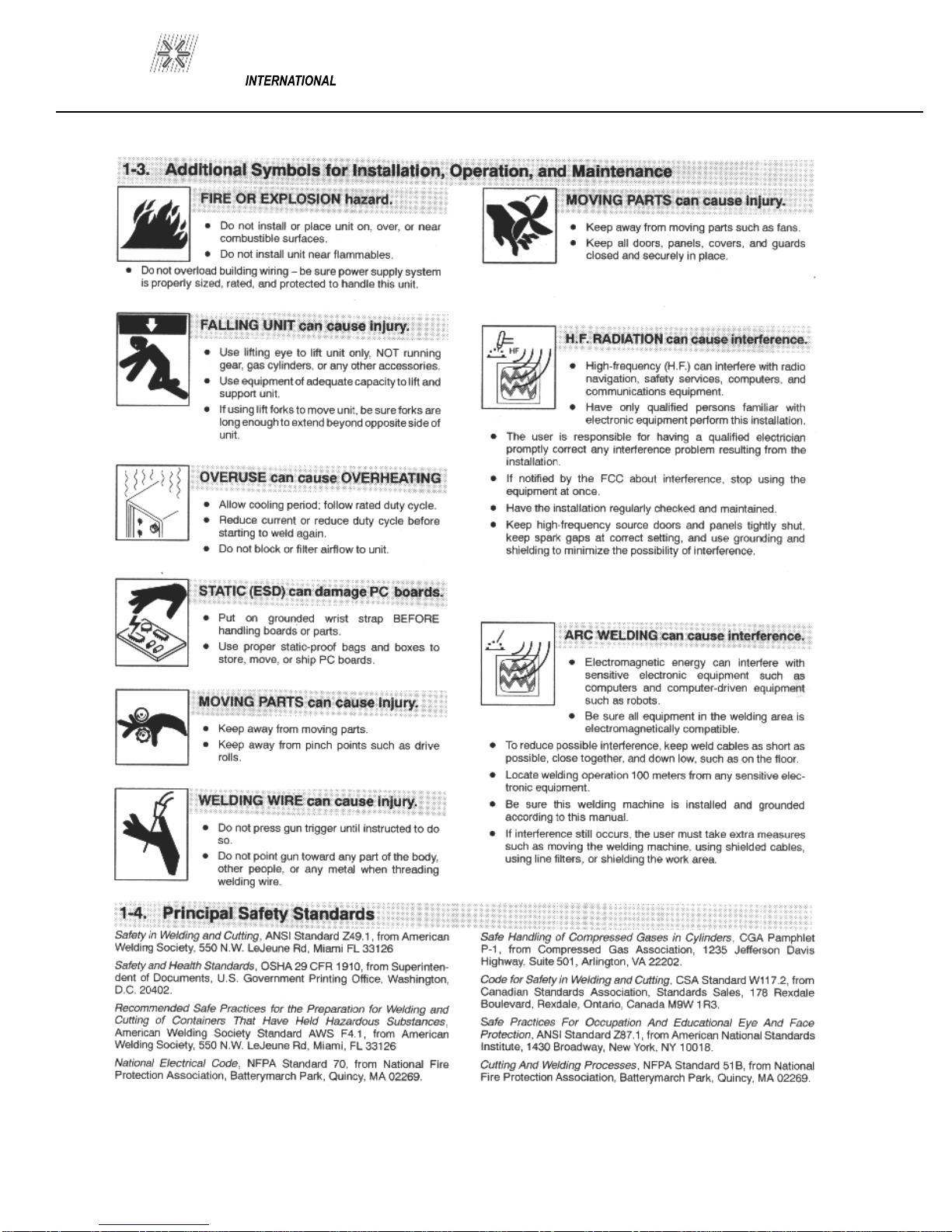

The following is a step by

step explanation of the

co

r

rect way to set up the gun. (Refer to Figure 6

-

1)

1. A different, and correctly sized, chuck and ferrule

grip are needed for e

ach different stud diameter and

style that will be welded. The appropriate chuck, or

stud holder, is inserted into the tapered

chuck adapter

and tapped lightly to insure a tight fit. The ferrule

grip is inserted in the hole in the foot and secured

with the locking screws to hold it in place.

