Processor Technology Sol-PC User manual

Sol SYSTEMS MANUAL,

6200 Hollis Street

Emeryville, CA. 94608

Phone: (415) 652-8080

Copyright 1976,

1977, Processor Technology Corporation

Third Printing, June, 1977

Manual No.106000

PREFACE

This new edition of the Sol Systems Manual contains many

revisions and additions. Its release coincides with the release

of a new "2708" Personality Module, and the Revision E version

of the main circuit board: Sol-PC. The new "Sol-PC Rev

E"

has

several improvements: resistors have been added which increase

the reliability of the cassette motor relays, jumper options have

been added, and traces moved to improve performance. Many

improvements which had been accumulating as update information

have been integrated into the text. Section VII, Operating

Procedures, and Appendix 5, IC Pin Configurations, are now

included. A subsection, Modification for 625 Line Video, has

been added. If your copy is missing Section VIII, Theory of

Operation, it will be available soon. New divider pages with

plastic-coated tabs are included to make it easier to flip to

frequently referenced sections.

Much effort has gone towards making this manual complete

and accurate. The process of updating and revision always

continues, however, and we invite your input.

find an error, If you should

documentation, or have suggestions for improving any of our

please submit your suggestions in writing to our

Technical Documentation Department, and they will be given

thorough consideration.

The three-ring binder you are holding, is an "easel" binder.

The cover is hinged from side to side, as well as down the bind-

ing, so that it may form its own "easel" stand. To use this

feature,

lay the manual open on a table. Bend the full width of

the manual along the creased hinge, until a resistance to further

bending is felt. Then set the manual up on the table, with the

bottom of the pages down against the table, and the top inclining

away from you. It is supported from falling by the portion of

the binder you have bent back.

free for building, In this position your hands are

making measurements, or troubleshooting.

The first part of this manual you should read is at the

very end: the Updates section. Integrate this information into

your manual before you begin.

I INTRODUCTION and GENERAL INFORMATION

II Sol POWER SUPPLY ASSEMBLY and TEST

III Sol-PC ASSEMBLY and TEST

IV PERSONALITY MODULE ASSEMBLY

V KEYBOARD ASSEMBLY and TEST

VI Sol CABINET-CHASSIS ASSEMBLY

VII OPERATING PROCEDURES

VIII THEORY OF OPERATION

IX SOFTWARE

X DRAWINGS

APPENDICES

UPDATES

CONTENTS OUTILNE

Detailed contents precede each section.

PROCESSOR TECHNOLOGY CORPORATION

Sol TERMINAL COMPUTER

TM

LIST OF ILLUSTRATIONS

FIGURE

TITLE

PAGE

2-1

sol-20 fan closure plate assembly

........

II-7

2-2

Coaxial cable preparation

............

II-9

2-3

Aluminum heat sink installation

.........

II-12

2-4

Sol-10 power supply subchassis assembly

.....

II-15

2-5

Sol-20 power supply subchassis assembly

.....

II-16

2-6

Sol-PC power connector and voltage measurements .

II-19

2-7

Sol-20 power connector and voltage measurements .

II-19

3-1

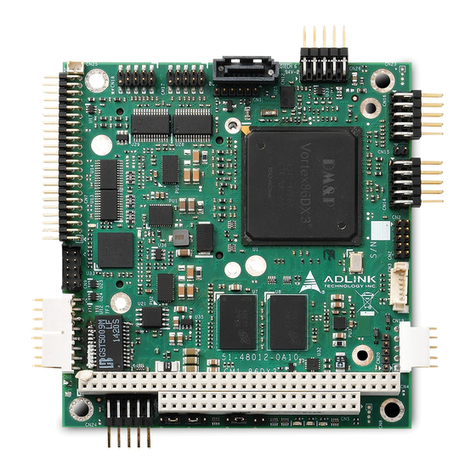

Identification of components

..........

III-5

3-2

Clock circuit waveforms

.............

