Prodigit 3301A User manual

3301A

使 用 手 冊 (E)

S/N: 90033013 rev:A

3301A Mainframe Operation Manual

Table of contents

ˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍ

Chapter 1 Introduction.........................................................................................................1

1-1.Features .................................................................... 1

1-2.Option ...................................................................... 1

1-3.Specifications .............................................................. 1

1-4.System block diagram ........................................................ 2

Chapter 2 Installation........................................................................................................... 3

2-1.Inspection .................................................................. 3

2-2.Check line voltage .......................................................... 3

2-3.Grounding requirements ...................................................... 4

2-4.Adjust the feet ............................................................. 4

2-5.Rack mount .................................................................. 4

2-6.Enviremental requirements ................................................... 4

2-7.Repairing ................................................................... 4

2-8.Accessories ................................................................. 5

2-9.GPIB connection ............................................................. 5

2-10.Remote control Port ........................................................ 6

2-11.Master/Slave operating mode ................................................ 7

Chapter 3 Mainframe operation........................................................................................... 9

3-1.Feet stands ................................................................. 9

3-2.Power switch ................................................................ 9

3-3.STORE/RECALL operation ..................................................... 10

Chapter 4 GPIB programming operation.......................................................................... 11

4-1.The summary of GPIB command ................................................ 11

4-2.The description of abstraction ............................................. 11

4-3.GPIB command description ................................................... 13

4-4.3301A Operation flowchart .................................................. 21

4-5.GPIB Command listing ....................................................... 22

Figure

Figure 1-1 Block diagram ........................................................ 2

Figure 2-1 Set of the power switch .............................................. 3

Figure 2-2 AC line receptacle socket ............................................ 4

Figure 2-3 rear panel ........................................................... 5

Figure 2-4 Address switch ....................................................... 6

Figure 2-5 Diagram of Remote Control Port ....................................... 6

Figure 2-6 The channel number of Master/Slave operation ......................... 7

Figure 2-7 25PIN 〝D〞type cable ................................................ 8

Figure 3-1 3301A front panel .................................................... 9

Figure 4-1 3301A Operation flowchart ........................................... 21

