progeo MOTOTRONIK User manual

REHATEAM s.r.l.—vicolo Negrelli 5—31038 Castagnole di Paese TV—www.rehateamprogeo.com Service Manual MOTOTRONIK 1

S E R V I C E M A N U A L

MOTOTRONIK

Rev. 0 - 2021/12

SERVICE MANUAL

ENGLISH

REHATEAM s.r.l.—vicolo Negrelli 5—31038 Castagnole di Paese TV—www.rehateamprogeo.com Service Manual MOTOTRONIK 2

SERVICE MANUAL

MOTOTRONIK

GENERAL WARNINGS

ANY ADJUSTMENT CAN BE CARRIED OUT EXCLUSIVELY BY QUALIFIED AND AUTHORIZED

BY REHATEAM S.R.L. PERSONNEL.

It is forbidden to carry out any modifications to the Mototronik, even when possible, to the original

design.

Any adjustments and/or any modification that is carried out by non-authorized personnel will

immediately void the warranty on the product and it relieves Rehateam s.r.l. from any responsibility

on any malfunctioning and/or damage due to such adjustments/modifications.

Always contact Rehateam s.r.l. and its technicians for any non-standard requirements or

modifications to allow them to evaluate such modifications and verify that they will not compromise

the normal and safe use of the wheelchair.

Any adjustment of the Mototronik could seriously compromise the safe use of the combination with

the wheelchair causing damage to both the user and the wheelchair itself.

After every adjustment made to the Mototronik, check carefully that all parts are correctly fixed.

Check that all screws and nuts are tightened and that all moving parts are functioning correctly.

After any adjustment, always test the Mototroink combined to with wheelchair before giving the

product to the user.

Rehateam s.r.l. disclaims any responsibility for damage to the product, to any object or to people

due to any modification that is not properly performed or that, in any case, does not guarantee

safety to the user.

The Mototronik device is compatible with most of the manual wheelchairs in the market, neverthe-

less, it is always advisable to consult Rehateam s.r.l. and/or the wheelchair’s manufacturer to know

about the actual compatibility or possible directions to be followed.

REHATEAM s.r.l.—vicolo Negrelli 5—31038 Castagnole di Paese TV—www.rehateamprogeo.com Service Manual MOTOTRONIK 3

SERVICE MANUAL

MOTOTRONIK

CONTENTS

Page Title

4 DESCRIPTION OF PARTS

5 GENERAL INFORMATION

7 NECESSARY TOOLS

8 MOTOR UNIT ASSEMBLY

WITH STANDARD HANDLEBAR

10 MOTOR UNIT ASSEMBLY

WITH ”TETRA” HANDLEBAR

11 CLAMP ASSEMBLY

12 COUPLING PAD

ASSEMBLY AND ADJUSTMENT

14 COUPLING FORK ASSEMBLY

15 CHECKING THE CONNECTION FRAME’S ARMS

16 CONNECTION FRAME’S ARMS

SIZES AVAILABLE

17 CONNECTION FRAME ASSEMBLY

17 —COUPLING UNIT

18 —ASSEMBLY OF ARMS ON COUPLING UNIT

19 —ASSEMBLY OF CONNECTION FRAME TO WHEELCHAIR

20 —WIDTH ADJUSTMENT

21 —DEPTH ADJUSTMENT

22 COUPLING SUPPORT ADJUSTMENT

23 FINAL ADJUSTMENT

25 CONTROL TOOLS

STANDARD HANDLEBAR

26 CONTROL TOOLS

”TETRA” HANDLEBAR

27 BRAKE LEVER

STANDARD HANDLEBAR

28 ACCELERATOR GRIP

STANDARD HANDLEBAR

29 DISPLAY

30 SPOILER

30 —REMOVAL/MOUNTING

31 —FITTING

32 LED HEAD LIGHT

33 STANDARD HANDLEBAR ADJUSTMENT

35 “TETRA” HANDLEBAR ADJUSTMENT

36 STEM EXTENSION

STANDARD HANDLEBAR

44 STEM EXTENSION

”TETRA” HANDLEBAR

Page Title

45 DISK BRAKE CABLE ADJUSTMENT

STANDARD HANDLEBAR

46 DISK, CALIPER and BRAKE PADS

POSITIONING AND ADJUSTMENT

47 BRAKE CALIPER

POSITIONING AND ADJUSTMENT

49 BRAKE DISK

REPLACING AND CETRING

50 BRAKE PADS

REPLACEMENT

52 REMOVING/ MOUNTING THE WHEEL

53 TYRE AND TUBE

REPLACEMENT

55 REMOVING / MOUNTING THE MUD GUARD

56 EASY RELEASE LEVER

57 BALLASTS

58 BASKET

61 REMOVING/MOUNTING THE ELECTRONIC UNIT

62 REAR VIEW MIRROR

63 SETTINGS

PARAMETRI DI GUIDA

65 TYPES OF CLAMPS AND ASSEMBLY

FOR WHEELCHAIR MODEL

65 —PROGEO

REHATEAM s.r.l.—vicolo Negrelli 5—31038 Castagnole di Paese TV—www.rehateamprogeo.com Service Manual MOTOTRONIK 4