III-15

3-3

Test probe for Steps

16B

and 25B

........

III-16

3-4

Coaxial cable preparation

............

III-19

3-5

Display section timing waveforms

........

III-21

3-6

Bending selected pins on U42, 59 and 75

.....

III-23

3-7

U14 through U21 socket jumpers

.........

III-24

3-8

Display circuits test pattern

..........

III-25

3-9

CPU Functional Test No. 1 display

........

III-29

3-10

CPU Functional Test No. 2 display

........

III-31

3-11

Personality module bracket/guide installation . .

III-31

4-l

4-2

R1

through R4 installation

...........

Handle bracket (Sol-1045) installation

.....

Types of screws used in Sol cabinet-chassis

assembly

....................

Brackets used in Sol cabinet-chassis assembly . .

Sol-20 with covers removed

...........

Sol-20 with covers removed

...........

Sol-PC coaxial cable connector assembly

.....

Backplane board (Sol-BPB) installation

.....

Backplane board (Sol-BPB) installation

.....

Protective foot pad installation

........

Connecting

the basic Sol system

.........

Sol control switch settings for terminal mode . .

Location Of positioning adjustments, VR1 and VR2

IV-4

IV-5

6-l

6-2

6-3

6-4

6-5

6-6

6-7

6-8

7-l

7-2

7-3

VI-4

VI-4

VI-11

VI-11

VI-14

VI-16

VI-17

VI-20

VII-6

VII-7

VII-8

PROCESSOR TECHNOLOGY CORPORATION

Sol TERMINAL COMPUTERTM ILLUSTRATIONS/TABLES

FIGURE

7-5

7-6

7-7

7-8

TITLE

PAGE

Connecting Sol to two cassette recorders . . . . . . . VII-29

Connecting Sol SDI to current loop device such as TTY VII-31

Connecting Sol SDI to communications modem . . . . . .

Connecting Sol PDI to parallel device . . . . . . .

VII-31

VII-32

TABLE TITLE

PAGE

2-1 Sol Regulator Parts List . . . . . . . . . . . . . . . . II-2,3

2-2 Sol-10 Power Supply Parts List . . . . . . . . . . . . . II-4

2-3 Sol-20 Power Supply Parts List . . . . . . . . . . . . . II-4

3-1

4-1

5-1

6-l

6-2

7-l

7-2

7-3

7-4

7-5

Sol-PC Parts List . . . . . . . . . . . . . . . . . .

PM2708 Personality Module Parts List . . . . . . . .

III-2,3,4

IV-1

Sol Keyboard Parts List . . . . . . . . . . . . . . .

Sol-10 Cabinet-Chassis Parts List . . . . . . . . . .

Sol-20 Cabinet-Chassis Parts List . . . . . . . . . .

V-2,3

VI-2

VI-3

Sol Operating Controls and Their Functions . . . . . VII-2

Baud Rate Selection with Switch S3 . . . . . . . . . VII-15

Word Length Selection with S4-2 & 3 . . . . . . . . VII-15

Sol Keyboard Assignments . . . . . . . . . . . . . . VII-18

Control Character Symbols and Definitions . . . . . . VII-23

I INTRODUCTION and GENERAL INFORMATION

1.1 Introduction . . . . . . . . . . . . . . . . I-1

1.2 General Information . . . . . . . . . . . . I-2

1.2.1 Sol-PC Description . . . . . . . . I-1

1.2.2 Receiving Inspection . . . . . . . I-2

1.2.3 Warranty Information . . . . . . . I-2

1.2.4 Replacement Parts . . . . . . . . I-2

1.2.5 Factory Service . . . . . . . . . I-2

PROCESSOR TECHNOLOGY CORPORATION

Sol-PC SINGLE BOARD TERMINAL COMPUTERTM SECTION I

1.1

INTRODUCTION

This

manual

supplies the information needed to assemble,

test and use the Sol-PC Single Board Terminal Computer. We suggest

that you first scan the entire manual before starting assembly.

