Proconx MODG-100 User manual

MODG-100

Modbus/TCP

Gateway

Usermanual

UMMODG100-2201

MODG-100

Modbus/TCP Gateway: Usermanual

Copyright © proconX Pty Ltd. All rights reserved.

No part of this material may be reproduced or transmitted in any form or by any means or used to make any derivative work without

express written consent from the copyright holders.

proconX is a trademark of proconX Pty Ltd. Modbus is a registered trademark of Schneider Automation Inc. All other product and brand

names mentioned in this document may be trademarks or registered trademarks of their respective owners.

Disclaimer

proconX Pty Ltd makes no warranty for the use of its products, other than those expressly contained in the Company’s standard warranty

which is detailed in the Terms and Conditions located on the Company’s Website. The Company assumes no responsibility for any errors

which may appear in this document, reserves the right to change devices or specifications detailed herein at any time without notice,

and does not make any commitment to update the information contained herein. No licenses to patents or other intellectual property

of proconX are granted by the Company in connection with the sale of proconX products, expressly or by implication. proconX products

are not authorized for use as critical components in life support devices or systems.

Support & product feedback

We provide an electronic support and feedback system for our proconX products. It can be accessed through the following web link:

https://www.proconx.com/support

Your feedback and comments are always welcome. It helps improving this product.

Contact

For further information about the MODG-100 product please visit https://www.proconx.com/modg100

UMMODG100-2201 iii

Contents

Important user information ......................................................................................... v

Safety Precautions ................................................................................................ v

Document conventions ........................................................................................ vi

1 Introduction ............................................................................................................. 1

Features ................................................................................................................ 2

Quick start checklist ............................................................................................. 2

2 Description ............................................................................................................... 3

LED indicators ...................................................................................................... 3

3 Installation ................................................................................................................ 5

Regulatory notes .................................................................................................. 5

Unpacking, handling and storage ........................................................................ 5

Before connecting anything ................................................................................. 5

DIN rail mounting and removal ........................................................................... 6

Mounting rules .................................................................................................... 6

Powering the MODG-100 ..................................................................................... 7

Wiring the RS-485/422 interface .......................................................................... 7

Wiring the RS-232 interface ................................................................................. 8

Connecting Ethernet ............................................................................................ 9

4 Ethernet & IP configuration ................................................................................... 11

IP setup using a web browser and a cross-over network cable .......................... 11

IP setup using a terminal program like HyperTerminal ....................................... 12

Temporarily changing the IP settings on your PC ............................................... 13

5 Web browser based management ......................................................................... 15

Connecting to the MODG-100 ........................................................................... 15

Monitoring and diagnostic ................................................................................ 16

Device status .............................................................................................. 16

Modbus connection status ......................................................................... 17

Finding the firmware version and serial number ........................................ 19

Configuring and commissioning ........................................................................ 19

Configuring Ethernet and IP ....................................................................... 20

Configuring Modbus network .................................................................... 21

Remote restarting the device ..................................................................... 23

Backup and restoring of configuration settings ......................................... 24

Password protection ................................................................................... 25

Firmware upgrade ...................................................................................... 26

6 Decommissioning ................................................................................................... 27

Disconnecting ..................................................................................................... 27

Disposal .............................................................................................................. 27

A Specifications ......................................................................................................... 29

Dimensions ......................................................................................................... 30

Glossary ..................................................................................................................... 31

Index .......................................................................................................................... 33

Figures

2.1 Location of connectors .......................................................................................... 3

5.1 Device management and configuration via the web browser .............................. 15

iv UMMODG100-2201

5.2 Overview page .................................................................................................... 16

5.3 Modbus status page ........................................................................................... 17

5.4 About page ......................................................................................................... 19

5.5 Ethernet and IP settings page ............................................................................. 20

5.6 IP settings changed to static IP confirmation ...................................................... 21

5.7 IP settings changed to DHCP confirmation ......................................................... 21

5.8 Modbus parameters page ................................................................................... 21

5.9 Restart device page ............................................................................................. 23

5.10 Restart confirmation page ................................................................................. 23

5.11 Backup/Restore page ......................................................................................... 24

5.12 Password page .................................................................................................. 25

5.13 Authentication dialog ........................................................................................ 26

A.1 Enclosure dimensions .......................................................................................... 30

Tables

2.1 LED diagnostic codes ............................................................................................ 4

3.1 Power supply connector pinout ............................................................................ 7

3.2 RS-485/RS-422 connector pinout ........................................................................... 7

3.3 Modbus RS-232 connector pinout ........................................................................ 8

3.4 Ethernet connector pinout .................................................................................... 9

Important user information

UMMODG100-2201 v

Important user information

This manual explains how to install, operate and configure a MODG-100. This device may

only be used for the applications described in this document.