SERVICE MANUAL

DESCRIPTION OF PARTS

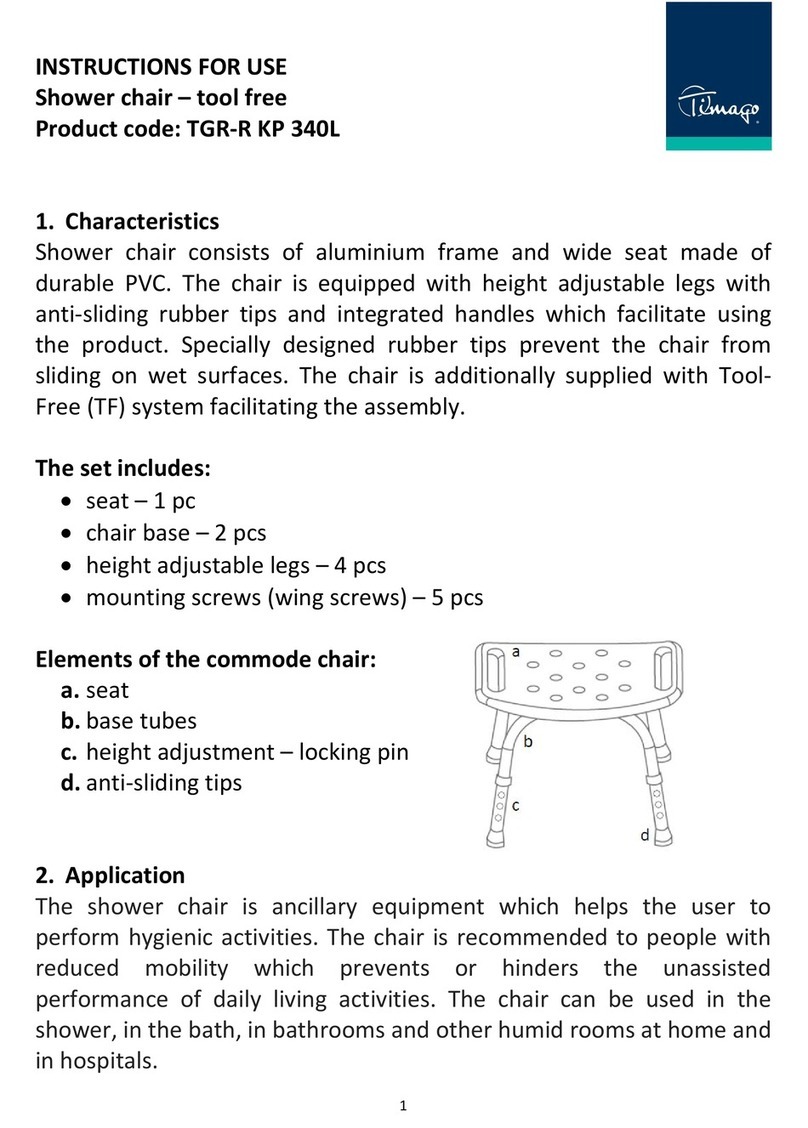

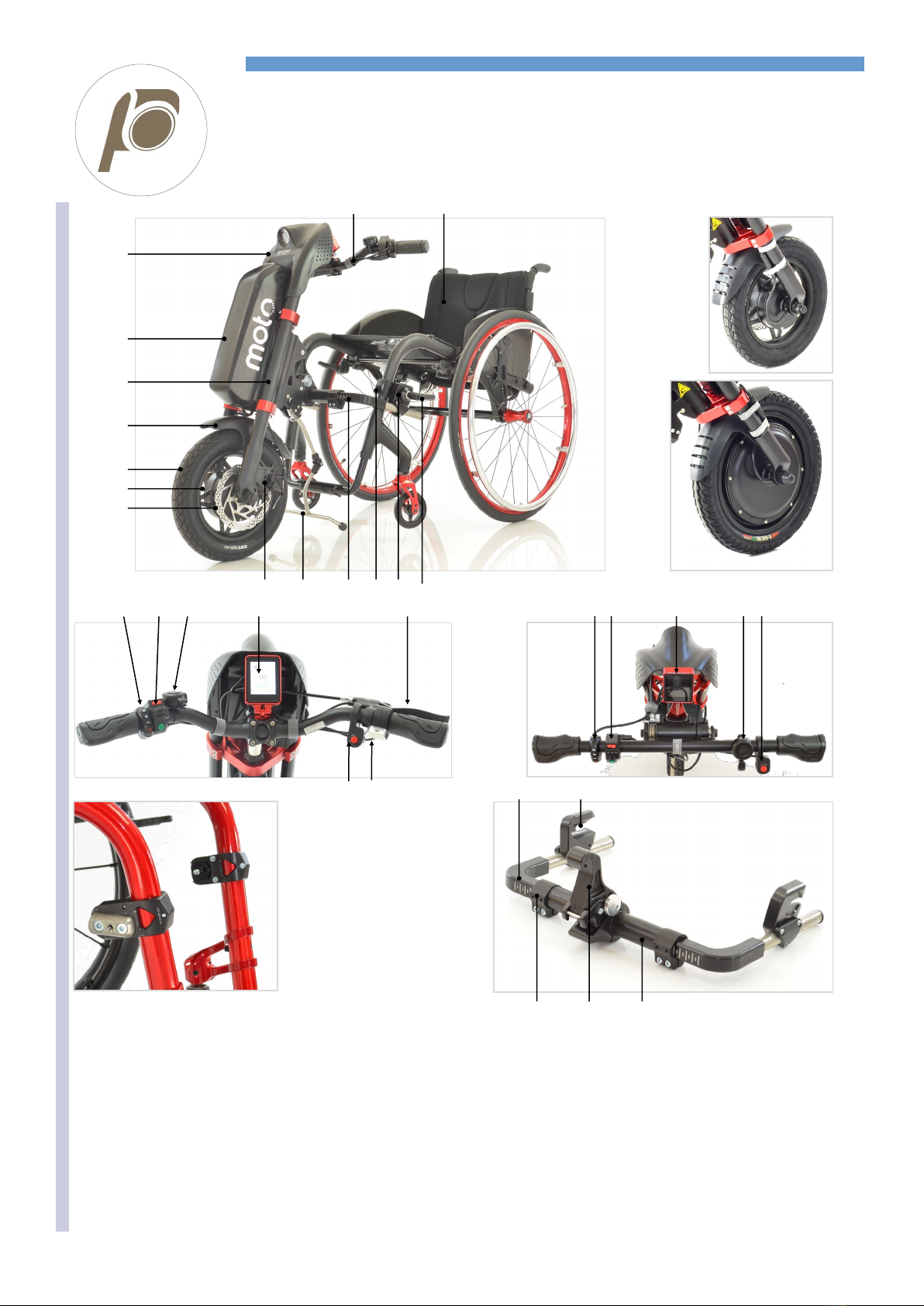

1. Spoiler

2. Battery

3. Two cane frame

4. Fender

5. Steering wheel

6. Motor unit

7. Brake disk

8. Disk brake caliper

9. Stand

10. Connection frame

21. Electronic brake button

22. Acceleration lever

23. Handlebar “Tetra”

24. Arm (ambidextrous)

25. Arm’s fixing clamp

26. Coupling support

27. Connection frame’s central tube

28. 12” motorised wheel

29. 14” motorised wheel

11. Clamps (fixed to the wheelchair’s frame)

12. Coupling fork

13. Lock lever

14. Handlebar

15. Manual wheelchair

16. On/off and settings switch

17. Driving direction and cruise control switch

18. Bell

19. Display

20. Brake lever

8 9 10 11 12 13

1

2

3

4

14 15

24 12

25 26 27

28

29

11

21 22

16 17 18 19 20 16 17 19 18 21

23

REHATEAM s.r.l.—vicolo Negrelli 5—31038 Castagnole di Paese TV—www.rehateamprogeo.com Service Manual MOTOTRONIK 5