Table

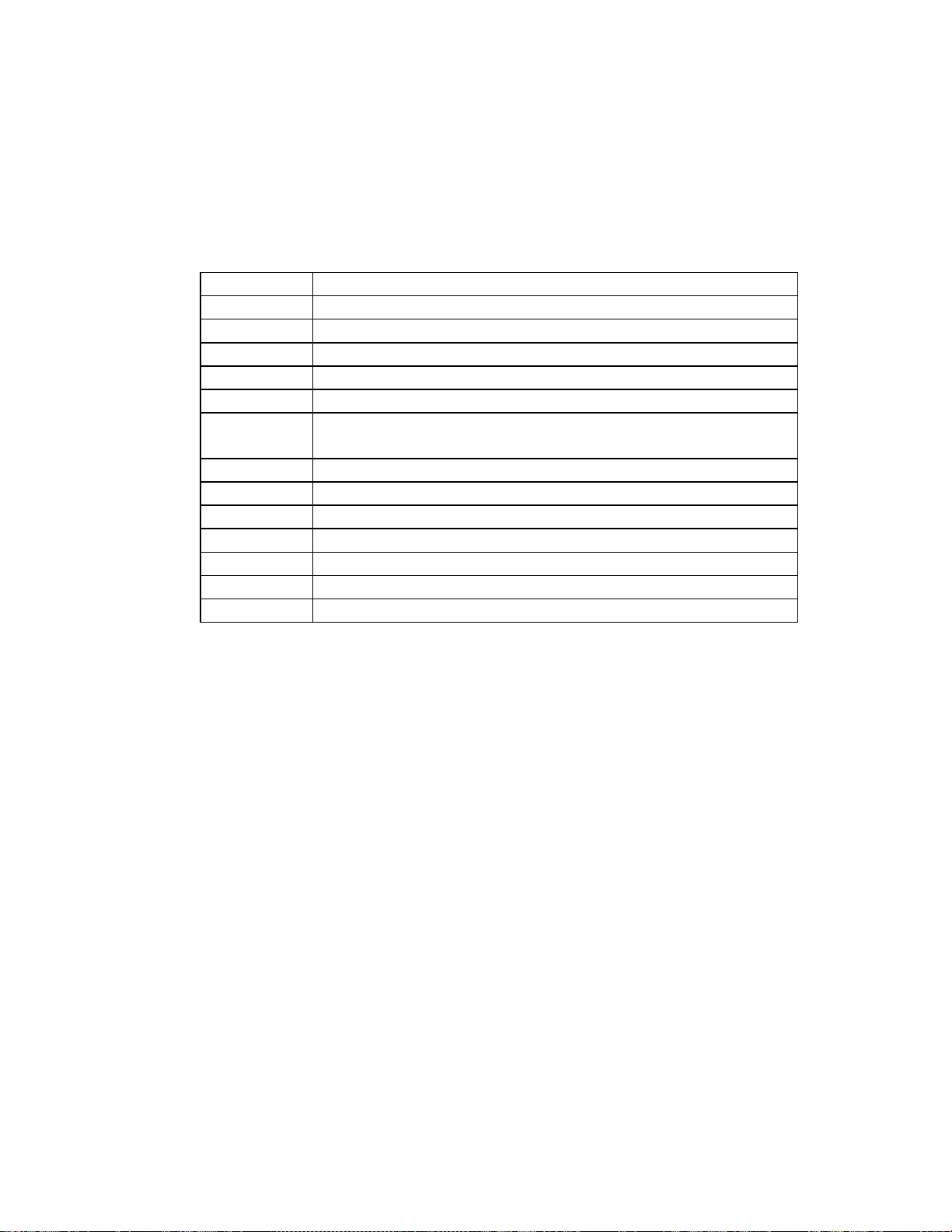

Table 1-1 Specification ......................................................... 1

Table 4-1 GPIB Command listing ................................................. 11

Table 4-2 GPIB command terminator .............................................. 12

Table 4-3 Maximun load current level ........................................... 16

Table 4-4 Slew rate code for SLOW, MID, and FAST ............................... 17

Table 4-5 specification code for 3320 series load module ....................... 19

3301A MAINFRAME OPERATION MANUAL 1

ˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍ

Chapter 1 Introduction

The 3301A Electronic load mainframe is designed to install up to 4 channels 3320 series plug-

in load module, 3320 (60V/30A 150W), 3321 (60V/60A 300W) or 3322 (250V/10A, 300W) plug-in

module can be installed to any slot of the 3301A mainframe. A total 1200W maximum capacity can

be implemented in 3301A mainframe.

1-1.Features

3301A mainframe provides easy operation and cost effective solution for power source testing,

the features of the 3301A Electronic load mainframe is described in the following:

1.Plug-in design, it is easy to replace different specifications load module.

2.Flexible configuration, each slot of 3301A mainframe can be installed one of 3320, 3321 or

3322 load module.

3.STORE/RECALL up to 5 states, it can reduce the testing time in incoming inspection as well

as production line.

4.Master/Slave operation two 3301A mainframe only occupy one GPIB address when operating in

Master/Slave mode.

5.Built-in GPIB interface.

1-2.Option

1. Blank panel

2. GPIB cable 1M

3. GPIB cable 2M

4. 25 pins "D" type cable 1M

5. Model 9931 Remote Controller

1-3.Specifications

The detail specifications of 3301A mainframe is shown in Table 1-1.

AC INPUT LINE 100V/115V ±10﹪ 200V/230V ±10﹪

FREQUENCY 50/60 Hz

FUSE 2A/250V (5*20mm) 1A/250V (5*20mm)