Then make sure you have all the parts and components listed in the

"Parts List" (Table 3-l) in Section III. When assembling the module,

follow the instructions in the order given.

Should you encounter any problem during assembly, call on us

for help if necessary. If your completed module does not work pro-

perly

,

recheck your assembly step by step. Most problems stem from

poor soldering, backward installed components, and/or installing

the wrong component. Once you are satisfied that the module is cor-

rectly assembled, feel free to ask for our help.

1.2

GENERAL INFORMATION

1.2.1

Sol-PC Description

The Sol-PC is a single board microcomputer/terminal built

around an 8080 microprocessor. Support circuitry permits full im-

plementation of every 8080 function.

It features both parallel and serial communications inter-

faces,

a keyboard interface, an audio cassette interface, a video

display generator, 1024 8-bit words of system RAM (random access

memory), 1024 8-bit words of display RAM, and a plug-in personality

module with up to 2048 bytes of ROM (read only memory) stored pro-

gram,

and bus compatibility with all Processor Technology hardware

and firmware products.

Power requirements for the Sol-PC are

+5

V

dc +-5% at 2.5 A, +12 V dc +-5% at 150 mA and -12 V dc

+-5%

at 200

mA.

Parallel interfacing is eight bits each for input and output

plus control handshaking signals, and the output bus is tristated

TTL for bidirectional interfaces. The serial interface circuit in-

cludes both asynchronous RS-232 and 20 mA current loop provisions,

75 to 9600 baud (switch selectable).

Seven-level ASCII encoded, TTL keyboard interfacing re-

quires a 2 to 10 usec strobe pulse after data is stable. The dual

rate,

300 or 1200 bps (bits per second), audio cassette interface is

program controlled and self clocking with phase-lock loop. It

includes automatic level control in both the record and playback

modes. Recording is CUTS/Byte standard compatible, asynchronously

Manchester coded at 1200/2400 Hz or 600/1200 Hz.

The video display circuitry generates sixteen 64 character

lines from data stored in an on-card 1024 8-bit word display RAM.

Alphanumeric and control characters (the full 128 upper and lower

case plus control ASCII character set) are displayed black on white

I-l

PROCESSOR TECHNOLOGY CORPORATION

Sol-PC SINGLE BOARD TERMINAL COMPUTER

TM

SECTION I

or reverse (switch selectable). Solid video inversion cursors, with

switch selectable blink, are programmable. The display output is

standard EIA, 1.0 to 2.5 V p-p with composite negative sync, with a

nominal bandwidth of 7 MHz. It can consequently be used to drive any

standard video monitor. (A monochrome TV, converted for video input,

can also be used. See Appendix VI.)

Included on the card are 1024 words of static, low power sys-

tem RAM capable of full speed operation and a plug-in personality

module which contains the software control program. Three personality

modules are available for Sol:

CONSOL

TM

--allows simple terminal operations plus

direct control of the basic computer functions for

entering or examining data in any memory location,

or executing a program stored at a known location

in memory.

SOLED

TM

--allows advanced terminal operations with

CONSOL plus screen, file and cassette tape editing/

transmission operations.

SOLOS

TM

--allows full stand-alone terminal-computer

operation.

1.2.2

Receiving Inspection

When your kit arrives, examine the shipping container for

signs of possible damage to the contents during transit. Then in-

spect the contents for damage. (We suggest you save the shipping

materials for use in returning the kit to Processor Technology

should it become necessary to do so.) If your Sol-PC kit is damaged,

please write us at once describing the condition so that we can take

appropriate action.

1.2.3

Warranty Information

In brief, parts which fail because of defects in materials or

workmanship are replaced at no charge for 3 months for kits, and one

year for assembled products, following the date of purchase.

Also,

products assembled by the buyer are warranted for a period of 3

months after the date of purchase; factory assembled units carry a

one year warranty. Refer to Appendix I for the complete "Statement

of Warranty".