SERVICE MANUAL

GENERAL INFORMATION

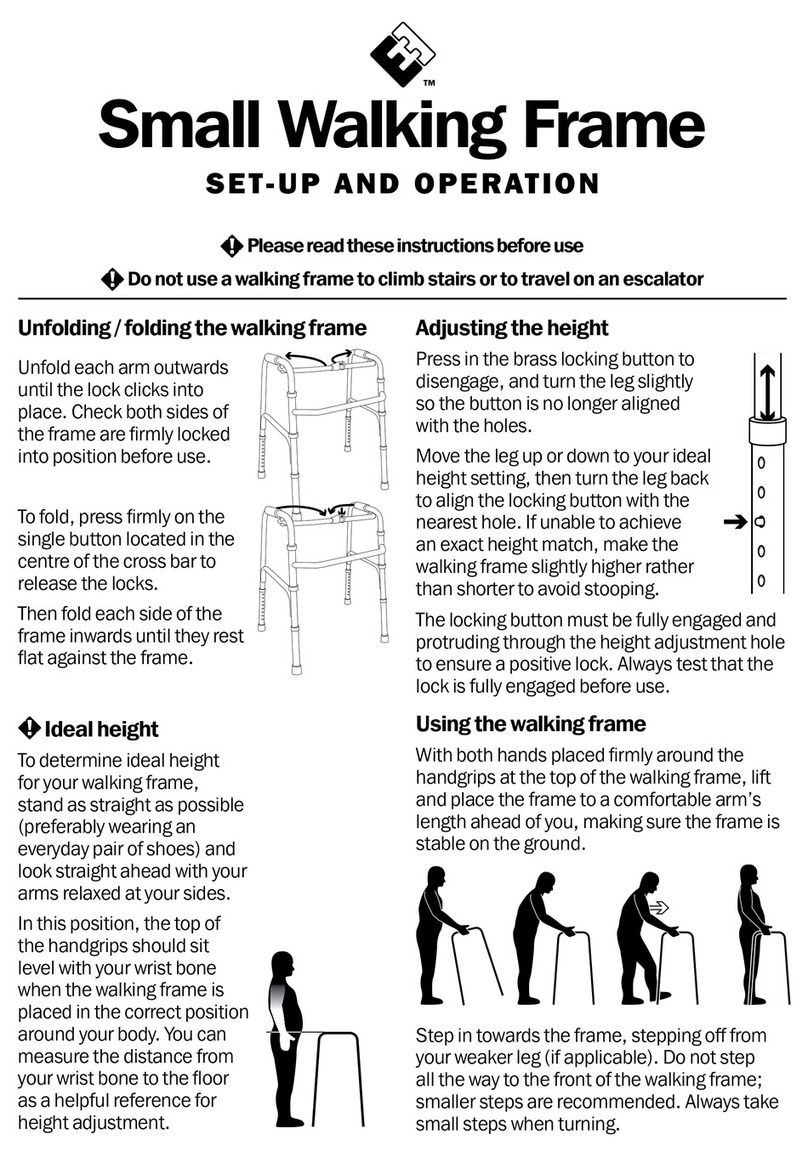

RIGID FRAME WHEELCHAIR

FOLDING WHEELCHAIR WITH

FIX FRONT FRAME

FOLDING WHEELCHAIR WITH SWING-AWAY,

REMOVABLE FRONT FRAME

The assembly of the clamps is always base on the same principle, that is, they must be mounted to a fixed part thus, not to the removable

footplate frame, for instance) of the folding or rigid wheelchair’s frame.

The positioning the clamp along such fixed part is variable and it depends on the model of the wheelchair that, according to its frame tube’s

section, also determines the type of the clamp and the suitable assembly - See also last chapter of this manual, sheet “CLAMPS TYPE

AND ASSEMBLY PER MODEL OF WHEELCHAIR”

The assembly procedure of the MOTOTRONIK system is always the same, but, according to the wheelchair, it is necessary the proper ad-

aptation and adjustment.

The instructions for the proper installation take as reference what we may call “standard” installation.

Nelle istruzioni di montaggio appariranno delle note con utili informazioni.

In the standard assembly instructions, you will see notes with useful information.

REHATEAM s.r.l.—vicolo Negrelli 5—31038 Castagnole di Paese TV—www.rehateamprogeo.com Service Manual MOTOTRONIK 6

SERVICE MANUAL

GENERAL INFORMATION

The clamp positioning in height depends on the wheelchair model and on its configuration: the front seat height, in particular, determines,

according to the usable stretch of frame where you can fix the clamps, the lowest and highest fixing point.

The longer the usable stretch, the greater the vertical adjustment.

If the clamp fixing point is one only point (fix point), there will be no vertical adjustment.

In this drawing, X1and X2show the points within which you can fix the clamps; H1and H2are two different front heights, whereas min.

max. indicate the clamp positioning heights.

The range between X1and X2can help to adjust the connection frame to a more convenient angle.

If X1(or X2) is a fix point, the connection frame inclination will depend on the final assembly of the device.

You can insert the connecting frame horizontally (fig. aand b), “downhill” (fig. c) and also “uphill” (fig. d).

That depends on the height positioning of the clamps and on the coupling forks X orientation: facing down ↓or facing up ↑.

In any case, the system works in the same manner.

The connection frame inclination will be the result of the combination of all parts involved in the installation.

X

REHATEAM s.r.l.—vicolo Negrelli 5—31038 Castagnole di Paese TV—www.rehateamprogeo.com Service Manual MOTOTRONIK 7

SERVICE MANUAL

NECESSARY TOOLS

REHATEAM s.r.l.—vicolo Negrelli 5—31038 Castagnole di Paese TV—www.rehateamprogeo.com Service Manual MOTOTRONIK 8

SERVICE MANUAL

MOTOR UNIT ASSEMBLY

WITH STANDARD HANDLEBAR

ASSEMBLY OF HANDLEBAR AND DISPLAY

Remove the four bolts of the stem’s head and remove the head.

Lean the central part of the handlebar onto the stem paying attention not to twist the

cables.

Lean the stem’s head and fit the two bolts on the lower side.