MAX.POWER

CONSUMPTION 100W

DIMENSIONS (W*H*D) 440mm * 177mm * 445mm

WEIGHT NET:9.3Kg

Table 1-1 Specification

2 PRODIGIT

ˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍ

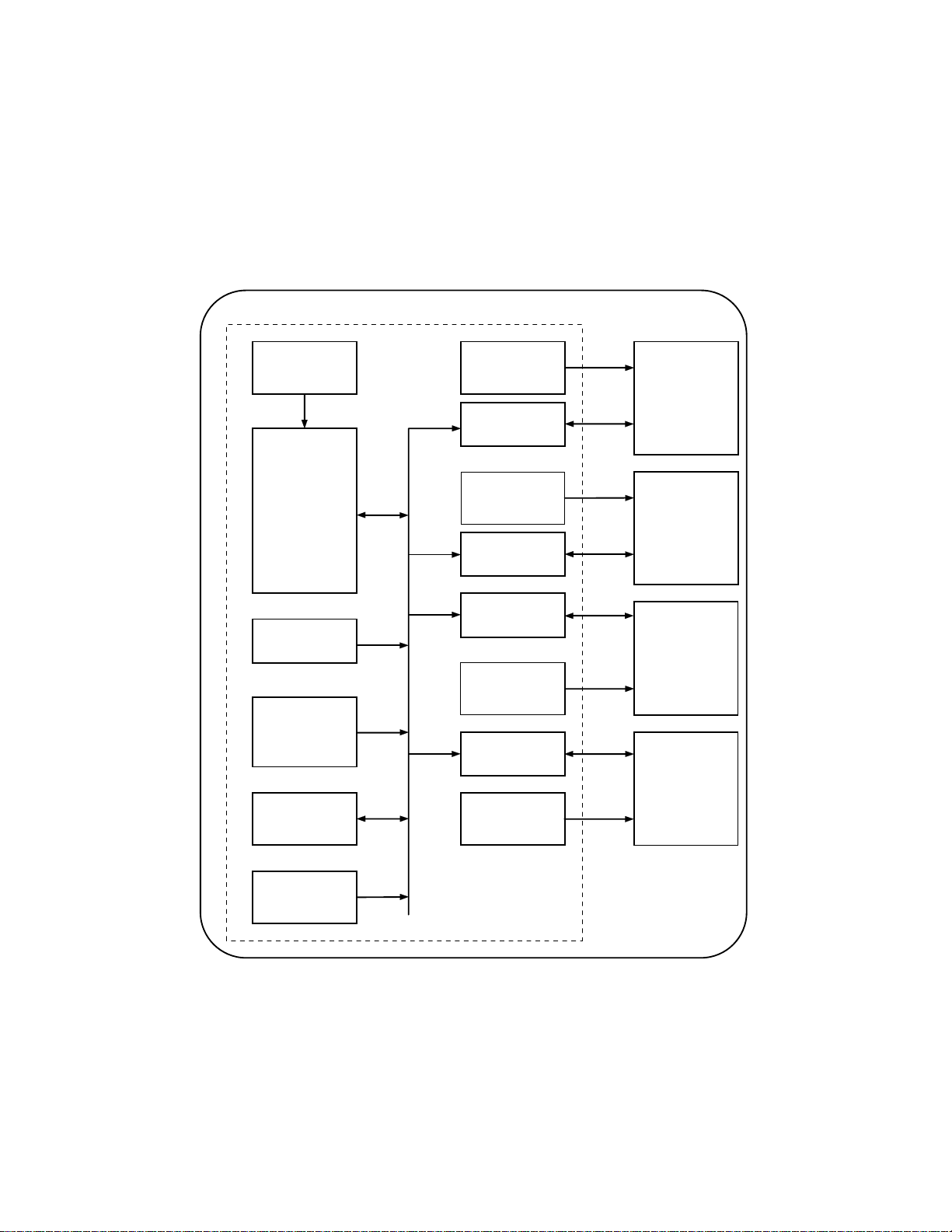

1-4.System block diagram

The system block diagram is shown in Fig 1-1, there are five power supplies in 3301A mainframe

one for 3301A mainframe, and others are for each channel respectively.

The 3301A mainframe is optically isolated with each load module.

3310 MAINFRAME

POWER

SUPPLY

#5

SYSTEM

CONTROLLER

(CPU,RAM,

NON-VOLATILE

RAM,I/O etc.)

POWER

SUPPLY

#1

ISOLATED I/O

INTERFACE #1

POWER

SUPPLY

#2

ISOLATED I/O

INTERFACE #2

ISOLATED I/O

INTERFACE #3

IEEE-488

INTERFACE

MAINFRAME

OPERATION

KEY

STORE/RECALL

MASTER/SLAVE

DIO INTERFACE

POWER

SUPPLY

#4

POWER

SUPPLY

#3

ISOLATED I/O

INTERFACE #4 3320

SERIES

PLUG-IN

LOAD

MODULE

#4

3320

SERIES

PLUG-IN

LOAD

MODULE

#3

3320

SERIES

PLUG-IN

LOAD

MODULE

#2

3320

SERIES

PLUG-IN

LOAD

MODULE

#1

9931 REMOTE

CONTROL

INTERFACE

Figure 1-1 Block diagram

3301A MAINFRAME OPERATION MANUAL 3

ˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍ

Chapter 2 Installation

2-1.Inspection

The 3301A mainframe was carefully inspected before shipment. If instrument damage has occurred

during transport, please inform Prodigit's sales and service office or representative.

Your 3301A mainframe was shipped with a power cord for the type of outlet used at your

location. If the appropriated cord was not included, please contact your nearest Prodigit

sales office to obtain the correct cord. Refer to " check line voltage " to check the line

voltage selection and fuse type.

2-2.Check line voltage

The 3301A mainframe and 3320 series Electronic load can operation with 100, 115, 200, 230Vac

input as indicated on the label on the rear panel.

Make sure that the factory check mark correspond to your nominal line voltage. Skip this

procedure if the label is corrected marked.

1.With the 3301A mainframe power OFF, disconnect the power cord, and remove two bottom cover

screws.

2.Turn the 3301A mainframe up side down, remove the bottom cover.

3.Refer the drawing on the PC board in Fig 2-1, set the switches to the proper voltage as

describe in the following:

a.115Vac:Set SW1 to left side (SW1Å).

b.230Vac:Set SW1 to right side (SW1Æ).