1.2.4 Replacement Parts

Order replacement parts by component nomenclature (DM8131 IC

or lN2222 diode, for example) and/or a complete description (680 ohm,

1

/4

watt, 5% carbon resistor, for example).

I-2

PROCESSOR TECHNOLOGY CORPORATION

Sol-PC SINGLE BOARD TERMINAL COMPUTERTM SECTION I

1.2.5

Factory Service

In addition to in-warranty service, Processor Technology also

provides factory repair service on out-of-warranty Processor Technol-

ogy products. Before returning the unit to us, first obtain our

authorization to do so by writing us a letter describing the problem.

After you receive our authorization to return the unit, proceed as

follows:

1. Write a description of the problem.

2. Pack the unit with the description in a container

suitable to the method of shipment.

3. Ship prepaid to Processor Technology Corporation,

6200 Hollis Street, Emeryville, CA 94608.

Your unit will be repaired as soon as possible after receipt

and return shipped to you prepaid.

(Factory service charges will not

exceed $20.00 without prior notification and your approval.)

I-3

II Sol POWER SUPPLY ASSEMBLY and TEST

2.1 Introduction . . . . . . . . . . . . . . . . II-1

2.2 Parts and Components . . . . . . . . . . . . II-1

2.2.1 Sol Regulator (Sol-REG) . . . . . II-1

2.2.2 Power Supply Subchassis and

Components . . . . . . . . . . . . II-2

2.3 Assembly Tips. . . . . . . . . . . . . . . . II-5

2.3.1 Electrical . . . . . . . . . . . . II-5

2.3.2 Mechanical . . . . . . . . . . . . II-5

2.4 Assembly Precautions . . . . . . . . . . . . 11-5

2.5 Required Tools, Equipment and Materials . . II-6

2.6 Orientation . . . . . . . . . . . . . . . . II-6

2.6.1 Sol-REG PC Board . . . . . . . . . II-6

2.6.2 Fan Closure Plate . . . . . . . . II-6

2.7 Assembly-Test . . . . . . . . . . . . . . . II-6

2.7.1 Fan Closure Plate Assembly . . . . II-7

2.7.2 Sol-REG Assembly and Test . . . . II-10

2.7.3 Power Supply Subchassis Assembly

and Test . . . . . . . . . . . . . II-14

PROCESSOR TECHNOLOGY CORPORATION

Sol POWER SUPPLY SECTION II

2.1 INTRODUCTION

The Sol power supply consists of a regulator board plus ad-

ditional chassis-mounted components. This section covers assembly

and test of the complete power supply.

2.2

PARTS AND COMPONENTS

2.2.1

Sol Regulator

(Sol-REG)

Check all parts and components against the appropriate

"Parts List", Tables 2-1, 2-2 and 2-3. If you have difficulty in

identifying any parts by sight, refer to Figure 3-1 on Page III-5

in Section III of this manual.

2.2.2

Power Supply Subchassis and Components

In addition to the Sol-REG, you will need the following

parts and components supplied with the Sol Cabinet-Chassis Kit.

Check these parts against the appropriate "Parts List(s)", Tables

6-l and 6-2, in Section VI and separate them from the other cabinet-

chassis parts.

Fan Closure Plate

Power Supply Subchassis (L-shaped)

4

each 4-40 x

3/16

Machine Screw

4

each 4-40 x

5/16

Machine Screw

4

each 4-40 Hex Nut

10 each #4 Lockwasher

14

each 6-32 x

1/2

Machine Screw

14

each 6-32 Hex Nut

16 each #6 Lockwasher

3

each 8-32 x

1/2

Machine Screw

3

each 8-32 Hex Nut

3 each #8 Lockwasher

11 each

#6

x

1/4

Sheet Metal Screw

1 each #6 x

5/16

Sheet Metal Screw

2 each #4 Solder Lug

2

each

1/4"

Spacer, 4-40 Tapped

Rev A

II-1

PROCESSOR TECHNOLOGY CORPORATION

Sol POWER SUPPLY SECTION II

Table 2-1. Sol Regulator Parts List.

