ProArc PT-200s Quick start guide

OPERATION MANUAL

Important:Read these instructions before installing, operating or servicing this product.

MODEL

:

PT‒200s

WELDING POSITIONER

Serial Number

:

202103005 ~ Later

Revised Date

:

Apr. 07, 2021

UNITED PROARC CORPORATION

No. 3 Gungye 10th Road, Pingjen Ind. Park Tel No: 88634696600

Pingjen City, Taoyuan 324, Taiwan Fax No: 88634694499

http://www.proarc.com.tw E-Mail: customerservice@proarc.com.tw

RD-8480E

MENU

Safety Instruction

Specification

Operation

Troubleshooting

Parameters

Part List

Circuit

Instruction................................................................................................................i

Protection................................................................................................................ii

1.1 Specifications....................................................................................................1

1.2 Control Box Specification...................................................................................2

1.3Connector..........................................................................................................3

2.1 HMI....................................................................................................................6

2.2 Main Screen......................................................................................................7

2.3 Manual Mode.....................................................................................................8

2.4 Auto Mode.........................................................................................................9

2.5Setting..............................................................................................................10

2.6Program Save/Load..........................................................................................11

2.7 Program Note...................................................................................................12

2.8Welding Sequence Setting ...............................................................................13

2.9Welding Current Setting....................................................................................14

2.10 Index Weld Setting .........................................................................................15

2.11 Autorun Function............................................................................................16

2.12 Password Setting............................................................................................17

2.13Program Backup.............................................................................................18

2.14 System Setting ...............................................................................................19

2.15 System Information.........................................................................................20

2.16 HMI Update....................................................................................................21

2.17PLC Update....................................................................................................22

2.18Alarm History..................................................................................................23

2.19 I/O Monitor......................................................................................................24

3.1Error Message..................................................................................................25

3.2 Troubleshooting................................................................................................26

4.1 PT Servo Amplifier Parameters ........................................................................27

5.1Part List - PT200s Mechanism..........................................................................28

5.2 Part List - HMI and Remote ............................................................................29

5.3 Part List - Control Box .....................................................................................30

6Circuit..................................................................................................................31

i

INSTRUCTION

Read and understand the entire manual regarding the rules for users’

safety before installing, operating, or servicing the equipment.

A procedure, when not properly followed, may cause injury to the

operator or others in the operating area.

Equipment Identification

Receipt of Equipment

The identification number (specification or part number), model, and serial

number of this unit usually appear on a nameplate attached to the control

panel; record these numbers for future reference.

When you receive the equipment, check it against the shipping documents.

Make sure it is complete and inspect the equipment for possible damage

during shipping. If there is any damage, notify the carrier immediately to file a

claim.

Move the equipment to the installation site before uncrating the unit. Use care

to avoid damaging the equipment when using bars, hammers, etc. to uncrate

the unit.

Falling machine due to lifting device failure may cause death or injury.

﹡Lifting device may fail when overloaded.

﹡Avoid sudden jerks, drops or swinging.

﹡Check lifting device components visually for loose spot and signs of metal fatigue.

﹡Before changing any hardware, check grade and size of bolts, and replace with bolts of equal or higher

size and grade.

WARNING

WARNING

WARNING

ii

Protection

Operation and maintenance involve potential hazards. All operators and

personnel should be alerted to possible hazards and precautions should

be taken to prevent possible injury.

Electrical

Maintenance

Personal

Machine:

﹡The system’s non-fuse breaker is compatible with its maximum power and main

voltage.

﹡The connection, single-phase or three-phase, is possible on a stand compatible with

the plug of its cable link.

﹡To prevent accidental electrical shock, do not leave the ground cable disconnected

when the system’s power is connected to local power network.

Work place:

﹡Be very careful to avoid contact between metal part of phase conductor and the

neutral of electric network.

﹡Electrical messes of different electrical machine and apparatus are connected

between themselves and with the terminal of earth neutral wire.

Interventions:

﹡Before control and repair, see that the apparatus is switch off and electrically

insulated.

﹡Connection with fixed installation cable is impossible.

﹡Switch off by fixed connection is multi-polar (phase and neutral).

﹡It’s on “STOP” and connection is impossible.

Some apparatus are provided with starting circuit HT HF (with a plate). Never enter

into the corresponding switch cupboard.

﹡Only qualified persons are authorized for intervention concerning electrical

installation.

*Check regularly the equipment’s power cords, switch, extension cords’s electrical

insulation and connection and make sure they are in good state

*Maintenance and repairing of cable insulation are important to prevent injury.

*Do request trained personnel for system repair and replacement of defective

accessories.

*Check regularly all electrical connections for any sign of overheating.

﹡Avoid touching metal area with bear hands..

﹡Wear safety clothes, gloves, apron, safety shoes and glasses for protection against

welding burns, welding radiation and slag.

WARNING

1

LIMITED WARRANTY

UNITED PROARC CORPORATION warrants all new equipment to be free from defects in material and

workmanship, provided that the equipment is installed and operated according to instructions stated in this

manual.

UNITED PROARC’s obligation under this warranty policy is expressly limited to the replace or repair, at its

option, of the defected part only. ProArc’s option to repair or replacement of a defected part under this

warranty shall be based on FOB Taiwan basis.

The warranty period begins on the date of sale to the original-purchase user of the equipment.

