Prodif 592SH User manual

OILLESS COMPRESSOR / AUTOLUBRICATED:

592SH

SYNOPSIS:

INSTALLATION AND SITE....................P 1

INSTRUCTIONS, USES OPERATING..P 1

FOR YOUR SECURITY.......................P 2

MAINTENANCE..................................P 2

TABLES - ILLUSTRATIONS..................P 3/4

FAULTS / SOLUTIONS..............................P 5

MARKING - TRACKING.............................P 5

PICTOGRAMS LEGEND............................P 6

GUARANTEE ADVICE...............................P 6

GUARANTEE...........................................P 6

STAMPOFTHERETAILER

A-NOTICE592SH-ce .pmd (2012-06-20)

WARNING:

FIRST USE OF

COMPRESSOR

Duringthecommissioningof

your compressor, it is possible that

oil mist escapes from the vents of

theplasticcover:

This is quite normal, a lubricant is

deposited on the piston to facilitate

the mechanical running, it burns in

the first minutes.

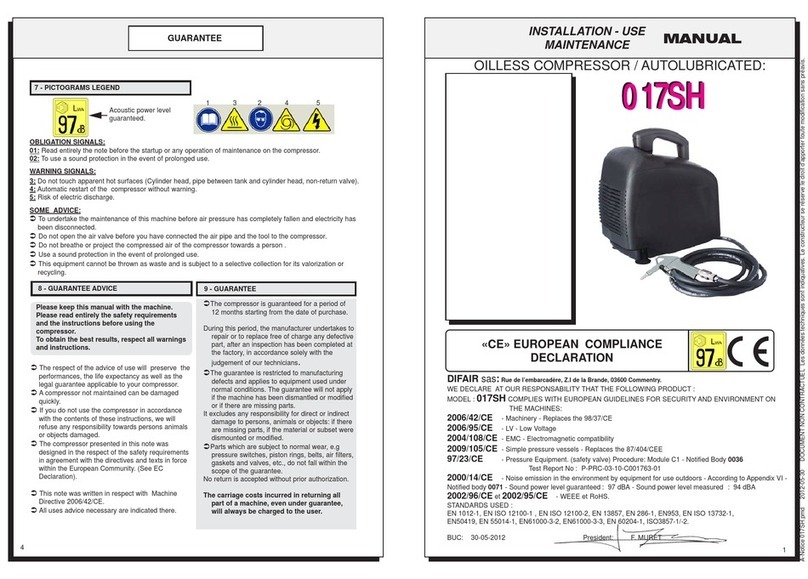

WE DECLARE AT OUR RESPONSABILITY THAT THE FOLLOWING PRODUCT :

1)MODEL: Shown on the label.

2) SERIAL NUMBER : Shown on the label.

3)YEAROF MANUFACTURE: Shown on the label.

”CE” EUROPEAN COMPLIANCE

DECLARATION MANUAL

INSTALLATION

USE

MAINTENANCE

COMPLIES WITH EUROPEAN GUIDELINES FOR SECURITY AND ENVIRONMENT ON THE MACHINES:

2006/42/CE - Machinery - Replaces the 98/37/CE

2006/95/CE - LV - Low Voltage

2004/108/CE - EMC - Electromagnetic compatibility

2009/105/CE - Simple pressure vessels - Replaces the 87/404/CEE

97/23/CE - Pressure Equipment. (safety valve)

Procedure: Module C1 - Notified Body 0036

Test Report No : P-PRC-03-10-C001763-01

2000/14/CE - Noise emission in the environment by equipment for use outdoors

According to Appendix VI - Notified body 0071

Sound power level guaranteed: 97 dBA

Sound power level measured : 94 dBA

2002/96/CE et 2002/95/CE - WEEE et RoHS.

STANDARDS USED :

EN 1012-1, EN ISO 12100-1 , EN ISO 12100-2, EN 13857, EN 286-1, EN953, EN ISO 13732-1,

EN50419, EN 55014-1, EN61000-3-2, EN61000-3-3, EN 60204-1, ISO3857-1/-2.

BUC: 20-06-2012 President: F . MURET

6

PICTOGRAMS

GUARANTEE

2 - INSTRUCTIONS, OPERATING ADVICE

To obtain the best efficiency, please respect the

following indications:

- PLACE: Use the compressor indoors or under

shelter, do not expose it to the rain or near water

jets. Do not use the compressor in an explosive

atmosphere.

- VENTILATION: The compressor must be in a place

which allows ventilation, do not cover the ventilation

openings.

- TEMPERATURE: Use the compressor between

(+ 5°C and +35°C) (Otherwise, there are risks for

the electrical motor.)