INTEGRATED CIRCUITS**

1

1458

(U2)

1

7812

(U1)

1

7912

(U3)

TRANSISTORS

2

2N2222

(Q2

&

3)

1

T1P41 (Q1)

DIODES and RECTIFIERS

1

MDA101A

(FWB2)

1

MDA970-1

(FWB1)

1

IR106B2

or

MCR106-2

(SCR1)

2

1N4001

(D3

&

4)

1

1N4148

(D2)

1

1N5231B

(D1)

RESISTORS CAPACITORS

1

0.1 ohm,

3

watt, 5%

2

.1

ufd, disc

or

5

watt, 5%

3

15

ufd, tantalum dipped

1

68 ohm,

1/4

watt, 5%

2

2500

ufd, tubular electrolytic

1

330 ohm,

1/4 watt, 5%

1

"18,000 ufd, electrolytic

2

1

K ohm,

1/4 watt, 5%

4

10 K ohm,

1/4 watt, 5%

1

56 K ohm,

1/4 watt, 5%

1

1690

ohm, 1/4 watt, 5%

1

4020 ohm,

1/4 watt, 5%

CABLE ASSEMBLIES

1 *Single wire, 3" (Fuse Holder to Power Switch)

1 *Single wire,

3 1/4

(Power Switch to Commoning Block)

1 Two wire,

10"

(C8 to Regulator Board)

*Chassis-mounted component

**When identifying

IC's,

you can iqnore prefix and suffix characters

in the IC nomenclature since these vary with the manufacturer.

For

example a

1458CP,

1458CPI and MC1458N are all 1458

IC's. This

applies to all Parts Lists in this manual.

II-2

PROCESSOR TECHNOLOGY CORPORATION

Sol POWER SUPPLY

Table 2-1. Sol Regulator Parts List (Continued).

SECTION II

MISCELLANEOUS

1 Sol REG Circuit Board

1 Heat Sink, 690-220-P

1 Heat Sink,

203-AP

1 Heat Sink, aluminum

1 Package Heat Sink Compound

2 Coax Connector, female* (Video Output)

1 Coax Connector, male (Video Output Cable)

1

Coax Connector Adapter Sleeve (Video Output Cable)

1

*AC Receptacle, female

1

*Fuse Holder

1 *SPST Power Switch, pushbutton

(S5)

1 AC Power Cord

2

*Commoning Blocks

1 *Clamp for C8,

11/2"

4

Tie Wraps

3

Mica Insulators

1

4-40 x

7/16

screw

1

4-40 x

5/8

screw

2

4-40 Hex Nut

1

6-32 x

1/2

screw, metal

2

6-32 x

1/2

screw, Nylon

3

6-32 Hex Nut

5 #4 Lockwasher, internal tooth

1

Length Solder

*Chassis-mounted component

II-3

PROCESSOR TECHNOLOGY CORPORATION

Sol POWER SUPPLY SECTION II

Table 2-2. Sol-10 Power Supply Parts List.

The Sol-10 Power Supply Kit includes all Sol-REG parts listed in

Table 2-l plus the following components:

.__-_--------------------------------------------------------------.

1 *Power Transformer,

T1

1 *Fuse,

3 amp Slo-Blo

(F1)

*Chassis-mounted component

Table 2-3. Sol-20 Power Supply Parts List.

