6

Product Introduction

POWER CUT series isregarded as metal cutter equipment with high efficiency. Its working principle is to use

the compressed air as the ionization medium, and then form the high density plasma arc heat source by the torch

nozzle’s compress effect, which melt the metal as a result. The melted metal will be blown off by the high speed

gas flow at the same time to form into narrow cutting slot, thus the metal can be melted and cut very rapidly.

This series cutting equipment possesses good features like easy operation, energy saving, high speed cutting,

narrow and glabrous cutting slot, less deformation of work pieces, reliable and safe apply, low investment etc. It is

suitable for almost all metal plate and pipe materials, including mild steel, stainless steel, aluminum, copper,

titanium, nickel alloy, cast iron etc. It is widely used in every work of life such as ship building, motor

manufacturing, metal structure, boiler, pressure vessel and pipe making, medical appliance and machinery making

etc.

The feature of POWER CUTseries:

◇Small and light ,the weight of POWER CUT 60/70HFШis only 18Kg.

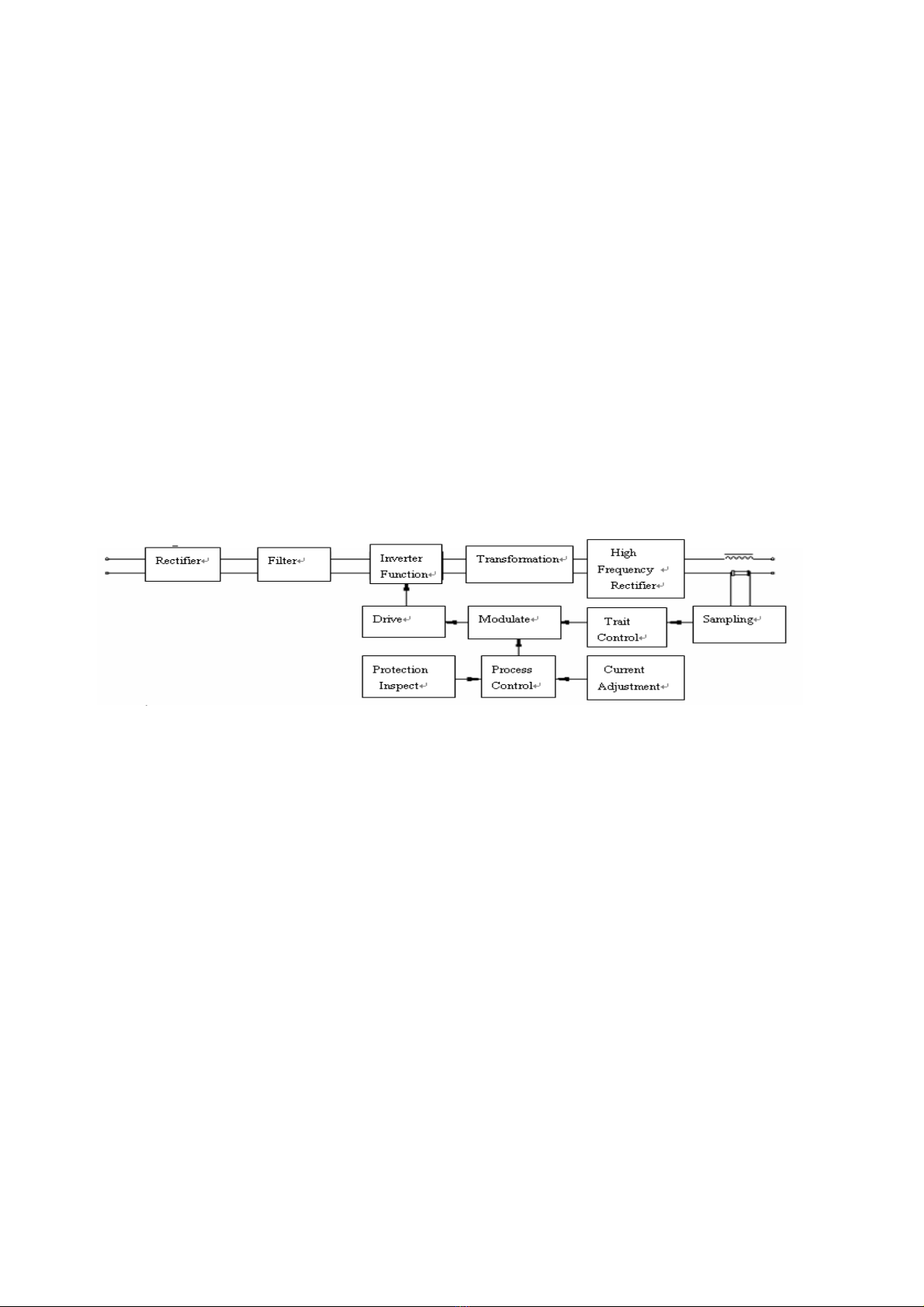

◇advanced IGBT inverter technology attributes to stable capability ,high efficiency and energy

saving

◇workcanbereliableat ±15% of fluctuation for input voltage.

◇visible gas adjustment and easy operation, specially suitable for decoration。

◇Thecutting thickness capacity of machine typewill reach 22mm.

◇cutting slot both narrow and glabrous;no damage to the work pieces. Commendatory thickness attributes to

high quality.

◇Complete protective function. include the protections of overheat.

Safety Operation

Operator’s Self Protection

*Please always follow the rules that conform to safety and hygiene. Wear protective garments to avoid injuries

to eyes and skins

*No touch to the working piece while operation in case of the electric leaking accident occurred

*No touch to the two output polarity (The polarity of the torch and the polarity of the work piece.) at the same

time without any insulationprotection.

*No permission to cut the vessel with inflammable and explosive materials or the sealed pressure vessel.

*Avoid operation under water or high humidity places.

*Shut off the power supply before changing the connect tip or electrode.

*Prohibit aiming the torch at any part of the body.

*Prohibit touching the contact part of the torch after the cutter is on.

Attention

*POWER CUT 60/70HFШseries cutter is electronic products whose spare parts are very tender, do not change

oradjust with a rush otherwise the switch will be damaged.

*Check the connection to see if it is well connected, whether the earth (ground) connection is reliable, etc.

*Fumes and gases produced when cutting are hazardous to health. Make sure to work in places where there are

exhaust or ventilation facilities to keep fumes or emissions away from the breathing zone.