This manual is to be used with a MODG-100 with firmware version 2.12.

These instructions are intended for use by trained specialists in electrical installation

and control and automation engineering, who are familiar with the applicable national

standards and safety procedures.

Safety Precautions

ELECTRICAL HAZARD

• This equipment must be installed and serviced only by qualified personnel. Such

work should be performed only after reading this entire set of instructions.

• Before performing visual inspections, tests, or maintenance on this equipment,

disconnect all sources of electric power. Assume that all circuits are live until they

have been completely de-energized, tested, and tagged. Pay particular attention

to the design of the power system. Consider all sources of power, including the

possibility of backfeeding.

• Apply appropriate personal protective equipment and follow safe electrical

practices.

• Turn off all power supplying the equipment in which the MODG-100 is to be

installed before installing, wiring or removing the MODG-100.

• Always use a properly rated voltage sensing device to confirm that power is off.

• The successful operation of this equipment depends upon proper handling,

installation, and operation. Neglecting fundamental installation requirements

may lead to personal injury as well as damage to electrical equipment or other

property.

Failure to follow these instructions could result in death or serious injury!

vi UMMODG100-2201

Document conventions

Throughout this manual we use the following symbols and typefaces to make you aware

of safety or other important considerations:

Indicates a potentially hazardous situation that, if not

avoided, could result in death or serious injury.

Indicates a potentially hazardous situation that, if not

avoided, could result in damage to equipment.

Indicates information that is critical for successful applica-

tion and understanding of the product.

Provides other helpful user information that does not fall in

above categories.

Provides supplemental user information.

Acronym This typeface is used to introduce acronyms or product

names.

Command This typeface is used to represent commands, prompts, in-

put fields and filenames. In the context of programming

it is used for functions, variable names, constants or class

names.

Placeholder This typeface is used to represent replacable text. Replace-

able text is a placeholder for data you have to provide, like

filenames or command line arguments.

User input This typeface is used to represent data entered by the user

or buttons.

Screen output

Screen output or program listing

Introduction

UMMODG100-2201 1

Chapter 1.Introduction

The MODG-100 is a Modbus/TCP to Modbus Serial Line gateway.

The gateway features an Ethernet port and one serial port which can be configured as

either RS-232, RS-485 or RS-422 port.

It can be mounted on a DIN rail.

Usage and configuration of the gateway is simple and conveniently performed using a

web browser which connects to the embedded web server.

Possible areas of application are:

• PLC connection

• Operator panel interfacing

• HMIs

• SCADA integration

• Remote control & monitoring

• Data logging

2UMMODG100-2201

Features

The MODG-100 gateway provides the following key features:

• Modbus/TCP protocol (Ethernet)

• Modbus RTU and ASCII protocols

• RS-232, RS-485 or RS-422, software configurable

• Embedded web server for easy configuration and commissioning using a web browser

• Firmware upgradeable via Ethernet

• DIN rail mountable

• 24 V DC (10-30 V) power supply

• Status LEDs for power, Ethernet link, device status and communication status

Quick start checklist

• Read this set of instructions properly and in its entirety.

• Mount the unit.

• Connect the power. Do not connect yet serial ports.

• Configure the Ethernet communications settings with a web browser (using an

Ethernet crossover cable) or with a terminal program like HyperTerminal (using a null

modem cable)

• Configure the serial line communication settings.

• Configure the operational aspects of the device.

• Wire serial line interfaces.

