Prodigy Powder Spray Gun User manual

Prodigyr

Manual Powder Spray Guns

Customer Product Manual

Part 1053680E05

Issued 6/07

NORDSON CORPORATION •AMHERST, OHIO •USA

For parts and technical support, call the

Finishing Customer Support Center at (800) 433-9319.

This document is available on the Internet at http://emanuals.nordson.com/finishing

C

APPROVED

US

FM

Part 1053680E05 E2007 Nordson Corporation

Table of Contents

Safety 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Qualified Personnel 1. . . . . . . . . . . . . . . . . . . . . . . . .

Intended Use 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Regulations and Approvals 1. . . . . . . . . . . . . . . . . .

Personal Safety 1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fire Safety 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Grounding 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Aggressive Substances 2. . . . . . . . . . . . . . . . . . . . .

Action in the Event of a Malfunction 3. . . . . . . . . . .

Disposal 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Features 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air Quality Requirements 6. . . . . . . . . . . . . . . . . . . .

Equipment Rating 6. . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ATEX Special Condition For Safe Use: 7. . . . . . . . .

Operation 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Presets 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gun ON LED 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pattern Control Trigger 7. . . . . . . . . . . . . . . . . . . . . .

Maintenance 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Nozzle Disassembly and Cleaning 8. . . . . . . . . . . .

Troubleshooting 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Continuity and Resistance Tests 11. . . . . . . . . . . . . .

Multiplier and Resistor Assembly

Resistance Test 11. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Resistance Test - Control Cable End

to Adapter Spring Plunger 11. . . . . . . . . . . . . . . .

Resistance Test Using the Optional

Shorting Plug 11. . . . . . . . . . . . . . . . . . . . . . . . . . .

Resistor Resistance Test 12. . . . . . . . . . . . . . . . .

Control Cable Continuity Tests 12. . . . . . . . . . . . . . .

Trigger Switch Continuity Test 13. . . . . . . . . . . . . . . .

Repair 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Nozzle and Powder Tube Replacement 14. . . . . . .

Control Cable Replacement 14. . . . . . . . . . . . . . . . .

Resistor and Electrode Replacement 15. . . . . . . . . .

Resistor and Electrode Removal 15. . . . . . . . . . .

Resistor and Electrode Installation 16. . . . . . . . .

Multiplier Replacement 17. . . . . . . . . . . . . . . . . . . . . .

Removal 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Assembly 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Prodigy Manual Spray Gun - Standard Length 18.

Prodigy Manual Spray Gun - Short Length 20. . . .

Service Kits 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Options 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Powder and Air Tubing 24. . . . . . . . . . . . . . . . . . . . . .

Conical Nozzles 23. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Conical Nozzle Components 23. . . . . . . . . . . . . .

Flat Spray, Cross, and Pinpoint Nozzles 24. . . . . . .

Flat Spray, Cross, and

Pinpoint Nozzle Components 25. . . . . . . . . . . . . .

Contact Us

Nordson Corporation welcomes requests for information, comments, and

inquiries about its products. General information about Nordson can be

found on the Internet using the following address:

http://www.nordson.com.

Address all correspondence to:

Nordson Corporation

Attn: Customer Service

555 Jackson Street

Amherst, OH 44001

Notice

This is a Nordson Corporation publication which is protected by copyright.

Original copyright date 2004. No part of this document may be

photocopied, reproduced, or translated to another language without the

prior written consent of Nordson Corporation. The information contained

in this publication is subject to change without notice.

Trademarks

Prodigy, HDLV, Nordson, and the Nordson logo are registered trademarks

of Nordson Corporation.

Viton is a registered trademark of DuPont Dow Elastomers. L.L.C.

ProdigyrManual Powder Spray Gun 1

Part 1053680E05

E2007 Nordson Corporation

ProdigyrManual Powder Spray Gun

Safety

Read and follow these safety instructions. Task-

and equipment-specific warnings, cautions, and

instructions are included in equipment

documentation where appropriate.

Make sure all equipment documentation, including

these instructions, is accessible to all persons

operating or servicing equipment.

Qualified Personnel

Equipment owners are responsible for making sure

that Nordson equipment is installed, operated, and

serviced by qualified personnel. Qualified

personnel are those employees or contractors who

are trained to safely perform their assigned tasks.

They are familiar with all relevant safety rules and

regulations and are physically capable of

performing their assigned tasks.

Intended Use

Use of Nordson equipment in ways other than

those described in the documentation supplied with

the equipment may result in injury to persons or

damage to property.

Some examples of unintended use of equipment

include

Susing incompatible materials

Smaking unauthorized modifications

Sremoving or bypassing safety guards or

interlocks

Susing incompatible or damaged parts

Susing unapproved auxiliary equipment

Soperating equipment in excess of maximum

ratings

Regulations and Approvals

Make sure all equipment is rated and approved for

the environment in which it is used. Any approvals

obtained for Nordson equipment will be voided if

instructions for installation, operation, and service

are not followed.

All phases of equipment installation must comply

with all federal, state, and local codes.

Personal Safety

To prevent injury follow these instructions.

SDo not operate or service equipment unless you

are qualified.

SDo not operate equipment unless safety

guards, doors, or covers are intact and

automatic interlocks are operating properly. Do

not bypass or disarm any safety devices.

SKeep clear of moving equipment. Before

adjusting or servicing any moving equipment,

shut off the power supply and wait until the

equipment comes to a complete stop. Lock out

power and secure the equipment to prevent

unexpected movement.

SRelieve (bleed off) hydraulic and pneumatic

pressure before adjusting or servicing

pressurized systems or components.

Disconnect, lock out, and tag switches before

servicing electrical equipment.

STo prevent injury, be aware of less-obvious

dangers in the workplace that often cannot be

completely eliminated, such as hot surfaces,

sharp edges, energized electrical circuits, and

moving parts that cannot be enclosed or

otherwise guarded for practical reasons.

SObtain and read Material Safety Data Sheets

(MSDS) for all materials used. Follow the

manufacturer’s instructions for safe handling

and use of materials, and use recommended

personal protection devices.

ProdigyrManual Powder Spray Gun

2

Part 1053680E05 E2007 Nordson Corporation

Fire Safety

To avoid a fire or explosion, follow these

instructions.

SDo not smoke, weld, grind, or use open flames

where flammable materials are being used or

stored.

SProvide adequate ventilation to prevent

dangerous concentrations of volatile materials

or vapors. Refer to local codes or your material

MSDS for guidance.

SDo not disconnect live electrical circuits while

working with flammable materials. Shut off

power at a disconnect switch first to prevent

sparking.

SKnow where emergency stop buttons, shutoff

valves, and fire extinguishers are located. If a

fire starts in a spray booth, immediately shut off

the spray system and exhaust fans.

SClean, maintain, test, and repair equipment

according to the instructions in your equipment

documentation.

SUse only replacement parts that are designed

for use with original equipment. Contact your

Nordson representative for parts information

and advice.

