Pro2 625 User manual

2010-2339NM Rev A 17 July 2018 Page 1 of 4

Instructions for Use

Pro 5 – Pro 8 – Pro 10

Oxygen Generators

For models: 625, 725, 685, 785, 695 and 795 (and

variants thereof)

This device supplies highly concentrated oxygen

enriched product gas that promotes rapid

burning.

DO NOT allow smoking or open flames within the

same room of this device.

Failure to observe this warning can result in

severe fire, property damage, and / or cause

physical injury or death.

Oxygen accelerates the combustion of flammable

substances.

DO NOT use oil, grease, petroleum based or other

flammable products on the device.

This device is intended for industrial use. It

should be placed in a well-ventilated area, free

from smoke and atmospheric pollution, where

the intake filter ventilation is not obstructed or

blocked.

DO NOT use in an explosive environment.

DO NOT use in a magnetic environment.

DO NOT open the device while in operation.

Failure to observe this warning can result in

electrical shock.

DO NOT remove the cabinets unless you are a

qualified service technician.

DO NOT use extension cords or adapters. Use the

power cord provided.

Check that the electrical characteristics of the

power outlet used match those indicated on the

manufacturer’s plate on the rear panel of the

device.

This unit may be equipped with a polarized plug.

That is one blade wider than the other. If it does

not fit into the outlet, reverse the plug. If it still

does not fit, contact a qualified electrician. Do not

defeat this safety feature.

Only persons who have read and understood this

entire manual should be allowed to operate the

device.