Description

UMMODG100-2201 3

Chapter 2.Description

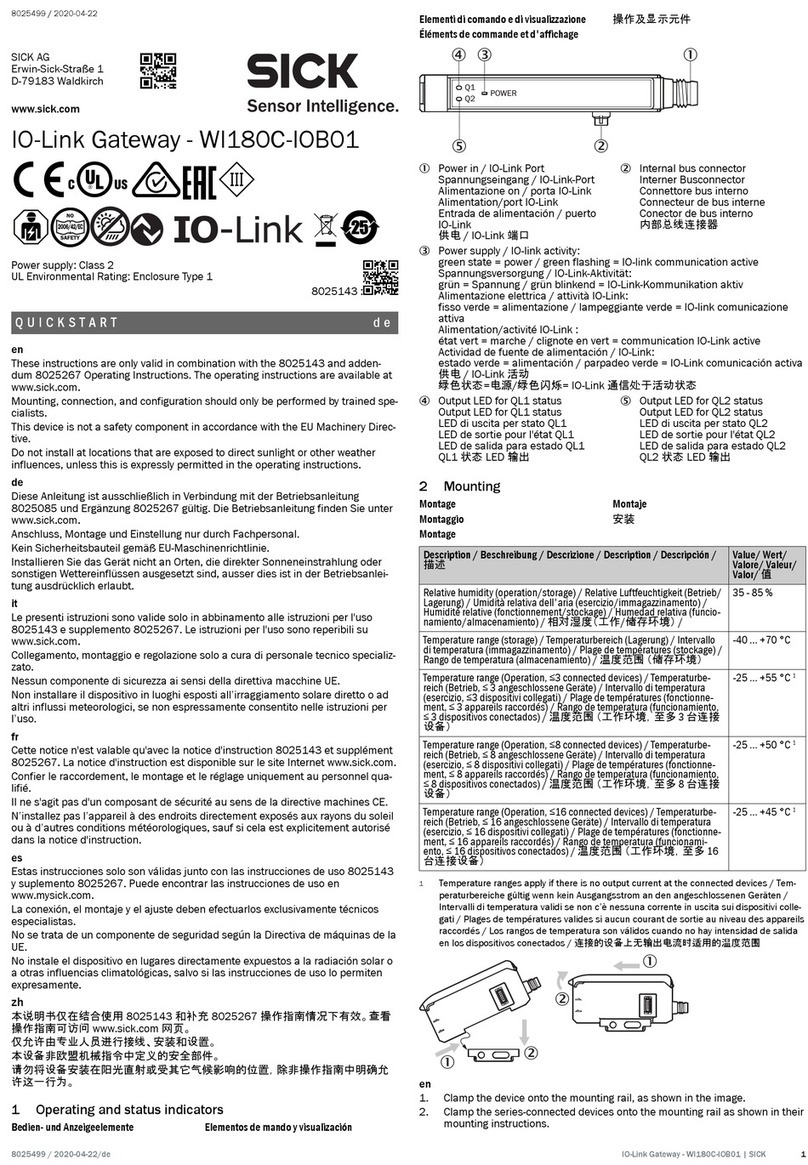

The power and RS-485/RS-422 terminals are placed on the top side of the unit. The

RS-232 and Ethernet connectors are placed on the bottom side of the unit as shown in

the following illustration:

TOP VIEW

BOTTOM VIEW

FRONT VIEW

Figure2.1:Location of connectors

Clear front cover

RS-232 connector

Ethernet connector

DIN rail clip

Power LED

Ethernet link LED

Device status LED

Communication status LED

Power terminals

RS-485/RS-422 terminals

LED indicators

Four LEDs located at the front panel indicate the status of the device. The LEDs assist

maintenance personnel in quickly identifying wiring or communication errors.

A LED test is exercised at power-up, cycling each LED off, green and then red for

approximately 0.25 seconds. At the same time the power-on self test of the device is

performed.

4UMMODG100-2201

The following table outlines the indicator condition and the corresponding status after

the power-on self test has been completed:

LED Function Condition Indication

Off No power applied to the device.

Power Power Green Power supply OK

Off No Ethernet link

Link Ethernet link Green Ethernet link OK

Off The device has an unrecoverable fault; may need replacing.

Flashing green

1 s rate

Device operational but needs commissioning due to configuration

missing, incomplete or incorrect.

Green The device is operating in normal condition.

Flashing red

1 s rate

Device operational but has a fault listed which requires acknowledg-

ment.

Status1 Device status

Red The device has an unrecoverable fault; may need replacing. Flashing

sequence and rate of Status2 LED indicates fault class.

Off No Modbus/TCP connection.

Status2 Communica-

tion status Green Modbus/TCP connection established.