Grounding

WARNING: Operating faulty

electrostatic equipment is hazardous and

can cause electrocution, fire, or

explosion. Make resistance checks part

of your periodic maintenance program. If

you receive even a slight electrical shock

or notice static sparking or arcing, shut

down all electrical or electrostatic

equipment immediately. Do not restart

the equipment until the problem has

been identified and corrected.

Grounding inside and around the booth openings

must comply with NFPA requirements for Class II,

Division 1 or 2 Hazardous Locations. Refer to

NFPA 33, NFPA 70 (NEC articles 500, 502, and

516), and NFPA 77, latest conditions.

SAll electrically conductive objects in the spray

areas shall be electrically connected to ground

with a resistance of not more than 1 megohm

as measured with an instrument that applies at

least 500 volts to the circuit being evaluated.

SEquipment to be grounded includes, but is not

limited to, the floor of the spray area, operator

platforms, hoppers, photoeye supports, and

blow-off nozzles. Personnel working in the

spray area must be grounded.

SThere is a possible ignition potential from the

charged human body. Personnel standing on a

painted surface, such as an operator platform,

or wearing non-conductive shoes, are not

grounded. Personnel must wear shoes with

conductive soles or use a ground strap to

maintain a connection to ground when working

with or around electrostatic equipment.

SOperators must maintain skin-to-handle contact

between their hand and the gun handle to

prevent shocks while operating manual

electrostatic spray guns. If gloves must be

worn, cut away the palm or fingers, wear

electrically conductive gloves, or wear a

grounding strap connected to the gun handle or

other true earth ground.

SShut off electrostatic power supplies and

ground gun electrodes before making

adjustments or cleaning powder spray guns.

SConnect all disconnected equipment, ground

cables, and wires after servicing equipment.

Aggressive Substances

If the equipment is likely to come into contact with

aggressive substances, then it is the responsibility

of the user to take suitable precautions that prevent

it from being adversely affected, thus ensuring that

the type of protection provided by the equipment is

not compromised.

Aggressive substances: e.g. acidic liquids or

gases that may attack metals, or solvents that may

affect polymeric materials.

Suitable precautions: regular check as part of

routine inspections or establishing from the

material’s data sheets that it is resistant to specific

chemicals.

Please contact Nordson Corporation if you are

concerned or unsure about the suitability of the

product with relation to coming into contact with

particularly aggressive substances.

ProdigyrManual Powder Spray Gun 3

Part 1053680E05

E2007 Nordson Corporation

Action in the Event of a Malfunction

If a system or any equipment in a system

malfunctions, shut off the system immediately and

perform the following steps:

SDisconnect and lock out electrical power. Close

pneumatic shutoff valves and relieve pressures.

SIdentify the reason for the malfunction and

correct it before restarting the equipment.

Disposal

Dispose of equipment and materials used in

operation and servicing according to local codes.

Description

The Prodigy Manual Powder Spray Guns use

specially designed conical and flat-spray nozzles to

atomize, shape, and spray dense-phase powder

delivered by Nordson HDLVr(high-density powder,

low-velocity air) pumps.

The spray gun is available in a standard length and

a short length.

Features

S8-mm tubing used for powder delivery

SSeparate high voltage and powder paths.

SSpecial pattern control trigger toggles between

user-programmable high and low pattern air

and powder flows.

SShipped with a 70_conical nozzle and a

dual-slot flat-spray nozzle. Optional conical, flat

spray, cross, and pinpoint nozzles are available.

SUser-friendly controller with LCD display.

SUp to 10 user-programmable coating recipes.

1

2

3

45

6

78

9

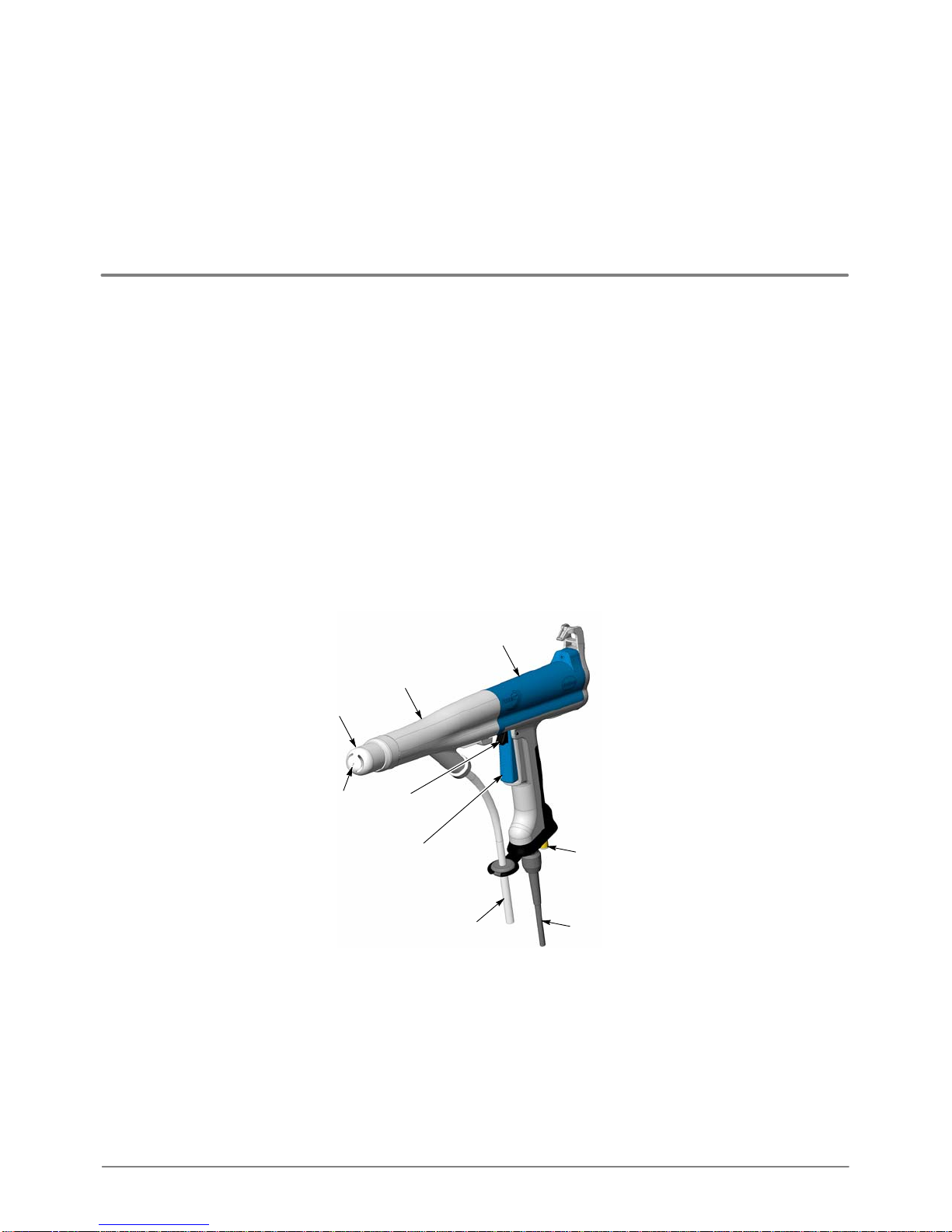

Figure 1 Prodigy Manual Powder Spray Gun

1. Gun body

2. Adapter

3. Conical nozzle

4. Nozzle electrode

5. Pattern control trigger

6. Trigger

7. Powder tubing (8 mm)

8. Control cable

9. Pattern air fitting (6 mm)

Note: Powder and pattern air tubing are not shipped with the spray gun. Tubing is included in manual gun systems.

