Procentec ProfiHub B5 Plus User manual

ProfiHub B5+ / B5+RD User Manual

_______________________________________________

Version 2.0 – July 2014 Page 1 / 56

ProfiHub-B5-Plus-Manual-EN.docx © PROCENTEC 2014 - Copyright - all rights reserved

User Manual

ProfiHub B5+ / B5+RD

5 Channel DP Spur and Repeater component

with Redundancy and optional Diagnostics Device

Integrated Diagnostics Device (on type B5+RD)

5 Isolated outgoing Channels.

Transparent for all PROFIBUS DP protocols.

RS 485 specifications for each channel.

Cable Redundancy

Max. 12 Mbps.

Max. 31 devices per channel.

Max. 1200 m spur line length.

No limit in serial placement.

Integrated termination facilities.

Configurable grounding system.

IP 20 classification.

Extended temperature range.

UL and DNV approved

ProfiHub B5+ / B5+RD User Manual

_______________________________________________

Version 2.0 – July 2014 Page 2 / 56

ProfiHub-B5-Plus-Manual-EN.docx © PROCENTEC 2014 - Copyright - all rights reserved

Safety Guidelines

This manual contains notices which you should observe to ensure your own personal safety, as well

as to protect the product and connected equipment. These notices are highlighted in the manual by a

warning sign and are marked as follows according to the level of danger:

Draws your attention to important information on handling the product, a particular part of the

documentation or the correct functioning of the product.

Warning

This device and its components may only be used for the applications described in this manual and

only in connection with devices or components that comply with PROFIBUS and an RS 485 interface.

This product can only function correctly and safely if it is transported, stored, set up, installed,

operated and maintained as recommended.

Qualified Technicians

Only qualified technicians should be allowed to install and work with this equipment. Qualified

technicians are defined as persons who are authorized to commission, to ground, to tag circuits and

systems in accordance with established safety practices and standards. It is recommended that the

technicians carry a Certified PROFIBUS Installer or Certified PROFIBUS Engineer certificate.

Disclaimer of Liability

We have checked the contents of this manual as much as possible. Since deviations cannot be

precluded entirely, we cannot guarantee full agreement. However, the content in this manual is

reviewed regularly and any necessary corrections included in subsequent editions. Suggestions for

improvement are welcomed.

Copyright © 2014 PROCENTEC

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or

transmitted, in any form or by any means, electronic, mechanical, photocopying, recording or

otherwise, without the prior written permission of the publisher.

PROCENTEC

Klopperman 16

2292 JD WATERINGEN

The Netherlands

Tel.: +31-(0)174-671800

Fax: +31-(0)174-671801

Web: www.procentec.com

ProfiHub B5+ / B5+RD User Manual

_______________________________________________

Version 2.0 – July 2014 Page 3 / 56

ProfiHub-B5-Plus-Manual-EN.docx © PROCENTEC 2014 - Copyright - all rights reserved

Important Information

Purpose of the Manual

This manual explains how to put the ProfiHub B5+ into operation.

Recycling and Disposal

The parts of the ProfiHub can be recycled. For further information about environment-friendly recycling

and the procedure for disposing your old equipment, please contact:

PROCENTEC

Klopperman 16

2292 JD WATERINGEN

The Netherlands

Tel.: +31-(0)174-671800

Fax: +31-(0)174-671801

Document Updates

You can obtain constantly updated information on PROCENTEC products on the Internet at

www.procentec.com

You can also contact PROCENTEC Customer Support:

- by phone at +31-(0)174-671800

- by fax at +31-(0)174-671801

ProfiHub B5+ / B5+RD User Manual

_______________________________________________

Version 2.0 – July 2014 Page 4 / 56

ProfiHub-B5-Plus-Manual-EN.docx © PROCENTEC 2014 - Copyright - all rights reserved

Important Notices

WARNING

When the product is in use at an ambient temperature of 63 degrees Celsius or 145 degrees

Fahrenheit, the housing of the ProfiHub B5+ will be hot. Do not touch the housing!

At normal operating temperatures of 25 degrees Celsius, the temperature of the housing will not

exceed 35 degrees Celsius.

WARNING

When the product is in use at an ambient temperature of 63 degrees Celsius or 145 degrees

Fahrenheit, the housing of the ProfiHub B5+ will be hot. Do not touch wires which are in contact

with the housing!

WARNING

When the product is in use at an ambient temperature of 63 degrees Celsius or 145 degrees

Fahrenheit, the housing of the ProfiHub B5+ will be hot. Use wires suitable for these temperatures!

HOT HOUSING warning located on the side of the housing. Make sure this warning is visible after wall

installation. UL certification demands the warning to be visible during operation.

To comply with UL certification regulations (UL60950-1) the power supply must be a Limited Power

Source (LPS) or NEC Class 2 or CEC Class 2 that cannot exceed 100VA.

According to UL60950-1, if a copper PROFIBUS cable is used outside, it is required to install surge

protection that is suitable for PROFIBUS.

To comply with UL certification regulations the ProfiHub B5+ is to be used on altitudes under 2000 m.

ProfiHub B5+ / B5+RD User Manual

_______________________________________________

Version 2.0 – July 2014 Page 5 / 56

ProfiHub-B5-Plus-Manual-EN.docx © PROCENTEC 2014 - Copyright - all rights reserved

Contents

Important Notices .................................................................................................................................. 4

1Product Description...................................................................................................................... 7

1.1Product Features.................................................................................................................... 8

1.2Application areas.................................................................................................................... 9

1.3Additional Benefits ................................................................................................................. 9

1.4Channel Structure ................................................................................................................ 10

1.5Grounding System ............................................................................................................... 10

1.6Cable lengths for PROFIBUS DP ........................................................................................ 11

1.7Cable types for PROFIBUS DP............................................................................................ 12

1.8Status LEDs ......................................................................................................................... 13

1.9Comparison table ................................................................................................................. 14

2Installation Instructions ProfiHub B5+ ..................................................................................... 15

2.1Location................................................................................................................................ 15

2.2Position................................................................................................................................. 15

2.3Mounting............................................................................................................................... 15

2.4Power Supply ....................................................................................................................... 16

2.5Grounding of the power........................................................................................................ 17

2.6Relay contact ....................................................................................................................... 18

2.7Backbone ............................................................................................................................. 18

2.8Spur Segments .................................................................................................................... 19

2.9Termination .......................................................................................................................... 20

2.10Baudrate switch.................................................................................................................... 21

2.11Channel Redundancy........................................................................................................... 22

3Diagnostics Device..................................................................................................................... 23

3.1Setting up the Diagnostics Device ....................................................................................... 24

3.1.1Enabling the Diagnostics Device ..................................................................................... 24

3.1.2Changing the default PROFIBUS address ...................................................................... 24

3.1.3GSD file............................................................................................................................ 25

3.2Configuring the Diagnostic Device....................................................................................... 25

3.2.1Info data (mandatory module).......................................................................................... 25

3.2.2Alarm Confirmation .......................................................................................................... 25