2. Studs must NOT bind or hang up on the foot, fe

r-

rule grip, or ferrule during the entire stud welding

process. To assure this, the foot/ferrule arrangement

must be centered in

relation to the stud to be welded.

To assure centering, loosen the locking screws that

hold the foot to the legs. Place a stud

in the chuck

and a ferrule in the grip. With the locking screw

loosened, the foot will move freely in all directions.

Adjust the foot so that the stud is centered in the fe

r-

rule and no contact occurs between the stud and the

ferrule during retraction or forward plunge of the stud.

Tighten the lockin

g screws after centering the stud.

3. The “Plunge Length” is the amount of stud exposed

beyond the ferrule during initial set

-

up. Set the plunge

by loosening the leg adjusting screws and moving the

foot until the stud extends 1/8” to 3/16” past the end

of

the ferrule. Tighten the leg adjusting screws after se

t-

ting the plunge and re

-

check centering to be sure the

stud is aligned properly in the ferrule.

4. The lift height, which deter

mines the arc length,

has been pre

-

set at the factory and will automatically

lift and plunge the stud during the welding process.

“Lift” is the distance the gun will raise the stud above

the welding surface during the weld. This distance

governs the volta

ge and the arc. Improper lift will

cause unsatisfactory welds.

To measure the lift, turn the stud welding unit on and

set the

timer to maximum time. (On certain units there

may be a Lift Check switch available, and in these

cases this switch can be used

to check lift.) Trigger

the gun in the air or on a non-

grounded or insulated

surface, to observe the lift cycle. Measuring the di

s-

tance the stud or gun mechanism moves equals lift.

Usually this can be easily done by visual observation

or simple measurement

against a static reference point

(i.e. the ferrule properly seated in the ferrule grip).