POWER SUPPLY PCB

SW1

115V 230V

Figure 2-1 Set of the power switch

4.Replace the cover and mark the correct voltage on the rear panel of 3301A mainframe.

5.Check the rating of the line fuse and replace it with the correct fuse if necessary.

6.The line fuse is located below the AC line receptacle see Fig 2-2. With the power cord

removed, use a small screwdriver to extract the fuse holder from under the AC socket.

Replace the fuse with the appropriate type as indicated in table 1-1. These fuses are

normal-blow fuses.

4 PRODIGIT

ˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍ

Figure 2-2 AC line receptacle socket

7.Reinstall fuse holder and connect the power cord.

2-3.Grounding requirements

Model 3301A mainframe and 3320 series Plug-in load is equipped with three conductor calbe

which plugges in an appropriate receptacle to ground the instrument's cover.

2-4.Adjust the feet

The 3301A Electronic load mainframe is equipped with feet and tilt stands installed and is

ready for used as a bench instrument. The feet provide a good viewing angle for bench-top use.

2-5.Rack mount

The 3301A mainframe is designed to permit mounted in a standard 19 inches rack for system

application.

2-6.Enviremental requirements

The operating temperature should keep etween 0 degree and 40 degree, while the ideal operating

temperature 25 ±5 degree.

2-7.Repairing

If the instrument is damaged, please attach a tag to the instrument to identify the owner and

indicated the require service or repairing. And inform the Prodigit sales and service office

or representative.

3301A MAINFRAME OPERATION MANUAL 5

ˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍ

2-8.Accessories

The following parts should be include in the shipment.

1.Three conductor power cord 1pc

2.3301A mainframe operation manual 1pc

2-9.GPIB connection

The GPIB connector on the rear panel connects the 3301A mainframe to the controller and to

other GPIB devices. An GPIB system can be connected in any configuration ( star, linear, or

both ) as long as;

1.The maximun number of devices including the controller is no more than 15.

2.The maximum length of all cable in no more than 2 meters times the number of devices

connected together, up to 20 meters maximum.

Please make sure the lock screws are firmly hand - tightened, use a screwdriver only for

the removal of screws.

Fig 2-3 shows the rear panel of 3301A mainframe, the GPIB connector and GPIB address

setting switch is located on the rear panel of 3301A mainframe.

0

1

16842

LINE FUSE RATING

100V

115V

200V

230V

50/60 Hz

2A

1A

LINE INPUT

GPIB ADDRESS

1DIO CONTROL ANALOG PROGRAMMING INPUT

CH2 CH1CH3CH4

3310 SERIES USED ONLY.

PRODIGIT ELECTRONICS CO., LTD

0 10 Vac+dc

R

EXTERNAL REMOTE CONTROLLER

(5 RECALL MEMORY)

MADE IN TAIWAN, TAIPEI, R.O.C.

MASTER/SLAVE

Figure 2-3 rear panel

The GPIB address of the 3301A mainframe is factory set to address 05. The GPIB address can

be set by adjust the GPIB address switch setting the weighting of the address switch is

following from left to right in 1, 2, 4, 8, 16 sequence.

The unused switch should set to OFF position.

6 PRODIGIT

ˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍ

The switch 1 and 3 are in ON position for address 05 when the 3301A mainframe is shipped

from Prodigit. Fig 2-4 shows the detail outlook of the address switch.

12345678ON

124816

ADDRESS

No.

Figure 2-4 Address switch

2-10.Remote control Port

The D-sub 9 pin connector on the rear panel connects the 3301A mainframe to the PRODIGIT mode

9931 remote controller and to replace the RECALL option key 1 to 5 on the front panel of 3301A

mainframe.

1

2

3

4

5

STORE

1

2

3

4

5

6

7

8

9

NC

NC

NC

NC

D-sub 9 Pin

PRODIGIT

INSTRUMENT PRO.

9931 REMOTE INTERFACE

9 Pin to 9 Pin 1.5M Cable

1

2

3

4

5

Figure 2-5 Diagram of Remote Control Port

3301A MAINFRAME OPERATION MANUAL 7

ˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍ

2-11.Master/Slave operating mode

Fig 2-6 shows the connection of two 3301A mainframe is Master/Slave operating mode. The

connection method is shown below:

1.The Master unit of 3301A mainframe's rear panel connects the GPIB cable to the controller

(computer)

2.Use 25 pin "D" type cable to connect two 3301A mainframe (Master and Slave unit)

3.The channel number of Master / Slave operating is shown in Fig 2-7, i.e.; in the Master

unit from left to right:ch1, ch2, ch3 and ch4, and in Slave unit from left to right: ch5,

ch6, ch7 and ch8 respectively.

4.Please disconnect the 25 pin "D" type cable when Master / Slave operating mode is not used.