ProdigyrManual Powder Spray Gun

4

Part 1053680E05 E2007 Nordson Corporation

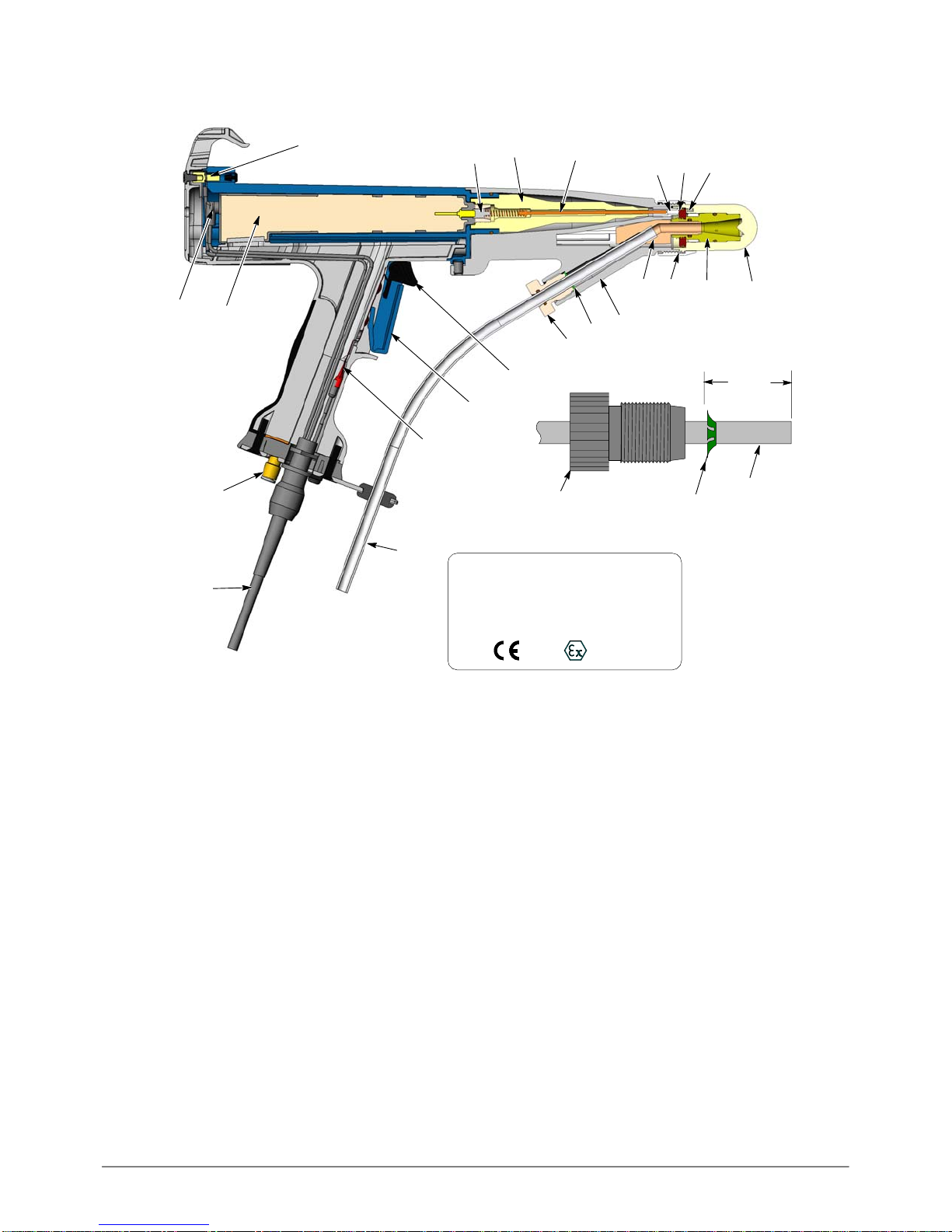

Description (contd)

1

23

22

54

76

8

9

10

11

15

21

18

12

17

16

13

14

19

2

20

1/2in.

18 19 14

24

3

PRODIGY

NORDSON CORPORATION

SIRA05ATEX5212X EEx 2mJ

1180 II 2D

Figure 2 Standard Length Spray Gun Section View

1. Nozzle electrode*

2. Nozzle electrode ring*

3. Spring plunger

4. Electrode

5. Electrode holder

6. Resistor

7. Resistor holder

8. Contact spacer

9. Voltage multiplier

10. Ground stud

11. Cable/multiplier connection

12. 6-mm tube fitting (pattern air)

13. Control cable

14. 8-mm powder tubing

15. Switch keypad

16. Spray trigger

17. Pattern control trigger

18. Lock knob

19. Grip ring

20. Adapter

21. Powder tube

22. Retainer nut

23. Nozzle Insert*

24. Nozzle*

Note: Parts marked with an asterisk (*) are part of the nozzle assembly. Powder and pattern air tubing are included with

manual gun systems only.

ProdigyrManual Powder Spray Gun 5

Part 1053680E05

E2007 Nordson Corporation

PRODIGY

NORDSON CORPORATION

SIRA05ATEX5212X EEx 2mJ

1180 II 2D

23

22

76

8

10

15

21

18

12

17

16

13

14

19 20

18 14

24

11 9

1/2in.

19

1

2

3

Figure 3 Short Length Spray Gun Section View

Note: Use the legend from Figure 2 for the numbered components.

ProdigyrManual Powder Spray Gun

6

Part 1053680E05 E2007 Nordson Corporation

Specifications

Specifications are subject to change without notice.

Electrical Output

Maximum rated output voltage at the electrode: 95 kV ±10%

Maximum rated output current at the electrode: 100 µA ±10%

Air Pressure and Flow Requirements

Minimum input air: 4 bar (60 psi)

Maximum input air: 6.9 bar (100 psi)

Pattern air: 5.9 bar (85 psi), 6-57 l/min. (0.2-2.0 scfm)

Temperature Requirements

Maximum ambient temperature 40 _C (104 _F)

Air Quality Requirements

Powder spray systems require clean, dry, oil-free

compressed air. Moist or oil-contaminated air can

cause the powder to clog in the pump, powder feed

tubing, or spray gun.