- BLOCK OF COMPRESSION: Keep the

compressor at 50 cm at least from any wall to

ensure a correct circulation of air.

- TENSION: Check that the sector tension and

tension indicated on the label are the same :

(Single phase:230 Volts - 50 Hz)

Connect as near to the electrical meter as

possible (Less than 10 meters in order to avoid a

rise in intensity, the engine would not start in cold

weather):

- Of 16 Amps under 230V.

- Connected to the ground.

- Connected to a differential protection.

Check that the compressor has not been damaged

during the transport.

The switch must be in position "Off". (Fig. 2)

Verify under the tank that the drain valve is closed

(fig. 3).

- USING AN ELECTRIC EXTENSION:

- BEFORE USE:

Please only use an extension if absolutely

necessary.

We recommend the following dimensions: 5 meters

maximum length with section of wire of 2,5mm ².

Too small diameter wire sections and big lengths

would cause serious damage to the engine.

It is better to extend the air pipe, which also will

give you stock of air.

INSTALLATIONANDSITE

INSTRUCTIONS

You have just bought your air compressor, it will

give you appreciable services.

Please ensure first that your compressor is powerful

enough, you may use it for:

- Inflating Tyres - Balloons - Swimming pools -

Rafts etc......

- Blowing / vacuum-cleaning / painting

- Using pneumatic tools :(ex. gun nailer, stapler,

screw driver, impact wrench, sand blasting, etc...)

Before use, it is imperative to read ENTIRELY the

present NOTE.

1 - INSTALLATION AND SITE

1

- ADJUSTMENT OF PRESSURE:

Adjust the pressure of use and the consumption of

air to the characteristics of the tools you wish to use.

(See the documentation provided with your tools).

The quantity of air consumed depends on the type

of tool used: do not use a tool consuming more than

60% of the possibilities of your compressor.

The pressure controller is adjusted in factory and

needs no re adjustment.

Pressure gauge A (Fig. 4) indicates the pressure

inside the tank.

To adjust the output of air pressure , it is necessary to

turn the button ( Fig. 4)

In clockwise direction to increase pressure, and

opposite to decrease it.

The pressure gauge B (Fig. 4) indicates the useful

exit air pressure, you must use the tool only when the

pressure in the tank is higher than the pressure of use

of the tool.

9- GUARANTEE

The compressor is guaranteed for a period of 12

months starting from the date of purchase.

During this period, the manufacturer undertakes to

repair or to replace free of charge any defective

part, after an inspection has been completed at the

factory, in accordance solely with the judgement of

our technicians.

The guarantee is restricted to manufacturing

defects and applies to equipment used under normal

conditions. The guarantee will not apply if the

machine has been dismantled or modified or if there

are missing parts.

It excludes any responsibility for direct or indirect

damage to persons, animals or objects: if there are

missing parts, if the material or subset were

dismounted or modified.

Parts which are subject to normal wear, e.g

pressure switches, piston rings, belts, air filters,

gaskets and valves, etc., do not fall within the

scope of the guarantee.

No return is accepted without prior authorization.

The carriage costs incurred in returning all part

of a machine, even under guarantee, will always

be charged to the user.

The respect of the advice of use will preserve

the performances, the life expectancy as well as the

legal guarantee applicable to your compressor.

A compressor not maintained can be damaged

quickly.

If you do not use the compressor in accordance

with the contents of these instructions, we will refuse

any responsibility towards persons animals or objects

damaged.

The compressor presented in this note was

designed in the respect of the safety requirements in

agreement with the directives and texts in force within

the European Community. (See EC Declaration).

This note was written in respect with Machine

Directive 2006/42/CE.

All uses advice necessary are indicated there.

Please keep this manual with the machine.

Please read entirely the safety requirements and

8- GUARANTEE ADVICE

7 - PICTOGRAMS LEGEND

5: Risk of electric discharge.

3: Do not touch apparent hot surfaces (Cylinder

head, pipe between tank and cylinder head, non-

return valve).

To undertake the maintenance of this machine

before air pressure has completely fallen and

electricity has been disconnected.

Do not open the air valve before you have

connected the air pipe and the tool to the

compressor.

Do not breathe or project the compressed air of

the compressor towards a person .

Use a sound protection in the event of

prolonged use.

This equipment cannot be thrown as waste and

is subject to a selective collection for its

valorization or recycling.

4: Automatic restart of the compressor without

warning.

01: Read entirely the note before the startup or any

operation of maintenance on the compressor.

02: To use a sound protection in the event of

prolongeduse.

WARNINGSIGNALS:

OBLIGATIONSIGNALS:

Acoustic power level

guaranteed.

