4-4. Using the Pressure Washer at

High Altitudes

Engine carburetor is factory adjusted for

optimum operation from Oto 1500 meters

above the sea level. Approximately 10% of

power drop in the engine is expected with

respect to each 1000 meters of altitude. To

maintain proper emissions compliance and

optimum performance & fuel consumption,

high altitude adjustment may be required for

altitudes above 1500 meters. If adjustment is

required, contact Promate Service.

5. STARTING THE

PRESSURE WASHER

Prior to starting the Pressure Washer, make

sure to have the following:

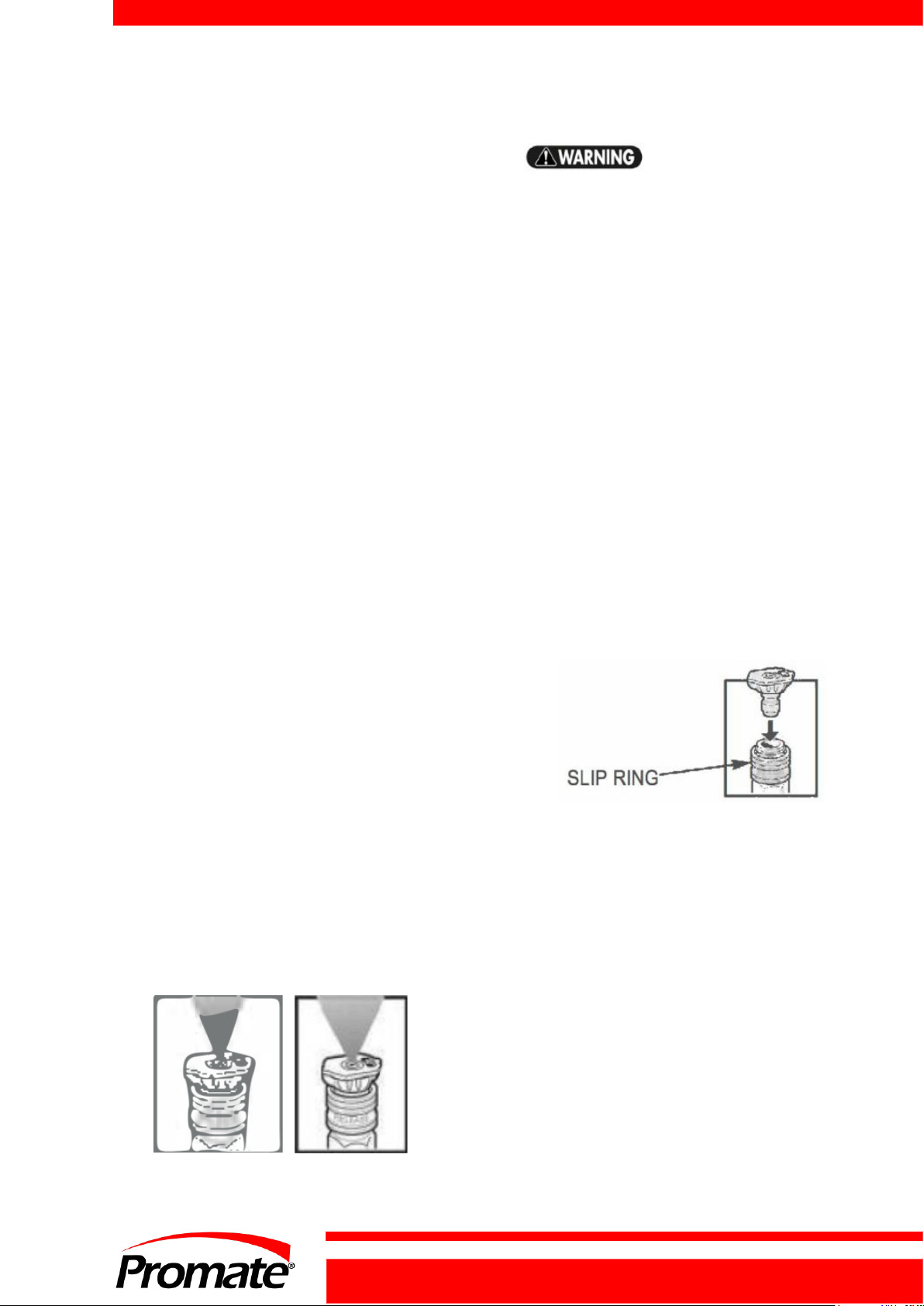

1. Selected a proper size nozzle for the job

at hand (see “Selecting the Right

Nozzle for the Job”).

2. Attached the pressure washer to the

water source and turned on the source

(see “Pressure Pump to Water

Supply”).

3. For your protection, wear the protective

safety glasses provided.

4. Move the pressure washer outside in a

fully ventilated area.

5. Place the pressure washer on a FLAT and

level surface and close to the working

surface. Keep a minimum of 5 ft. (1.5

meters) CLEARANCE on all sides of the

engine including top. Face the engine

exhaust outlet AWAY from dwellings.