Make sure the assembly side is correct, that is, with the brake lever facing forward.

Align the display support’s holes with those of the stem and screw the two bolts all

the way down.

Center the handlebar by taking the marks as reference - if necessary, loosen the

two bolts that also fix the display.

Turn the handlebar to the position you may consider initial.

Tighten the two bolts that also fix the display and then the other two..

UNPACKAGING

Remove all packaging elements as carefully as to avoid damaging any part of the product.

If you use scissors or a cutter, pay attention not to cut any cables or scratch any part.

STAND

Insert the stand - see also the user’s manual - and remove the spoiler to make the following steps easier.

Follow next page

REHATEAM s.r.l.—vicolo Negrelli 5—31038 Castagnole di Paese TV—www.rehateamprogeo.com Service Manual MOTOTRONIK 9

SERVICE MANUAL

MOTOR UNIT ASSEMBLY

WITH STANDARD HANDLEBAR

CABLES CONNECTION

The rear side of the display shows four different coloured sockets that should match with the same coloured plug to connect.

Be careful when fitting the plugs, in fact, there is one only position that allows the connection: the groove on the plug, that is externally indi-

cated by the arrow on the rubber cover, should fit along the tooth of the socket.

Light blue: accelerator cable; Black: power cable; Green: headlight

It is advisable to cover the unused sockets with the rubber cap.

Within the cables holder bag (or sticking out of it) you will find two

other plugs: one light blue and one red; these are not used and,

as long as it is possible, you should stow them within the bag.

BATTERY

Insert the battery - see also user’s manual.

SWITCH-ON TEST

Switch the battery on.

Switch the display on.

Lift the driving wheel and try to accelerate and brake.

Switch off the display and then the battery.

See also user’s manual.

Before using the device, you need to centre the handlebar (with

respect to the driving wheel) and make sure the bolt B is hard

tightened—see sheet “STANDARD HANDLEBAR ADJUSTMENT

—1 post height”

B

REHATEAM s.r.l.—vicolo Negrelli 5—31038 Castagnole di Paese TV—www.rehateamprogeo.com Service Manual MOTOTRONIK 10

SERVICE MANUAL

MOTOR UNIT ASSEMBLY

WITH “TETRA” HANDLEBAR

Follow the instruction of the sheet “MOTOR UNIT ASSEMBLY - with standard handlebar” and the following directions.

Make sure the assembly side is correct, that is, with the accelerator lever Aon the right hand side; this way, by turning the handlebar down-

ward, you accelerate, whereas, by turning it upward, you will activate the brake.

Pay particular attention to the route of the cables that should be as rational as possible and without squeezing them; furthermore, the brake

cable, should not form tight curves.

Stow the cables in the cable holder bag Bin such a way to leave out just the necessary. This operation may require a little of patience and ,

if needed, fit one cable at time detaching the plug and then plug it back after routing it rationally, that is, avoiding entanglement, squeezing

and stretching. Plugs and sockets should always be matched according to colour and their fitting is guided by the arrow on the plug’s rubber

cover —see also sheet “DISPLAY”.

The support Cfor the display has a longer fixing plate.

A

A

B

B

C

C

To activate the brake

To accelerate

REHATEAM s.r.l.—vicolo Negrelli 5—31038 Castagnole di Paese TV—www.rehateamprogeo.com Service Manual MOTOTRONIK 11

SERVICE MANUAL

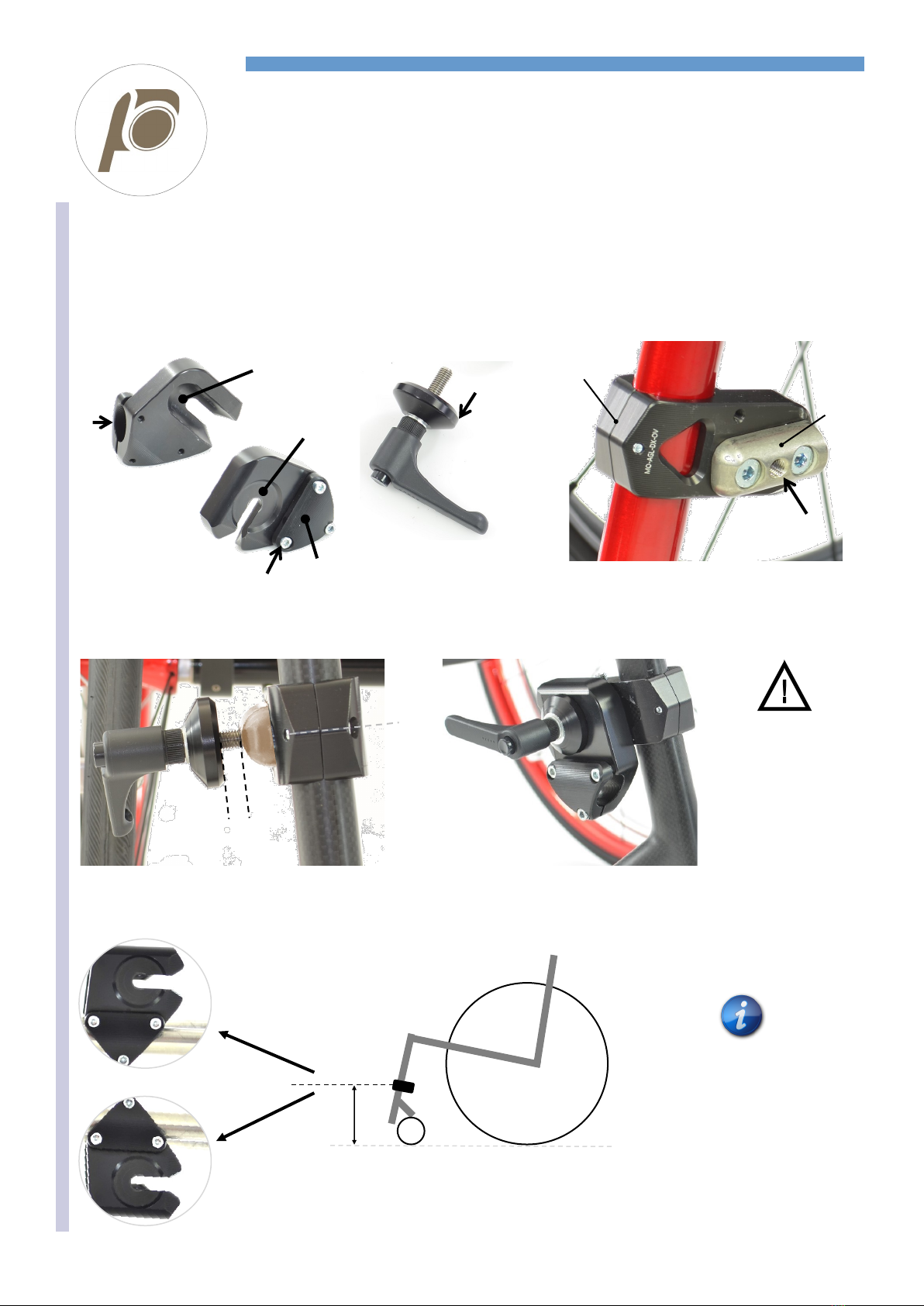

CLAMP ASSEMBLY

Mount the two clamps so that its mid-line in front is approximately between 32 and 35 cm form the ground and check they are at the same