Use 3-micron filter/separators with automatic drains

and a refrigerated or regenerative desiccant-type

air dryer that can produce a 3.4 _C (38 _F) or lower

dewpoint at 6.9 bar (100 psi).

Equipment Rating

This applicator is rated for use in a potentially

explosive environment: Class II, Division I, Group

F & G, Zone 21 or Zone 22.

Installation

WARNING: Allow only qualified

personnel to perform the following tasks.

Follow the safety instructions in this

document and all other related

documentation.

WARNING: Installation in Europe shall

carried out by suitably trained personnel

in accordance with the applicable code of

practice. EN60079-14

See Figure 2.

1. Connect the control cable (13) to the gun

controller receptacle labeled GUN and tighten

the cable nut securely.

NOTE: Refer to page 22 for optional

four-meter extension cables. Do not use more

than two extension cables.

NOTE: Powder and pattern air tubing are supplied

only with manual gun systems or can be ordered

separately. Refer to page 22 for tubing part

numbers.

2. Connect blue 6-mm pattern air tubing from the

appropriate pattern air outlet fitting on the pump

control cabinet to the tube fitting (12) on the

gun handle.

3. Use a tubing cutter to cut the 8-mm powder

delivery and suction tubing to the desired

lengths. The ends must be square. Refer to

page 22 for an optional tubing cutter.

Delivery tubing (pump to gun)

Minimum length: 9 m (30 ft)

Maximum length: 32 m (75 ft)

Suction tubing (pump to powder supply)

Minimum length: 1 m (3.5 ft)

Maximum length: 3.65 m (12 ft)

4. Push one end of the powder delivery tubing

through the grommet in the tubing bracket, then

install the lock knob (18) on the tubing (14).

5. Install a grip ring (19) 12.7-mm (1/2-in.) from the

end of the delivery tubing.

ProdigyrManual Powder Spray Gun 7

Part 1053680E05

E2007 Nordson Corporation

Installation (contd)

6. Push the delivery tubing into the adapter (20)

until it bottoms out against the powder tube

(21). Thread the lock knob into the adapter and

finger-tighten it until snug.

7. Route the delivery tubing to the appropriate

powder pump. Remove the outlet fitting (rear

fitting) and O-ring and install them on the

tubing, then screw the fitting back onto the

pump.

8. Connect suction tubing as described in the

powder pump manual or Color-on-Demand

installation manual.

9. Use cable ties or spiral-cut tube wrap to bundle

together the gun control cable, pattern air

tubing, and powder tubing.

ATEX Special Condition For Safe Use:

This applicator shall only be used with the Prodigy

Manual Controller.

Operation

WARNING: This equipment can be

dangerous unless it is used in

accordance with the rules laid down in

this manual.

All gun functions are set and controlled by the

manual gun controller.

Presets

A preset is a group of spray settings. The gun

controller provides 10 presets. Use the presets to

save optimal spray settings for parts with different

features.

Gun ON LED

The LED on the end plate lights when the spray

trigger is pulled and high voltage is generated.

Pattern Control Trigger

The pattern control trigger toggles between the

preset settings (High mode) and the Low mode

settings. Use it to change the pattern air and

powder flow as needed when part features change.

When in Low mode, a down-pointing arrow (⇓) is

appears to the right of the gun icon.

NOTE: If you change presets while spraying in

Low mode, the controller immediately switches to

High mode, spraying with the new preset settings.

Maintenance

WARNING: Inspection and maintenance

of this equipment in Europe shall carried

out by suitably trained personnel in

accordance with the applicable code of

practice. EN60079-17

Daily: Blow off the gun exterior with low-pressure

compressed air and wipe it clean with a soft cloth.

Weekly: Manually perform a hard purge, then

remove the retaining nut, nozzle, and powder tube.

Inspect the powder tube and nozzle for wear.

Replace any worn parts.

Periodically: Check the resistance of the voltage

multiplier and resistor with a megohm meter as

described in Continuity and Resistance Checks on

page 11. Replace any components that do not

meet the specifications.

As Required: Disassemble the nozzle and clean

the internal parts. Replace any worn parts. Refer

to Nozzle Disassembly and Cleaning on the

following page for instructions.