6. Make sure the Throttle level is set to the

"FAST" position (left).

7. Slide the fuel valve lever to "ON" position

(right) to allow the fuel to flow to the

engine.

8. Slide the Choke lever to "START" position

(left).

9. Turn the Engine ON/ OFF switch clockwise

to ON position.

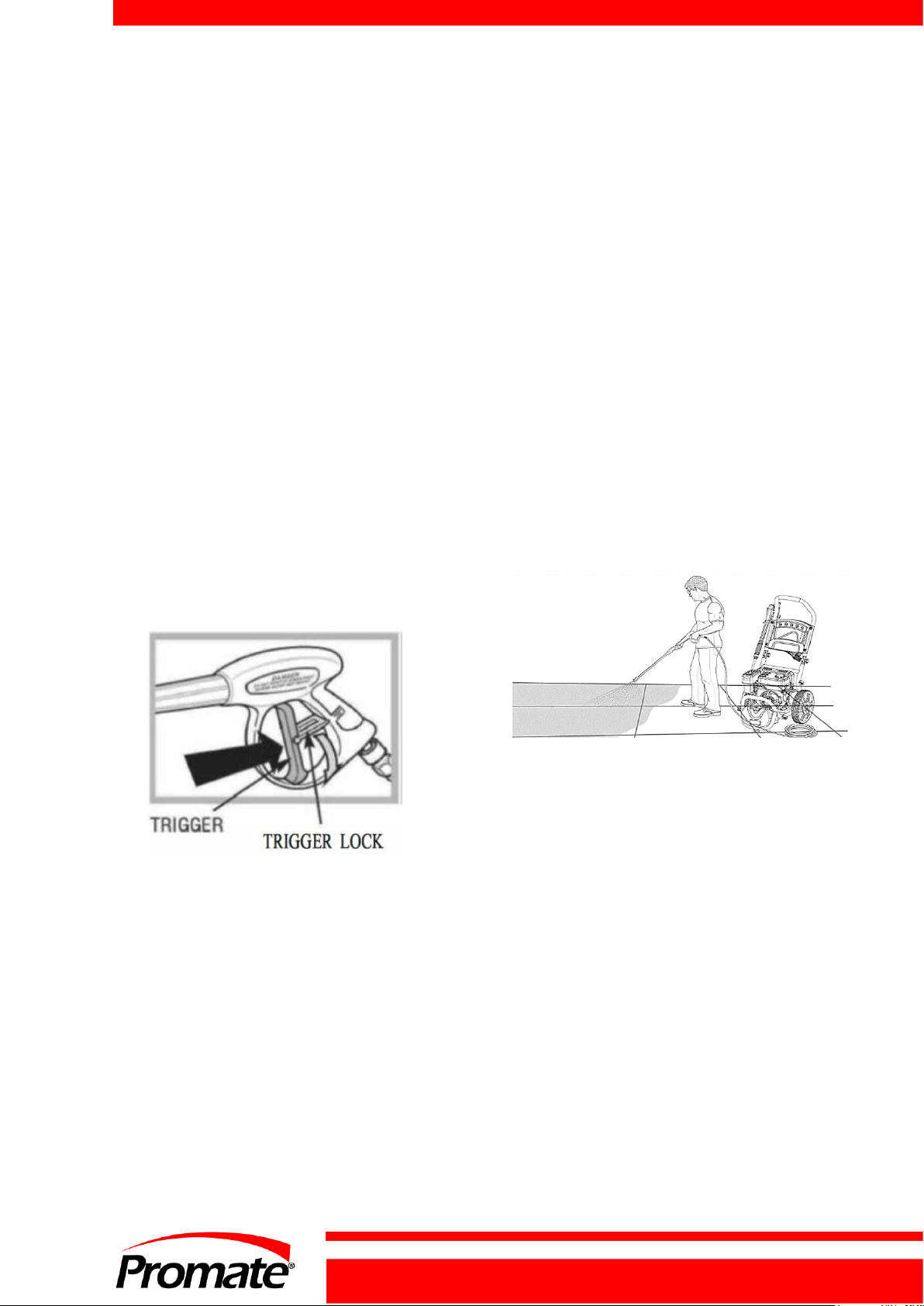

10. Point nozzle to a safe direction and

squeeze the spray gun trigger to allow for

easier engine start.

11. To start the engine, pull starter cord

slowly until resistance is felt, then pull

rapidly to avoid kick back. Repeat until the

engine starts to run. Then, release the

trigger.

12. Slide the chocke lever to “RUN” (right)

position.

6. OPERATING THE

PRESSURE WASHER

DO NOT leave pressure washer in by-pass

mode for more than two minutes at a

time. Water temperature inside the

pressure pump will rise to a dangerous

level resulting in damage to the internal

components of the pump. Failure to follow

this warning will void warranty.