height (it is advisable to use a rod and spirit level).

Should be impossible to fix the clamps at that height, just position them where possible according to what the wheelchair and its configura-

tion allow for.

Screw up the bolt A5 until the two parts touches and unscrew it by half of a turn to keep them sligtly apart.

Then, tighten the two bolts A4.

On some models, the assembly has the clamps facing frontward (therefore, opposite to

the standard assembly). The assembly instruction is very much the same, but the hole

A2 may be above the mid-line. See also last chapter of this manual, sheet “CLAMPS

TYPE AND ASSEMBLY PER MODEL OF WHEELCHAIR”

A3

A5

OUTER SIDE OF THE WHEELCHAIR INNER SIDE OF THE WHEELCHAIR AERIAL VIEW

A1

A2

A1

A4 A5

A3

A1

C

B

B2 B1

A4

A5

A2

A

The clamps A, are symmetrical to one another and, except for specific

cases, they can be mounted both on the right and on the left side of the

wheelchair.

The external face A1 has an off-set threaded hole A2 which, according to

the assembly, will result to be above or below the clamp’s mid-line.

In most cases, the clamp is mounted with the hole A2 below the mid-line as

shown hereafter.

Position the clamp on the frame so that its externa face is facing backward

and parallel to the driving line of the wheelchair (to be checked, especially,

when fixing on round tubes), with the threaded hole A2 below the mid-line.

Now mount the plate A3 and fit the bolts A4 A5 on the clamp.

Follow next page

REHATEAM s.r.l.—vicolo Negrelli 5—31038 Castagnole di Paese TV—www.rehateamprogeo.com Service Manual MOTOTRONIK 12

SERVICE MANUAL

COUPLING PAD

ASSEMBLY AND ADJUSTMENT

A3

The coupling pad Bis fixed to the clamp Awith the bolts B1 (M8 x 20 mm) and

B2 (M8 x 30 mm)

The pad’s rounded side should be facing frontward.

The bolt B1 screws into the clamp’s threaded hole A2, whereas the bolt B2 goes

through the slot A6 and screws into the one of the two holes of the hexagon C.

Screw the bolt B1 all the way down without tightening; this way, you will be able

to swing the pad with no effort and, consequently, to easily fix the bolt B2 to the

hexagon.

The six sides of the hexagon are marked with the numbers from 1 to 6, while

the two faces, marked with the letters A and B, have the two threaded holes

(for fixing the bolt B2). In total, 12 possible fixing position.

12

B1

B2

Rounded side

B

Side number

Face letter

For the inner side of the clamp, fit the hexagon into the housing and screw the bolt B2 into either of the two holes.

Before fully screwing the bolt, make sure the upper and the lower sides of the hexagon are completely leaning on the housing’s walls.

If not, you can either change hole or, as in the example below, if you need to keep the same coupling pad inclination, reverse the hexagon

horizontally (from face A to B, or vice-versa) and keep the same side and the same hole.

B2 B2

5

A

B2

5

B

Follow next page

B1

B2

A2 A6

A

C

Rounded side

REHATEAM s.r.l.—vicolo Negrelli 5—31038 Castagnole di Paese TV—www.rehateamprogeo.com Service Manual MOTOTRONIK 13

SERVICE MANUAL

COUPLING PAD

ASSEMBLY AND ADJUSTMENT

A3

As initial position, it is advisable to adjust the coupling pads at an intermediate inclination between minimum and maximum, in

fact, il will be useful during the next installation steps; you will make the final adjustment afterward.

If the clamp is mounted facing to the front of the wheelchair, the

assembly is the same, but make sure the rounded side of the pad is

facing frontward.

To fix the second pad, replicate the fixing of the first pad symmetrically, that is, using the same side (1, 2 , 3, 4, 5 or 6) and the same hole,

but the opposite face (A or B).

Accordingly, if letter A on the hexagon is visible on the right clamp, then the letter B should be visible on the left clamp.

This way, the two pads will be fixed at the same inclination that can be taken as initial. You will probably need to adjust it later.

It is advisable to start with a mid way inclination as in the pictures, just ensure right and left side are equally adjusted.

Tighten the bolts that fix the two pads..

Rounded side

B2

B

B2

A

Minimum inclination Maximum inclination Minimum inclination Maximum inclination

A2

A2

Front of wheelchair

REHATEAM s.r.l.—vicolo Negrelli 5—31038 Castagnole di Paese TV—www.rehateamprogeo.com Service Manual MOTOTRONIK 14

SERVICE MANUAL

COUPLING FORK ASSEMBLY

A3

The coupling forks Dshow, on one side, a half-moon housing D1 that couples the shape of the pad B, while, on the opposite side, a round

housing D2 for the washer E1 of the lock lever E; on this last side the plate D3 and related bolts D4 are meant to fix the connection frame’s

tubes.

The two forks are not ambidextrous, but you can mount them both on the right and on the left hand side, thus, the connection frame’s tube

can either be above or below the clamp A.

Insert and screw the lever E into the hole B3 leaving approximately a 10 mm gap to allow sliding the fork in.

Slide the fork in and lock it with the lever.

D

D3 D2

D1

D3

D4

E1

E

≈ 10 mm

XX cm

Due to the several variants that affect

the final adjustment of the complete

system, you may need to reverse the

fork assembly regardless the instruc-

tion here reported.

B

A

B3

The lever’s washer must

couple with the round

housing of the fork.

