AirSep®Corporation

Topaz/Topaz+/Topaz Ultra Instruction Manual i

Table of Contents

1.0 Introduction...............................................................................................................1-1

1.1 General.................................................................................................................1-1

1.2 Warnings, Cautions, and Notes............................................................................1-1

2.0 Safety .......................................................................................................................2-1

2.1 General.................................................................................................................2-1

2.2 Potential Hazards .................................................................................................2-1

2.3 Safety Publications...............................................................................................2-2

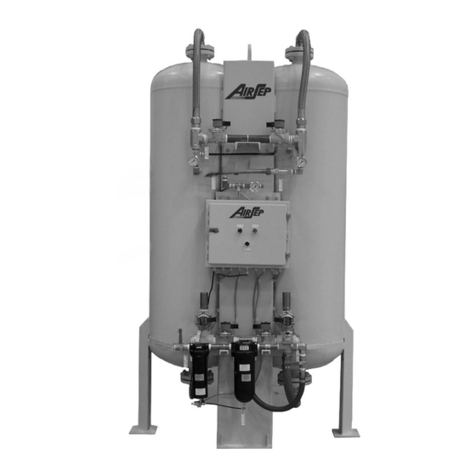

3.0 System Description ..................................................................................................3-1

3.1 General.................................................................................................................3-1

4.0 Components Description ..........................................................................................4-1

4.1 External Components...........................................................................................4-1

4.2 Internal Components ............................................................................................4-3

5.0 Installation ................................................................................................................5-1

5.1 Handling and Unpacking ......................................................................................5-1

5.2 Pre-installation Operational Check.......................................................................5-2

5.3 Installation Instructions.........................................................................................5-3

6.0 System Operation.....................................................................................................6-1

6.1 Start-up.................................................................................................................6-1

6.2 Operation..............................................................................................................6-1

6.3 Shutdown .............................................................................................................6-1

7.0 Maintenance.............................................................................................................7-1

7.1 Cleaning the Gross Particle Filter.........................................................................7-1

7.2 Cleaning the Enclosure ........................................................................................7-2

7.3 Solenoid Valves....................................................................................................7-2

7.4 Air Compressor ....................................................................................................7-3

8.0 Troubleshooting........................................................................................................8-1

8.1 Technical Support ................................................................................................8-1

8.2 Troubleshooting Chart..........................................................................................8-1

AAppendix: Technical Data ...................................................................................... A-1

BAppendix: Warranty/Returns .................................................................................. B-1

CAppendix: Parts List ............................................................................................... C-1

DAppendix: Component Literature............................................................................. D-1