4 of 6

Document Number: MSC-017 4/20

Subject: Restoring Ice Machine to Service Procedures

nWARNING

Wear rubber gloves and safety goggles (and/or face shield)

when handling ice machine cleaner / descaler or sanitizer.

Cleaner / Descaler (9405463)

and Sanitizer (9405653)

Usage

Important

Ice machine cleaner /descaler is

used to remove lime scale and

mineral deposits. Ice machine

cleaner / descaler should

be used every six months,

although in cases of extremely

hard water conditions it may

be necessary to descale more

often. For the range of water

hardness allowed for potable

water standards, it should not

be necessary to descale more

frequently than every two

months. Use of an approved

filtration system with a

polyphosphate scale inhibitor

is highly recommended for all

ice machine installations and

will significantly reduce the

need to descale in hard water

applications.

Ice machine sanitizer disinfects

and removes algae and slime.

Sanitizer must be used a

minimum of once every six

months.

,CAUTION

Do not immerse the water

pump motor or electrical

connector in liquids. Only

soak the water pump

impeller and impeller

housing. Do not immerse

above the red line on the

graphic.

Notice

Electrical connectors must never be exposed to any

liquids.

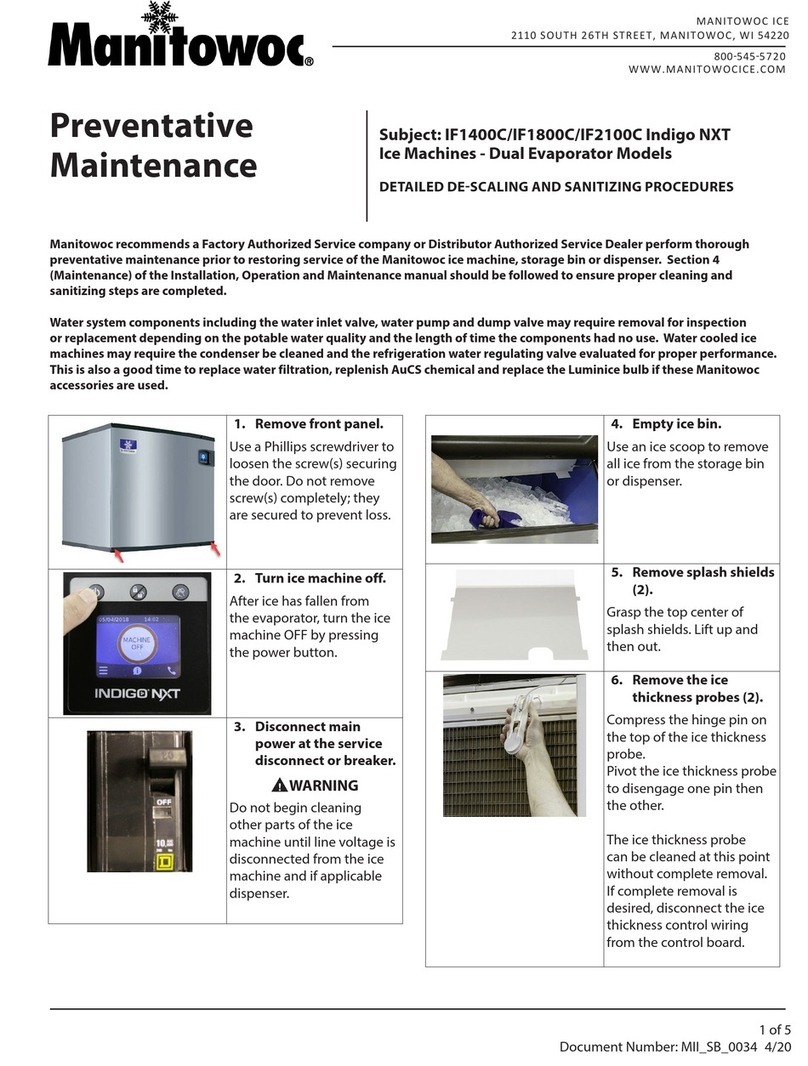

15. Remove scale deposits

from removed parts.

Mix 16 oz Manitowoc ice

machine cleaner / descaler

(9405463) with one gallon of

potable water in a three-

compartment sink.

Place the plastic parts in the

solution and allow to soak

for 10-15 minutes. Use a

soft bristle brush on heavy

scale or mineral buildup as

required.

16. Clean scale deposits

from surface areas of

ice machine.

Use a clean towel or sponge

soaked in cleaner / descaler

solution to wipe ice machine

surfaces, including the sides

walls, base (area above

water trough), and the bin

or dispenser.

17. Rinse Surface Areas of

Ice Machine.

Use a clean towel or sponge

soaked in potable water to

wipe ice machine surfaces,

including the sides walls,

base (area above water

trough), and the bin or

dispenser.

,CAUTION

Do not soak the water pump

motor in rinse water or

sanitizer solution. Be sure

to only rinse/soak the water

pump impeller and impeller

housing. Do not immerse

above the red line on the

graphic.

Notice

Electrical connectors must never be exposed to any

liquids.