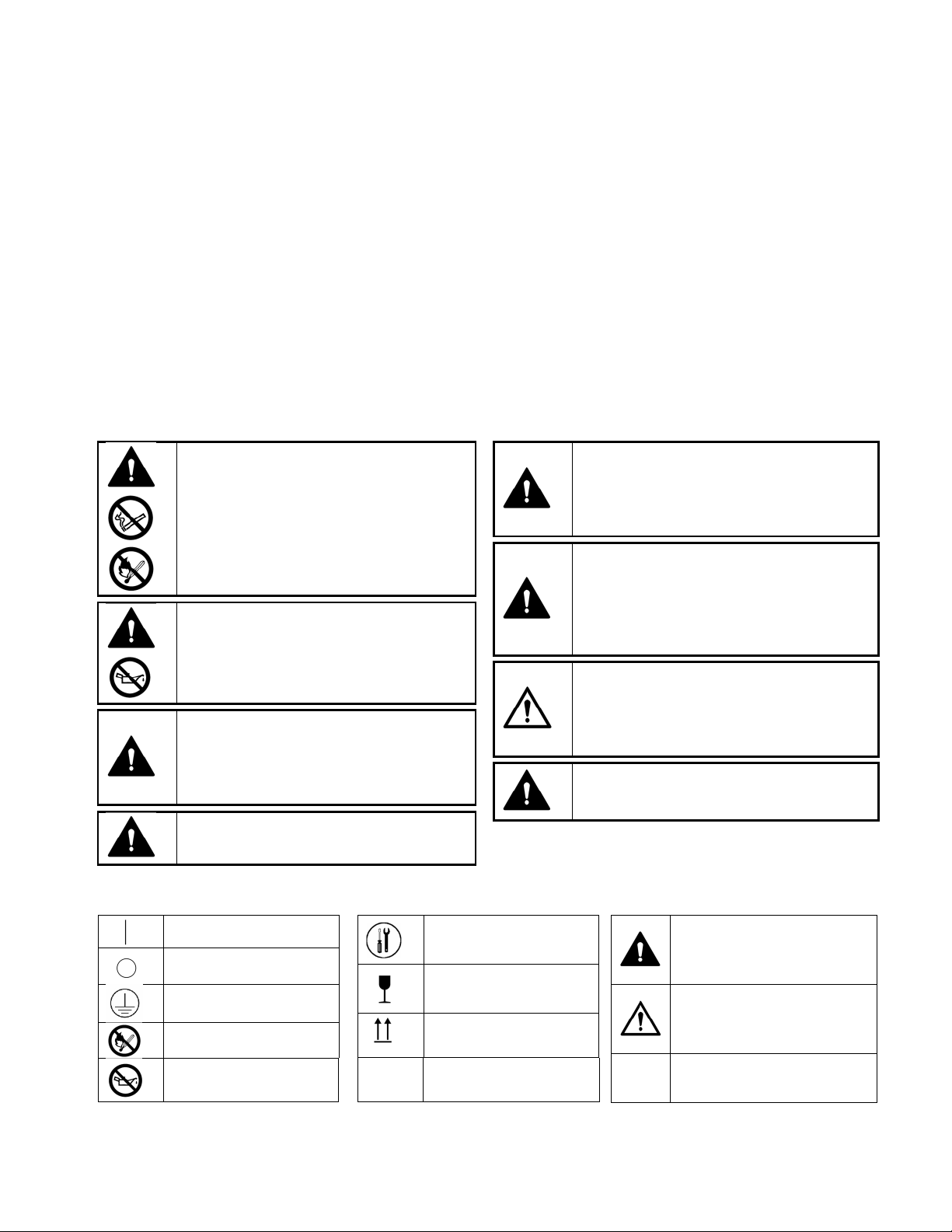

1 Glossary of Symbols

ON (Power switched on)

OFF (Power switched off)

Class I (Protective Earth)

Do Not Expose to Open

Flames

Do Not Expose to Oil or

Grease

Tools Required /

Technician Only

FRAGILE – Handle with

Care

Keep in Vertical Position

IPX1 Protection from vertically

falling water drops

WARNING – A hazard or unsafe

practice that can result in serious

injury or death if conditions are

not avoided.

Caution - A hazard or unsafe

practice that can result in minor

injury and / or property damage if

conditions are not avoided.

Note – Information important

enough to emphasize or repeat

2010-2339NM Rev A 17 July 2018 Page 2 of 4

2 Purpose and Principles of Operation

This device is intended to supply oxygen for applications requiring high concentration. It produces an enriched

product gas by concentrating the oxygen contained in room air.

The operation of the device begins with air being pulled into the external air intake filter. This filtered air enters the

compressor via a suction resonator and fine filter. Pressurized air then exits the compressor and into an electronic

valve system that directs the air into one of two tubes that contain molecular sieve (sieve beds). The molecular sieve

adsorbs (physically attracts) the nitrogen from the air as it is pushed through the sieve beds. This allows the oxygen

enriched product gas to pass through before being delivered to the pressure regulator. As one tube is generating

the product gas, the other is being purged of the adsorbed nitrogen, this process is called pressure swing adsorption

(PSA). After passing through the regulator, the rate of product gas is set by the flow meter adjusting valve. Finally,

it passes through a fine particle filter (product filter) and then exits the device through a fire-resistant outlet.