UNITED PROARC CORPORATION shall not be liable for any loss or consequential damage or express

accruing directly or indirectly from the use of equipment covered by this warranty.

This warranty supersedes all previous ProArc warranties and is exclusive with no other guarantees or

warranties expressed or implied.

This warranty excludes the consumable parts that are used in normal operation.

1

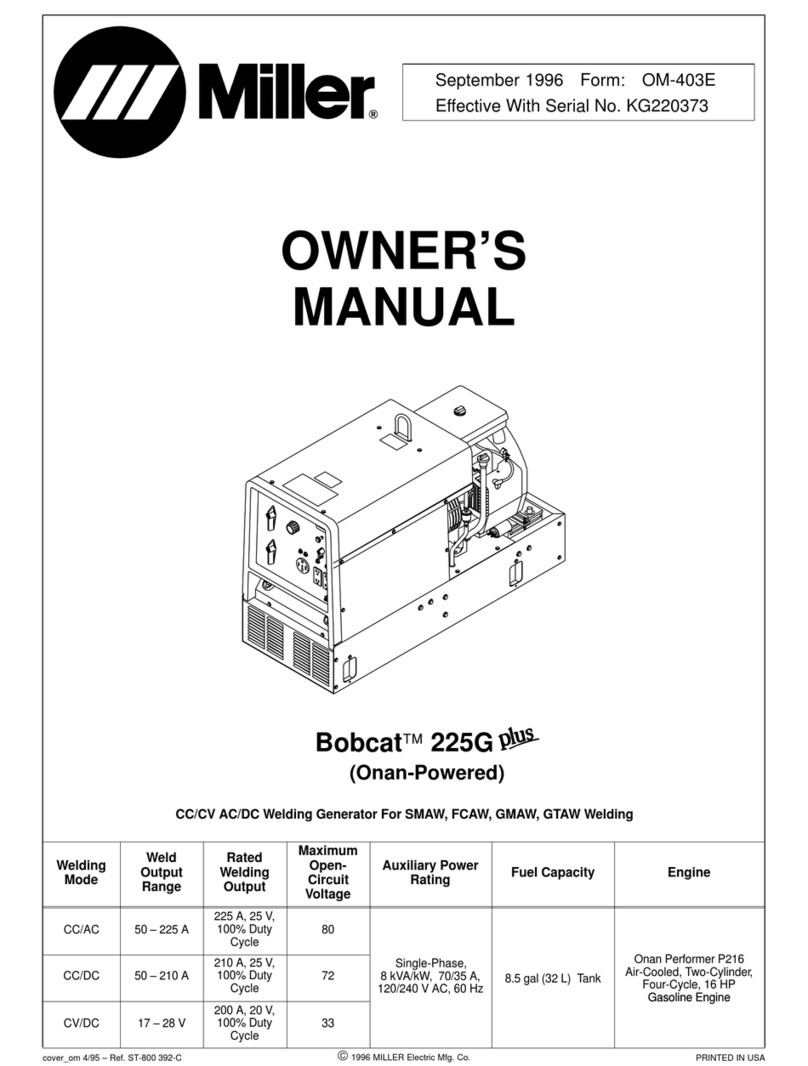

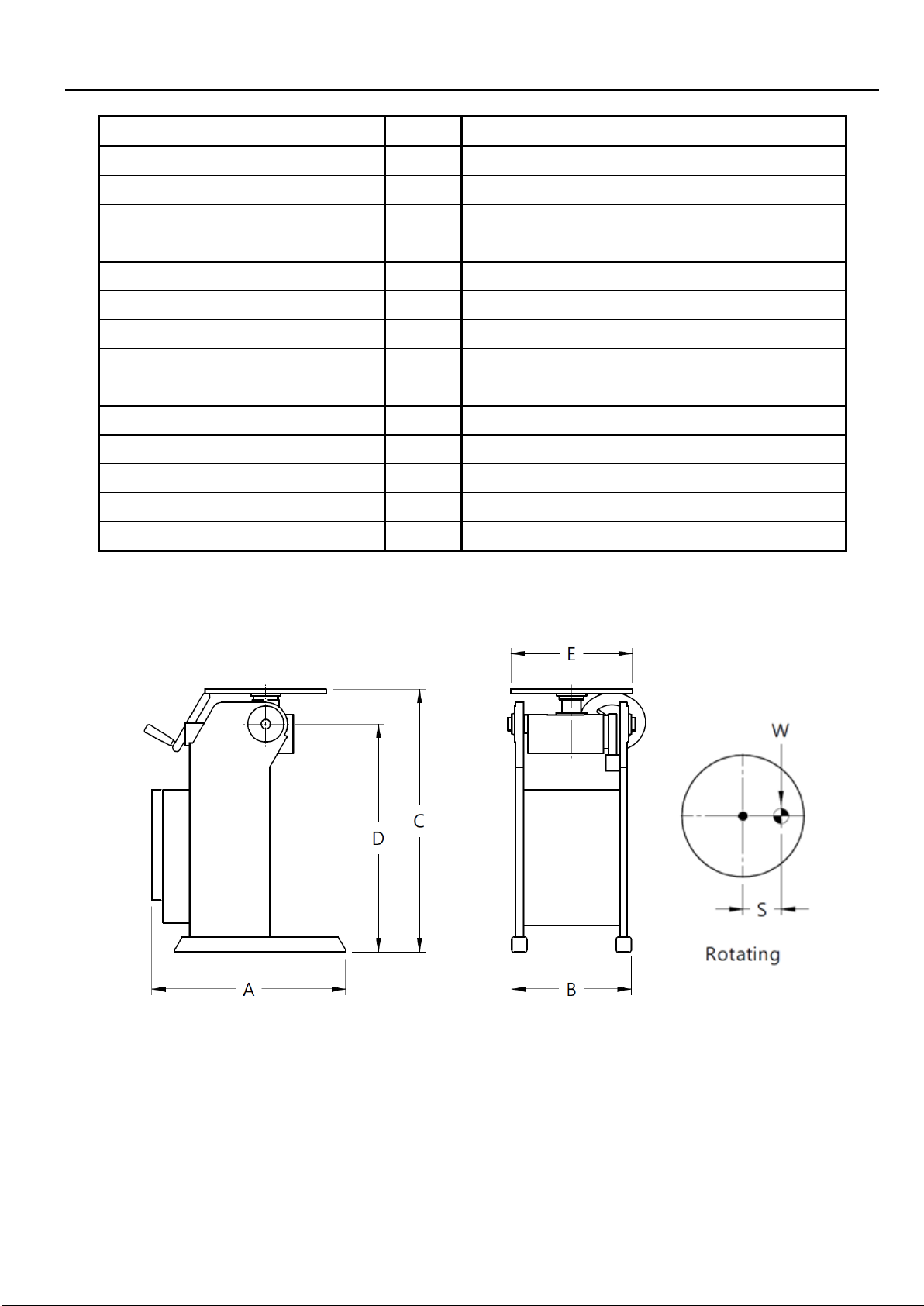

1.1 SPECIFICATION

MODEL

Unit

PT- 200s

Power Input

~

1 Phase 220V 50/60Hz

Capacity (Horizontal / Vertical )(W) kg 200 / 130

Rated center of gravity(S) mm 25

Rotation speed rpm 0.01 ~ 30

Tilt range deg. 0 ~ 120

Earthing

amp

300

Overall length (A) mm 530

Overall width (B) mm 315

Overall height (C) mm 690

Center to floor (D) mm 600

Table diameter (E)