CH1 CH2 CH3 CH4 CH1 CH2 CH3 CH4

COMPUTER

GPIB CABLE DC LOAD

MASTER SLAVE

D-SUB 25Pin

CABLE DC LOAD

Figure 2-6 The channel number of Master/Slave operation

8 PRODIGIT

ˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍ

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

CABLE

DATA5

DATA6

DATA7

DATA8

CLK5

CLK6

CLK7

CLK8

CONTROL

MASTER/SLAVE

STATIC LOAD

D-SUB 25P Con.

MASTER/SLAVE

STATIC LOAD

D-SUB 25P Con.

TO

SELECTOR TO

SELECTOR

TO DETECTOR

NC

NC

NC

NC

NC

NC

NC

NC

Figure 2-7 25PIN 〝D〞type cable

3301A MAINFRAME OPERATION MANUAL 9

ˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍ

Chapter 3 Mainframe operation

The front panel of 3301A mainframe is shown in Fig 3-1.

MAINFRAME

ELECTRONIC LOAD

3301A

POWER

SLAVE

1

0

PROT

REM

OTP

LOAD

LOADELECTRONIC

3320 60V

DC 30A,150W

PRODIGIT

INSTRUMENT PROFESSIONAL

SLOWMID.FAST

OFF

ON

OFF

ON

I

- DC INPUT +

SENSEMONITOR V

I

F.S. 10V

II

RATE

SLEW

RANGE SHORT

LOAD PRES

SLOWMID.FAST

OFF

ON

OFF

ON

I

- DC INPUT +

SENSEMONITOR VI

F.S. 10V

II

RATE

SLEW

RANGE SHORT

LOAD PRES

PRODIGIT

INSTRUMENT PROFESSIONAL

300W60A,

DC 60V

3321

ELECTRONICLOAD

LOAD

OTP

REM

PROT V

A

PRODIGIT

INSTRUMENT PROFESSIONAL

300W10A,

DC 250V

3322

ELECTRONICLOAD

LOAD

OTP

REM

PROT V

A

PRODIGIT

INSTRUMENT PROFESSIONAL

300W10A,

DC 250V

3322

ELECTRONICLOAD

LOAD

OTP

REM

PROT V

A

SLOWMID.FAST

OFF

ON

OFF

ON

I

- DC INPUT +

SENSEMONITOR V

I

F.S. 10V

II

RATE

SLEW

RANGE SHORT

LOAD PRES

SLOWMID.FAST

OFF

ON

OFF

ON

I

- DC INPUT +

SENSEMONITOR VI

F.S. 10V

II

RATE

SLEW

RANGE SHORT

LOAD PRES

STATE:

STORE 1 234 5

Figure 3-1 3301A front panel

3-1.Feet stands

There are four feet which are located in each corner of the 3301A bottom plate.

The two feet on the front panel side are equipped with stainless tilt stands, you can pull up

the tilt stands to provide a good view angle of the 3320 series Electronic load module in the

manual operation.

3-2.Power switch

Before connecting AC power to the 3301A mainframe, make sure the power source matches the

power requirements of the 3301A Electronic load mainframe (as mark on the rear panel) Power

switch turns 3301A mainframe and 3320 series Electronic load module ON or OFF, when the 3301A

mainframe is first turn ON, the 3301A mainframe and 3320 series Electronic load module's front

panel status is indicated with the following configuration.

3301A: 1.Local manual operation mode.

2.STORE / RECALL:No function;3320 series Electronic load is in power on initial

state.

3320 : 1.Load OFF

2.Preset OFF

3.Range I

4.Short OFF

5.Slew rate:SLOW

6.Load current level:OA

10 PRODIGIT

ˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍ

3-3.STORE/RECALL operation

The six function keys on the front panel of 3301A mainframe are designed for high testing

throughput purpose. There are five operating states or testing steps can be stored in the non-

volatile memory of 3301A mainframe, each state can save or recall the load status and load

level four 3320 series Electronic load modules simultaneously.

STORE procedure:

1.Set the load status and load level from channel 1 to channel 4 respectively.

2.Press the STORE key on the 3301A mainframe, the STORE LED annuciator is flashing. (about

two times *every second)

3.Press one of the state 1-5 key, the appropriate state key's LED annuciator will be lit

immediately, the load level and status of 4 channel's 3320 load module is stored into the

non-volatile memory this time. Then, the STORE LED annuciator turn to blank, it means the

STORE procedure is completed.

Note:

1.After press the STORE key, the STORE LED annuciator will flash for 10 seconds, if the STATE 1-5

key is not pressed within this 10 seconds, the STORE LED annuciator will be blank, it indicated the

STORE process is not available now, please repeat the STORE procedure for a new STORE

operation.

2.After press the STORE LED key, then press the STORE key again, the STORE LED annuicator will

be blank, it indicate the STORE process in not available.