ProdigyrManual Powder Spray Gun

8

Part 1053680E05 E2007 Nordson Corporation

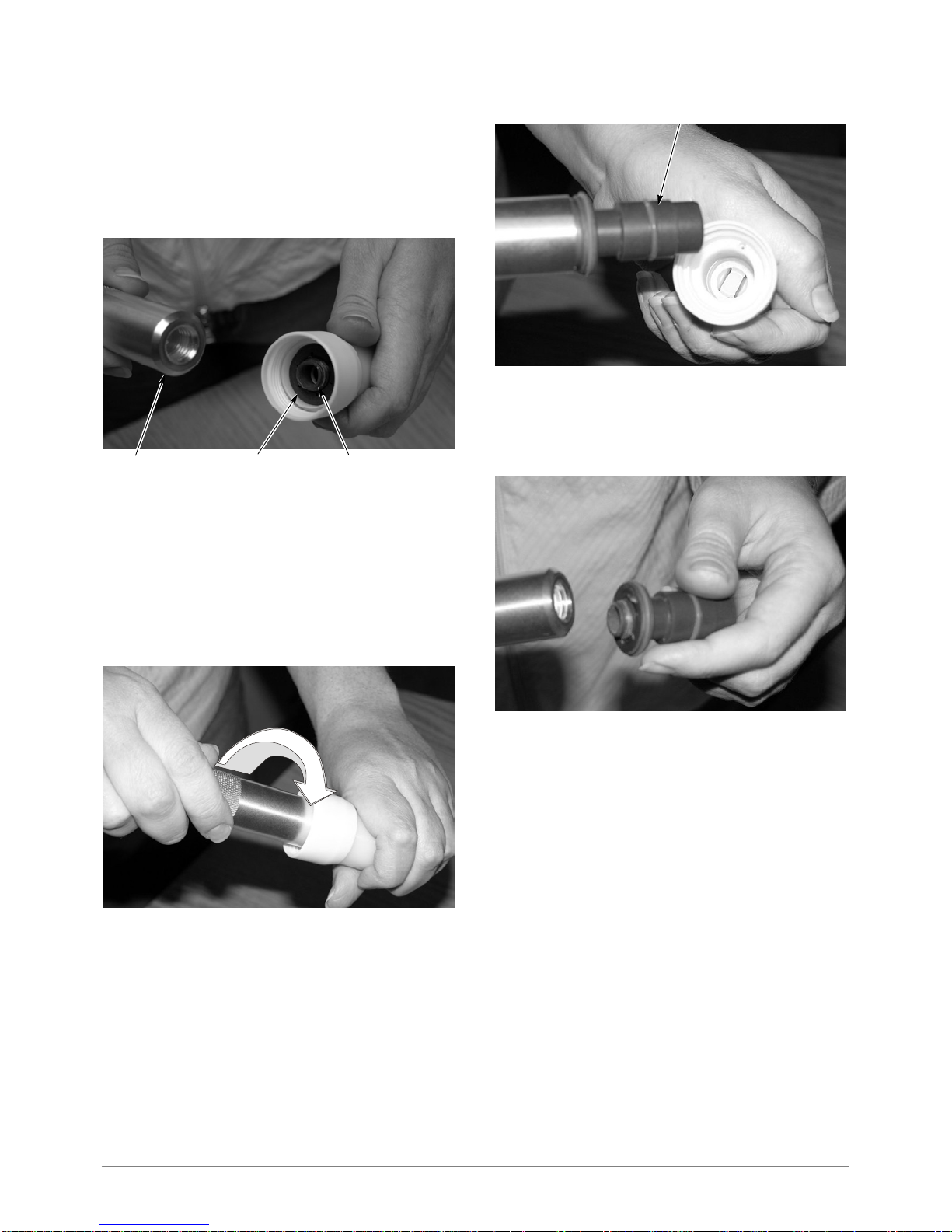

Nozzle Disassembly and Cleaning

Requirements: Nozzle Tool 1073682

1. Hold the nozzle firmly in one hand. Thread the

tool onto the threaded end of the insert until it

bottoms out on the electrode ring.

Insert

Electrode Ring

Tool

Figure 4 Nozzle Disassembly Step 1 (Shown with Nut

Installed)

2. Turn the tool clockwise while pulling on it until

the electrode ring/insert assembly comes out of

the nozzle.

NOTE: If the electrode is pulled out of the nozzle

shell, be careful to not lose it. The dual slot nozzle

has the electrode glued in.

Figure 5 Nozzle Disassembly Step 2A

Electrode Ring/Insert Assembly

Figure 6 Nozzle Disassembly Step 2B (New Style

Assembly Shown)

3. Unscrew the tool from the electrode ring/insert

assembly and blow off the assembly with

compressed air.

Figure 7 Nozzle Disassembly Step 3 (New Style

Shown)

4. Place the nozzle and nozzle nut in an ultrasonic

cleaner to remove any impact fusion, then blow

them off with compressed air. If desired,

remove the nozzle nut from the nozzle by

sliding the nut forward then turning it clockwise

to unscrew it.

NOTE: See Figure 9. Old style nozzles have a

disk-shaped filter (3) installed on the outside of the

insert (6) and held on by the electrode ring (2).

New style nozzles have a conical filter that is

installed inside the front end of the insert. The old

style filter and insert are obsolete. if you are

replacing the filter on an old style nozzle, you must

also order a new insert. The new filters are

available in quantities of 10.

ProdigyrManual Powder Spray Gun 9

Part 1053680E05

E2007 Nordson Corporation

5. Blow off the insert and filter. If the filter is

clogged with powder, remove it and replace it

with a new one. When removing the new style

filter from the insert, be careful not to scratch

the inside surface of the insert.

To re-assemble the nozzle:

1. Make sure the electrode ring is threaded all the

way onto the insert.

2. Thread the tool onto the threaded end of the

insert.

3. Turn the tool counterclockwise to remove it

from the insert. Check the nozzle. The

electrode ring should be approximately 1/4inch

inside the nozzle lip.

Electrode Ring

Nozzle Lip

Figure 8 Nozzle Re-assembly

7

6

5

4

3

2

1

OLD STYLE NOZZLE COMPONENTS

12

3

45

7

6

NEW STYLE NOZZLE COMPONENTS

8

8

Figure 9 Internal Components of Nozzle Assemblies

1. O-ring

2. Electrode ring

3. Filter

4. O-ring

5. O-ring

6. Insert

7. Electrode

8. Nozzle shell

Note: All internal components, except the electrodes, are the same for all nozzles. For flat-spray, cross, and pinpoint

nozzles, the electrode is glued into the nozzle shell with epoxy and cannot be replaced separately.

ProdigyrManual Powder Spray Gun

10

Part 1053680E05 E2007 Nordson Corporation

Troubleshooting

WARNING: Allow only qualified

personnel to perform the following tasks.

Follow the safety instructions in this

document and all other related

documentation.

These procedures cover only the most common

problems that you may encounter. If you cannot

solve the problem with the information given here,

contact your local Nordson representative for help.

Problem Possible Cause Corrective Action

1. Unsteady or

inadequate powder

flow

Problem with powder pump Refer to pump manual for

troubleshooting.

Blockage in powder tubing Perform a hard purge to clear tubing.

Replace tubing if partially or

completely blocked.

Plugged nozzle Remove nozzle and clean.

2. Uneven pattern Insufficient pattern air flow Increase pattern air flow.

Worn powder tube Remove powder tube from gun and

check for worn passageway.

3. Loss of wrap, poor

transfer efficiency Low electrostatic voltage Increase the electrostatic voltage (kV

or µA setting).

Poorly grounded parts Check the conveyor chain, rollers,

and part hangers for powder buildup.

The resistance between the parts

and ground must be 1 megohm or

less. For best results, 500 ohms or

less is recommended.

Poor connection in high voltage

path inside spray gun Perform the Multiplier and Resistor

Assembly Resistance Tests on

page 11.

Fault in controller Refer to Troubleshooting in the gun

controller manual.

4. No kV output from the

spray gun (LED on

the spray gun does

not light)

Damaged control cable Perform the control cable continuity

tests on page 12.

If an open or short is found, replace

the cable.

Fault in controller Refer to Troubleshooting in the gun

controller manual.

5. No kV output from the

spray gun (LED on

the spray gun lights)

Faulty voltage multiplier or poor

connection in high voltage path

inside spray gun

Perform the resistance tests on

page 11.

Check all high voltage path

connections.

6. No kV output and no

powder output Faulty trigger switch or control

cable Perform the control cable continuity

tests on page 12, and the trigger

switch test on page 13.

Faulty controller wiring harness Check the wiring between the GUN

receptacle and the circuit board.

Faulty controller circuit board Check the circuit board as described

in the controller manual.

ProdigyrManual Powder Spray Gun 11

Part 1053680E05

E2007 Nordson Corporation

Continuity and Resistance Tests

WARNING: Turn off the electrostatic

voltage and ground the spray gun

electrode before performing the following

tasks. Failure to observe this warning

could result in a severe shock.

Use the following tests to isolate problems with the

voltage multiplier or resistor, control cable, and

trigger switch.

Multiplier and Resistor Assembly

Resistance Test

Resistance tests must be made with a 500 volt

megohm meter.

CAUTION: Short together the three pins

in the multiplier receptacle, or the

designated pins in the control cable,

before testing the continuity and

resistance of the

multiplier/resistor/electrode assembly. If

not shorted, the multiplier could be

damaged.

Use the optional shorting plug shown in Figure 11

when testing resistance from the multiplier

receptacle to the adapter spring plunger. Refer to

Options in Parts for the shorting plug part number.

Resistance Test - Control Cable End to

Adapter Spring Plunger

1. See Figure 10. Remove the nozzle.

2. Disconnect the control cable from the manual

control unit.