The Sol-20 Power Supply Kit includes all Sol-REG parts listed in

Table 2-l plus the following components:

,------------------_---------

RESISTORS

1

*39

ohm, 2 watt, 5%

RECTIFIERS

1

*MDA980-1 (FWB3)

MISCELLANEOUS

1

*Fan

1

*Fan Guard

1

*Fuse, 3 Slo-Blo

amp

-------------------------------------

CAPACITORS

1 *54,000 ufd, electrolytic

TRANSFORMERS

1 *Power Transformer, T2

1

5-wire Cable Assembly

1 *Clamp for

C9,

2 1/2"

2 *#l0 solder lug, internal tooth

*Chassis-mounted component

II-4

PROCESSOR TECHNOLOGY CORPORATION

Sol POWER SUPPLY SECTION II

2.3

ASSEMBLY TIPS

2.3.1

Electrical

For the most part the assembly tips given in Paragraph 3.2

of Section III (Page III-l) apply to assembling the Sol regulator

board and power supply.

In addition, scan Section II completely before you start to

assemble the power supply.

2.3.2

Mechanical

1. If you do not have the proper screwdrivers (see Para-

graph

2.5),

we recommend that you buy them rather than using a knife

point,

a blade screwdriver on a Phillips screw, and other makeshift

means.

Proper screwdrivers minimize the chances of stripping

threads, disfiguring screw heads and marring decorative surfaces.

2. To assure a correct fit and tight assembly, be sure you

use the screws specified in the instructions.

3. Lockwashers are widely used in the power supply assembly

so that screws will not loosen when subjected to stress or vibration.

When a lockwasher is specified, do not omit it and make sure you

install it correctly.

4.

Some instructions call for prethreading holes. This is

done to make assembly easier by giving you maximum working space for

installing relatively hard-to-drive sheet metal screws. If you by-

pass prethreading instructions you will only make subsequent

cabinet-chassis assembly more difficult.

To prethread a hole, insert specified screw in the hole

and position it as straight as possible. While holding the screw in

this position, drive it into the metal with the proper screwdriver.

If started straight the screw will continue to go straight into the

metal so that the head and sheet metal surfaces are in full contact.

5. The diameter of the shank (threaded portion) of a screw

increases in relation to its number. For example, a 6-32 screw is

larger in diameter than a 4-40 screw.

Also,

a #8 lockwasher is

larger than a #4 lockwasher.

6. Heat sink compound is supplied with this kit in a small

clear plastic package. It is a thick white substance which improves

transfer between components and their heat sinks. To use

the compound, pierce a small hole near the edge of the top surface

of the plastic package, using a pin or sharp knife point. Squeezing

the package will cause a small amount of the compound to ooze out

Rev B

II-5

PROCESSOR TECHNOLOGY CORPORATION

Sol POWER SUPPLY SECTION II

out of the hole, which may then be applied with a toothpick or small

screwdriver blade. Spread a thin film of the compound on the mating

surfaces of both the heat-generating component and the heat sink

surface which it will contact. Then assemble as directed.

2.4

ASSEMBLY PRECAUTIONS

The precautions concerning soldering and the installation

and removal of integrated circuits given in Paragraph 3.3 of Section

III (Page 111-6) also apply to assembling the Sol regulator board.

2.5

REQUIRED TOOLS, EQUIPMENT AND MATERIALS

The following tools, equipment and materials are recommended

for assembling the Sol regulator board:

1

.

Needle nose pliers

2

.

Diagonal cutters

3

.

Sharp knife

4.

Screwdriver, thin

1/4"

blade

5.

Screwdriver,

#2

Phillips

6

.

Controlled heat soldering iron, 25 watt

7

.

60-40 rosin-core solder (supplied)

8

.

Volt-ohm meter

9

.

Ruler

2.6

ORIENTATION

2.6.1

Sol-REG PC Board

Location C5 (2500 ufd capacitor) will be located in the

lower

right-hand corner of the circuit board when locations

SCR1,

Q1

and

FWB1 are positioned along the top of the board. In this position

the component (front) side of the board is facing up and the

horizontal legends will read from left to right; the other legends

will read from bottom to top. Subsequent position references

related to the Sol-REG board assume this orientation.