PAGE 3

Chuck Adaptor

Chuck

Locking Screws

Ferrule

Plunge Length

Stud

Ferrule Grip

(2) Foot

Screws

Foot

Leg

Leg Adj. Screw

Figure 6

-

1 GUN SET

-

UP

300-0805

PRO WELD

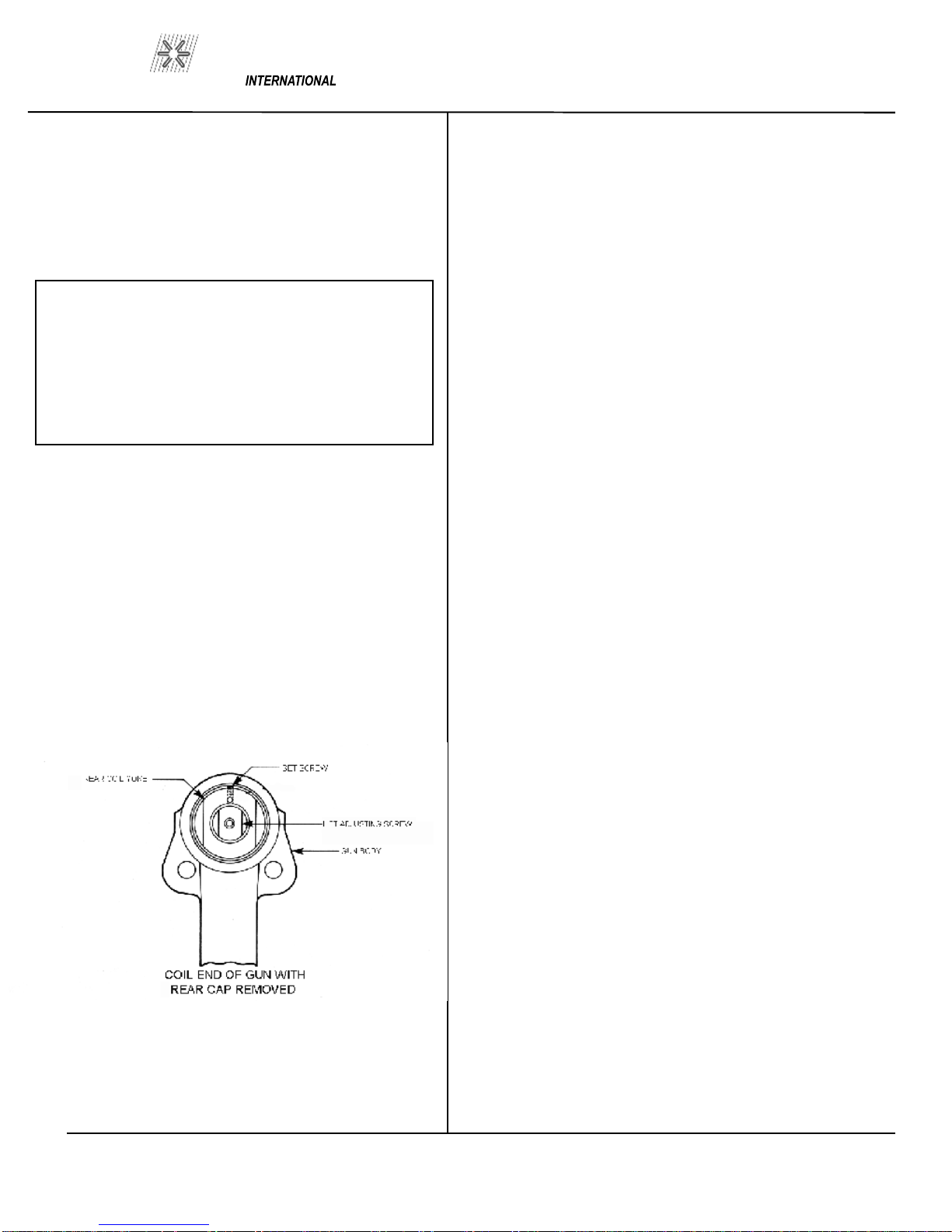

W

hen it does become necessary to adjust the lift,

you do so by removing the rear cap from the gun.

This will expose the rear coi

l choke assembly, the

set screw, and the lift adjusting screw (Refer to Fi

g-

ure 6

-

2).

Loosen the set screw.

To increase lift: turn the adjusting screw out

(counter clockwise).

To decrease lift: turn the lift adjusting screw in

(clockwise).

Once the lift has been set, tighten the set screw and

replace the rear cap.

Figure 6

-

2 LIFT ADJUSTMENT

RECOMMENDED LIFT SETTINGS

Stud Base Dia.

Lift Setting

Less than 1/2”

1/16”

1/2” through 3/4”

3/32”

Greater than 3/4”

7/64”

PAGE 4

5

. Make sure that the cables are connected to the

power source (standard set

-

up is straight polarity

–

Negative to controller, or gun, and Positive, ground c

a-

ble, to work surface).

6. Turn on the power supply and adjust the current and

time for the weld base diameter of the fastener

to be

welded.

7. Place the gun, loaded with the stud and ferrule,

squarely against the ground work surface. The main

spring i

n the gun will take up the “plunge length” and

the ferrule will seat against the base plate.

8. Pull the trigger holding the g

un completely still as

above. The gun will lift the stud from the base plate

and draw an arc. The end of the stud and the adja

cent

metal of the base plate will be melted by the weld arc.

The gun will then plunge the stud into the molten pool,

extinguish

ing the arc, to end the controlled portion of

the weld cycle

.DO NOT MOVE THE GUN DURING THE WELD

CYCLE.

9. After the contro

lled weld cycle, allow the molten

metal to solidify briefly with the work surface to assure

completion of the cycle (about an ex

tra second holding

“still” after the weld is usually sufficient).