3.After press the STORE key, it is available and useful to operate the front panel key on the 3320

series Electronic load module.

STORE function:

Please refer Chapter section on the 3320 series Electronic load module operation manual to

more detail operating flow chart for the store and recall operation.

It can store up to 5 states of four channel's load module setting simultaneously, if you store

2 different states in the same state key, then the later state will overcome the previous

state, it acts as update the new data.

RECALL operation:

Press one of the state 1 through 5 key, the appropriate LED annuciator will be lit, the store

state on the 3301A mainframe is sending to the 4 channel's 3320 series Electronic load module

simultaneously. Before press the state key, you press any key on any channel, then the state

LED annuicator is blank immediately, it indicates the STORE state has been changed by

readjustment on the load module's front panel.

3301A MAINFRAME OPERATION MANUAL 11

ˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍ

Chapter 4 GPIB programming operation

4-1.The summary of GPIB command

Table 4-1 GPIB command listing

COMMAND FUNCTION

CHAN Channel selecting

CLE Clear to initial state

CURR Current level programming

LOAD Set load input ON OFF condition

MASTER Select Master or Slave operation mode

PRES Preset load current level to be display on DCM and

Imonitor

RANGE Select the full scale current range

RECALL Recall the store state

SHOR Set load input to short circuit

SLEW Load current slew rate control

SPEC Set the specification for each load module

STORE Store the present load state and load level

TRIG Excecute the commands which is waiting for trigger

Table 4-1 GPIB Command listing

4-2.The description of abstraction

1.SP:Space, the ASCII code is 20 Hexadecimal.

2.;:Semicolon, Program line terminator, the ASCII code is OA Hexadecimal.

3.NL:New line, Program line terminator, the ASCII code is OA Hexadecimal.

4.N:Integer number from 1 tp 8.

5.NR2:Digits with decimal point. It can be accepted in the range and formate of ##.#####.

For example:30,12345, 5.0

The description of GPIB programming command syntax.

1.{ }:The contents of the { } symbol must be used as a part or data of the GPIB command, it

can not be omitted.

2. [ ]:The contents of the [ ] symbol indicts the command can be used or not. It depends on

th testing application.

3.|:This symbol means option. For example "A|B" means it can only use A or B as the

command, it can choose only one as the setting command.

12 PRODIGIT

ˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍ

4."TRIG":The command will not be excuted immediately until the GPIB TRIG command is sent by

computer, the load level or load status are stored in the data buffer before the GPIB TRIG

command program line is excuted.

5.Terminator: You have to send the program line terminator charactor after send the GPIB

command, the available command terminator characters which can be accepted in 3301A

mainframe is listed in table 4-2.