2.6.2

Fan Closure Plate

The large circular cutout will be located in the upper right

quadrant of the plate when the heavy guage doubler plate is facing

UP.

In this position the rectangular cutouts are on the left, the

front side of the plate is facing down, the back side is facing

up,

and the

small circular cutout is at the

bottom.

-

We suggest you

---

2.7

ASSEMBLY-TEST

NOTE:

Instructions that apply only to the Sol-20 are

preceded by an asterisk.

Skip these instructions

if you are assembling a Sol-lo.

Rev B

II-6

PROCESSOR TECHNOLOGY CORPORATION

Sol POWER SUPPLY SECTION II

2.7.1 Fan Closure Plate Assembly

Refer to Assembly Drawings dn Pages X-1 and 2 in Section X.

(Figure 2—1 shows a completed fan closure plate assembly.)

Figure 2—1. Sol-20 fan closure plate assembly.

(Top of plate in foreground.)

*( ) Step 1. Mount cooling fan and guard to fan closure plate.

Insert four 6—32 x ½” binder or pan head screws from back

side of fan closure plate. (Use the holes positioned in

each quandrant of the large circular cutout.) Slip fan

guard over screws on front side of plate. Position fan so

that air flow will be from front to back side of plate and

with its leads next to the rectangular cutouts in the place.

Place #6 lockwasher on each screw and secure with 6—32 hex

nut.

WARNING

FAILURE TO INSTALL FAN GUARD MAY RESULT

IN DAMAGE TO THE Sol AND/OR PERSONAL

INJURY.

( ) Step 2. Install power on-off switch in upper rectangular

cutout in fan closure plate.

(Step 2 continued on Page il-S.)

ReVB 11—7

PROCESSOR TECHNOLOGY CORPORATION

Sol POWER SUPPLY SECTION

II

( )

( )

( )

( )

( )

Rev B

Bend four retainer tabs on switch in and position switch

with terminals facing front side

of fan

closure plate.

Push

switch unit from back side of plate through mounting hole

and bend retainer tabs outward if needed to hold switch in

place.

Step 3. Install commoning blocks (Item 6 on drawing on Page

X-l) on front side of fan closure plate, one on each side of

on-off switch.

Position each block with terminal

#1

at top and terminal

#5

at bottom and attach each block to front side of fan closure

plate with two 6-32 X

1/2

binder or pan head screws.

Insert

screws from back side of plate, place block over screws, on

front side of plate, put

#6

lockwasher on each screw and

secure with 6-32 hex nut.

Step 4. Install fuse holder in mounting hole located between

the two rectangular cutouts in the fan closure plate.

Insert fuse holder from back side of plate, poition large

tab at top, next to on-off switch,and secure holder to plate

with the large lockwasher and nut supplied with holder.

plate.

Step 5. Install AC Power cord receptacle on fan closure

Position receptacle on front side of fan closure plate over

the rectangular cutout below fuse holder. Orient receptacle

with green lead at the botton and align the receptacle and

closure plate mounting holes. Insert two 6-32 x

1/2

binder or

pan head screws from back side of plate through each mount-

ing hole, put

#6

lockwasher on each screw and secure with

6-32 hex nut. Be sure receptacle is properly seated in cut-

out before tightening to avoid damage.

Step 6.Install female coaxial connector on fan closure plate.

Insert connector from front side of plate so that the threaded

end projects through to the back side. Then insert four 4-40

X

5/16

binder or pan head screws from back side of plate

through the four connector and plate mounting holes. Place

#4

lockwasher on each screw except the upper one which is closest

to the AC receptacle. Secure

with 4-40

hex nuts.

(Leave

---

upper nut closest to receptacle loose.)

Step 7.

Prepare RG59/U coaxial cable.

Cut a

13"

piece of coaxial cable from that supplied with the

Sol-PC kit. Strip away one inch of the outer insulation at

both ends to expose shield. Unbraid shield at one end and

twist it into a single lead. Do the same thing at the other

end.