Table 2.1: LED diagnostic codes

Installation

UMMODG100-2201 5

Chapter 3.Installation

Regulatory notes

1. The MODG-100 is suitable for use in non-hazardous locations only.

2. The MODG-100 is not authorized for use in life support devices or systems.

3. Wiring and installation must be in accordance with applicable electrical codes in

accordance with the authority having jurisdiction.

4. This is a Class A device and intended for commercial or industrial use. This

equipment may cause radio interference if used in a residential area; in this case it

is the operator’s responsibility to take appropriate measures.

5. The precondition for compliance with EMC limit values is strict adherence to the

guidelines specified in this set of instructions. This applies in particular to the area

of grounding and shielding of cables.

FCC Notice (USA only)

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated

in a commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the

user will be required to correct the interference at his own expense.

Industry Canada Notice (Canada only)

This Class A digital apparatus complies with Canadian ICES-003.

Unpacking, handling and storage

1. Please read this set of instructions. carefully before fitting it into your system.

2. Keep all original packaging material for future storage or warranty shipments of

the unit.

3. Do not exceed the specified temperatures.

Before connecting anything

1. Before installing or removing the unit or any connector, ensure that the system

power and external supplies have been turned off.

2. Check the system supply voltage with a multimeter for correct voltage range and

polarity.

6UMMODG100-2201

3. Connect the power supply cable and switch on the system power. Check if the

Power LED is lit.

4. Turn off system power.

5. Connect all I/O cables.

6. Once you are certain that all connections have been made properly, restore the

power.

DIN rail mounting and removal

The MODG-100 gateway is designed to be mounted on a 35 mm DIN rail according to

DIN/EN 50022. The enclosure features a 35 mm profile at the back which snaps into the

DIN rail. No tools are required for mounting. Please observe the rules outlined in the

section called “Mounting rules”.

2

1

Click

To mount the unit on a DIN rail, slot the top part of the

MODG-100 into the upper guide of the rail and lower

the enclosure until the bottom of the red hook clicks into

place.

2

1

To remove the MODG-100 from the DIN rail, use a screw

driver as a lever by inserting it in the small slot of the red

hook and push the red hook downwards. Then remove

the unit from the rail by raising the bottom front edge of

the enclosure.

Mounting rules

The enclosure provides protection against solid objects according to IP20 / NEMAType1

protection rating. When mounting the unit observe the following rules:

• No water splash and water drops

• No aggressive gas, steam or liquids

• Avoid dusty environments.

• Avoid shock or vibration

Installation

UMMODG100-2201 7

• Do not exceed the specified operational temperatures and humidity range.

• Mount inside an electrical switchboard or control cabinet.

• Make sure there is sufficient air ventilation and clearance to other devices mounted

next to the unit.

• Observe applicable local regulations like EN60204 / VDE0113.

Powering the MODG-100

Before connecting power please follow the rules in the section called “Safety Precau-

tions” and the section called “Before connecting anything”.

Power is supplied via a 3.81 mm 2-pin pluggable terminal block located at the top side

of the mounted unit (refer to Figure2.1, “Location of connectors”). The following table

and picture shows the power terminal socket pinout:

V+

V-

Pin Signal Function

1 V+ Positive voltage supply (10 - 30 V DC)

2 V- Negative voltage supply, DC power return

Table 3.1: Power supply connector pinout

Make sure that the polarity of the supply voltage is correct before connecting any

device to the serial ports! A wrong polarity can cause high currents on the ground

plane between the V- power supply pin and the serial port ground pins, which can

cause damage to the device.

Wiring the RS-485/422 interface

The RS-485/422 port is used for integrating the MODG-100 into a two-wire or four-

wire Modbus over Serial Line network. The use of either the RS-485 or RS-422 interface

must be configured using the web interface (See the section called “Configuring Modbus

network”). The MODG-100 is a Modbus Master device on this interface.

The RS-485 and RS-422 signals are located at the 3.81 mm 6-pin pluggable terminal

block on the top side of the mounted unit (refer to Figure2.1, “Location of connectors”).