3. Short together cable connector pins J1-2, J1-3,

and J1-4 and connect them to the positive

megohm meter probe.

4. Connect the negative megohm meter probe to

the adapter spring plunger.

The megohm meter reading should be

350-420 megohms. If the reading is out of this

range, test the resistor separately. If the resistor

passes the test, replace the multiplier.

Pin 2 Pin 3

Pin 4

350-420

megohms

Figure 10 Cable End to Spring Plunger Test

Resistance Test Using the

Optional Shorting Plug

1. See Figure 11. Remove the end cap and

nozzle from the spray gun.

2. Disconnect the multiplier connector from the

multiplier receptacle.

3. Connect the shorting plug connector to the

multiplier receptacle.

4. Connect the megohm meter positive probe to

the shorting plug ring-tong terminal and the

negative probe to the spring plunger. (If the

reading is infinite, switch the probes).

5. The megohm meter should read

350-420 megohms. If the reading is out of this

range, test the resistor separately. If the

resistor passes the test, replace the multiplier.

ProdigyrManual Powder Spray Gun

12

Part 1053680E05 E2007 Nordson Corporation

Resistance Test Using the Optional Shorting Plug (contd)

Shorting Plug

350-420

megohms

Figure 11 Test with Shorting Plug

Resistor Resistance Test

1. Remove the resistor/electrode assembly as

described in Resistor and Electrode

Replacement on page 15.

2. See Figure 12. Connect the megohm meter

probes to the resistor spring and electrode

spring.

The megohm meter reading should be

153-187 megohms. If it is out of this range,

replace the resistor. If it is within this range, but the

multiplier/resistor resistance check was out of

range, replace the multiplier.

153-187

megohms

Figure 12 Resistor Resistance Test

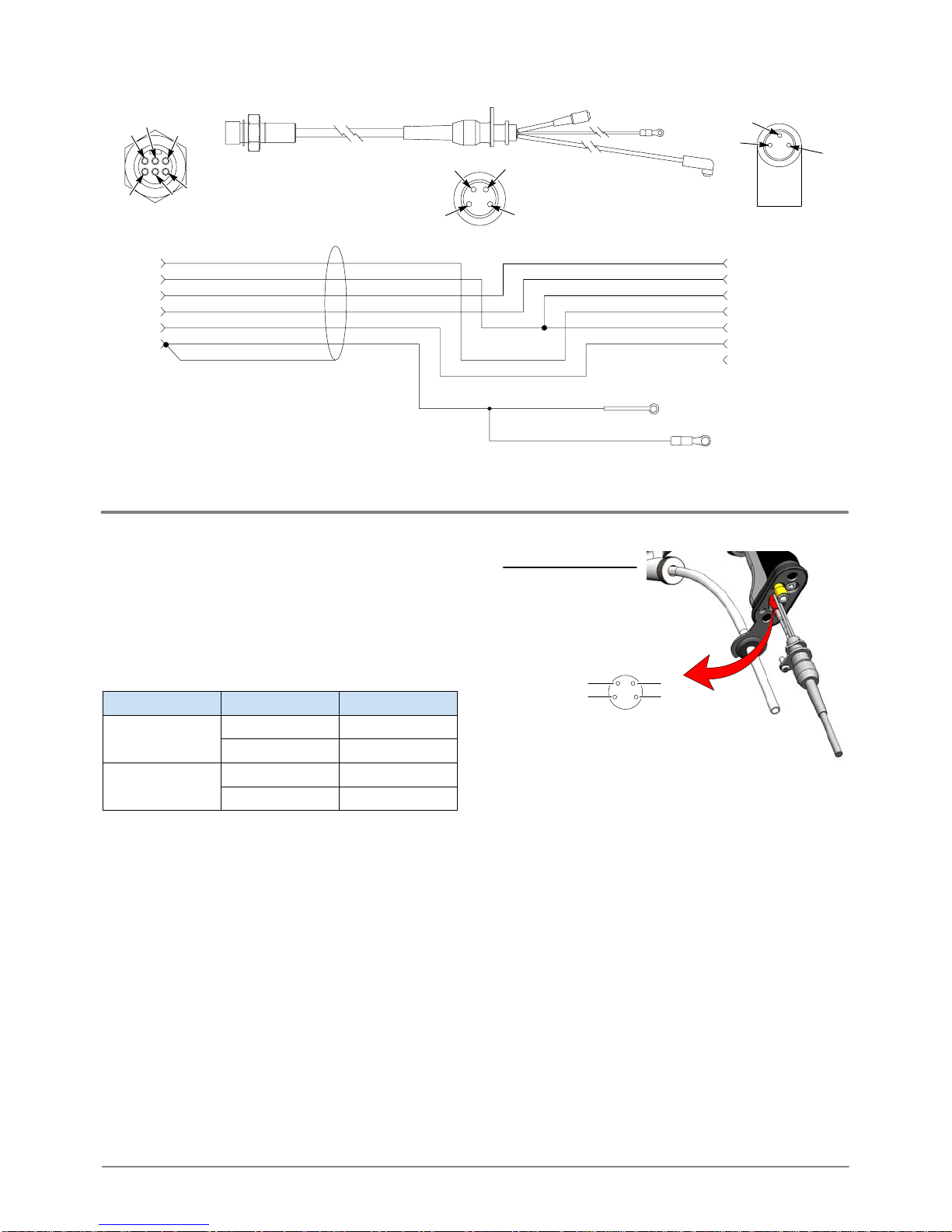

Control Cable Continuity Tests

Make continuity tests with a standard ohmmeter.

Use the following table and Figure 13.

NOTE: The first two tests in the following table can

be made by disconnecting the cable from the

manual control unit. All other tests require

disconnecting the J2, J3, and ground connectors

from the gun as described in Cable Replacement

on page 14.

Test for continuity between:

J1 pins 1 and 2, spray trigger pressed

J1 pins 2 and 5, pattern air trigger pressed

J1 pin 1 and J3 pin 1

J1 pin 2 and J2 pin 3 and J3 pin 2

J1 pin 3 and J2 pin 1

J1 pin 4 and J2 pin 2

J1 pin 5 and J3 pin 3

J1 pin 6 and ground terminal

ProdigyrManual Powder Spray Gun 13

Part 1053680E05

E2007 Nordson Corporation

J3

J2

J1

123

4

5

6

12

3

42

1

3

J1 J2

J3

Ground

(N/C)

J1-1

J1-2

J1-3

J1-4

J1-5

J1-6 J3-4

J3-3

J3-2

J3-1

J2-1

J2-3

J2-2

SPRAY TRIGGER +

COMMON

+VDC

uA FEEDBACK

PATTERN TRIGGER +

GND

SHIELD

CABLE GND

IC WIRE

MOLDED INTO

STRAIN RELIEF

+VDC

uA FEEDBACK

COMMON

SPRAY TRIGGER +

COMMON

PATTERN TRIGGER +

Figure 13 Control Cable Continuity Tests

Trigger Switch Continuity Test

Disconnect the control cable from the trigger

switch, as described in Cable Replacement on

page 14.