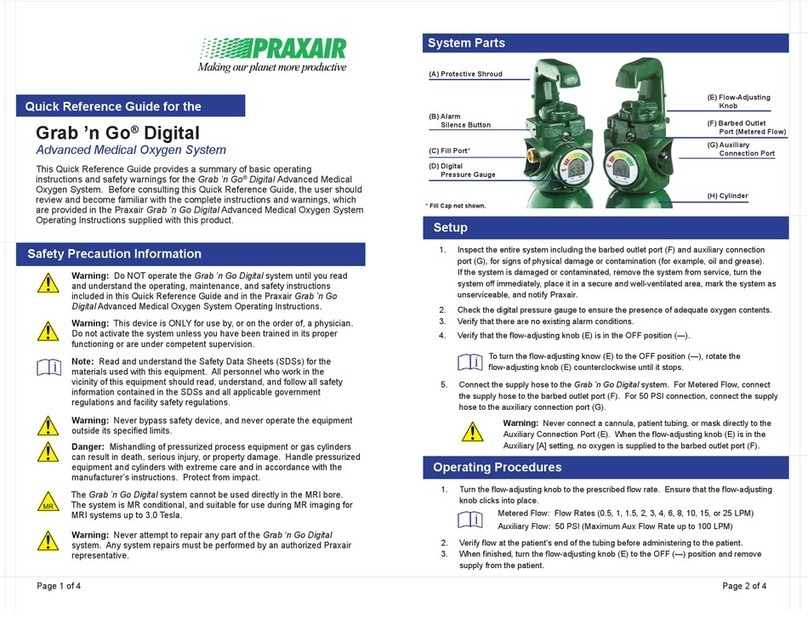

3 Device Features

Features

1. Power Switch (On and Off)

2. Indicator Lights (Ok and Caution)

3. Circuit Breaker

4. Oxygen Outlet

5. Flow Knob (Pro 5 models only)

6. Flow Meter (with Adjustment Knob – Pro 8 and

10 models only)

7. Intake Ventilation

(consists of 10 – and 11 for Pro 5 models)

8. Technical Label

9. Power Cord

10. Cabinet Air Filter

11. Air Filter Grille

Accessories

Accessories used with this device must be oxygen

compatible and rated for the pressure. The filters

notated in this section, available from your distributor,

comply with these requirements.

Filters

Cabinet Air Filter – PN 8400-1025 / 9250-1025

Inlet Filter – PN 8400-1180 / 9250-1180

Product Filter – PN 7631-1053

4 Installation and Operation

The Pro Oxygen Generator is packaged to protect the device from damage while being transported and stored. After

the device is removed from the package, inspect for damage. If damage is detected, please contact your equipment

supplier.

The device should be placed and operated in a space where the Intake Filter Ventilation (7) is not obstructed and

the Power Cord (9) is accessible for easy disconnection but does not present a tripping hazard.

2010-2339NM Rev A 17 July 2018 Page 3 of 4

To use your device safely, follow the directions below.

1. Ensure that the Power Switch (1) is in the “O” (OFF) position.

2. Ensure the Intake Ventilation (7) is not obstructed or blocked.

3. Plug the Power Cord (9) into an outlet of the correct voltage and frequency as defined on the Technical

Label (8).

4. Connect supply tubing, that is rated for oxygen use at the designated pressure, to the Oxygen Outlet (4).

5. Move the Power Switch (1) to the “I” (ON) position.

6. Turn the Flow Knob / Flow Adjustment Knob (5/6) to the desired flow rate.

7. At the end of use, move the Power Switch (1) to the “O” (OFF) position to stop the device.

The required oxygen concentration is normally obtained within five minutes of the start up of the

device.

The oxygen enriched air flow continues for approximately one minute after shut down of the device.

5 Cleaning and Maintenance

Only the outside of the device is to be cleaned. After making sure the Power Switch (1) is in the "O"(OFF) position,

use a soft, dry cloth or, if necessary, a damp sponge with mild soap. Do not use acetone, solvents, abrasive

powders or any inflammable products to clean the cabinet.

The removable Cabinet Air Filter (10) must be cleaned, at least weekly, in warm water and household detergent. It

should be rinsed thoroughly and dried completely before reinstalling. The Inlet Filter (not pictured, located inside

the device) should be inspected monthly and replaced if required – at least annually. The product filter (not

pictured, located inside the device) should only be replaced by a technician if required (not common).