mm

320

Spindle thru hole mm 22

Table slot bolt size M10

Weight Kg 45

2

1.2 CONTROL BOX SPECIFICATION

Control Model Unit CB-500

Power Requirement 1 Phase 220V 50/60Hz 3A

Main power switch

3

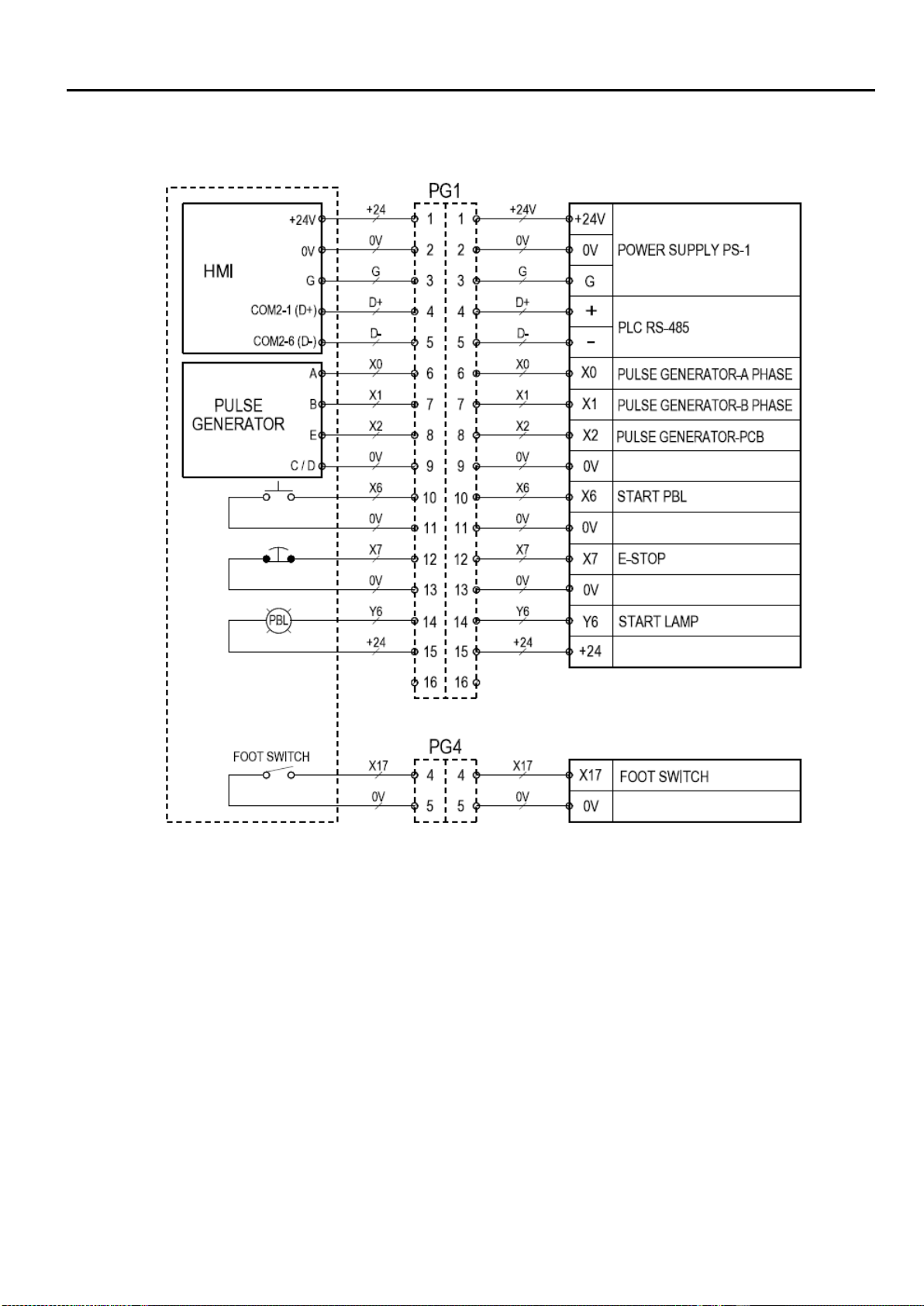

1.3 CONNECTOR

