Contents

Important user information ....................................................................................... vii

Safety Precautions .............................................................................................. vii

Document conventions ...................................................................................... viii

1 Introduction ............................................................................................................. 1

Features ................................................................................................................ 2

Quick start checklist ............................................................................................. 2

2 Description ............................................................................................................... 3

LED indicators ...................................................................................................... 3

3 Installation ................................................................................................................ 5

Regulatory notes .................................................................................................. 5

Unpacking, handling and storage ........................................................................ 5

Before connecting anything ................................................................................. 5

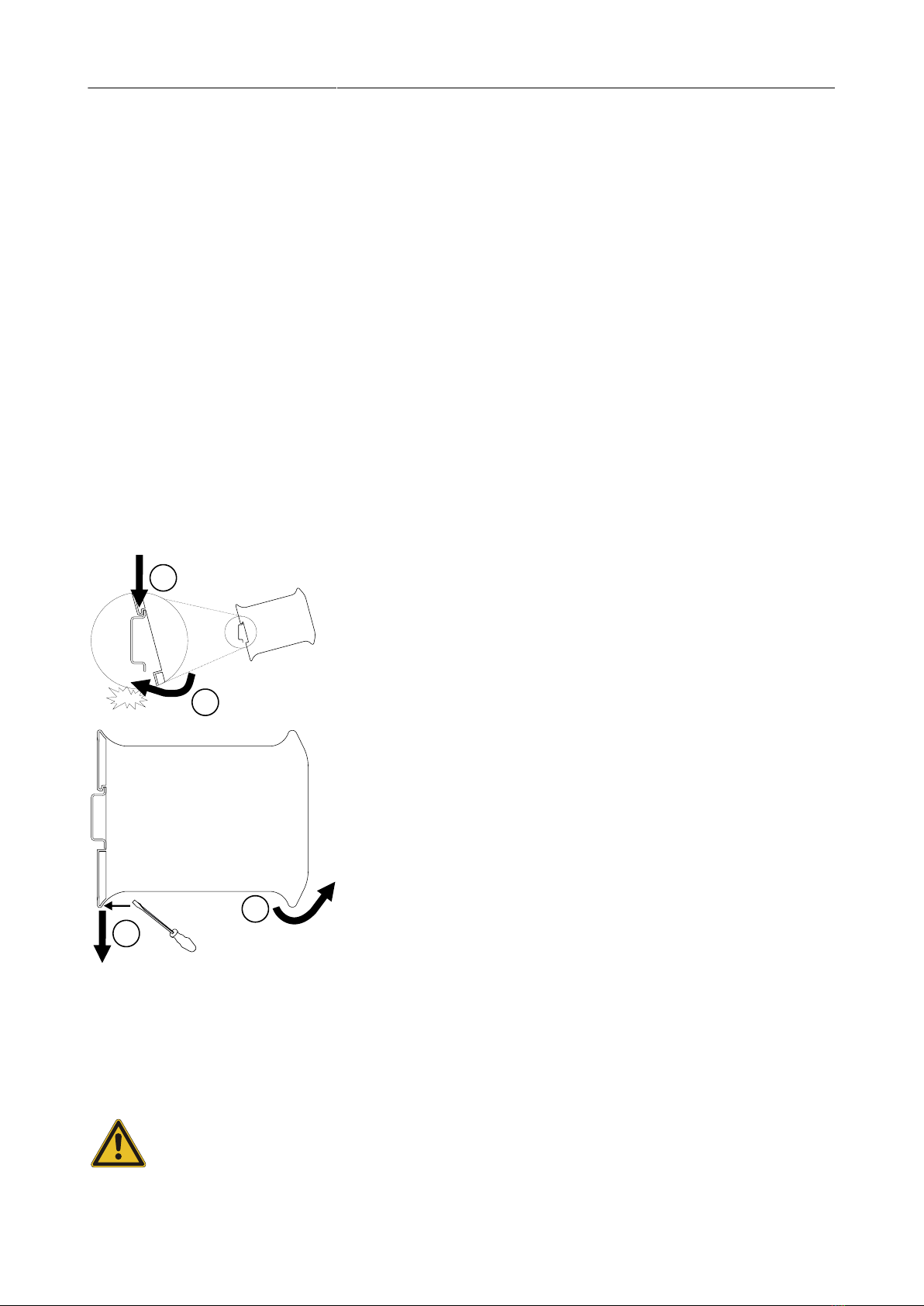

DIN rail mounting and removal ........................................................................... 6

Mounting rules .................................................................................................... 6

Powering the ESEPRO .......................................................................................... 7

Wiring the Profibus interface ............................................................................... 7

Wiring the CAN interface ..................................................................................... 8

Connecting Ethernet ............................................................................................ 9

4 Profibus configuration ............................................................................................ 11

Mapping of Woodward devices into the process I/O ......................................... 12

Direct mapping ........................................................................................... 12

Indexed mapping ....................................................................................... 14

Generic Woodward device module ............................................................. 15

RPDO Profile ............................................................................................... 18

5 Profibus operation .................................................................................................. 21

Organisation of the data in Woodward CANopen devices ................................. 21

Addressing of Woodward CANopen devices ...................................................... 22

Methods of data transfer ................................................................................... 22

DP-V0 indexed data mapping ............................................................................ 23

Read Mux object ........................................................................................ 23

Read parameter .......................................................................................... 25

Write parameter ......................................................................................... 26

DP-V1 functions ................................................................................................. 27

Writing/reading data with STEP 7 .............................................................. 27

Read MUX objects ...................................................................................... 28

Read Remote Control word ........................................................................ 28

Write Remote Control word ....................................................................... 29

Remote Control Word IDs .......................................................................... 29

Remote Control Examples .......................................................................... 30

6 Configuration of connected Woodward controls ................................................... 33

Specific information for Easygen-3000 series controls ....................................... 35

CAN interface ............................................................................................. 35

Transmit PDOs ............................................................................................ 36

Specific information for LS-5 controls ................................................................ 37

CAN interface ............................................................................................. 37

Transmit PDOs ............................................................................................ 38

7 Decommissioning ................................................................................................... 39

Disconnecting ..................................................................................................... 39

UMESEPRO-2201 iii