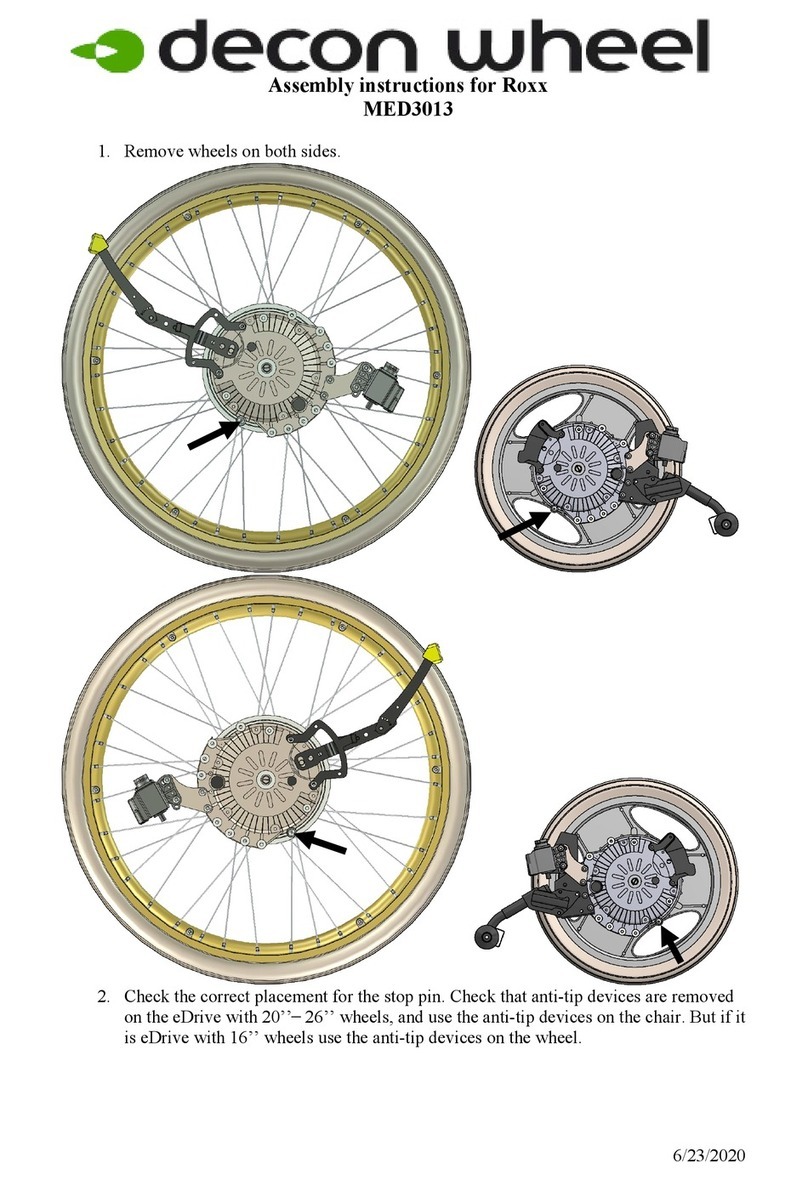

If the positioning in height of the clamps is lower than 34 cm, mount the forks with the tube low fixing (D↓ );

If the positioning in height of the clamps is higher than 34 cm, mount the forks with the tube high fixing (D↑);

34 cm

> 34 cm

< 34 cm

D↓

D↑

REHATEAM s.r.l.—vicolo Negrelli 5—31038 Castagnole di Paese TV—www.rehateamprogeo.com Service Manual MOTOTRONIK 15