Test for continuity using the following table and

Figure 14.

Pins Trigger Results

1 and 2

Off (Open) No continuity

1 and 2 On (Closed) Continuity

2 and 3

Off (Open) No continuity

2 and 3 On (Closed) Continuity

Pin

2

14

3

J3

1 Spray Trigger

2 Common

3 Pattern Control Trigger

4 N/C

Function

Figure 14 Trigger Switch Continuity Test

ProdigyrManual Powder Spray Gun

14

Part 1053680E05 E2007 Nordson Corporation

RepairWARNING: Allow only qualified

personnel to perform the following tasks.

Follow the safety instructions in this

document and all other related

documentation.

WARNING: Turn off the electrostatic

voltage and ground the spray gun

electrode before performing the following

tasks. Failure to observe this warning

could result in a severe shock.

Nozzle and Powder Tube Replacement

1. Shut off the controller power switch.

2. See Figure 15. Unscrew the lock knob (7) and

pull the powder tubing out of the adapter (9).

7

9

Figure 15 Disconnecting the Powder Tubing

3. See Figure 16. Unscrew the retaining nut (12)

and remove it from the spray gun.

4. Unscrew the nozzle (11) from the retaining nut.

5. Pull the powder tube (10) out of the adapter.

12

11

10

Short gun powder tube

Standard gun

powder tube

Figure 16 Removing the Air Cap and Powder Tube

6. Slide a new powder tube into the adapter.

7. Screw the nozzle back into the retaining nut,

then install the nozzle onto the powder tube and

screw the retaining nut back onto the adapter.

8. See Figure 15. Push the powder tubing into the

adapter until it bottoms out against the powder

tube. Screw the lock knob into the adapter and

tighten until snug.

Control Cable Replacement

1. Shut off the gun controller power switch and

remove the powder tubing from the gun. Refer

to step 2 of Nozzle and Powder Tube

Replacement.

2. Remove the gun from the spray area (at least

one meter (3 ft) from the spray booth).

3. See Figure 17. Remove the screw (36)

securing the cable (37) to the bottom of the gun

handle.

4. Rotate the cable to release it from the handle

base. Gently pull down on the cable until you

can grasp the trigger switch receptacle (28).

5. Disconnect the trigger cable plug (J3) from the

trigger switch receptacle.

28

37

36

J3

Figure 17 Disconnecting the Control Cable from the

Handle

ProdigyrManual Powder Spray Gun 15

Part 1053680E05

E2007 Nordson Corporation

Control Cable Replacement (contd)

6. See Figure 18. Remove the end cap

screw (21) and end cap (20) from the gun body.

20

2121

Figure 18 Removing the End Cap

7. See Figure 19. Disconnect the multiplier

connector (J2) from the multiplier receptacle.

8. Remove the post and lock washer (17, 16) to

disconnect the ground terminal (GND).

J2

GND

17

16

Figure 19 Disconnecting the Control Cable

9. See Figure 20. Lift up on the back of the gun

body (14) to unsnap it from the handle, then

push the body forward to separate it from the

handle (23).

Feed cable

through here

14

23

Figure 20 Separating the Gun Body from the Handle

10. Feed the ground and multiplier wiring through

the opening in the handle.

11. Perform the previous steps in reverse to install

a new cable.

Resistor and Electrode Replacement

Resistor and Electrode Removal

1. See Figure 15. Unscrew the lock knob (7) and

pull the powder tubing out of the adapter (9).

2. See Figure 21. Loosen the set screw (5) in the

bottom on the adapter.

5

9

Figure 21 Loosening the Adapter Set Screw

ProdigyrManual Powder Spray Gun

16

Part 1053680E05 E2007 Nordson Corporation

Resistor and Electrode Removal (contd)

3. See Figure 22. Pull the adapter (9) straight off

the gun body (14).

14

9

Short length spray gun

Standard length spray gun

Figure 22 Removing the Adapter

4. See Figure 23. Unscrew the resistor holder (3)

from the multiplier (19).

3

19 Short length resistor holder

Standard length resistor holder

Figure 23 Removing the Resistor Holder

5. See Figure 24. Remove the contact

spacer (18) from the multiplier well. Wipe the

dielectric grease off the contact spacer.

Multiplier Well

18

Figure 24 Removing the Contact Spacer

6. See Figure 25. Remove the resistor (4) from

the resistor holder (3). Clean the resistor

holder.

43

Resistor Well

Figure 25 Removing the Resistor from the Holder

7. See Figure 26. Standard Length only: To

replace the electrode (2), pull it out of the

electrode holder (1).

2

1

Figure 26 Replacing Electrode

Clean and inspect the resistor holder and electrode

holder. Replace the holders If you find carbon

tracks or pin holes in them.

Resistor and Electrode Installation

1. See Figure 26. If removed, install the electrode

in the electrode holder, then thread the

electrode holder into the resistor holder.

2. See Figure 25. Inject approximately 0.60 cc of

dielectric grease into the resistor well.

3. Insert the resistor into the resistor holder until it

bottoms out, then fill the resistor well with

approximately 0.8 cc of dielectric grease.

4. See Figure 24. Insert the contact spacer into

the multiplier well. Fill the multiplier well with

dielectric grease.

5. See Figure 23. Screw the resistor holder onto

the multiplier.

6. See Figures 22 and 21. Install the adapter on

the gun body. Tighten the set screw.

7. See Figure 15. Push the powder tubing into the

adapter until it bottoms out against the powder

tube. Screw the lock knob into the adapter and

tighten it snugly.

ProdigyrManual Powder Spray Gun 17

Part 1053680E05

E2007 Nordson Corporation

Multiplier Replacement

Removal

1. Remove the resistor holder. Refer to steps 1-4

of the Resistor and Electrode Replacement

procedure.

2. Remove the end cap and disconnect the control

cable. Refer to steps 6-8 of the Control Cable

Replacement procedure.

3. Push the multiplier out of the gun body from the

front.