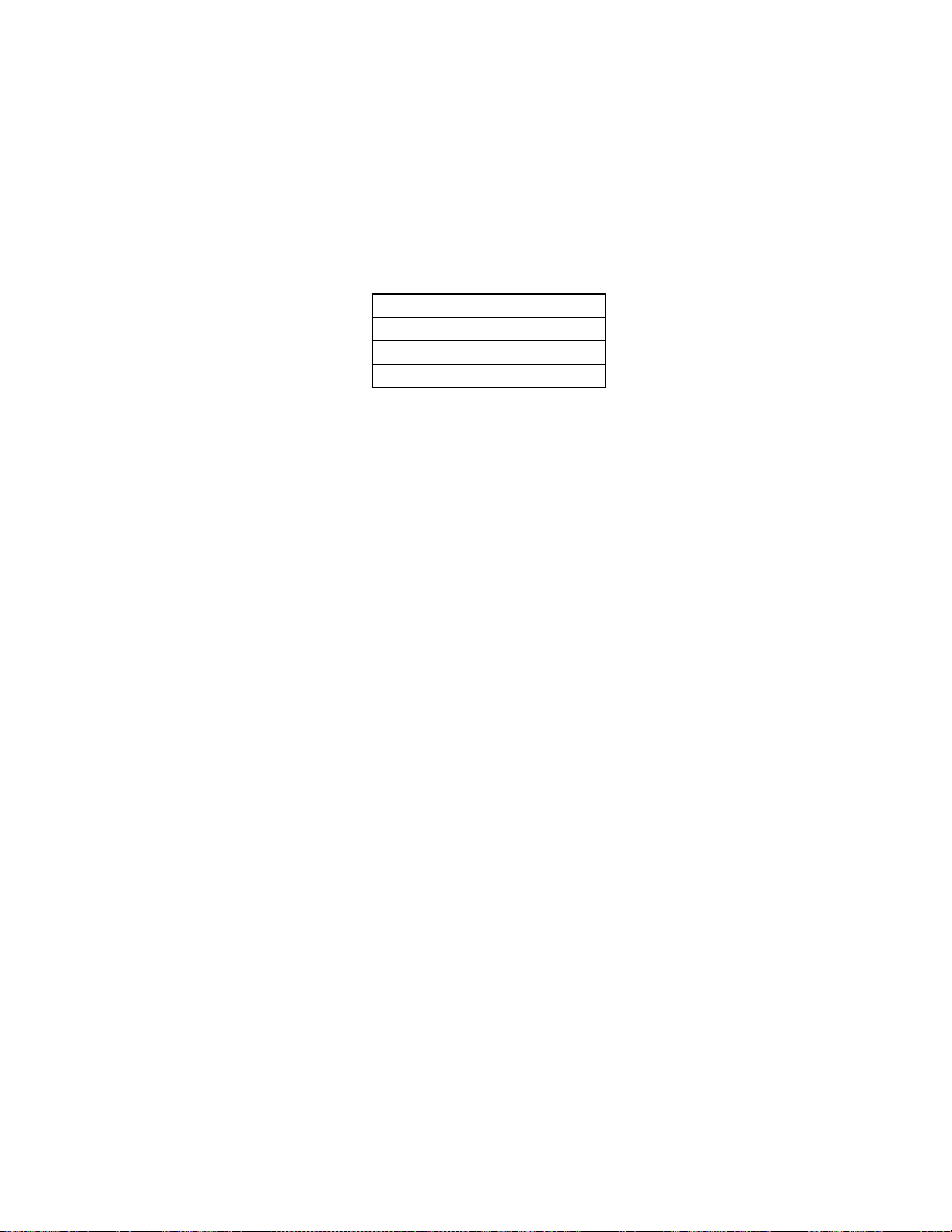

LF

LF WITH EOI

CR,LF

CR,LF WITH EOI

Table 4-2 GPIB command terminator

A terminator informs GPIB that it has reached the end of statement. Normally, this is sent

automatically by your GPIB programming statements. In this manual, the terminator is

assumed at the end of each example line of code. If it needs to be indicated, it is shown

by symbol (nl); which stand for " new line "and represents ASCII code byte the OA

Hexadecimal or 10 decimal.

6.Semicolon ";":The semicolon " ; " is a back-up command, it instructs the parser to return

to the previous colon, the semicolon allows you to combine command statement on one line to

create command message.

7.GTL : The REM LED annuciator of each load module will turn ON when the 3320 series

Electronic load module is in remote operation mode. The GTL (GO TO LOCAL) command returns

the Electronic load module to manual or front panel operation, the LED annuciator will turn

OFF as well in the manual operation mode. The ACSII code for GTL command is 01 Hexadecimal.

3301A MAINFRAME OPERATION MANUAL 13

ˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍ

4-3.GPIB command description

CHAN

Purpose :

" CHAN " selects the multiple Electronic load channel to which all subsequent channel

specific command will be directed.

Command syntax :

CHAN {SP}{N}{;NL}

Description :

" CHAN " command selects the specified Electronic load module from 1 through 8 as the

Electronic load module number. It can be installed up to 4 channels of the Electronic load

module in one mainframe or up to 8 channels of the Electronic load module if the Master /

Slave 25 pin "D" type cable is connected between two 3301A mainframe.

The load channel number is arranged as 1,2,3,4 from left hand side to the right hand side

respectively, or 1,2,3,4 for from the left hand side to the right hand side of the Master

3301A mainframe, and 5,6,7,8 for from the left hand side to the right hand side of the

Slave 3301A mainframe.

Example :

Select Channel 1

CHAN 1

Select Channel 5

CHAN 5

CLE

Purpose :

Clear to the initial state

Command syntax :

CLE{;NL}

Description :

This command clear the Electronic load's load status and load level to the initial power

ON state.

The power ON state of the 3320 Electronic load module is Load OFF Preset OFF Range I Short

OFF Slew rate:Slow Load current level OA

The CLE command does not clear or effect the data which is stored by STORE command, for the

data is stored in the non-volatile memory on the 3301A mainframe.

Example :

a.CLE

14 PRODIGIT

ˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍ

CURR

Purpose :

Constant load current setting.

Command syntax :

CURR:[:TRIG]{SP}{NR2}{;NL}

Description :

This command is used to set the load current level of 3320 series Electronic load module.

Note:

1.The load current data must include decimal point, otherwise this command is unable to excute.

2.Unit for load current is ampere.

3.Please make sure the SPEC command and range I / II command before excute the load current

setting command.

4.If the programming load current level over the maximum specification of 3320 series load module,

the full scale current will be sent to the load module.

5.The most effective load current level can be set is the fifth digit after the decimal point.

Example :

1.CURR:TRIG 10.20

2.CURR:3.0

3.CURR:5.123

LOAD

Purpose :

Turn the Electronic load module input ON or OFF.