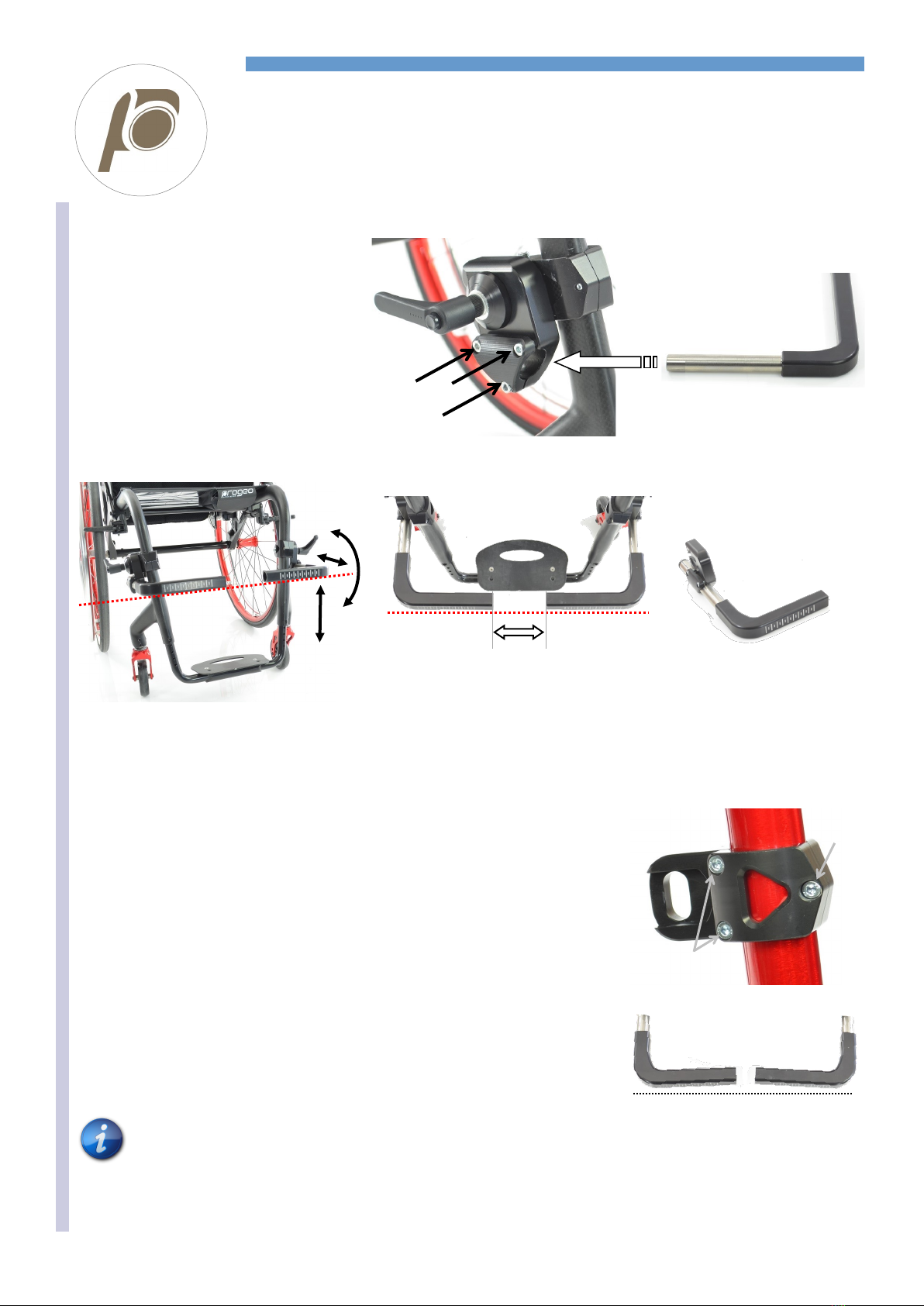

SERVICE MANUAL

CHECKING

THE CONNECTION FRAME’S ARMS

Loosen the three bolts D4 of the plate and slide in

the tube F1 of the arm F.

Screw the bolts just enough to eliminate the play

but without preventing the tube from being moved.

Repeat the same operation on the other side.

Now position the two arms so as to be able to

check whether, at the same height, inclination and

depth, they are horizontally aligned.

Also check that the distance between the two arms

is at least 25 mm, but not more than 190 mm.

Finally, unscrew the lever and remove the unit

arm/coupling fork.

Min. 25 mm

D4

F1

F

IF THE TWO ARMS ARE NOT ALIGNED,

check that the two coupling forks are well fixed with the locking levers and that the three bolts D4 of the clamps that fix the tubes do not

allow any play to the tubes themselves. If this is not enough, it is necessary to fix the clamps fixed to the frame.

If the tube on which the clamp is fixed is round, slightly loosen the clamp bolts A4 and A5 and

leverage the arm until alignment. This may be necessary for one or both sides.

Once alignment is achieved, tighten the clamps tightly.

If the tube on which the clamp is fixed is NOT round, you need to give the external side of the

clamp a compensation move by working on the three fixing bolts.

Loosen the bolt A5 hall a turn, tighten the two bolts A4 and check the alignment of the arms.

If that is not enough, repeat the same operation by another half of a turn of the bolt A5.

If the result is opposite to what expected, repeat the same operation, but start with loosening the

bolts A4 and then tightening the bolt A5.

This operation may be needed for one or both sides and it may not lead to a perfect alignment,

however, a few millimetres tolerance is acceptable.

Finally, tighten the clamps.

If the arms are too wide, you can cut off the exceeding part; on the other hand, if they are too narrow, you need to replace them

with wider ones.

We will check the length of the tubes later on.

See chapter “FRAME CONNECTION’S ARMS” for further information on sizes of the arms.

A4

A5

Few mm tolerance

REHATEAM s.r.l.—vicolo Negrelli 5—31038 Castagnole di Paese TV—www.rehateamprogeo.com Service Manual MOTOTRONIK 16

SERVICE MANUAL

CONNECTION FRAME’S ARMS

SIZES AVAILABLE

The connection frame’s arms are available in three widths and two lengths.

f necessary, you can cut both the steel round tube and the aluminium sqaure tube.

Always put the cap into the steel tube end to avoid scratching the surface you will lean the device on.

X Y

NARROW 16 SHORT 25

LONG 35

MEDIUM 21 SHORT 25

LONG 35

WIDE SHORT 25

26 LONG 35

If you need to cut the tubes:

• When using the Mototronik, the square tube must be inserted (and tightened) into connection frame’s central tube for at

least 30 mm, otherwise the stability of the system is not guaranteed.

• The steel round tube must always be embraced along the entire width of the clamp; the exceeding part may be cut off until

reaching the line of the rearmost side of the clamp.

Min. 30 mm

Exceeding part

Clamp

width

56 mm

16 cm

21 cm

26 cm

35 cm

25 cm

X Y

The size Y includes

the L-shaped tube.

The length of the

straight tube is 310

or 210 mm

REHATEAM s.r.l.—vicolo Negrelli 5—31038 Castagnole di Paese TV—www.rehateamprogeo.com Service Manual MOTOTRONIK 17