Control box connector:

PG1 HMI Box (16Pin) PG3 Start output (7Pin)

PG2 Weld Machine (10Pin) PG4 Foot switch (5Pin)

4

1.3 CONNECTOR

HMI & Food switch connection:

5

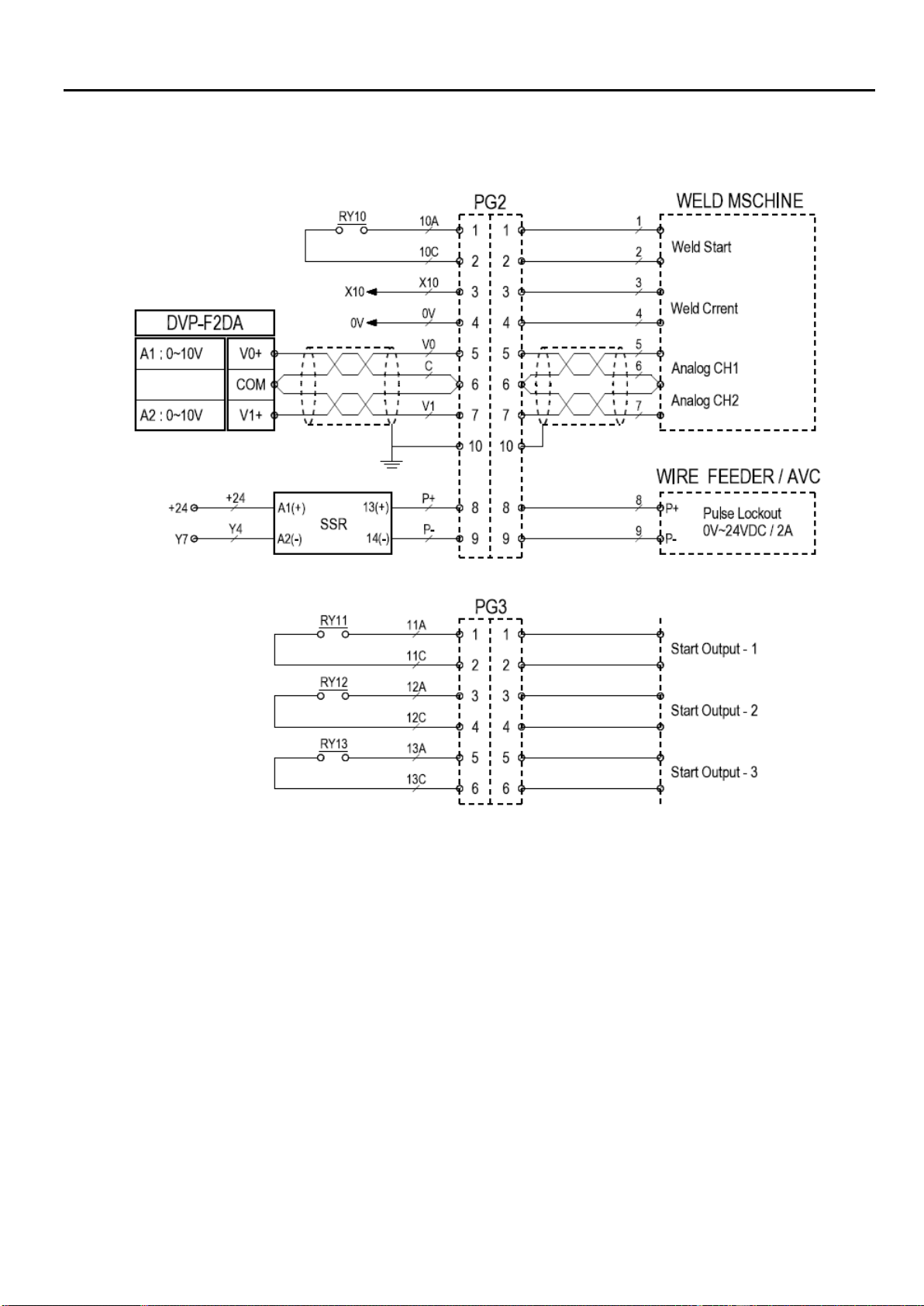

1.3 CONNECTOR

Welding equipment connection:

6

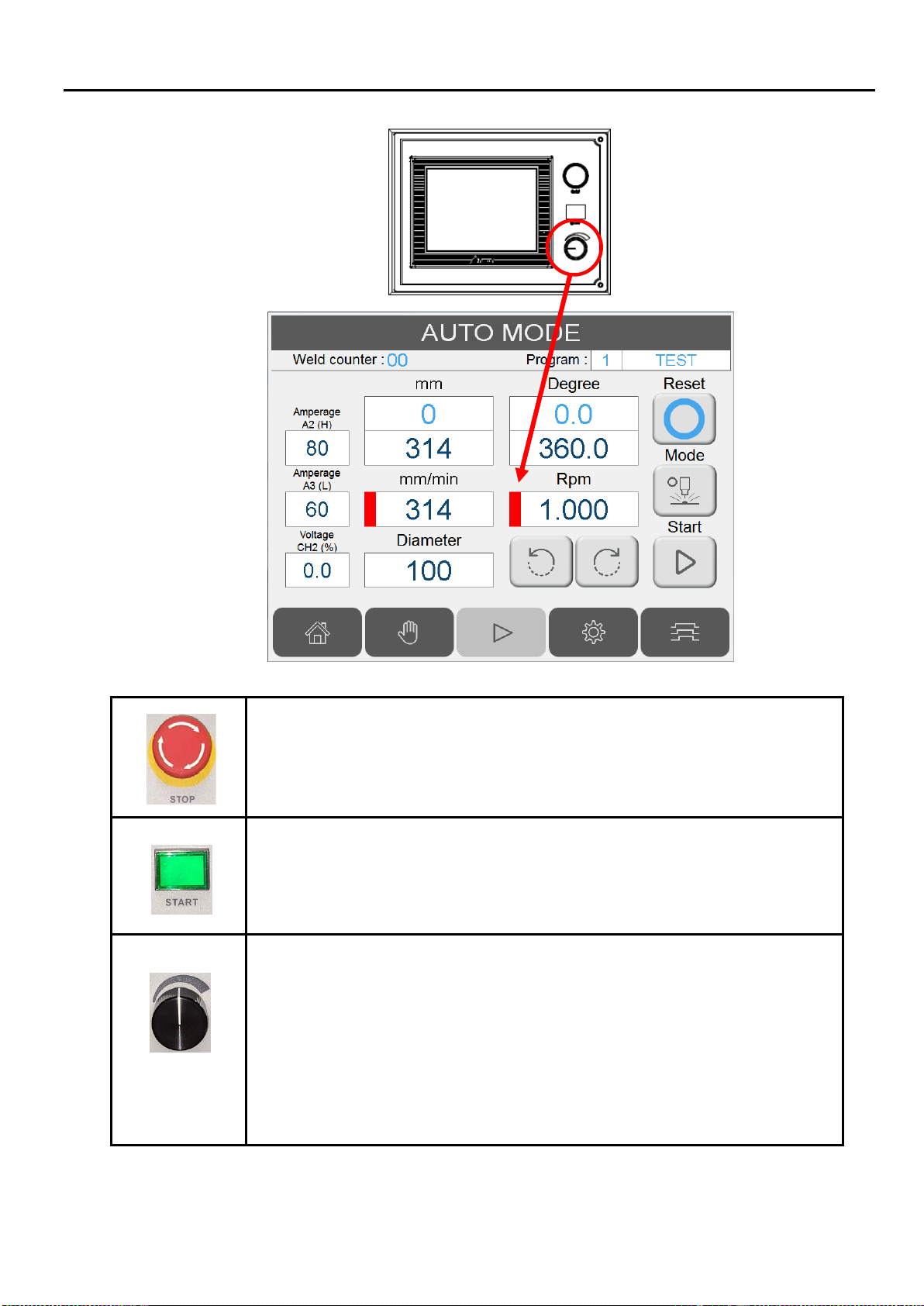

2.1 HMI OPERATION

Emergency stop.

Auto start / Auto stop.

Pulse adjustment knob:

1. Press the pulse adjustment knob to display red flashing cursor beside

Rpm and mm/min. Rotate the knob to modify speed.

2. Press the pulse adjustment knob again to display red flashing cursor

beside Amperage A2(H) & A3(L). Rotate the knob to modify both A2(H)

& A3(L).

3. Press the pulse adjustment knob again to cancel red flashing cursor and

disable online adjustment feature.