3.2.3Redundant Status ............................................................................................................ 25

3.2.4Baudrate Status ............................................................................................................... 26

3.2.5Relay Status..................................................................................................................... 26

3.2.6Power Status.................................................................................................................... 26

3.2.7Termination Status........................................................................................................... 27

3.2.8Channel Status ................................................................................................................ 27

3.2.9Livelist Status................................................................................................................... 27

3.2.10Statistics (Short Format, Long Format ........................................................................ 28

3.3Parameterizing the Diagnostic Device ................................................................................. 30

3.3.1Diagnostics ...................................................................................................................... 30

3.3.2Statistics........................................................................................................................... 31

3.3.3Extended Diagnostics on Events change ........................................................................ 31

3.3.4Extended Diagnostics on Statistics change..................................................................... 32

3.3.5Alarm Relay on Events change ....................................................................................... 33

3.3.6Alarm relay on Statistics change ..................................................................................... 33

3.3.7Changing the Diagnostics duration/timeout..................................................................... 34

3.3.8Changing the Device Lost timeout................................................................................... 34

3.3.9Changing the data format ................................................................................................ 35

3.4ProfiTrace plugin for the Diagnostic Device......................................................................... 35

ProfiHub B5+ / B5+RD User Manual

_______________________________________________

Version 2.0 – July 2014 Page 6 / 56

ProfiHub-B5-Plus-Manual-EN.docx © PROCENTEC 2014 - Copyright - all rights reserved

3.4.1Installing the Plugin.......................................................................................................... 35

3.4.2Using the Plugin............................................................................................................... 36

4Technical Data ProfiHub B5+ / B5+RD...................................................................................... 37

5Sales offices and Distributors ................................................................................................... 39

6Order codes................................................................................................................................. 42

7Glossary....................................................................................................................................... 43

8Certificates .................................................................................................................................. 46

9Revision History.......................................................................................................................... 53

10Notes ............................................................................................................................................ 54

ProfiHub B5+ / B5+RD User Manual

_______________________________________________

Version 2.0 – July 2014 Page 7 / 56

ProfiHub-B5-Plus-Manual-EN.docx © PROCENTEC 2014 - Copyright - all rights reserved

1 Product Description

ProfiHub B5+ is an advanced, flexible and robust network component for PROFIBUS DP

installations, to create backbone structures and long multi-device star/tree segments.

PROFIBUS DP is a high speed communication bus that must comply with strict rules concerning spur

lines, because of possible reflections that could lead to communication disturbances. If spur lines or

star segments are required, costly investments in repeaters have to be done.

The innovative ProfiHub B5+ is the perfect component for such applications. It is an economic solution

to realise reliable spur lines in high speed DP networks. They have the functionality of 5 galvanic

isolated transparent repeaters. This allows network structures with extended spur lines that

individually can handle a maximum of 31 devices and a length equal to the main bus. The ProfiHub

B5+ refreshes a received message on one Channel and transfers it to all the other Channels

(chicken foot topology).

Because the ProfiHub B5+ creates isolated segments, the devices can now be removed and added

during operation. Also most electrical bus problems and EMC disturbances in a spur do not spread to

the other segments. The intelligent logic and isolation circuits of the ProfiHubs do not change the bit

width. This means the ProfiHubs do not have limitations in serial placement. The logic also detects the

transmission speed automatically.

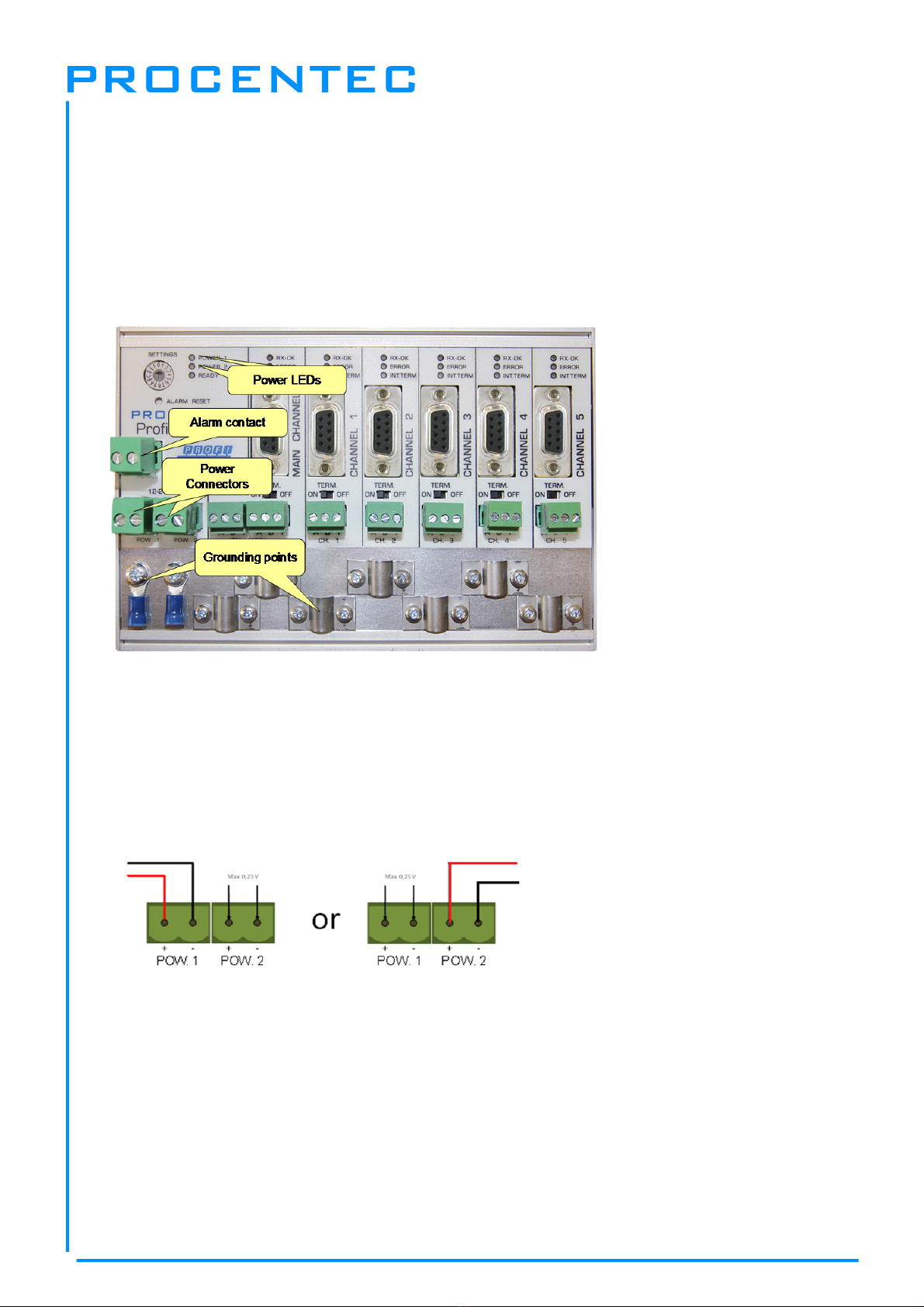

To assist the installation work, termination is integrated and

can be switched on/off. The grounding concept is also

selectable: direct or capacitive grounding. The ProfiHubs are

powered by a 10 to 24 DC Voltage. For troubleshooting,

maintenance and commissioning the ProfiHubs are equipped

with LEDs on the outside, which indicate the status of each

Channel (Data and Error).