- USING A PNEUMATIC EXTENSION:

For pressures higher than 7 bar, use pipes

reinforced with steel braid.

the instructions before using the compressor.

To obtain the best results, respect all warnings

and instructions.

SOME ADVICE:

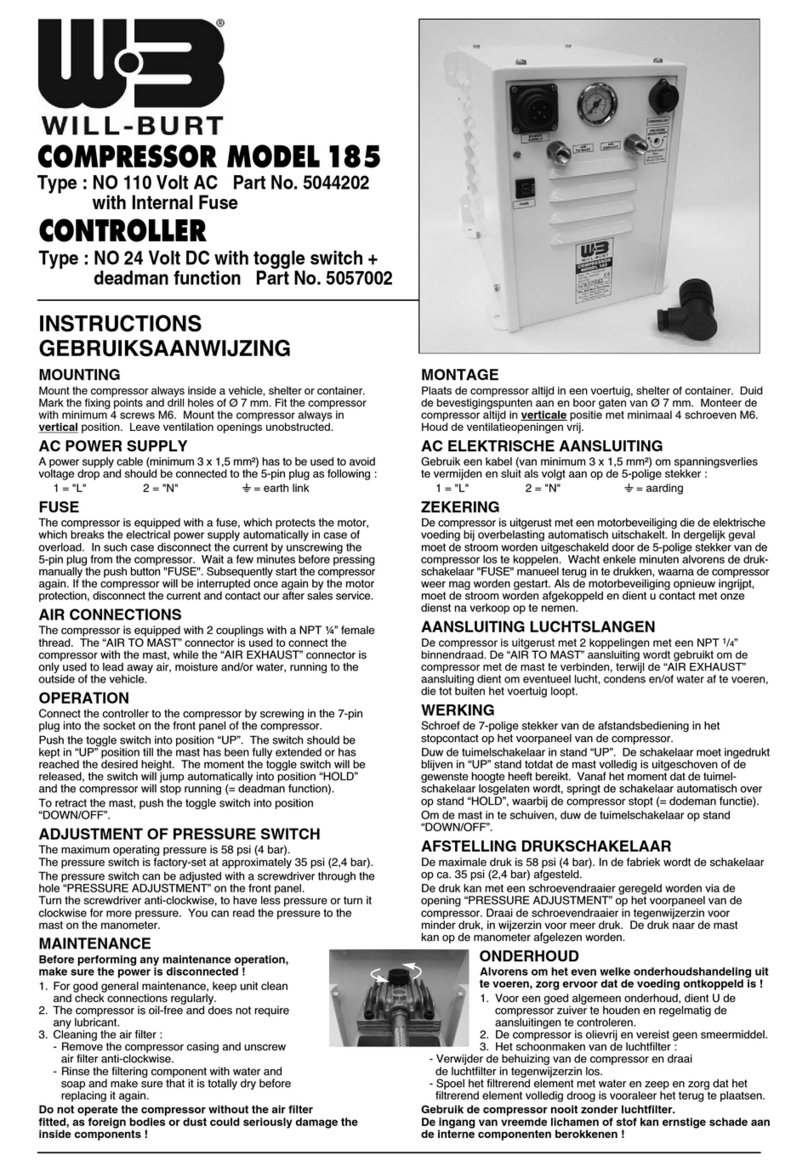

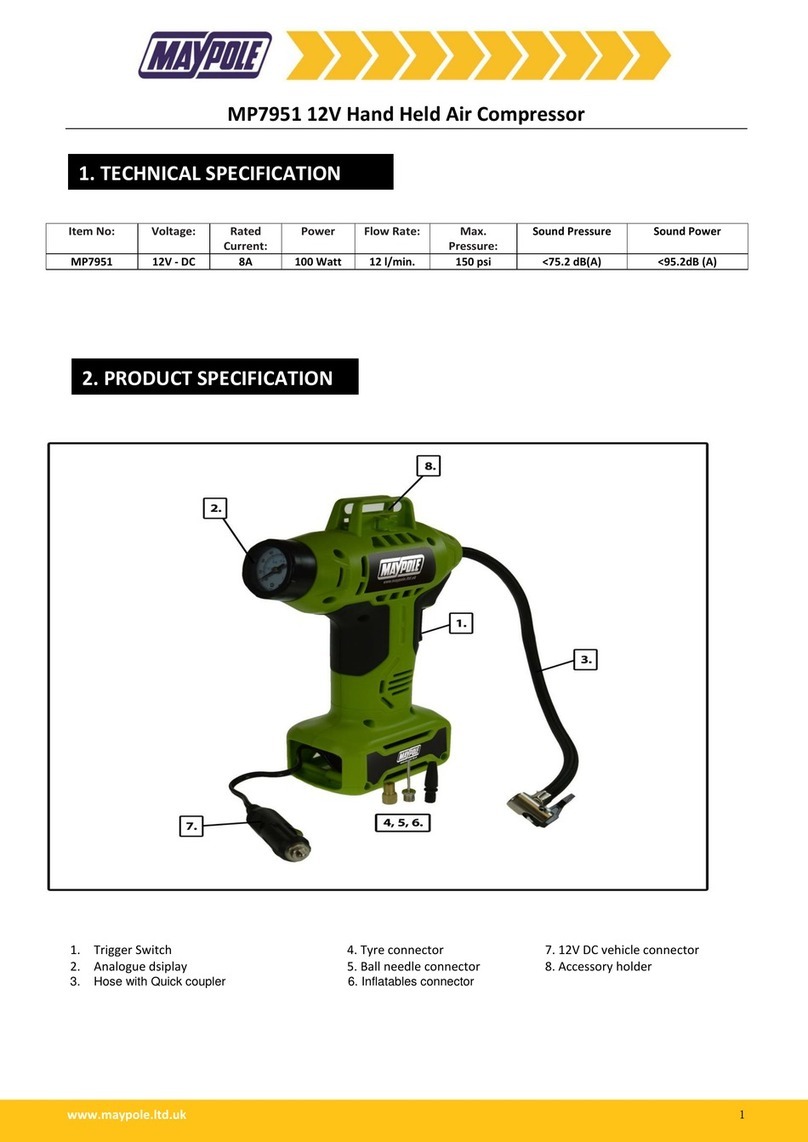

1 - Producer

2 - Tank capacity

3 - Power

4 - Tension- Phase Qty

and frequency.

5- Maximum pressure

6 - Compressor weight

7- Air delivery at 7 bar

8 - Revolutions per minute

9 - Measured noise level

10- Serial number

11 - Code model

12- Reference

13 - Year of manufacture

1 3 2 4 5

ATAD-NOITCETORPCIRTCELE REWOP Wk 5,12,2345,5

elgniS esahP ESUFWOLBWOLS A0161

zH05-V032

NOITCESELBAC

muminiM ²mm 5,25,2

52

4- MAINTENANCE

Before any intervention on the compressor:

- Disconnect electrical cable.

- Empty the tank.

- Let cool the compressor.

A regular maintenance ensures working

without problem and increases the longevity

of the compressor.

FOR HANDLING: do not carry the compressor,

use the wheels (not the handles).

See table of the programmed maintenance(page 3)

Purge condensates: Advised after each use:

Purge to avoid the corrosion of the tank, .see (fig. 3).

These condensates contain oil , so you must recover

the condensates in a suitable container not to reject

into the sewers.

Clean or change the air filter: To guarantee the flow

of the compressor.( Fig. 7)

controls checking: By the tank pressure gauge,

check maximum value of the compressor.

Electric connector blocks checking: Tighten

correctly electric wires to have a good engine power.

3 - FOR YOUR SECURITY

The air delivered by your compressor allows you

to use many tools, follow conditions, advice and in

