8. SERVICE INFORMATION

HOW TO ORDER REPLACEMENT

PARTS

Even quality-built equipment such as the

generator you have purchased will need

occasional replacement parts to maintain its

good condition over the years.

To order replacement parts and consumable

parts, please contact Promate Service (details

below) and be ready with the following

information:

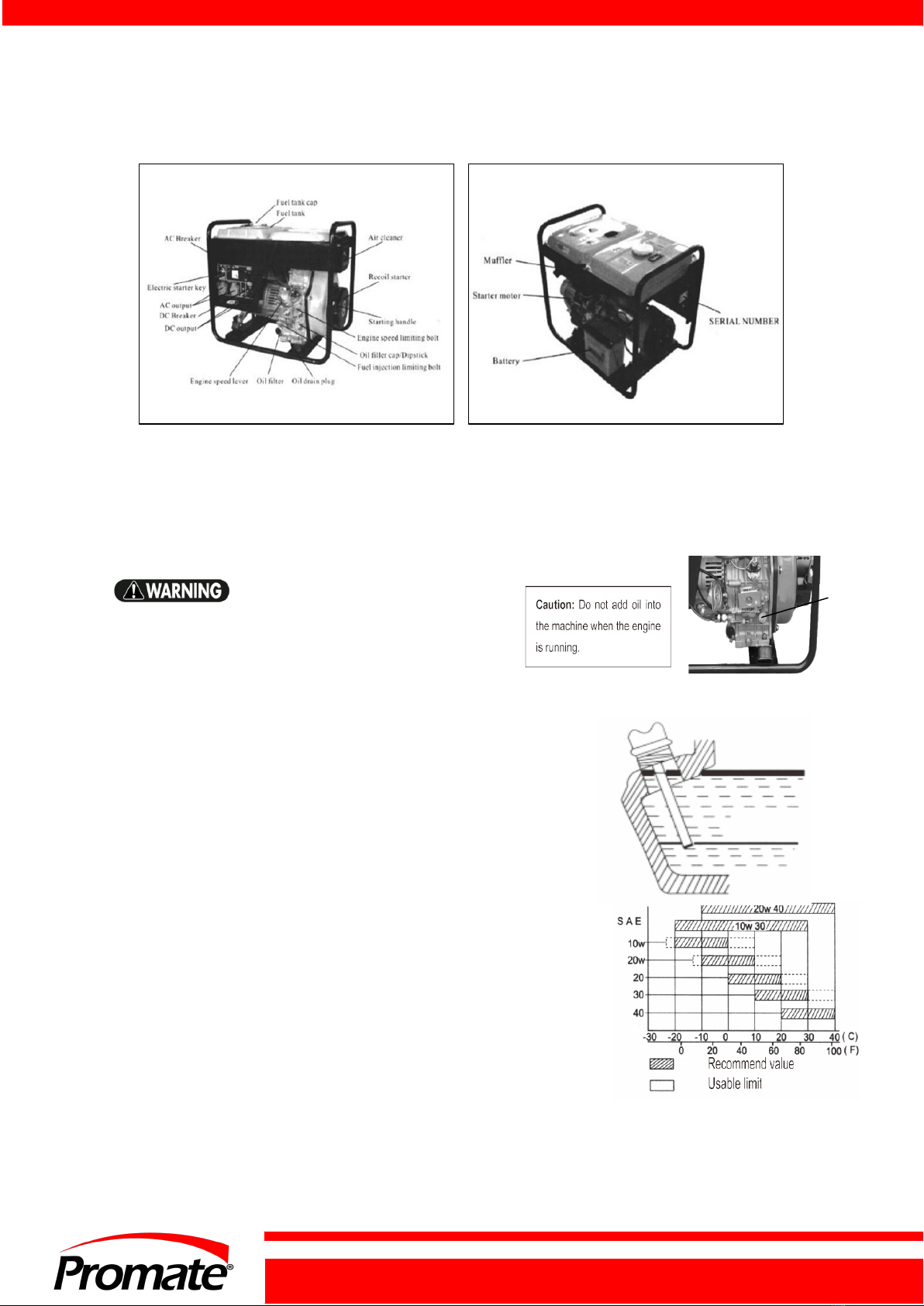

1. Model No., Serial No. and all

specifications that are shown on

the Model No./Serial No. plate.

2. Part number or numbers as shown

in the Parts List section.

3. A brief description of the trouble

with the generator.

LIMITED WARRANTY

Warranty Coverage: Powertech Asia Pacific

Inc., (the Company) warrants to the original

retail customer that it will repair or replace,

free of charge, any parts found by the

Company or its authorized service

representative to be defective in material or

workmanship. This warranty covers the cost

of replacement parts and labor for defects in

material or workmanship.

Not Covered:

•Shipping/Handling charges for sending

the product to the Company or its

authorized service representative for

warranty service. Shipping/Handling

repaired or replaced products back to the

customer; these charges must be borne

by the customer.

•If a separate operator's manual and

engine warranty from the engine

manufacturer is included with this

product, only that warranty will apply to

the engine.

•Damage caused by abuse, accident, the

effects of corrosion, erosion and normal

wear and tear.

•Warranty is void if the customer fails to

install, maintain and operate the product

in accordance with the instructions and

recommendations of the Company set

forth in the owner's manual, or if the

product is used as rental equipment.

•The Company will not pay for repairs or

adjustments to the product, or for any

costs of labor performed without the

Company's prior authorization.

•Consumable parts such as battery, spark

plugs, and air cleaner.

Warranty Period: One (1) year from the date

of purchase on products used solely for

consumer applications; if a product is used for

business or commercial applications,

the warranty period will be limited to ninety

(90) days from the date of purchase.

For warranty service, the customer must

provide dated proof of purchase and must

notify the Company within the warranty

period.

EXCLUSIONS AND LIMITATIONS: THE

COMPANY MAKES NO OTHER WARRANTY OF

ANY KIND, EXPRESS OR IMPLIED. IMPLIED

WARRANTIES, INCLUDING WARRANTIES OF

MERCHANTABILITY AND OF FITNESS FOR A

PARTICULAR PURPOSE, ARE HEREBY

DISCLAIMED. THE WARRANTY SERVICE

DESCRIBED ABOVE IS THE EXCLUSIVE

REMEDY UNDER THIS WARRANTY;

LIABILITY FOR INCIDENTAL AND

CONSEQUENTIAL DAMAGES IS EXCLUDED

TO THE EXTENT

PERMITTED BY LAW.

This warranty gives you specific legal rights,

and you may also have other rights which

vary from state to state. Some states do not

allow a disclaimer of implied warranties or the

exclusion or limitation of incidental and

consequential damages, so the above

disclaimers and exclusions may not apply to

you.

CONTACT THE POWERTECH Asia Pacific Inc.,

PRODUCT SERVICE DEPARTMENT AT (02) 8 984 2620 | (+63) 9228741679

service@powertechasiapacific.com www.facebook.com/PromateServicePH/