If bus redundancy is enabled, 2 segments will form a

redundant pair which is completely compatible with the ABB

RLM01. An alarm contact is linked to events based on the

status of the power supply and the bus redundancy status.

Fig. 1 - ProfiHub B5+

ProfiHub B5+ / B5+RD User Manual

_______________________________________________

Version 2.0 – July 2014 Page 8 / 56

ProfiHub-B5-Plus-Manual-EN.docx © PROCENTEC 2014 - Copyright - all rights reserved

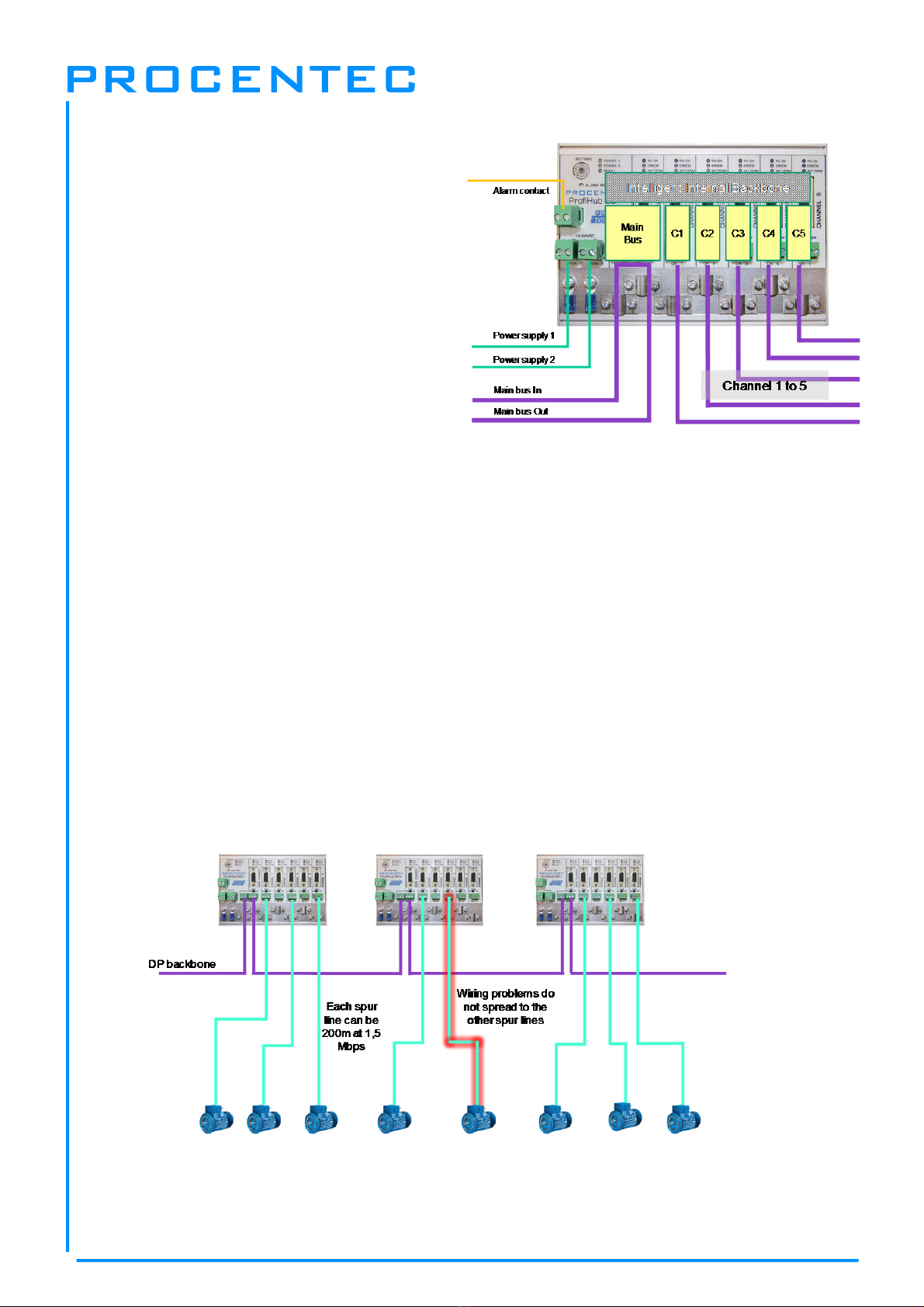

Fig. 2 - ProfiHub connections

1.1 Product Features

5 Galvanic isolated outgoing channels

(repeater segments).

Advanced Diagnostic capabilities (B5+RD)

Transparent for all PROFIBUS DP

protocols.

DP - RS 485 specifications for each

channel.

Cable redundancy for channel 4+5

9.6 Kbps to 12 Mbps.

31 devices per channel.

1200 m spur line length (depends on transmission speed).

Redundant power supply

No limit in serial placement or cascading of ProfiHubs.

Alarm contact, with manual reset button.

No address required (except for the B5+RD option).

Integrated termination facilities (switches).

Configurable grounding system (direct or capacitive).