Tin shield lead at each end and solder a #4

lug to each lead. Then remove

1/2"

of the inner conductor

insulation at both ends. (See Figure 2-2.)

II-8

PROCESSOR TECHNOLOGY CORPORATION

Sol POWER SUPPLY SECTION II

Figure 2-2. Coaxial cable preparation.

()

Step 8.

Connect coaxial cable to coaxial connector in-

stalled in Step 6.

Solder inner conductor on one end to the pin of the connec-

tor.

Remove hex nut on upper

connector

mounting Screw

closest to AC receptacle, place lug (coaxial shield) on

screw and reinstall hex nut.

( ) Step 9.

Connect fan closure plate wiring.

()

Install the 3" power switch-to-commoning block cable

supplied with your Sol-REG kit. Connect the female

spade lug end to the upper terminal of the on-off switch

and the commoning block lug end to the

#1

terminal of

the commoning block closest to the fan.

NOTE:

To install

commoning block lugs,

position lug with

its

open

side

facing away from the terminal numbers on the block. Then

gently push

lug into

appropriate terminal receptacle until

it is fully seated.

()

Install the

3

1/4"

fuse holder-to-power switch cable sup-

plied with your Sol-REG kit. (This cable has female

spade lugs at both ends.) Connect one end to the bottom

terminal of the on-off switch and the other to the

longer male spade lug on the fuse holder.

()

Connect the AC receptacle wire closest to the fan to the

other fuse holder lug.

NOTE:

wire will be connected later. The green AC receptacle

()

Connect other AC receptacle wire to terminal

#4

on the

commoning block furthest away from the fan.

*( )

Connect upper wire of fan cord to terminal

#3

of the

commoning block closest to fan.

*( )

Connect lower wire of fan cord to terminal

#5

of common-

ing block furthest from fan.

Rev B

( )

Put fan closure assembly aside.

II-9

PROCESSOR TECHNOLOGY CORPORATION

Sol POWER SUPPLY SECTION II

2.7.2

( )

( )

( )

Sol-REG Assembly and Test

Circuit references, values and outlines are printed on the

component side of the board to assist in assembly.

Step 10.

Visually check Sol-REG board for solder bridges

(shorts) between traces, broken traces and similar defects.

If visual inspection reveals any defects, return the board

to Processor Technology for replacement. If the board is

not defective, proceed to next paragraph.

Step 11.

Install the following resistors in the indicated

locations. Bend leads to fit distance between mounting

holes,

insert leads, pull down snug to board, solder and

trim.

LOCATION

VALU

E (ohms) COLOR CODE

R1

R2

R3

R4

R5

R6

R7

R8

R9

R10

R11

R12

.1, 3 watt

330

10 K 5 watt

10 K

1 K

68

10 K

1 K

56 K

10 K

1690

4020

none

orange-orange-brown

brown-black-orange

" " "

brown-black-red

blue-gray-black

brown-black-orange

brown-black-red

green-blue-orange

brown-black-orange

bronw-blue-white-brown

yellow-black-red-brown

step

12.

Install

U2

(1458) in its location between C2 and C3.

U2

is positioned with pin 1 in the lower left-hand corner and

soldered into place.

See

"Loading DIP Devices" in Appendix IV.

Step 13.

Install diodes

D1

(1N5231B),

D2

(1N4148),

D3 and D4

(1N4001).

Bend leads to fit distance between mounting holes,

insert leads, pull down snug to board, solder and trim. BE

SURE to position

D1

with its cathode (dark band) to the left,

D2 and D3 with their cathode at the bottom, and D4 with its

cathode at the top.

Step 14.

Install the following capacitors in the indicated

locations.

Take care to observe the proper value, type and

orientation, if applicable, for each installation. Bend

leads outward on solder (back) side of board, solder and

trim.

Rev B

(See NOTE on Page 11-11.

II-10

Table of contents