The following table and picture shows the pinout:

GND

D-

D+

RS-485

GND

TX-

TX+

GND

RX-

RX+

RS-422

Pin RS-485 signal RS-422 signal Description

3 GND GND Modbus Common

4 D+ TX+ Modbus D1 or TXD1

5 D- TX- Modbus D0 or TXD0

6 GND Modbus Common

7 RX+ Modbus RXD1

8 RX- Modbus RXD0

Table 3.2: RS-485/RS-422 connector pinout

8UMMODG100-2201

• Line termination is required and is typically done with a 120 Ohm 1/4 W resistor. For

RS-485 operation the bus must be terminated at both ends. For RS-422 operation a

termination resistor must be inserted between the RX+/RX- signals.

• Maximum number of RS-485 nodes without repeater is 32.

• Stub connections off the main line should be avoided if possible or at least be kept as

short as possible. Stub connections must not have terminating resistors.

• Maximum cable length to 1200 m (4000 ft).

• To assure a high degree of electromagnetic compatibility and surge protection the

cable should be twisted pairs and shielded. An additional cable conductor or pair may

be used for the GND reference.

Do not connect the cable shield to the GND pins! Use an external chassis ground

connection to terminate the shield.

Wiring the RS-232 interface

The RS-232 port can alternativly be used for serial communication to a Modbus Slave

device instead of RS-485. The use of the RS-232 interface must be configured using the

web interface (See the section called “Configuring Modbus network”). The MODG-100

is a Modbus Master device on this interface.

The Modbus RS-232 connector is a male 9-pin D-sub type located at the bottom side of

the mounted unit (refer to Figure2.1, “Location of connectors”). It has industry standard

EIA-574 data terminal equipment (DTE) pinout as shown in the following table and

picture:

GND

TDX

CTS DTR

RI

RXD

RTS

1

6

CD

DSR

Pin Signal Function Direction

1 DCD (unused) in

2 RXD Receive data in

3 TXD Transmit data out

4 DTR (unused) out

5 GND Signal ground

6 DSR (unused) in

7 RTS (unused) out

8 CTS (unused) in

9 RI (unused) in

Table 3.3: Modbus RS-232 connector pinout

• Maximum cable length is 15 m (50 ft) or a length equal to a line capacitance of 2500

pF, both at the maximum standard bit rate of 20 kbps. If operating at higher bit rates

the maximum cable length drops to 3 m (10 ft) at a bit rate of 57.6 kbps.

• To assure a high degree of electromagnetic compatibility and surge protection the

RS-232 cable should shielded. The shield shall be connected to an external chassis

ground at the either or both ends, depending on the application.

Installation

UMMODG100-2201 9

• The shield must not be connected to the GND pin.

To connect the MODG-100 to a PC (Personal Computer) or any other device with

data terminal equipment (DTE) pinout you need a null-modem or cross-over cable.

Connecting Ethernet

The following table describes the 10BASE-T Ethernet RJ-45 connector pinout:

TX+

TX-

RX-

RX+

1

Pin Signal Function

1 TX+ Non-inverting transmit signal

2 TX- Inverting transmit signal

3 RX+ Non-inverting receive signal

4 Internal termination network

5 Internal termination network

6 RX- Inverting receive signal

7 Internal termination network

8 Internal termination network

Table 3.4: Ethernet connector pinout

• We recommend to use Category 5 UTP network cable.

• Maximum cable length is 100 m (3000 ft).

This page intentionally left blank

10 UMMODG100-2201

Ethernet & IP configuration

UMMODG100-2201 11

Chapter 4.Ethernet & IP configuration

Before configuring the MODG-100, obtain a unique static IP address, subnet mask, and

default gateway address from your network administrator.

The factory default IP address of the MODG-100 is 169.254.0.10 which is in the

Automatic Private IP Addressing (APIPA) address range.

There are several methods of configuring the unit’s IP address:

1. Removing your PC from your corporate network and using a cross-over network

cable (see the section called “IP setup using a web browser and a cross-over network

cable”).

2. Via the Serial Port 1 and a terminal program like HyperTerminal (see the section called

“IP setup using a terminal program like HyperTerminal”).

3. Leaving your PC connected to your corporate network and temporarily changing the

IP settings on your PC to match the subnet of the MODG-100 (see the section called

“Temporarily changing the IP settings on your PC”).

In order to connect to the MODG-100 via TCP/IP, your PC must be on same IP subnet

as the gateway. In most situations this means that the first three numbers of the

IP address have to be identical.