10. Remove the gun from the work by lifting straight

away fr

om the welded stud (this will assure better life

to the gun’s expendable accessories). The ferrule may

now be removed by breaki

ng it away from the welded

stud to allow inspection of the weld results. After i

n-

spection of sample welds the gun can be adjusted, as

per the steps in this procedure, for optimum results

PRO WELD 300-0805

7

.0 WELD TEST AND INSPECTIONS

Testing of weld quality beyond visual inspection

varies with stud characteristics. Refer to AWS

(American Welding Society) Structure Welding

Code AWS D.1

-

Rev. 1

-

76. Welding procedures

are covered in Sections 4.28 and 4.29

. Weld test

and inspection is covered in Section 4.30, par

a-

graphs 1 through 4. (American Welding Society,

Inc., 2501 N.W. 7th, Street, Miami, Fla. 33125).

7.1 Weld Test

A. Bend Test

A bend test may be used to test weld results if the

stud may be destroyed. This is usually done with a

bending tool (a hollow

pipe with an inside diameter

just large enough to fit over the diameter of the

studs). The bend tool is placed over the stud, d

own

to the base material. The stud is then be repeatedly

bent away from its axis until failure occurs.

B. Torque Test

–

Threa

ded Studs

A torque test may be used on threaded studs. The

stud is twisted to the point of failure. A twisting

tensile load i

s applied by using a collar, washer and

nut. A bend test can be used on threaded studs as

well.

C. Test Results

In an accept

able weld, failure will occur in the stud

material or tear out of a thin base plate. Failure in

the weld requires adjustment of

procedure, weld

time and current setting.