7

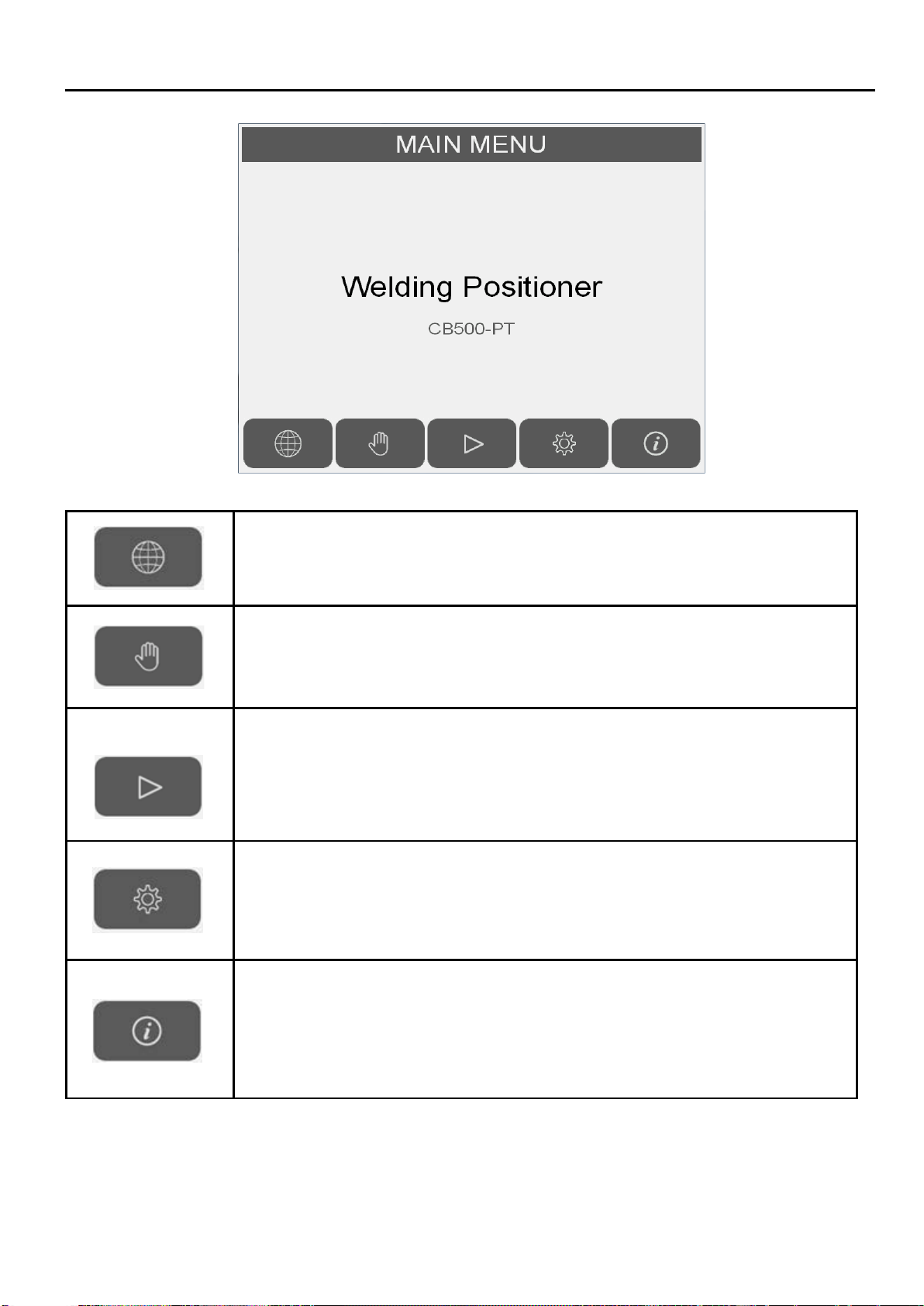

2.2MAIN SCREEN

Switch language Chinese / English.

Switch to "Manual Mode" screen.

Switch to "Auto Mode" screen

User level 1 clearance is required.

Default user level 1 clearance password:123

Default user level 2 clearance password:456

Refer to section 「2.11 Password」to disable auto mode password protection.

Switch to "Setting" screen.

Switch to "System Info" screen.