IP 20 classification

Increased temperature range

DNV / offshore Certification

UL approvals

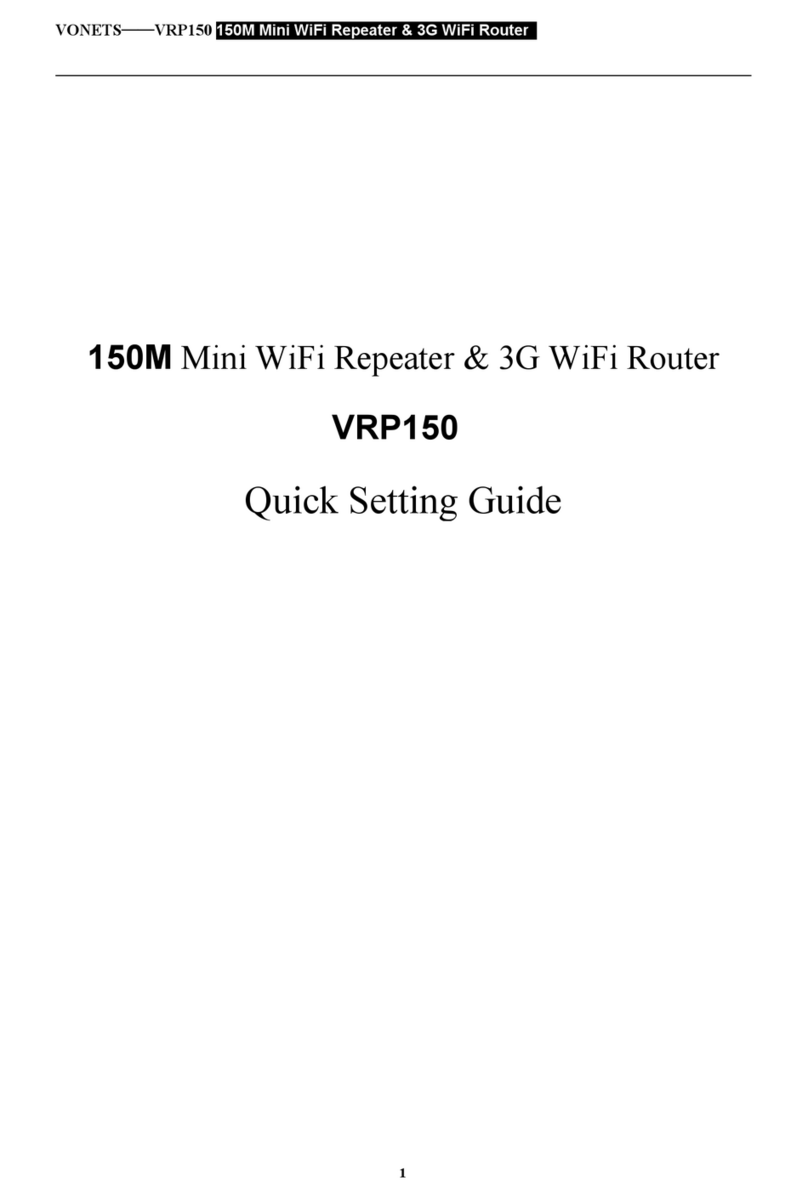

Fig. 3 - Long spur lines to instruments and the possibility to remove/insert them during operation. Short

circuit protection on each spur line is automatically provided.

ProfiHub B5+ / B5+RD User Manual

_______________________________________________

Version 2.0 – July 2014 Page 9 / 56

ProfiHub-B5-Plus-Manual-EN.docx © PROCENTEC 2014 - Copyright - all rights reserved

Noisy signalNoisy signal

Clean signalClean signal

1.2 Application areas

Dynamic spur lines to actuators, flow meters and pH analyzers.

Removable drives and motors.

Pull/Plug motor control centers (drawers).

Roof mounted devices in tank farms.

Barrier for non galvanic isolated equipment.

Networks with requirement for High Availability/uptime

Large star/tree structured networks.

1.3 Additional Benefits

Hot slave insertion and removal during operation.

Short circuit protection on each Channel.

Option to create a redundant path to other Hubs or COMbricks

Compact and robust construction.

Status and error display (per Channel).

Suitable for all DP cables.

Conveniently arranged networks.

Easy extendable installations.

On-board DB9 female connector on each channel for maintenance activities.

Cost Savings.

Fig. 4 - Because of the isolation and intelligence the ProfiHub provides, it can be used as a

barrier for electrically sensitive segments. This keeps the backbone and other Channels

clean.

ProfiHub B5+ / B5+RD User Manual

_______________________________________________

Version 2.0 – July 2014 Page 10 / 56

ProfiHub-B5-Plus-Manual-EN.docx © PROCENTEC 2014 - Copyright - all rights reserved

