PRODIS CL20 User manual

CL20

ICE MAKER

ICE MAKER

CL161019SM Rev 1.0

SERVICE MANUAL

PART I - ERROR CODES & EXPLANATIONS

PART II - MAINTENANCE

PART III - TECHNICAL DATA

PART IV - SPARE PARTS DIAGRAM & LIST

PART V - WIRING DIAGRAM

TABLE OF CONTENTS

CL161019SM Rev 1.0

PART I

Error

Code Description Solution

E1 Water Shortage Check mains water pressure is between 1.4 - 5.5 bar

Check mains water supply is connected and turned on

Check for kinks or blockages in mains water supply line externally

replace where necessary

Check for kinks or blockages in mains water supply line internally,

replace where necessary

Check oat valve for operation, replace where necessary

E2 Harvest Overtime Refer to page 2

E3 Condenser sensor open

circuit

Check condenser sensor connection, replace where necessary

E4 Evaporator sensor open

circuit

Check Evaporator sensor connection, replace where necessary

E5 Ambient sensor open

circuit

Check Ambient sensor connection, replace where necessary

E6 Evaporator over tempera-

ture protection

Evaporator too hot, check hot gas valve, replace where necessary

E7 Ambient temperature out

of range

Ice maker is located in a room with too high or too low ambient, relo-

cate ice maker in a room with a temperature range of +10°c to +32°c

E8 Ice production over time Ice production has taken too long, allow sucient time for ice to fall

from the evaporator plate,

do not try to manually remove the ice from the evaporator.

Check ambient air temperature is within operating range of +10°c to

+32°c.

Check incoming water temperature is within operation range of +7°c

to +32°c.

Check hot gas valve for operation, replace where necessary

1CL161019SM Rev 1.0

ERROR CODES

2

CL161019SM Rev 1.0

E2

Error E2 is commonly caused by lime scale build up on the water distributor. This part needs to be cleaned and

de-scaled on a 6 monthly basis or whenever necessary.

The use of a water lter will assist in reducing lime scale build up and prolong the life of the ice maker.

When lime scale is allowed to build up within the water distributor water will not be able to ow correctly over

the evaporator.

If the water from the distributor is not owing over the evaporator and is instead “spraying” past the evaporator

and in to the storage bin the ice maker will constantly bring in fresh water to replace the lost water. The fresh

incoming water will then need to be cooled to near 0°c by owing over the evaporator. In this case the ice maker

will not be able to make any ice at all within the allotted cycle time as the water will never be able to be cooled

to 0°c.

The ice maker will then go into a harvest cycle, if the ice maker does not detect ice falling from the evaporator by

activating the bin full sensor the harvest cycle will time out after 5 minutes and E2 will be displayed.

De-scaling and cleaning procedure

Open the door of the ice maker.

Discard any ice in the storage bin

Prepare a solution of 50% water and 50% phosphoric acid

Holding both sides of the water distributor rotate the tube so that

the holes are facing towards your.

Using a sti brush clean the water distributor with the de-scaling

solution paying close attention to ensure water can freely ow

through the holes.

Rotate the water distributor back to its original location with the

holes facing down and slightly backwards.

Pour the phosphoric acid and water solution into the water reser-

voir

Put the ice maker into clean cycle

After the clean cycle has completed allow the ice maker to stand

with the descaling solution in the unit for 30 minutes.

Put the ice maker through another clean cycle and totally empty the water reservoir

Put the ice maker back in to production mode

Discard any ice made for the rst 3 hours after cleaning to ensure all traces of lime scale and de-scaling solution

has been removed.

ALWAYS WEAR SUITABLE GLOVES AND EYE

PROTECTION WHILST CARRYING OUT THIS

PROCEDURE

WARNING

DISCARD ANY ICE MADE FOR THE FIRST 3

HOURS AFTER WATER DISTRIBUTOR CLEANING.

MAINTENANCE AND CLEANING

PERIODIC CLEANING AND PROPER MAINTENANCE WILL

EXTENDTHE LIFE OFYOUR ICE MAKER, ENSURE MAXIMUM

EFFICIENCY AND DELIVER BETTER TASTING ICE TO YOUR

CUSTOMER.