7

.2 Weld Inspection

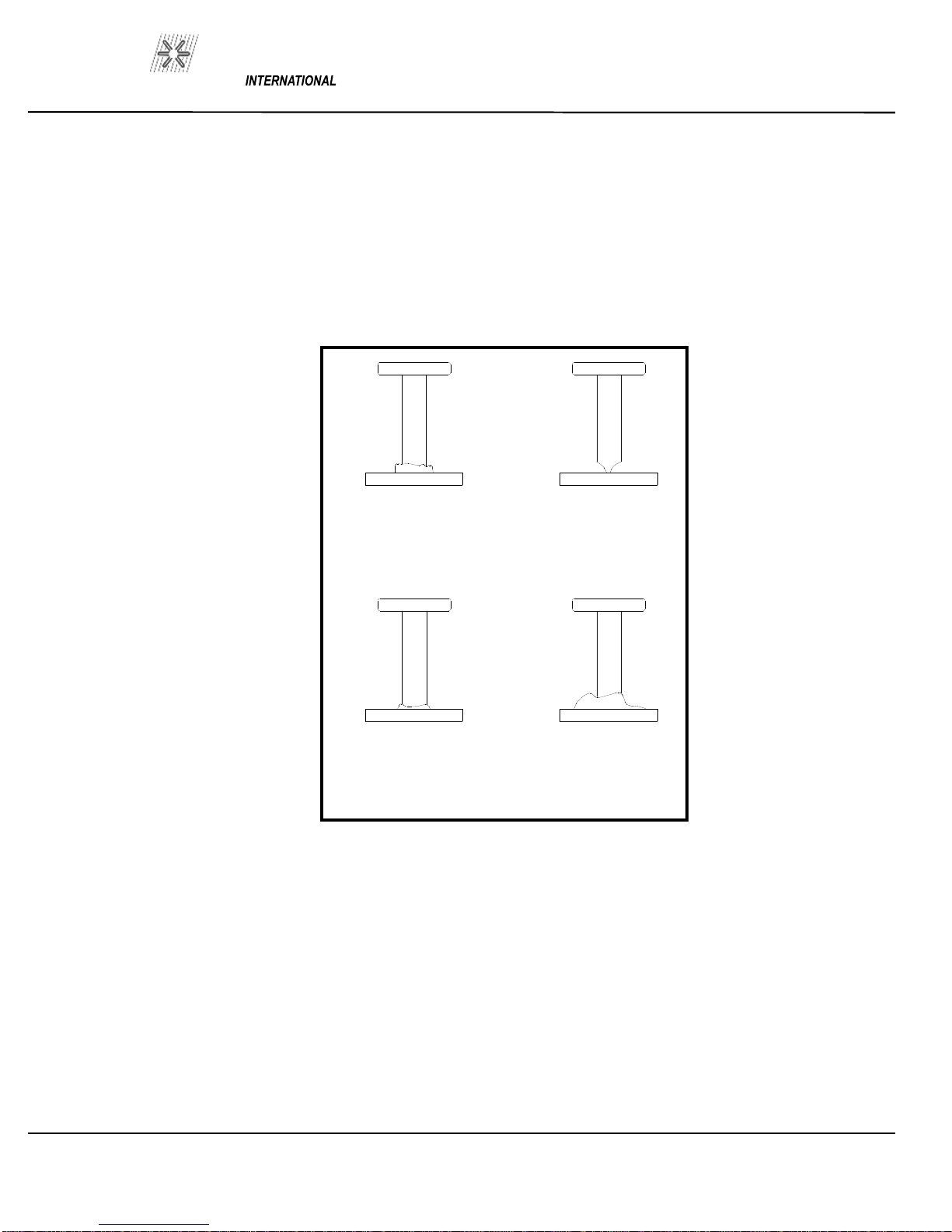

Weld quality can be visually inspected. Refer to Fi

g-

ure 7

-

1 as a reference to the quality of the weld.

7.3 Causes Of Poor Or Erratic Welds

1. Loose chuck. Does not grip stud t

ightly.

(replace) Not enough engagement of stud to

chuck. (Adjust stop)

3. Poor surface condition of base mat

erial, excessive

oil, grease, rust, etc. (Clean)

4. Weld current or weld time setting too low or too

high. (Adjust to dia

meter of studs)

5. Broken or loose cables. (Repair)

6. Dirt in gun. (Clean)

7. Incorrect polarity. (Cables hooked

-up wro

ng)

8. Cables too closely coiled.

9. Arc blow is evidenced by “one side” welds. In

severe cases there will be no melt

ing under one

edge of flange while the opposite side is gouged

out or appears excessively hot. The principle

cause of arc bl

ow is a magnetic field induced by

the current flow during the weld. It occurs most

often on long, narrow strips of metal or n

ear

edges of sheets or plates. In some cases, a

change in grounding positions, or two ground on

the work piece, one at each

end or edge of work,

will correct the problem

PAGE 5

300-0805

PRO WELD

Figure 7

-

1 WELD INSPECTION

GOOD STUD WELD

A good full fillet

STUD HANG UP

Adjust foot to

insure the stud is

centered in the

ferrule

COLD WELD

Increase weld

current and/or

weld time

HOT WELD

Reduce weld

current and/or

weld time

PAGE 6

PRO WELD 300-0805

F

or assistance in sever cases, contact your local

sales representative.

10. Incorrect plunge setting. (Adjust to proper

settin

g)

11. Incorrect lift setting. (adjust to proper se

t-

ting)

12. Poor stud quality.

13. Arc shield so far off center from weld end

of stud that stud catches on edge of arc shield

and is not driven back into pool of molten

metal.

7.4 Trouble Shooting Poor Welds

1. Weld Too Hot

A) Decrease weld t

ime.

B) Decrease weld current.

C) Increase stud protrusion.

2.

Weld too Cold

A) Increase weld time.

B) Increase weld curre

nt.

C) Decrease stud protrusion

3. Arc Blow

A) Use double grounds.

B) Ground too close or not spaced evenly.

4. Hang

-

Up

A) Re

-align arc shield

8

.0 MAINTENANCE

(Refer to LD ARC GUN EXPLODED VIEW in Section 10

of this manual for location for “()” numbers noted in this

text.)

8.1 Disassembly of Gun

1. Loosen leg set screws (28), remove foot and leg asse

m-

bly. Unscrew chuck adaptor and remove bellows (2).