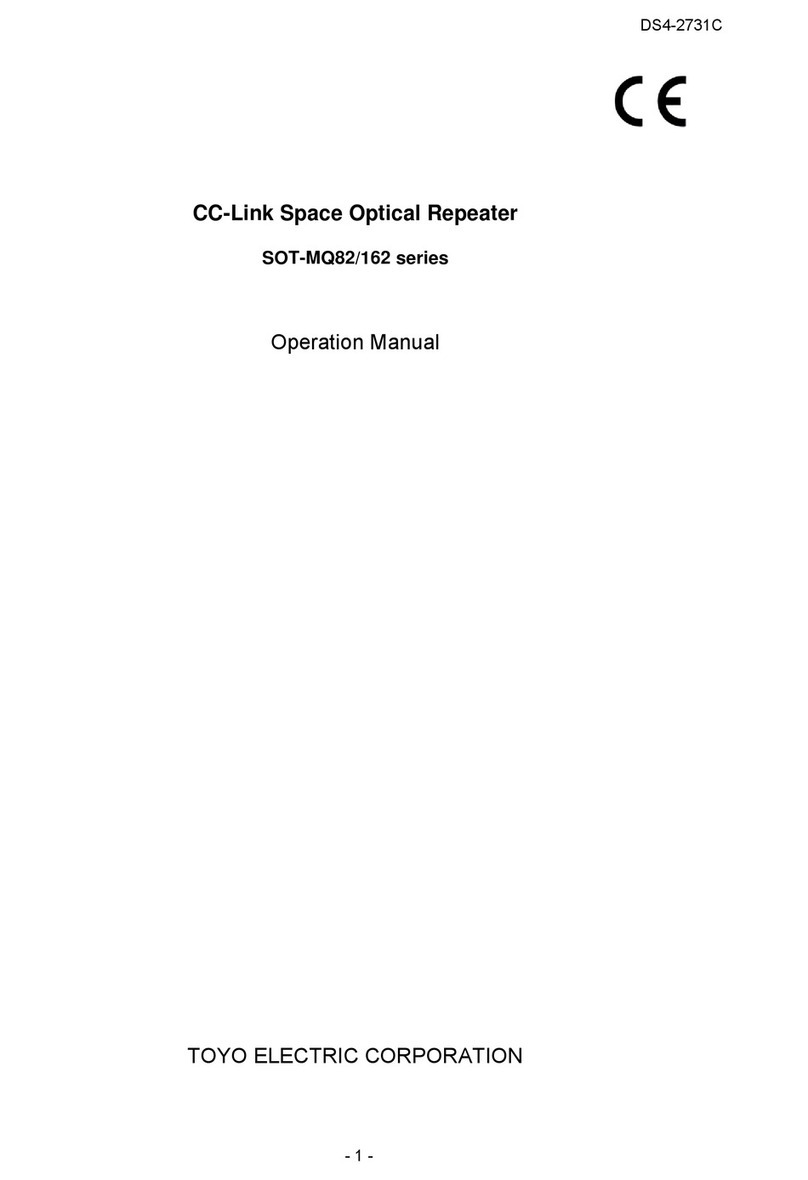

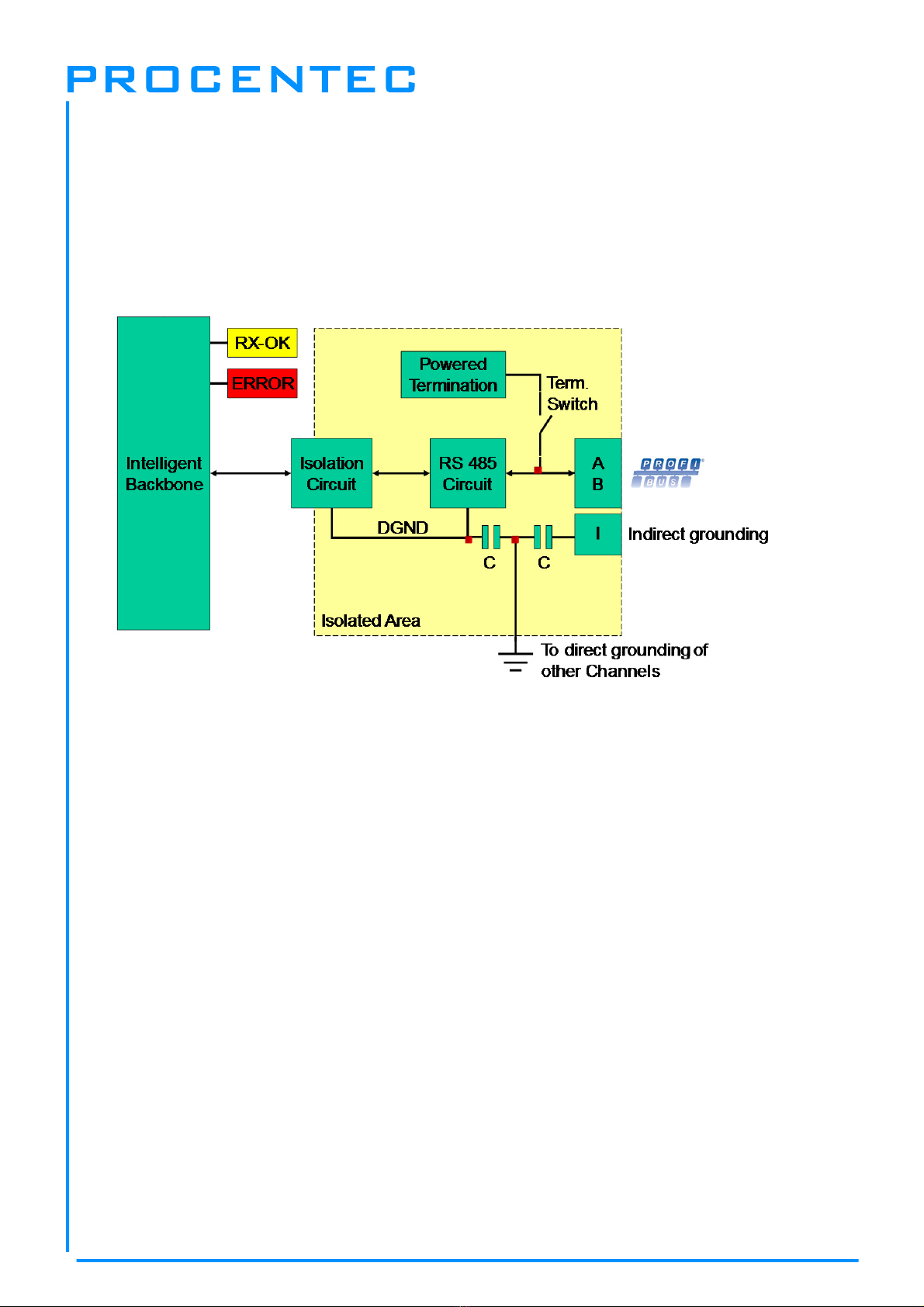

1.4 Channel Structure

Each Channel is electrically isolated and internally connected to the transparent intelligent backbone.

The termination is switchable and powered by the ProfiHub. The shielding of the PROFIBUS cable can

be directly grounded or indirectly grounded (see the next paragraph).

1.5 Grounding System

The ProfiHub B5+ can be grounded by 3 methods:

1) Direct grounding on the Ground Rail

2) Indirect grounding (through a capacitor)

3) Combination of direct and indirect.

The power supply must be grounded directly on the Ground Rail. The shielding of the PROFIBUS

cables can be directly or indirectly grounded. If you do not want to ground all or some cables to the

common ground, i.e. compensating current, the cable shielding must be connected to pin ‘I’ which

stands for Indirect grounding. A capacitor with a parallel high value resistor will separate the 2

potentials (

Fig. 5

), ensuring protection of the signal against non-DC disturbances.

If by accident on 1 channel the Direct Grounding is connected with the Indirect Grounding, the

connection to the Direct Grounding bypasses the capacitor in the Indirect Ground connection. The

current on the shield will flow to Direct Ground.

Fig. 5 - Channel structure

ProfiHub B5+ / B5+RD User Manual

_______________________________________________

Version 2.0 – July 2014 Page 11 / 56

ProfiHub-B5-Plus-Manual-EN.docx © PROCENTEC 2014 - Copyright - all rights reserved

Baudrate (kbit/s)

Segment length

(m)

9.6

1200 1200

19.2 1500 6000 120003000500187.593.7545.45

100100100200400100012001200

Segment length

(feet) 3940 3940 3283283286561310328039403940

Baudrate (kbit/s)

Segment length

(m)

9.6

1200 1200

19.2 1500 6000 120003000500187.593.7545.45

100100100200400100012001200

Segment length

(feet) 3940 3940 3283283286561310328039403940

Baudrate (kbit/s)

Segment length

(m)