8

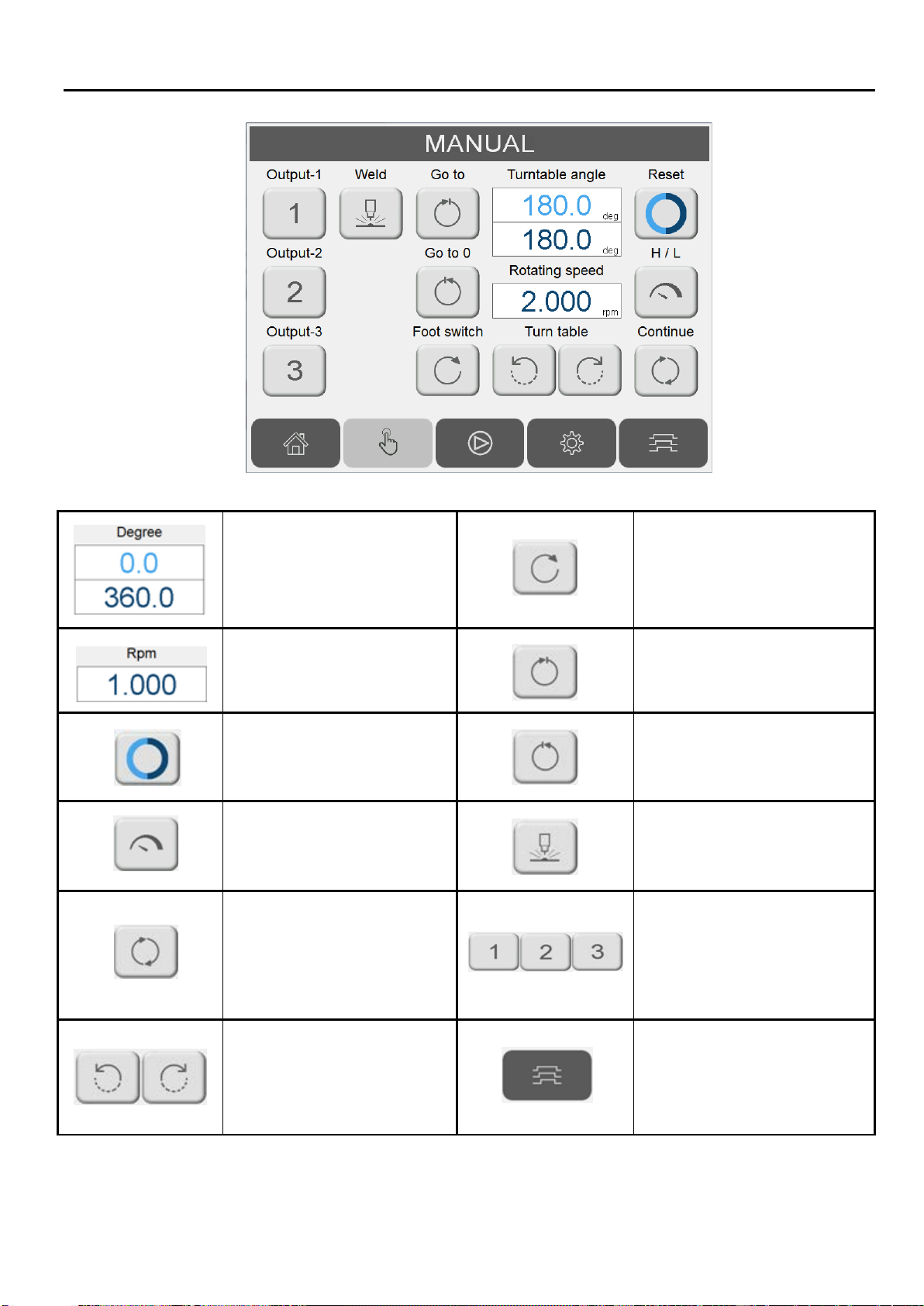

2.3 MANUAL MODE

Turn table current position:

Blue field: current position.

Red field: set position.

Foot switch.

direction selection.

Turn table rotation per round

(RPM) setting.

Move to set position.

Reset current position to 0.

Return to beginning position.

Toggle between

welding/high turn table

speed.

Manual activate welder.

Jog operation mode.

1. Hold/release the button

to rotate.

2. Press to toggle rotation

ON/OFF.

Force dry contact output

ON/OFF.

Turn table jog operation.

Switch to welding sequence

screen.