2. Unscrew end cap nuts (3) and remove front cover(4)

3. Disconnect weld ca

ble (31) from lifting rod assm (6) by

removing screw (8). Remove lifting rod assembly (6) and

main spring (7).

4. Slide out lift stop housing (10), lifting ring (11), mov

e-

able core (12), and core spring (13).

5. It is only necessary to remove rear cap (20) for adjusting

lift. It is not necessary t

o remove cap for normal cleaning of

gun.

6. To replace damper (33), unscrew plunge damper assemly

from front cap (4). The dampe

r will unscrew from the

damper cover (32).

8.2 Reassembly of Gun

1. Assemble lifting ring (11) with moveable core (12) and

core spring (13) into lift stop housing (10). Install into gun

body (14).

2. Install lifting rod assm (6) and main spring (7).

3. Connect weld cable (31) to lifting rod assembly (6) with

screw (8).

PAGE 7

300-0805

PRO WELD

3. Connect the

black

wire on the new cable (30) to

one terminal on the switch assembly (25).

4. Connect the

white wire to the ot

her terminal.

5. Connect

green

control cable wire to one of the

gun coil leads using wire nut.

6. Connect

red

control cable wi

re to the other gun

coil lead using a wire nut.

7. Re

-

install switch assembly and handle cover.

8.5 Gun Maintenance

If the g

un motion becomes sluggish or erratic the

gun should be disassembled, cleaned, and lubr

i-

cated.

A. Disassemble the gun as described. Blow or

wipe the gun body and parts clean.

B. The inside diameters of adjustabl

e core screw,

the lifting ring and mating diameters on the lifting

rod should be carefully examined for wear or rust.

Although the lubrication should prevent any oxid

a-

tion on these surfaces, if they reveal signs of dirt

or a dull reddish brown stain, clean and polish with

a fine abrasive paper,

grip #0 or finer.

C. Lubricate lifting rod surface with a thin coat of

high temperature bearing grease, Lubricate M

-24-

M or e

quivalent.

PAGE 8

4. Install front cap (4) end cap nuts (3), bellow (2),

and chuck adaptor (1). Make sure chuck adaptor is

securely tightened.

5.

Guns with plunge damper, replacement damper

(33) has to be screwed all the way into the damper

cover (32). Screw damper assembl

y into front cap

(4)

6. Install foot and leg assembly. Adjust the plunge

and lift.

7. Replace rear cap (20) and secure with sc

rew

(21).

8.3 Weld Cable Replacement

1. Disassemble gun as indicated in disassembly of

gun through step 4.

2. Remove handle

cover screws (26) lift off handle

cover (27).

3. Pull weld cable (31) out of gun body (14).

4. Place new weld cable into gun b

ody handle and

through cable hole in gun body.

5. Secure weld cable with screw (8) to lifting rod

assembly (6). Tighten securel

y.

6. Install handle cover and reassemble gun.

8.4 Control Cable Replacement

1. Remove handle cover screws (26) lift off hand

le

cover (27).

2. Remove wire nuts from the two wires going to

the gun coil (16). Disconnect the two wires from

the switch asse

mbly (25) and remove control cable

(30).

PRO WELD 300-0805

PAGE 9

ITEM

DESCRIPTION

PART NO.

1

CHUCK ADAPTOR

033

-

505

2

CONNECTOR STUD

033

-

506

3

BELLOWS

302

-

0018

4

SHAFT EXT.

302

-

0036

5

FRONT CAP

302

-

0003

6

NYLON BEARING.

033

-

491

7

LIFTING ROD

302

-

0012

8

SPRING

,MAIN

302

-

0017

9

DAMPER COVER

302

-

0011

10

DA

MPER

302

-

0007

11

NUT, END CAP

033

-

481

12

DAMPER STOP

302

-

0021

13

SCREW, #8

-

32 X 3/8 FSCS

115

-

0011

14

LIFT HOUSING

301

-

00

19

15

LIFTING RING

301

-

0014

16

MOVEABLE CORE

301

-

0013

17

SPRING

, CORE

301

-

0012

18

GUN BODY

302

-

0001

19

COIL YOKE BEARIN

G

301

-

0009

ITEM

DESCRIPTION

PART NO.