WARNING

DISCONNECT THE MACHINE FROM THE MAINS

ELECTRICITY BEFORE PERFORMING ANY CLEANING

OR MAINTENANCE

WARNING

INSPECTION, DE-SCALING AND SERVICING SHOULD

ONLY BE UNDERTAKEN BY A QUALIFIED ENGINEER

WARNING

NEVER CLEAN THE ICEMAKER WITH A PRESSURE

WASHER OR BY SPRAYING WATER

WARNING

NEVER USE ACIDIC OR ABRASIVE DETERGENTS, THESE

TYPES OF CLEANERS MAY TRANSFER TASTE AND

ODOUR TO THE MACHINE AND THE ICE. THIS TYPE

OF CLEANER MAY ALSO DAMAGE OR DISCOLOUR THE

ICE MAKER.

WARNING

NEVER CLEAN STAINLESS STEEL WITH A BLEACH

BASED CLEANER AS THIS MAY CAUSE CORROSION ON

THE STAINLESS STEEL.

EXTERIOR CLEANING

ALWAYS CLEAN THE EXTERIOR STAINLESS STEEL PARTS

OF THE ICE MAKER WITH A MICRO-FIBRE CLOTH AND OR

A SPONGE. ALWAYS CLEAN IN THE DIRECTION OF THE

GRAIN OF THE STAINLESS STEEL.

DO NOT USE ABRASIVE OR METALLIC PRODUCTS (WIRE

WOOL) WHICH COULD SCRATCH AND DAMAGE THE

SATIN FINISH OF THE ICE MAKER PERMANENTLY.

USING A METALLIC CLEANING PRODUCT SUCH AS

WIRE WOOL WILL DEPOSIT IRON PARTICLES INTO THE

STAINLESS STEEL WHICH COULD CAUSE CORROSION OF

THE STAINLESS STEEL FINISH.

INTERIOR CLEANING

CLEAN THE INTERIOR OF THE ICE BIN AND ALL

REMOVABLE PARTS BYWASHING THEM WITH A SOLUTION

OF LUKEWARM WATER AND A SMALL AMOUNT OF DISH-

WASHING LIQUID. RINSE AND DRY IMMEDIATELY.

WARNING

THE ICE STORAGE BIN IS FOR STORAGE OF ICE ONLY,

NEVER STORE ANYTHING OTHER THAN ICE IN THE

STORAGE BIN AS THIS IS A HEALTH HAZARD.

AIR FILTER

THE ICE MAKER IS EQUIPPED WITH AN AIR FILTER TO

PREVENT DIRT AND DUST ENTERING THE CONDENSER.

IT IS IMPORTANT THAT THE AIR FILTER IS CLEANED TWICE

A MONTH TO ENSURE EFFICIENT OPERATION OF THE ICE

MAKER.

TO CLEAN YOUR AIR FILTER SLIDE THE FILTER OUT FROM

THE FRONT GRILL AND REMOVE ANY DUST OR DIRT

USING A SOFT BRUSH AND A VACUUM CLEANER. IF THE

AIR FILTER IS HEAVILY BLOCKED WE RECOMMEND USING

WATER AND A MILD DETERGENT TO CLEAN THE FILTER.

IMPORTANT: AIR FILTER MUST BE CLEAN AND DRY

BEFORE REPLACING INTO THE MACHINE.

IMPORTANT: DO NOT OPERATE YOUR ICE MAKER

WITHOUT THE AIR FILTER IN PLACE

WARNING

FAILURE TO CLEAN YOUR AIR FILTER COULD CAUSE

COMPONENT FAILURE AND WILL INVALIDATE YOUR

WARRANTY.

CONDENSER CLEANING

A DIRTY OR CLOGGED CONDENSER WILL PREVENT

PROPER AIR FLOW. THIS WILL LEAD TO REDUCED

EFFICIENCY, REDUCED ICE PRODUCTION AND AN

INCREASE IN OPERATING TEMPERATURE WHICH MAY

LEAD TO COMPONENT FAILURE. WE RECOMMEND

THE CONDENSER IS CLEANED EVERY SIX MONTHS BY

A QUALIFIED ENGINEER. TO CLEAN THE CONDENSER

DISCONNECT THE ICE MAKER FROM THE MAINS

ELECTRICITY. REMOVE THE SCREWS FROM THE

BOTTOM PANEL AND GENTLY REMOVE THE GRILL.