9

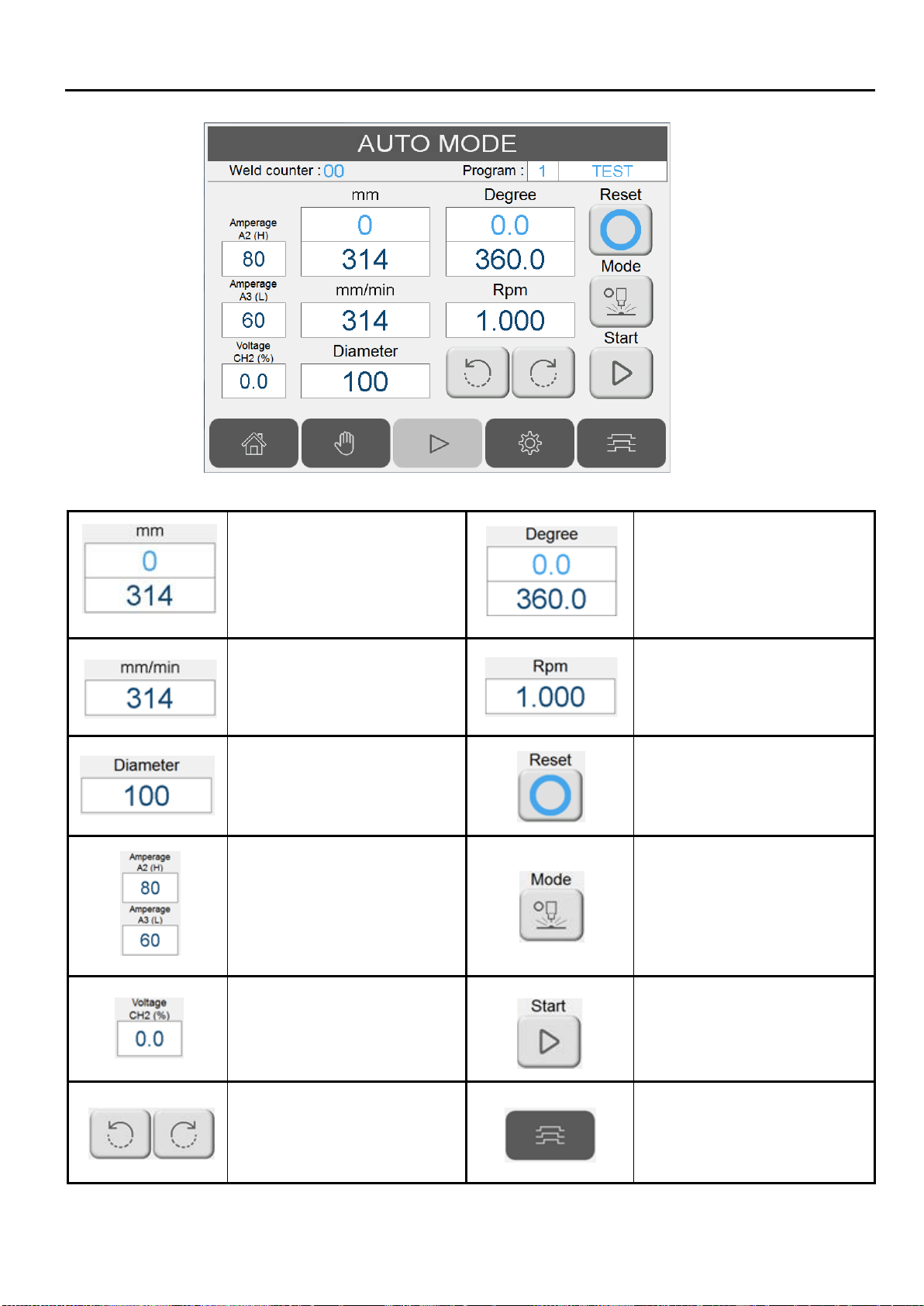

2.4 AUTO MODE

Turn table current position

according to angle &

diameter:

Blue field: current position.

Red field: set position.

Turn table current position:

Blue field: current position.

Red field: set position.

Turn table linear speed

(mm/min) setting.

Turn table rotation per round

(RPM) setting.

Welding diameter.

Reset current position to 0

Welding current (A).

0~100% = 0~10VDC

If pulse mode is active,

represents the peak (A2).

(please refer to sec 2.8)

Simulation/Auto mode toggle.

Welder ON is disable when

Simulation mode is active.

Second analog voltage

output. 0~100% = 0~10VDC

Activate/stop auto welding

sequence.

Turn table jog operation.

Switch to welding sequence

screen.

10

2.5 SETTING

Switch to Program screen.

Switch to Index Weld screen.

Switch to Program note screen.

Switch to system setting screen.

User level 1 clearance is

required.

Default user level 1 clearance

password: 123

Default user level 2 clearance

password: 456

Switch to Weld Sequence screen.

Switch to Password screen.

Switch to Weld Current screen.

Switch to Program Backup

screen.

Switch to Autorun function screen.

11

2.6 PROGRAM SAVE/LOAD

Enter the program number in No. field and press

“Load” button to load the program’s welding

parameter.

Enter the program number and program name, the

press “Save” to save the parameters.

Pressor button to scroll to next/previous sets

of parameters.

Switch to Program note screen.

12

2.7 PROGRAM NOTE

Enter letter or number as program reminder. 10 letters for sh ort field, 24 letters for long field.

13

2.8 WELDING SEQUENCE SETTING

T1 Welder ON delay after auto start is activated.

T2 Turn table rotation delay after arc on signal is received.

T3 Dry contact output-1 ON delay after arc on signal is received.

T4 Dry contact output-2 ON delay after arc on signal is received.

T5 Dry contact output-3 ON delay after auto start is activated.

Used for protective gas activation or pneumatic torch lifter.

T6 Welder OFF delay after turn table has reached target program position.

T7 Turn table stop delay after turn table has reached target program position.

T8 Dry contact output-1 OFF delay after turn table has reached target program position.

Also switches off when both T6 and T7 timer are finished.

T9 Dry contact output-2 OFF delay after turn table has reached target program position.

Also switches off when both T6 and T7 timer are finished.

T10 Dry contact output-3 OFF delay after turn table has reached target program position.

Output-3 is not limited by T6 and T7 timer, can be set for longer delay action like welding

protective gas or pneumatic torch lifter.

14

2.9 WELDING CURRENT SETTING

100% amperage value setting (analog output 1).

A1 Initial current (A) Initial current level after arc ON signal is received.

A2 Peak current (A) Main welding current. If pulse wave function is enabled, this

value is the peak current value.

A3 Valley(low) current(A) If pulse wave function is enabled, this value is the low current

value. Can’t set more than A2.

A4 Welding crater current(%) Welding ending current.

T1 Initial current time(sec) 0~10 sec, initial arc stabilize time after arc ON signal is received.

T2 Rise current time(sec) 0~10 sec, rise time from initial current A1 to peak current A2

T3 Peak current time(sec) 0.01~10 sec, peak current duration before change to valley

current.

T4 Valley current time(sec) 0.01~10 sec, valley current duration before change to peak

current.

T5 Current fall time(sec) 0~10 sec, amount of time current drop from A2 to A4. The count

starts after welder output is switched off. \

T6 Welding crater time(sec) 0~10 sec, amount of time for crater current.

CH2 Analog voltage(%) Channel 2 analog voltage 0~100% = 0~10VDC.

Note 1: If both T3 & T4 are set to 0, the wave pulse function is disabled.

Caution: Even though pulse wave function’s output voltage can reach a frequency of 50Hz, the

welder may not be able to change current at this rate.

This manual suits for next models

2

Table of contents

Popular Welding System manuals by other brands

Lincoln Electric

Lincoln Electric Square Wave TIG 200 Operator's manual

Kühtreiber

Kühtreiber 165 Instructions for use and maintenance

Lincoln Electric

Lincoln Electric WELD-PAK 90i FC Operator's manual

Helvi

Helvi MULTITECH 365 operating manual

Lincoln Electric

Lincoln Electric VANTAGE IM10044 Operator's manual

Riland

Riland MIG 135E user manual