21

WAVE WASHER

102

-

0117

22

REAR COIL YOKE

301

-

0016

23

SCREW, #8

-

32 X 1/4 SET

115

-

0010

24

LIFT ADJ

. SCREW

301

-

0008

25

REAR CAP

033

-

493

26

SCREW, #8

-

32 X 3/4 PAN HD.

037

-

521

27

HANDLE COVER

302

-

0009HD

28

SCREW, #10

-

32 X 1/2

OVAL HD

115

-

0009

29

SCREW, 5/16

-

18 X 3/8 SET

037

-

557

30

SPRING, TRIGGER

302

-

0016

31

SNAP RING

302

-

0023

32

TRIGGER BUTTON

30

2-

0013

33

TRIGGER SWITCH ASSY

302

-

0010

34

CABLE GUIDE ASSY

302

-

0024

34A

SCREW, #10

-

32 X .625 SHCS

115

-

0012

34B

CLAMP, CABLE

GUIDE

302

-

0024

-2

34C

SUPPORT, CABLE GUIDE

302

-

0024

-1

35

CONTROL CABLE ASSY

302

-

0028

36

WELD CABLE ASSY

036

-

904

WELD CABLE B

OOT

036

-

904

-1

37

CONTROL CABLE BOOT

036

-

897

300-0805

PRO WELD

S

ection 9.0

TROUBLE SHOOTING GUIDE

CAUTION:

Turn off the power when trouble shooting the control. Welding voltage can cause el

ectric shock and

burns.

Trouble shooting should be done by qualified personnel trained to work on this type of equi

p-

ment.

PROBLEM

POSSIBLE CAUSE

REMEDY

Control unit cycles but gun

Broken or loose control cable

Check all wires for conti

nuity

does not lift.

wires.

and repair.

Dirt in gun.

Disassembly and clean.

Misalignment of accessories

Re

-

align fastener in center of

i.e. legs, foot piece, grip)

by loosening the screws

holding the foot and the legs.

Lift incorrectly

set.

Adjust lift to recommend

settings (See section “Set

-up

of Weld Gun” for suggested

settings.)

Weld quality

appears

Faulty or loose ground

Clean area for grounding.

inconsistent from one

connection.

Repair or tighten clamp.

weld to

the next.

Poor surface condition,

Clean area at each weld.

excessive oil, grease,

rust etc.

Incorrect plunge setting.

Be sure plunge is adequate

for fastener being welded.

(See section “Set

-up

of Weld Gun” for suggested

setting

s.)

PAGE 10

PRO WELD 300-0805

TROUBLE SHOOTING GUIDE (continued)

CAUTION:

Turn off the power when trouble shooting the control. Welding voltage can cause e

lectric shock and

burns.

Trouble shooting should be done by qualified personnel trained to work on this type of equi

p-

ment.

PROBLEM

POSSIBLE CAUSE

REMEDY

Weld quality (continued)

Poor quality fasteners.

Loose chuck

Rep

lace chuck.

Gun lifts but fastener

Loose chuck.

Replace chuck.

Does not pull away from

The work plate.

Accessory misali

gnment.

See previous problem for

re

-

alignment suggestions.

PAGE 11

300-0805

PRO WELD

WELD

PRO

MANUFACTURED BY

MADE IN THE U.S.A.

Table of contents

Other Pro-Weld Welding System manuals

Popular Welding System manuals by other brands

ESAB

ESAB Aristotig 255 LTN 255 instruction manual

Kemppi

Kemppi FASTMIG MS 200 operating manual

Saf-Fro

Saf-Fro DIGIWAVE III Series Instruction for operation and maintenance

Sealey

Sealey POWERMIG2500 instructions

Lincoln Electric

Lincoln Electric SF7000 Operator's manual

Expondo

Expondo MSW S-SPOTTER 4000 user manual