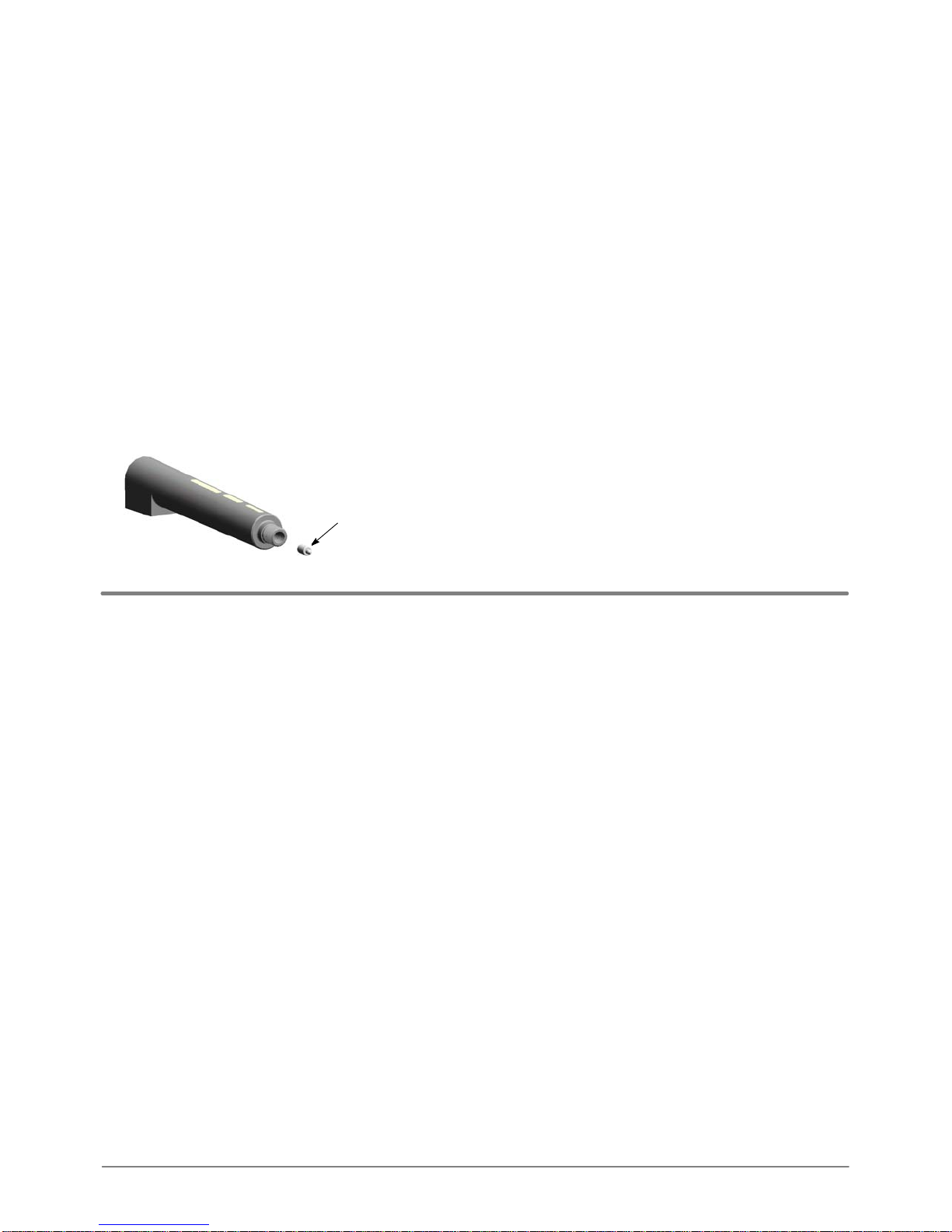

4. See Figure 27. Remove the contact spacer

(18) from the multiplier well. Clean the

dielectric grease off the contact spacer.

18

Figure 27 Removing the Contact Spacer

Assembly

1. See Figure 27. Insert the contact spacer into

the multiplier well. Fill the multiplier well with

dielectric grease.

2. Install the multiplier into the gun body.

3. Fill the resistor holder well with dielectric

grease. Refer to Resistor and Electrode

Installation instructions.

4. See Figure 23. Screw the resistor holder onto

the multiplier.

5. See Figures 22 and 21. Install the adapter over

the electrode and resistor holders. Tighten the

set screw.

6. See Figure 19. Connect the ground wire to the

gun body with the lockwasher and post.

Connect the multiplier connector (J3) to the

multiplier receptacle.

7. See Figure 18. Install the end cap on the gun

body with the screw.

8. See Figure 15. Push the powder tubing into the

adapter until it bottoms out against the powder

tube, then thread the lock knob into the adapter

and tighten it snugly.

ProdigyrManual Powder Spray Gun

18

Part 1053680E05 E2007 Nordson Corporation

Parts

Prodigy Manual Spray Gun - Standard Length

Item Part Description Quantity Note

— 1053594 GUN, manual, 95 kV, Prodigy 1

1 1010561 SHOLDER, electrode, M4 1

2 1064038 SELECTRODE, spring contact, 0.154 diameter 1

3 1049605 SHOLDER, resistor, Prodigy, manual 1

4 1053912 SKIT, resistor, cable, series 1

5 982455 SSCREW, set, M6 x 1 x 8, nylon, black 1

6 1047796 SGRIP RING, 8 mm, TE 1 A

7 1047934 SKNOB, lock, powder tube 1

8 940117 SO-RING, silicone, 0.312 x 0.438 x 0.063 in. 3

9 1053897 SKIT, adapter/spring plunger assembly 1 C

10 1049603 SPOWDER TUBE, Prodigy manual 1

11 1062223 SKIT, nozzle, 70 degree, conical 1 B

12 1047536 SNUT, retaining 1

13 940212 SO-RING, silicone, 0.938 x 1.063 x 0.063 in. 1

14 1053683 SBODY, handgun, Prodigy 1

15 288815 SRIVET, snap, 0.125 in. diameter, black, Nylon 1

16 983416 SWASHER, lock, internal, M4, steel, zinc 1

17 288553 SPOST, spacer, hex 1

18 1053595 SSPACER, contact 1

19 288552 SPOWER SUPPLY, 95 kV, negative 1 C

20 - - - - - - SCAP, end, handgun 1

21 982800 SSCREW, pan, recessed, M4 x 6, black, zinc 1

22 1069680 SGASKET, cover, handgun 1

23 288561 SHANDLE, w/cover, handgun 1

23A 288534 SS GASKET, base, hand gun 1

24 288541 STRIGGER, purge, handgun 1

25 288542 STRIGGER, actuator, handgun 1

26 288537 SPIVOT, threaded, gun, M5 1

27 288549 SSWITCH, keypad, trigger/purge 1

28 288550 SPAD, ground, small, handgun 1 C

29 288538 SBASE, handle, handgun 1

30 1062113 SGROMMET, Buna-N, 0.312 ID x 1.00 in. OD 1

31 288545 SBRACKET, hose, handgun 1

32 982801 SSCREW, oval, recessed, M4 x 20, black, zinc 2

33 328524 SCONNECTOR, male, w/integral hex, 6 mm

tube x M5 1

34 973402 SPLUG, pipe, socket, flush, 1/8in. NPT, zinc 1

35 982825 SSCREW, pan head, rec, M4 x 12, with integral

lock washer bezel, black, zinc 1

36 1053914 SKIT, cable, handgun, Prodigy, 6 meter 1

37 1073706 SKIT, nozzle, flat spray, dual slot, converging

angle, 1 mm 1 B

NOTE A: Also available in packages of 10. Refer to page 22 for service kits.

B: Refer to page NO TAG for conical nozzles and components; pages NO TAG and 25 for flat spray, cross,

and pinpoint nozzles and components.

C: Refer to page 22 for options.

NS: Not Shown

Table of contents