certain cases RESTRICTIONS OF USE for air tools

using compressed air.

Avoid any degradation of the electric cable and

move away from heat sources higher than 70°C.

At the end of work, unplug the cable and roll up it

around the handle of the compressor.

Do not use the compressor with bare or wet feet.

Do not to touch the compressor with wet hands.

Do not pull the cord to move the compressor or

to remove the plug.

Do not allow children to use the compressor.

Do not leave the compressor without monitoring

when it is connected; it can become source of

dangers.

Never introduce objects into the protection of the

transmission system.

- AFTER USING:

Never stop by disconnecting the electrical cable.

Never leave the compressor power connected

under pressure.

Switch the interruptor in "Off" position . (Fig. 2)

Empty the tank

Drain the tank (Fig.3)

Disconnect the electrical cable.

Ordinary maintenance does not require

specializedpersonnel.

The servicing of the group of compression as

well as other more complex bodies, must be

carried out by specialized personnel: Call for your

retailer.

The compressor does not start:

No electrical supply.

The compressor is already in pressure, empty

the tank.

The pressure switch is defective.

The compressor starts with difficulty, and

thermal protection sometimes operates:

The electric tension is insufficient. (210V

Minimum).

Electrical supply cord is too long, or wire section

too small. (electric cable coil)

Engine overload by cold weather.

Electrical supply cord is cut or disconnected.

You stopped your compressor by disconnecting

the cable and decompression did not take place.

Decompression defect, the tank is full, the

decompression did not take place.