Command syntax :

LOAD[:TRIG]{SP}{ON|OFF}{;NL}

Description :

This command sets the Electronic load to sink current from DC power source.

LOAD ON:Electronic load is ready to sink current from DC power source.

LOAD OFF:Electronic load can not sink current from DC power source.

Example :

a.LOAD ON

b.LOAD:TRIG ON

c.LOAD:TRIG OFF

3301A MAINFRAME OPERATION MANUAL 15

ˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍ

MASTER

Purpose :

Select 4 or 8 channel load modules to be controlled when Master/Slave "D" type cable is

connected between two 3301A mainframe and only one GPIB interface is used.

Command syntax :

MASTER{SP}{ON|OFF}{;NL}

Note:

Default Master OFF

Description :

MASTER ON control up to 8 channels of the Electronic load module if the Master/Slave "D"

type cable is connected on real panel of the two 3301A mainframe. At this time, the second

unit of 3301A mainframe ( it is connected by 25 pin "D" type connector only, the GPIB cable

is not connected in this unit ). SLAVE LED annuciator on the lower and right hand corner of

the 3301A mainframe is lit, and the REM LED annuciator of each load module is lit also to

indication remote programming operation.

MASTER OFF controls up to 4 channels of the Electronic load module in 3301A mainframe.

Example :

Master ON; Control channel 5 - channel 8 of another slave 3301A mainframe.

PRES

Purpose :

Set the 4 1/2 digit current Meter to display the programming load current level.

Command syntax :

PRES[:TRIG]{SP}{ON|OFF}{;NL}

Description :

The PRESET ON command set the 4 1/2 DCM and Imonitor BNC output to display or output the

programming load current level.

PRES OFF Command set the 4 1/2 DCM to display the actual load current which current is down

through the load input, and the Imonitor BNC output signal is proportional to the actual

load current.

Example :

a.PRES ON

b.PRES OFF

c.PRES:TRIG ON

16 PRODIGIT

ˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍ

RANG

Purpose :

Select the operating full scale current range.

Command syntax :

RANG{SP}{1|2}{;NL}

Description :

This command selects the full scale current range of the Electronic load. There are two

full scale current range for each 3320 series Electronic load module. Table 4-3 shows the

range I/II full scale current for each 3320 series load module.

When RANG command is excuted, the values of the current level are adjusted as follow:

1.IF the existing current setting is within the new range. Then the current level does not

change.

2.IF the existing current is setting in not within the new range. Then the current level

is set to the maximum of new range.

The maximum load current level is shows in table 4-3.Table 4-3 maximum full scale

current level for each module.When the programming load level setting is greater than

the maximum current level of each range of each module, then the load current will

adjust to the maximum current level which is listed in table 4-3.

MODEL 3320 3321 3322 3323 3324 3325

RANGE I 3.072 6.142 1.024 1.024 0.511 1.535

RANGE II 30.72 61.42 10.24 10.24 5.11 15.36

Table 4-3 Maximun load current level

RECALL

Purpose :

Recall the state of load level and load status which is stored by GPIB STORE command.

Command syntax :

RECALL{SP}{1|2|3}{;NL}

Description :

This command is used to recall the non-volatile memory state which is stored into the

memory by GPIB store command, up to 5 states can be recalled.

Example :

a.RECALL 1

b.RECALL 4

SHOR

3301A MAINFRAME OPERATION MANUAL 17

ˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍˍ

Purpose :

Short the DC input of Electronic load.

Command syntax :

SHOR[:TRIG]{SP}{ON|OFF}{;NL}

Description :

This command applies the short across the input of the Electronic load. The maximum short

resistance is 0.03, 0.02 and 0.04 ohms for 3320, 3321 and 3322 Electronic load module

respectively.Excuting SHOR does not effect any programmed settings and the Electronic load

will return to them when the short is removed.

Example :

a.SHOR ON

b.SHOR OFF

c.SHOR:TRIG ON

SLEW

Purpose :

SET the slew rate of load current change.

Command syntax :

SLEW{SP}{1|2}{;NL}

Description :

This command selects the load current slew rate SLOW, MIDDLE and FAST with its code 1, 2

and 3 respectively. The code for each slew rate is shown in Table 4-4.For detail load

current slew rate for SLOW, MIDDLE, FAST, and each model of 3320 series Electronic load

module, please refer the 3320 series Electronic load operation manual. Table 4-4 slew rate

code for SLOW, MID, AND FAST.

SLEW RATE CODE

SLOW 1

MIDDLE 2

FAST 3

Table 4-4 Slew rate code for SLOW, MID, and FAST

Example :

a.SLEW 1

b.SLEW 2

c.SLEW 3

Table of contents

Other Prodigit Motherboard manuals