REMOVE DIRT AND DUST FROM THE CONDENSER FINS

WITH A SOFT BRUSH AND VACUUM CLEANER. REATTACH

THE FRONT GRILL AND RECONNECT POWER TO THE

MACHINE.

WARNING

CONDENSER CLEANING MUST BE CARRIED OUT BY A

QUALIFIED ENGINEER

WARNING

FAILURE TO CLEAN YOUR CONDENSER COULD CAUSE

COMPONENT FAILURE AND WILL INVALIDATE YOUR

WARRANTY.

3CL161019SM Rev 1.0

PART II

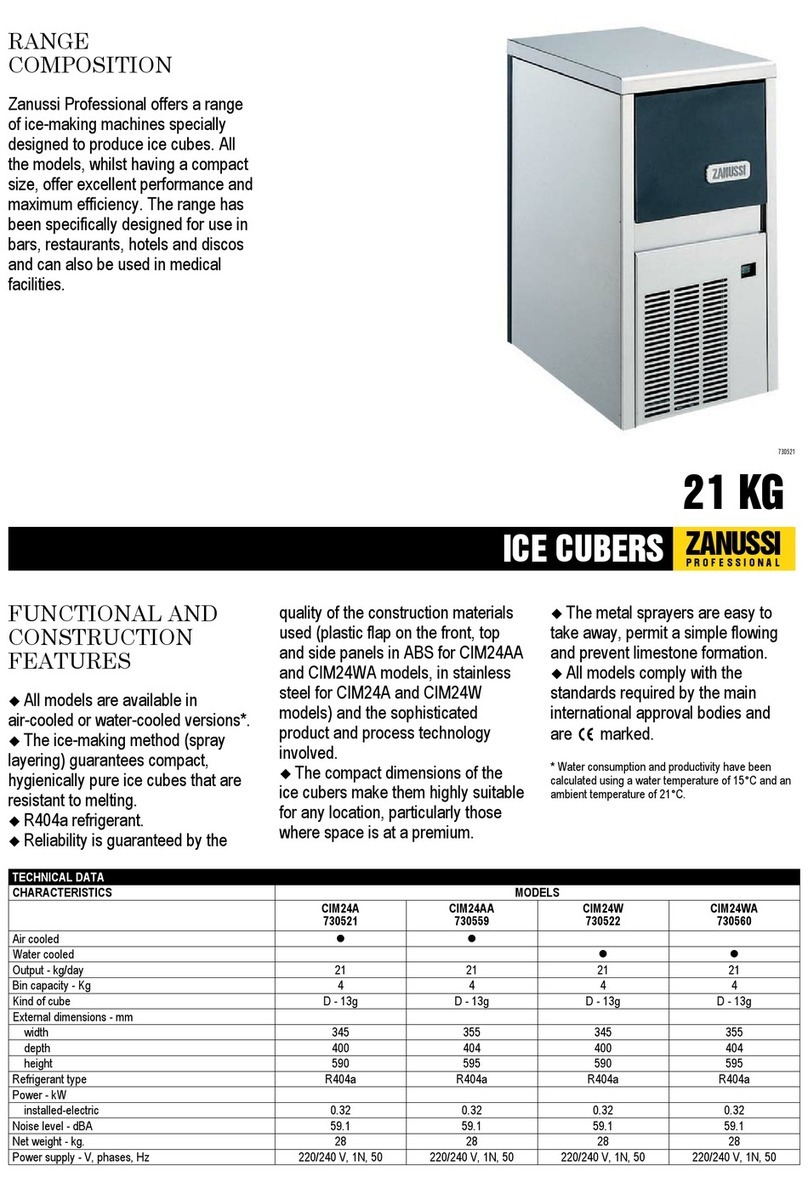

ICE PRODUCTION 22KG PER 24 HOURS

ICE STORAGE 6KG STORAGE BIN

VOLTAGE 230V/50HZ

RATED POWER 155W

CLIMATE CLASS SN,N,ST

REFRIGERANT R290

REFRIGERANT CHARGE 55G

UNIT DIMENSIONS 380 X 470 X 600 (W,D,H MM)