(Check: Correct restarting with empty tank).

High resistance of the group: after removing air

filter, pour 4 to 5 drops of engine lubricating oil at

the air entry of the compressor and make the

compressor working during one minute, in order to

deposit an oil film in the mechanism.

Thermal protection is out of order, needs to be

regulated or changed according to the type.

Abnormal noises, vibrations:

Loosened or worned parts.

Worn group (mechanical noises).

Bad chocking of the compressor.

Tension of the belt to be checked.

Air leakage in the pneumatic circuit.

Opening of the safety valve:

Bad adjustment of the pressure controller, you

need to check that pressure gauge A ( Fig. 4) does

not exceed the pressure indicated on the identifica-

tion plate, this must be regulated by a specialist.

The safety valve is badly regulated or is

defective, to be replaced by an approved

equivalent model.

5 - FAULTS / SOLUTIONS

Air leaking from the valve of air pressure switch :

- defective valve of the pressure switch, change it.

No return valve blocked by an impurity or worn,

clean or change the no return valve or the internal

rubber valve with its spring. ( Fig. 9)

Low flow rate, pressure does not increase:

air filter is dirty, you must clean it.(Fig. 7)

air pressured is leaking by the connections, check

the connections.

Cylinder valves are broken or valve seat gasket

torn, you must check the pump.

Excessive consumption by the segmentation,

gasket leakages, you must check the pump.

Impossible adjustment of the output air pressure:

The internal diaphragm of the pressure reducer is

torn (fig.4) replace it.

Please follow the advice below for the mainte-

nance of your compressor:

FAULTS/SOLUTIONS

COMMUNICATION-TRACKING PRODUCT SECURITY

MAINTENANCE

To use your compressor correctly, only use it

intermittently, i.e. 60% of use for 40% of downtime.

Beyond this limit, the engine risks overheating

problems.

- PRECAUTIONS TO PAINT:

If the electric motor and the interior of the pump are

dirty, your compressor life expectancy will be

reduced:

In order to avoid this problem, only move away

the compressor by lengthening the tube of your tool.

The electric safety of this machine is assured only

when it is correctly connected with an efficient

grounding connection , as recommended in the rules

of electric safety requirements.

The responsibility for the manufacturer will not be

committed if grounding connection of the installation

is incorrect.

To avoid burns, during the work and a few minutes

after working, never touch the pipes of connection of

the cylinder head, the non-return valve nor the parts

of the compressor subjected to heating.

-OPERATINGTIME:

For any communication with the distributor, please

indicate the identification sticker data of the

product [fig.1] The sticker is applied on the side of

the compressor.

IDENTIFICATION STICKER OF THE PRODUCT

[fig.1]

6 - COMMUNICATION- TRACKING PRODUCT

1 2 3 4 5 6

7

8

9

1

12

10

11 13

TABLES / ILLUSTRATIONS

34

Fig. 2

Fig. 4

Fig. 3

Fig.7 Fig.9

INTERNALVALVE

.PEREDOCNOITPIRCSED

940D030338revoccitsalP

2018102409leehW

3017418309toofnoitcuS

5012482149"4/1evlaV.teRnoN

6014022149gnilpuockciuQ

70136

03509"4/1evlaVniarD

8016111509recudeRerusserP

901185414905ØeguaG

901910250904ØeguaG

0110104149evlavytefaS

1111824149s

exaleehW

2116330509epip/epipwoblE

2119642149epip/haehwoblE

5114218309pilC

6111008309eldnahrebbuR

1310903609hctiwseru

sserP

2312325609elbaclacirtcelE

4312035609rotom-elbaclacirtcelE

5419162149evlavnruteron-ebuT

5416642149rednilyc-e

buT

SPARE PARTLIST

ecnanetniamehtfoyticidoireP "emmargorpecnanetniam"snoitarepo

hcaE

keewhtnomh005h0001

ehtgnigruP setasnednoc

riaehtgninaelC retlif

lriaehtgnignahC retlif

gninaelclareneG

gnikcehC stnemtsujda

gninethgitgnikcehC snoitcennocfo

cirtcelegnikcehC skcolbrotcennoc

Other Prodif Air Compressor manuals

Popular Air Compressor manuals by other brands

Bostitch

Bostitch CAP2041ST-OL Operation and maintenance manual

Max-Air Systems

Max-Air Systems MA-35 Use and maintenance manual

Coltri Compressors

Coltri Compressors MCH-8/EM STANDARD Use and maintenance manual

Becker

Becker DT 4.25K operating instructions

Sealey

Sealey SAC1903B instructions

Trotec

Trotec PCPC 10-1100 Original instructions