9.6

1200 1200

19.2 1500 6000 120003000500187.593.7545.45

100100100200400100012001200

Segment length

(feet) 3940 3940 3283283286561310328039403940

DeviceDevice Device Device Device Device

Maximum 31 devices

Example: 1000 m cable per channel at 187,5 kbps

Other channels

With the same

Cable length

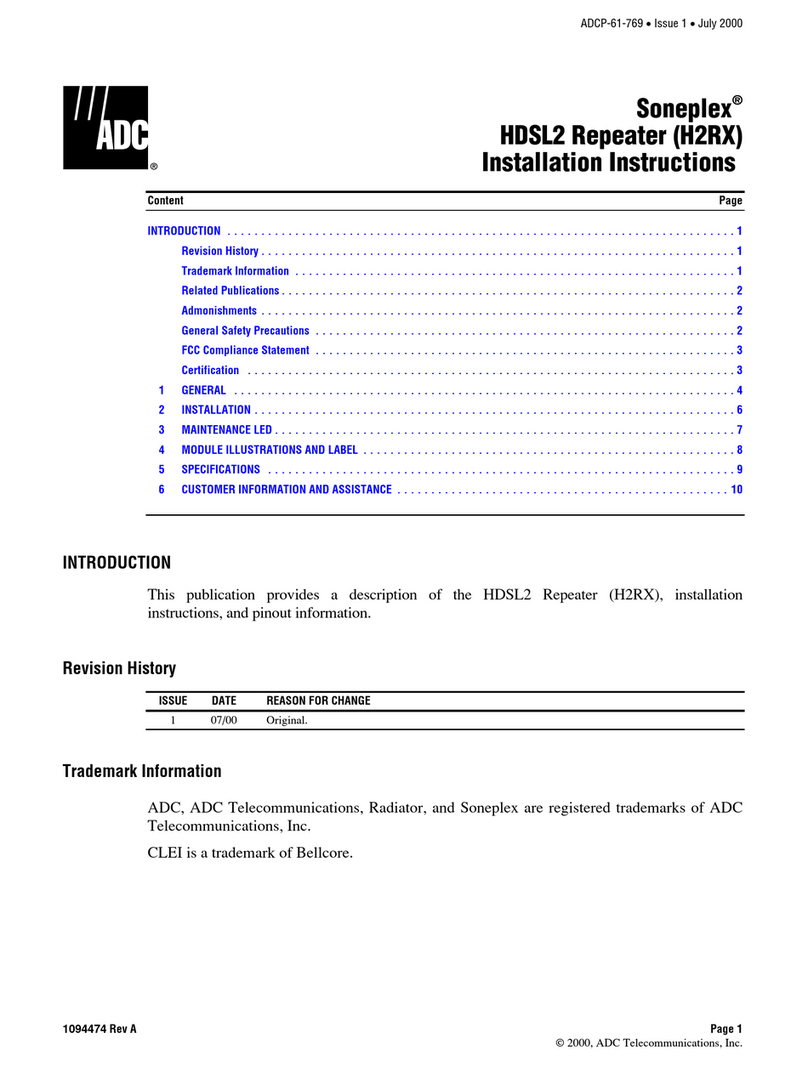

1.6 Cable lengths for PROFIBUS DP

The cables on the Channels and the Main-Channel must comply with the PROFIBUS DP cable

specifications for RS 485 (Fig. 6).

Fig. 6 - Cable lengths for PROFIBUS DP

ProfiHub B5+ / B5+RD User Manual

_______________________________________________

Version 2.0 – July 2014 Page 12 / 56

ProfiHub-B5-Plus-Manual-EN.docx © PROCENTEC 2014 - Copyright - all rights reserved

1.7 Cable types for PROFIBUS DP

The cable type must comply with the PROFIBUS DP cable specifications for RS 485 (Fig. 7).

The ProfiHub B5+ can handle cables based on multiple protection sheaths with an overall cable

diameter between 6 to 12 mm (Fig. 8).

Parameter Value

Wires 2 (twisted)

Impedance 135 .. 165 Ohm at 3 to 20 MHz

Capacity < 30 pF/m

Loop resistance < 110 Ohm/km

Wire diameter > 0.64 mm

Wire area > 0.32 mm2

FRNC cable

Shipboard cable

Festoon cable

Flexible cable

Food cable

Robust cable

Trailing cable

Hybrid cable

Fig. 7 - PROFIBUS DP cable specifications

Fig. 8 - Cables with different protection sheaths.

ProfiHub B5+ / B5+RD User Manual

_______________________________________________

Version 2.0 – July 2014 Page 13 / 56

ProfiHub-B5-Plus-Manual-EN.docx © PROCENTEC 2014 - Copyright - all rights reserved

1.8 Status LEDs

The Status LEDs on the ProfiHub are very useful for diagnostics.

OFF Blinking ON

POWER 1 / 2 Power is not

switched on or an

internal failure.

Power supply not

stable, redundant power

supply interrupted or an

internal failure.

Power supply OK.

READY Power is not

switched on or an

internal failure.

Trying to detect the

transmission speed, but

has not locked it yet.

The transmission

speed has been

detected.

Main RX-OK No communication

detected on the Main-

Channel.

1 or more devices

communicating on the

Main-Channel.

1 or more devices

communicating on the

Main-Channel.

Main ERROR No problem has

been detected.

Problem in the

cabling has been

detected (Main

Channel).

Problem in the

cabling has been

detected (Main

Channel).

Channel RX-OK There is no

communication

detected (on this

Channel).

1 or more devices

communicating (on this

Channel).

1 or more devices

communicating (on this

Channel).

Channel ERROR No problem has

been detected.

Problem in the

cabling has been

detected (on this

Channel).

Problem in the

cabling has been

detected (on this

Channel).

INT. TERM Termination for this

channel is OFF.

Internal failure. Termination for this

channel is ON.

ProfiHub B5+ / B5+RD User Manual

_______________________________________________

Version 2.0 – July 2014 Page 14 / 56

ProfiHub-B5-Plus-Manual-EN.docx © PROCENTEC 2014 - Copyright - all rights reserved