IP setup using a web browser and a cross-over network cable

This method applies only to operating systems like Windows, which support APIPA

(Automatic Private IP Addressing). It also requires your PC to be configured for DHCP. If

your computer is configured with a static IP address, follow the procedure in the section

called “Temporarily changing the IP settings on your PC”.

1. Disconnect your PC from your corporate network. If your computer is configured for

DHCP it should now automatically fall back to use a default IP address from the APIPA

range 169.254.x.x (Windows PCs only).

2. Connect an Ethernet crossover cable from the MODG-100 to the computer.

3. Start Internet Explorer.

4. In the address box, type 169.254.0.10 and then press Enter.

5. Click Configuration… and then Ethernet & IP in the menu on the left side of

the page.

6. Enter the IP address, subnet mask, and gateway address assigned to your MODG-100,

then click Save.

7. Reconnect your computer to your corporate network.

12 UMMODG100-2201

IP setup using a terminal program like HyperTerminal

1. Connect a null modem RS-232 cable between your PC and the MODG-100's Serial

Port 1.

2. In Windows XP, click Start, point to All Programs, point to Accessories, point

to Communications, and then click HyperTerminal.

3. When HyperTerminal starts, it opens a dialog box and asks for a name for the new

connection. Enter a name (for example, deviceconfig) then click OK.

4. The Connect to dialog opens. Select the COM port you will be using in the Connect

using drop-down list box, then click OK.

5. Select 9600, 8, None, 1, None in the COM Properties dialog, then click OK.

6. HyperTerminal is now connected to the serial line.

7. Keep the space bar pressed in HyperTerminal and power-cycle your device at the

same time.

8. A menu should appear after one or two seconds showing device information, the

current IP configuration and a > prompt.

9. Type SETIP, then press Enter within 10 seconds after the prompt is shown:

DIAG MODE

Ver: x.y

S/N: 1234

MAC: 00:50:C7:67:71:97

IP Address: 169.254.0.10

Subnet Mask: 255.255.0.0

Gateway Address: 0.0.0.0

>SETIP

IP Address (169.254.0.10): 10.0.0.100

Subnet Mask (255.255.0.0): 255.255.255.0

Gateway Address (0.0.0.0): 0.0.0.0

RUN MODE

10.The device will show current values and prompt for new values for IP address, net

mask and gateway address. Enter the new values and press Enter. A key press must

be received at least every 10 seconds otherwise the device will go back to RUN MODE

and resume normal operation.

11.The gateway will return to the main prompt. Type X and press Enter to leave DIAG

MODE and resume normal operation indicated with RUN MODE.

Ethernet & IP configuration

UMMODG100-2201 13

Temporarily changing the IP settings on your PC

This method involves manually assigning an IP address to your PC in the same subnet as

the gateway. The default subnet of the gateway is 169.254.0.0/16.

1. Connect the MODG-100 to your Ethernet network.

2. On a Windows PC, open the Control Panel and double-click on Network

Connections. Right-click on the Network Connection associated with your network

adapter and select Properties:

This will show the Local Area Connection Properties Dialog:

14 UMMODG100-2201

3. Select the Internet Protocol (TCP/IP) entry and click on Properties to open

the TCP/IP Properties dialog as shown below:

4. Write down your current settings so they can be restored later.

5. Select Use the following IP address and configure a static IP address in

the same subnet as the device, for example 169.254.0.1 and the subnet mask

255.255.0.0. Click OK to save the changes.

6. Start Internet Explorer.

7. In the address box, type 169.254.0.10 and then press Enter.

8. Click Configuration… and then Ethernet & IP in the menu on the left side of

the page.

9. Enter the IP address, subnet mask, and gateway address assigned to your MODG-100,

then click Save.

10.Restore your computer’s original settings.

Table of contents

Other Proconx Gateway manuals

Popular Gateway manuals by other brands

Amit

Amit BDG761-0P1 user manual

Multitech

Multitech MultiVOIP GSM SIP-to-Cellular Gateways... user guide

Commend

Commend Audiocodes MP-11 Series Setup guide

ZyXEL Communications

ZyXEL Communications P-660HN-51 - user guide

DAUDIN

DAUDIN iO-GRID m user manual

ZyXEL Communications

ZyXEL Communications P-660HW-TX Support notes