6 Performance Specifications and Alarm / Safety Features

Model 625 725 685 785 695 795

Description

5LPM

115V

5LPM

230V

8LPM

115V

8LPM

230V

10LPM

115V

10LPM

230V

Frequency 60Hz 50Hz 60Hz 50/60Hz 60Hz 50Hz

Average Power 330 Watts 300 Watts 500 Watts 490 Watts 700 Watts 600 Watts

Protection Class Class II

Mains Protection 10A 5A 10A 5A 10A 5A

Average Oxygen Content

At 2 LPM

> 90%

At 2 LPM

> 90%

At 2 LPM

> 90%

Average Oxygen Content

At 5 LPM

87% to 95.5%

At 8 LPM

87% to 95.5%

At 10 LPM

87% to 95.5%

Liter Flow 1 to 5 LPM 2 to 8 LPM 2 to 10 LPM

Outlet Pressure 12 Psig 15 Psig 20 Psig

Dimensions (L x W x H)

36 x 23 x 58.5 cm

(14 x 9 x 23 in.)

39 x 40 x 71 cm

(15 x 15.5 x 28 in.)

Weight 14.5 kg (32 lbs.) 24.5-26 kg (54-58 lbs.)

Indicator Lights (2) and Alarm Conditions

Green indicator: This light indicates that power is applied to the concentrator and that it is ready to provide oxygen

enriched product gas.

Yellow indicator: This light indicates that a system fault has occurred.

Power Failure detection: In the event of a loss of power, an intermittent audible alarm is activated (if equipped) and

the green light deactivates.

Process Failure detection: In the event of a process failure, an audible alarm and the yellow light is activated.

Electrical Protection: In the event of a surge or drop in power supply, the circuit breaker will trip. To restart the

device, depress the Circuit Breaker button (3).

2010-2339NM Rev A 17 July 2018 Page 4 of 4

7 Storage and Operating Conditions

The device should be stored in a dry area, with an ambient temperature between -20°C to 60°C (0°F to 140°F) at 15-

95% relative humidity. It must be stored, transported and used in the vertical position only. Oxygen concentration

can be affected after prolonged periods of storage – check device before use.

The device should be operated in a dry area, with an ambient temperature between 10°C to 40°C (50°F to 105°F) at

15-95% relative humidity. The device can be operated at an altitude of up to 1500m (5000ft) at a temperature of

21°C (70°F) without causing product degradation. Consult your equipment provider for further information

regarding 1500m to 4000m (5000ft to 13000ft).

8 Disposal

This device has been supplied by an environmentally aware manufacturer. A majority of the parts in the device are

recyclable. Follow local governing ordinances and recycling plans regarding disposal of the device or components

normally used in operation. Any accessories not original to the device must be disposed of in accordance with the

individual product markings for disposal.

9 Troubleshooting

OBSERVATIONS

POSSIBLE CAUSES

SOLUTIONS

The Power Switch (1) is in the “I” ON

position but the device does not operate.

The audible alarm sounds continuously

Power Cord (9) is not plugged into outlet

Power failure

Check that the device is properly

plugged into

the electrical outlet

Check the Circuit Breaker (3) and reset if

necessary

Yellow Light Indicator (2) remains lit

Product pressure or

concentration

is not

at an acceptable level Contact your Equipment Supplier

The audible alarm does not sound when

device is first turned on

Super capacitors not charged

Internal electrical fault

Leave device plugged in for approximately 10

minutes and retest.

Contact your Equipment Supplier

The device is operating but the Green Light

Indicator (2) is not lit Faulty indicator Contact your Equipment Supplier

The device is operating but there is no flow

(flowmeter ball not moving) Internal system failure

Stop device immediately and contact your

Equipment Supplier

The device is operating but the audible

alarm sounds continuously Internal fault

Stop device immediately and contact your

Equipment Supplier

The device suddenly stops and then starts

again in a few moments.

Dirty Filters

Compressor Thermal Shut-Off

Clean External Cabinet Filter (

10

)

Contact your Equipment Supplier

The oxygen flow is interrupted or the flow is

irregular

Tubing is disconnected or leaking

Tubing is restricted

Check tubing connections

Straighten tubing

Contact your Equipment Supplier

ProO2, LLC.

3949 Valley East Industrial Drive

Birmingham, Alabama 35217 U.S.A.

Tel: 205-856-7200 Fax: 205-856-0533

www.ProO2llc.com

This manual suits for next models

5