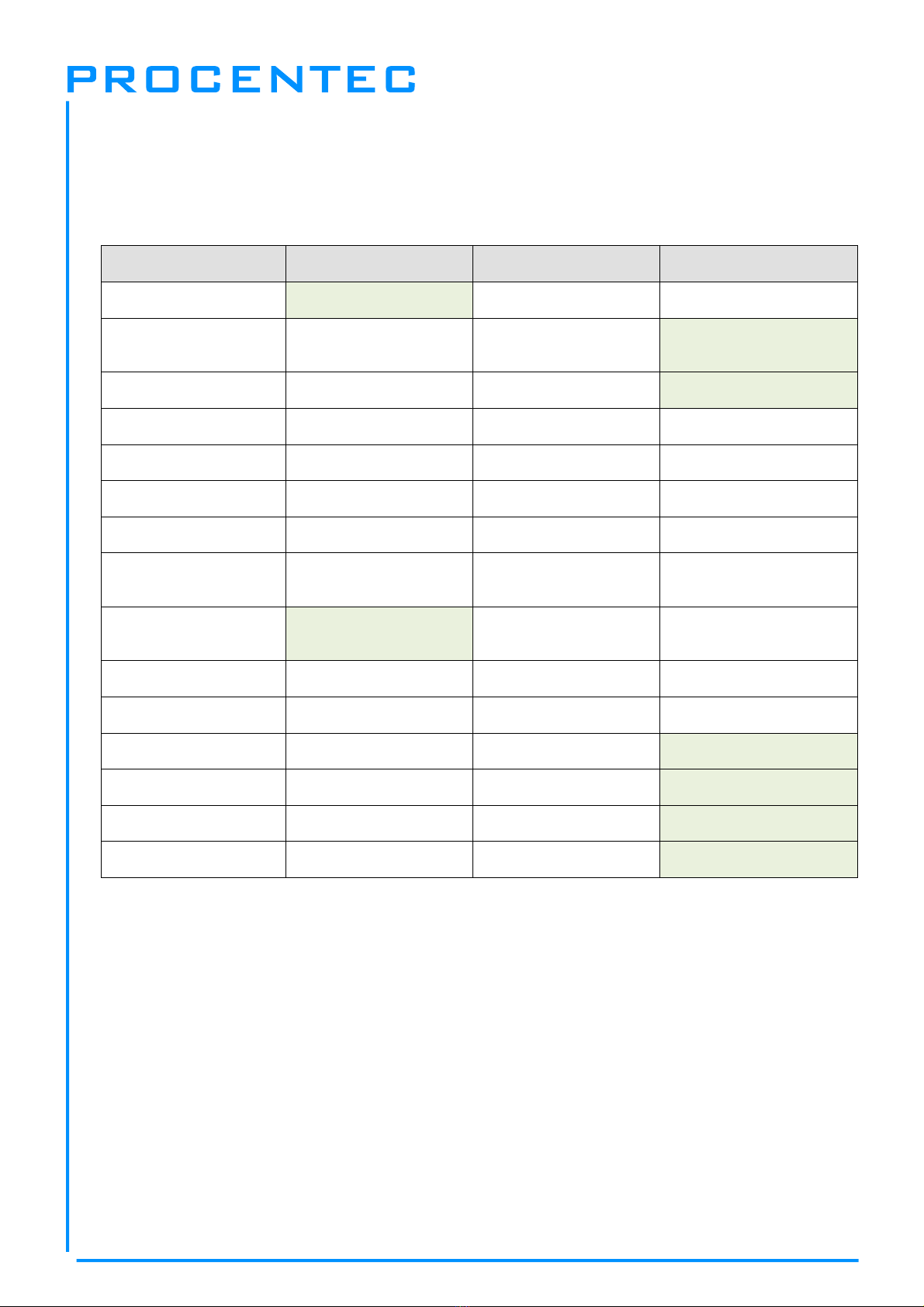

1.9 Comparison table

ProfiHub A5 ProfiHub B5 ProfiHub B5+ / B5+RD

Area IP 65 IP 20 IP 20

Redundant power

supply

No No Yes

Temperature range -20 to +60˚Celcius -20 to +60˚Celcius -25 to +70˚Celcius

Housing Plastic Metal Metal

Mounting Corner screws DIN-rail DIN-rail

Weight 800 g 650 g 650 g

Dimensions 213 x 210 x 95 mm 167 x 111 x 32 mm 167 x 111 x 32 mm

PROFIBUS connectors Screw terminals (inside)

Glands (outside)

Screw terminals and

DB9 connectors

Screw terminals and DB9

connectors

Alternative connectors Glands can be replaced

by M12 connectors

No No

Termination LEDs No Yes Yes

Ground rail Optional Yes Yes

Redundant channel No No Yes

Diagnostics Device None None Yes, in B5+RD

Offshore approvals None None Yes

UL approvals None None Yes

ProfiHub B5+ / B5+RD User Manual

_______________________________________________

Version 2.0 – July 2014 Page 15 / 56

ProfiHub-B5-Plus-Manual-EN.docx © PROCENTEC 2014 - Copyright - all rights reserved

2 Installation Instructions ProfiHub B5+

2.1 Location

The ProfiHub B5+ can be installed everywhere in a non-hazardous area that complies with IP 20 (DIN

40 050) and the specified temperature range of -25 to +70o Celsius.

2.2 Position

The ProfiHub B5+ can be installed in every position, but it is recommended to install it with the cables

pointing down. In this position it is also easier to read the status LEDs.

2.3 Mounting

The ProfiHub B5+ can be mounted on 35 mm DIN-rail with a minimum width of 167 mm. Mounting

brackets are available for mounting the B5+ directly on a wall. The ProfiHub B5+ has only been UL

and DNV approved with 35 mm DIN-rail mounting!

The supplied rubber studs need to be placed on the back of the housing of the ProfiHub B5+ for extra

fixation. This is to prevent the product to potentially slide off the DIN-rail. See

Fig. 9

for an example.

When used in DNV environments these rubber studs need to be installed!

Fig. 9

–

Rubber studs on backside of housing

ProfiHub B5+ / B5+RD User Manual

_______________________________________________

Version 2.0 – July 2014 Page 16 / 56

ProfiHub-B5-Plus-Manual-EN.docx © PROCENTEC 2014 - Copyright - all rights reserved

2.4 Power Supply

To comply with UL certification regulations the power supply must be a Limited Power Source (LPS) or

NEC Class 2 or CEC Class 2 that cannot exceed 100VA.

The two 2-pin screw type power connectors are located on the left of the ProfiHub B5+ (

Fig. 10

).

1 = +(left)

2 = -(right)

Both power connectors are linked 1-on-1 to the internal power supply of the B5+. If one power supply

fails, the other takes over without delay time. When redundancy is not required, it is sufficient to use

one power connector. Please note that when using only one power supply, a voltage of max. 0.25 V

will exist on the other unconnected power connector, as shown in

Fig. 11

.

If only one power supply is used, the alarm contact is closed. If two power sources are connected, the

contact is open. As soon as one of the power supplies fails, the contact will close and the Power

Indicator LED will blink.

For UL certified installations the power supply must comply with the following specifications:

- Limited Power Source (LPS) or NEC Class 2 or CEC Class 2

- Voltage: 12 - 24 VDC

- Current: min 275 mA

- Wire diameter: < 2.5 mm2

Fig. 10 - Power connecto

r

s and LEDs

Fig. 11

–

Maximum voltage on unconnected Power Connecto

r

ProfiHub B5+ / B5+RD User Manual

_______________________________________________

Version 2.0 – July 2014 Page 17 / 56

ProfiHub-B5-Plus-Manual-EN.docx © PROCENTEC 2014 - Copyright - all rights reserved

Procedure

To connect the 24V supply to the 2-pin screw-type terminal, proceed as follows:

- Strip the insulation from the cable or the conductors for the 24V power supply.

- Add cable crimp terminals/wire ferrules to the conductors.

- Secure the crimp terminals in the screw-type terminal.

To connect the power supply, you need a 3 mm screwdriver.

Testing

If the power is switched on it can be diagnosed by the following indicators:

- LEDs should be blinking in a circular animation for a short time.

- The POWER LED of the respective power connector (1, 2 or both) is ON.

- The READY LED is ON or Blinking, depending on baud rate lock.

2.5 Grounding of the power

It is recommended to use a power supply with a ground lead (3-wire). Connect the ground

lead of the power lead to the Ground Rail of the ProfiHub B5+. Connect the Ground Rail to the

common ground with a separate ground lead. See Fig. 12 for an example.

Fig. 12 - Connection to Ground Rail

ProfiHub B5+ / B5+RD User Manual

_______________________________________________

Version 2.0 – July 2014 Page 18 / 56

ProfiHub-B5-Plus-Manual-EN.docx © PROCENTEC 2014 - Copyright - all rights reserved

2.6 Relay contact

The ProfiHub B5+ features a potential-free relay contact. This alarm contact can be used to monitor

the power supplies. Example applications are: Connect a LED tower, alarm buzzer, SMS server or use

it as a digital signal for the PLC. On the B5+RD version the relay can also be used for alarming in case

of retires, illegals, or other events. For more information refer to Chapter 3.

If only one power supply is used, the alarm contact is closed after 60 seconds after start-up. If two

power sources are connected, the contact is open. When one of the power supplies fails for 3 seconds

or more, the contact will close and the Power Indicator LED will blink. If you are using only one power

source and wish to use the Relay contact, simply connect Power 1 to Power 2.