AMBIENT OPERATING AIR TEMPERATURE 10°C - 32°C

WATER SUPPLY TEMPERATURE 7°C - 32°C

WATER SUPPLY PRESSURE 1.4 - 5.5BAR

TECHNICAL DATA

4

CL161019SM Rev 1.0

PART III & IV

PARTS DIAGRAM

5CL161019SM Rev 1.0

PART IV

DRAWING # DESCRIPTION PART NUMBER

1 REAR PANEL CL20PANEL01

2 WATER INLET VALVE BRACKET CL20BRACKET01

3 POWER CORD CL20CABLE01

4 N/A N/A

5 LEFT PANEL CL20PANEL02

6 N/A N/A

7DRAINAGE THREE WAY TEE PIECE CL20TEE02

8 FILTER DRIER CL20DRIER01

9 COMPRESSOR CL20COMP01

10 FOOT CL20FOOT01

11 BASE PANEL CL20BASE01

12 N/A N/A

13 N/A N/A

14 WATER PUMP THREE WAY TEE PIECE CL20TEE01

15 WATER OUTLET VALVE CL20VALVE02

16 CONDENSER CL20COND01

17 WATER PUMP CL20PUMP01

18 N/A N/A

19 N/A N/A

20 CONDENSER FAN MOTOR CL20MOTOR01

21 N/A N/A

22 PCB HOUSING CL20HOUSING01

23 MAIN PCB BOARD CL20BOARD01

24 RIGHT PANEL CL20PANEL03

25 AIR FILTER CL20FILTER01

26 N/A N/S

27 FRONT GRILL CL20GRILL01

28 N/A N/A

29 N/A N/A

30 HINGE AXIS + BUSHING CL20BUSH01

31 SEE #30 N/A

32 DOOR CL20DOOR01

33 DOOR GASKET CL20GASKET01

34 N/A N/A

35 DISPLAY BOARD CL20BOARD02

36 TOP PANEL CL20PANEL01

37 WATER LEVEL FLOAT CL20FLOAT01

38 WATER TANK CL20TANK01

39 N/A N/A

40 BIN SENSOR CL20SENSOR01

41 N/A N/A

42 EVAPORATOR CL20EVAP01

MODEL CL20

PRODUCTION 20kg/24hr

STORAGE 7kg

CLIMATE CLASS N

VOLTAGE 230V

FREQUENCY 50Hz

POWER

REFRIGERANT

WATER PRESSURE 1.4 - 5.5 bar

SERIAL NUMBER

MANUFACTURED

CL20 COMPACT ICE MAKER

CIRCUIT DIAGRAM

barcode number

barcode number

155W

R290/55g

Water pump

Solenoid

value

Compressor

Display panel

Main Board

Condenser

Fan

Water outlet

value

Ice Full

Switch

Condenser

Sensor

Evaporating

Temperature Sensor

Environment

Temperature Sensor

WWW.PRODIS.CO.UK

PROJECT DISTRIBUTION LTD

WIRING DIAGRAM

6

CL161019SM Rev 1.0

PART III & IV

NOTES.......

NOTES.......

NOTES.......

CL161019SM Rev 1.0

Project Distribution Ltd

Unit 1 Sun Street

Stoke on Trent

United Kingdom

ST1 4JW

Tel: 01782 280289

www.project-distribution.co.uk

Other manuals for CL20

1

Table of contents

Other PRODIS Ice Maker manuals

Popular Ice Maker manuals by other brands

Caldura

Caldura IM06 operating instructions

Hoshizaki

Hoshizaki KM-2000SRE3 Final Parts List

Adler Europe

Adler Europe AD 8082 user manual

Hoshizaki

Hoshizaki KM-901MAH50 instruction manual

Ice-O-Matic

Ice-O-Matic ICE250 through ICE2100 SERIES Installation and maintenance manual

Polar Electro

Polar Electro G620-A instruction manual