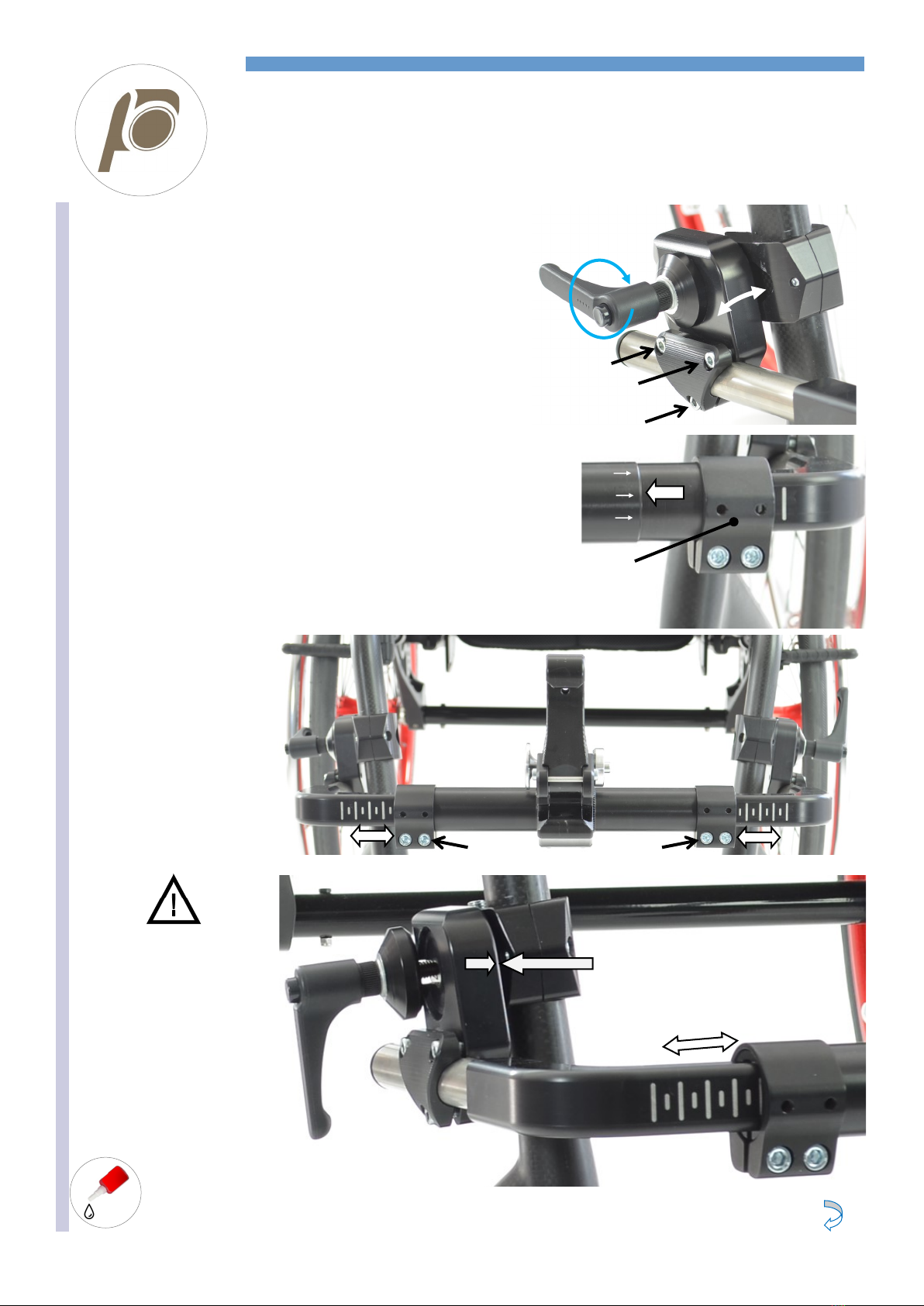

SERVICE MANUAL

CONNECTION FRAME ASSEMBLY

COUPLING UNIT

Mount the plate on the coupling

support by just fitting the bolts on

the 4 corners and making sure

the hole in the middle is aligned

with that on the coupling support.

Position the coupling support so

as to be able to fit the remaining

bolt that can pass only through

G

G1

G2

H TOOTHED PART

SMOOTH PART

GROOVE

TOOTHED

PART

Now, making sure the toothed side of the central tube fit to that of the coupling support, turn the unit coupling support/plate until positioning

their joining parts where the smooth and toothed sectors of the tube begins/ends.

Screw the bolts until fixing the parts, no need to tighten hard now.

Do not put the central bolt, you will fix it after final adjustment of the entire system.

Consider this position as initial reference because you will probably need to change it in a following step of the installation.

The coupling support G is fixed to the frame connection’s central tube Hby means of the plate G1 and the bolts G2.

The central tube shows two sectors with a wider diameter separated by a groove that determines the centre of the tube itself

Half of such sectors is smooth, whereas the other is toothed and it is designed to adjust and fix the coupling unit that, on its turn, has a cou-

pling toothed section.

Follow next page

G

G1

H

Without bolt

This unit may be

supplied assembled.

REHATEAM s.r.l.—vicolo Negrelli 5—31038 Castagnole di Paese TV—www.rehateamprogeo.com Service Manual MOTOTRONIK 18

SERVICE MANUAL

CONNECTION FRAME ASSEMBLY

ASSEMBLY OF ARMS ON COUPLING UNIT

Insert the two clamps Ithat fix the arms so as the bolts I1 are, for convenience, facing down front and insert the two arms facing backward

and in such a way that the coupling unit is approximately perpendicular to the connection frame (the other three positions given by the

square section clearly results wrong).

Now the two clamps and the arms are free to move and they are ready for the next step of installation.

Even the coupling forks, in this phase, be them facing down (as in the pictures here below) or up, are not securely fixed.

Follow next page

≈ 90°

I I1

D

I1

I

I1

anteriore

posteriore

F

F2

REHATEAM s.r.l.—vicolo Negrelli 5—31038 Castagnole di Paese TV—www.rehateamprogeo.com Service Manual MOTOTRONIK 19

SERVICE MANUAL

CONNECTION FRAME ASSEMBLY

ASSEMBLY OF CONNECTION FRAME TO WHEELCHAIR

You can now fit the connection frame to the wheelchair.

It is necessary that the two coupling pads A are always tilted at the same inclination; you can do that in two ways:

1) adjust and fix the pad at the same inclination —see chapter “assembly and adjustment of the coupling pads”;

2) for each pad, unscrew the bolt A2 and remove the hexagon C(do not remove the bolt); loosen the bolt A1 and swing the pad to its maxi-

mum upward inclination and tighten the bolt; this way, the pad is free to swing once you insert the connection frame.

It is suggested the second method because you will need to adjust the pad inclination in the next step of installation.

Slide the two arms in or out of the central tube to make the connection frame wider or narrower until being able to fit the coupling forks to the

pads. Make sure the lock lever Fis enough unscrewed to allow the

D

F

H

I

≈ 10 mm

B

E

E D

REHATEAM s.r.l.—vicolo Negrelli 5—31038 Castagnole di Paese TV—www.rehateamprogeo.com Service Manual MOTOTRONIK 20

SERVICE MANUAL

CONNECTION FRAME ASSEMBLY

WIDTH ADJUSTMENT

For each side of the system, loosen the bolts D4 and then tighten the lock

lever to secure the coupling fork.

This way the forks will match the inclination of the clamps A.

Position the clamps Iover their housing on the central tube and, making use

of the reference marks on the arms, centre the central tube and temporarily

tighten the bolts I1.

Now, unscrew the lock levers and remove the connection frame.

You will notice that it is a bit hard because you have just adjusted the system

with the coupling fork pressed against the clamps.

You then need to adjust the width of the connection frame in such a way to

allow for an easy fitting and removal.

Loosen the bolts I1 and move the arms sideward until reaching a 0.5~1 mm

gap between fork and clamp.

Check the central tube is centred.

Tighten the bolts and check the connection frame is easy to insert and re-

move.

Follow next page

I

D4

A

I1 I1

0.5 ~1 mm

DO NOT move the arm out ex-

cessively (more than 2 mm) be-

cause, when you screw up the

lock lever, the tubes flex to reach

the proper coupling position,

therefore, the wider the connec-

tion frame, the more flexion the

tubes require, and the system

will results more difficult to fix.

It is advisable to spread a

drop of mild lock thread

glue on the bolts D4.

Other manuals for MOTOTRONIK

1

Table of contents