In the case of an interrupted power supply you can reset the contact by pressing the ‘Reset’ button.

The contact will open and the LEDs will stop blinking.

The Alarm contact is also switched when the ProfiHub is in Redundant mode and one of the redundant

paths fails.

The maximum power to be connected to the alarm contact is 24 VDC. The maximum current

consumption is 500 mA.

It is advised to use a Limited Power Source (LPS) of NEC Class 2 or CEC Class 2 for powering the

alarm contact.

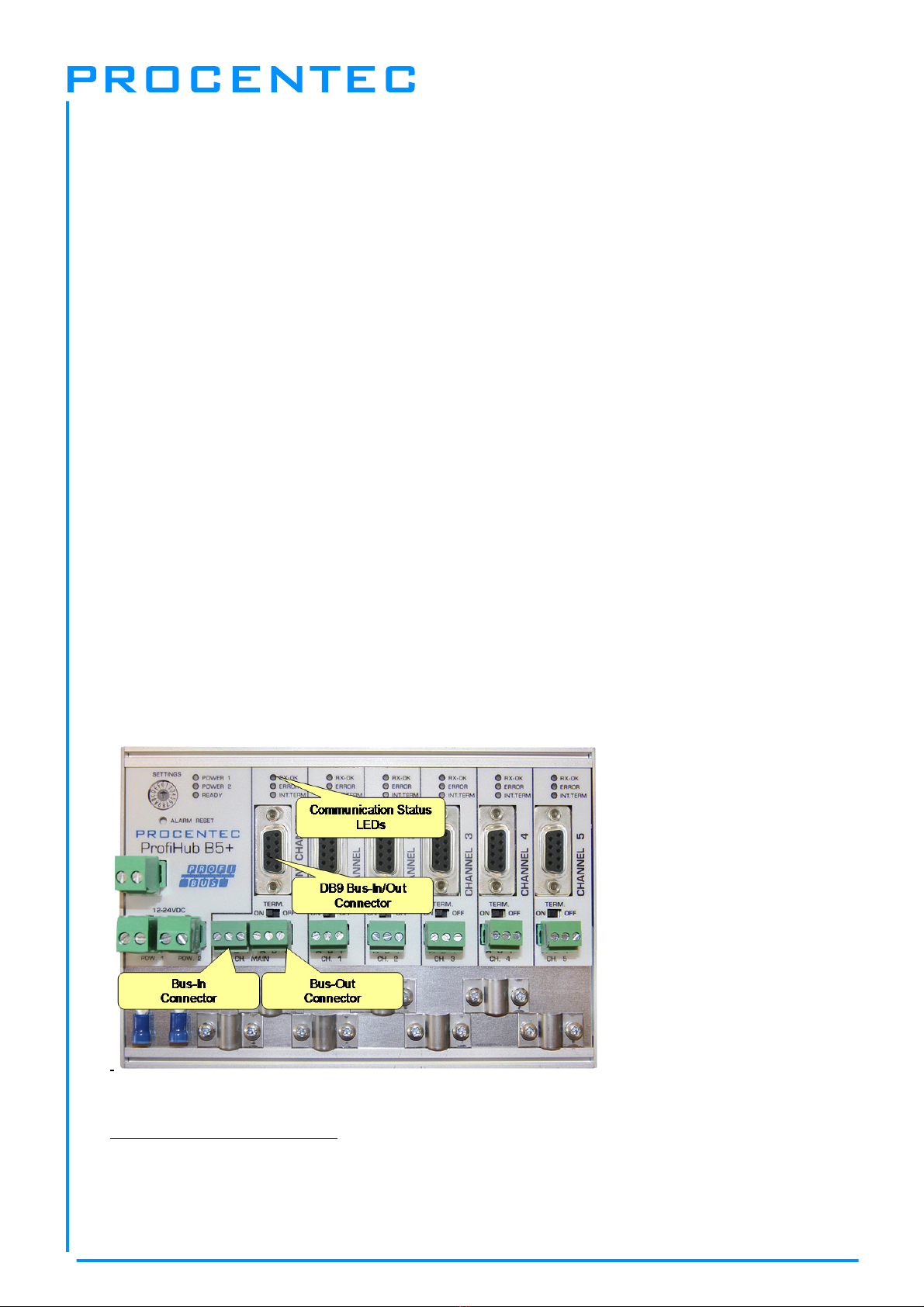

2.7 Backbone

Connect the DP backbone cable to the bottom-left connector of the Main-Channel (

Fig. 13

). If the

ProfiHub is not the last device on the bus segment, connect the Bus-Out cable to the right connector

of the Main-Channel (

Fig. 13

). The second method is to place a PROFIBUS standardized plug with an

in/out cable on the DB9 connector.

Pin layout of the screw terminals:

Pin “A”: Green wire

Pin “B”: Red wire

Pin “I”: Indirect cable shielding

Fig. 13 - PROFIBUS DP backbone connection

ProfiHub B5+ / B5+RD User Manual

_______________________________________________

Version 2.0 – July 2014 Page 19 / 56

ProfiHub-B5-Plus-Manual-EN.docx © PROCENTEC 2014 - Copyright - all rights reserved

Note: Connecting the Indirect cable shielding is not required when the ground clips are used.

Testing

- If the Main-Channel recognizes valid PROFIBUS messages from one or more connected devices,

the RX-OK LED of the Main Channel should be blinking.

2.8 Spur Segments

Connect the spur segments to the connectors of Channel 1 to 5 (

Fig. 14

). The second method is to

place a PROFIBUS standardized plug on the DB9 connector of the specific Channel.

Pin layout of the screw terminals:

Pin “A”: Green wire

Pin “B”: Red wire

Pin “I”: Indirect cable shielding

Note: Connecting the Indirect cable shielding is not required when the ground clips are used.

Testing

- If a Channel recognizes valid PROFIBUS messages from one or more connected devices, the RX-

OK LED of the Channel should be blinking.

According to UL60950-1, if a copper PROFIBUS cable is used outside, it is required to install surge

protection that is suitable for PROFIBUS.

Fig. 14 - PROFIBUS DP spur connectors

ProfiHub B5+ / B5+RD User Manual

_______________________________________________

Version 2.0 – July 2014 Page 20 / 56

ProfiHub-B5-Plus-Manual-EN.docx © PROCENTEC 2014 - Copyright - all rights reserved

2.9 Termination

The termination of the Main-Channel has been set to OFF by default. If the ProfiHub is the last device

on the segment, the termination must be set to ON (

Fig. 15

).

The termination of the Channels have been set to ON by default, because it is assumed that the new

segment is started at the ProfiHub (

Fig. 15

).

The termination LED of the corresponding Channel is activated when the termination switch is set to

ON.

When the DB9 connector is used and the cable starts at the ProfiHub, it is recommended to

use the termination on the DB9 plug and NOT the ProfiHub. This way, the connector can be removed

while maintaining termination on the bus.

Fig. 15 - Te

r

mination Switches

Table of contents