Promatic CMP25-2 User manual

PROMATIC CMP25-2

Régulateur de vanne mélangeuse pour circuits de chauffage

FRE

Witterungsgeführte Heizungsregler des Mischerheizkreises

DEU

Weather compensated controller for mixing heating circuits

ENG

Regolatore climatico per circuiti di riscaldamento miscelati

ITA

ENGDEUDUTFRE

Weather compensated controller for mixing heating circuits

PROMATIC CMP25-2

Witterungsgeführte Heizungsregler des Mischerheizkreises

PROMATIC CMP25-2

Weersafhankelijke regelaar voor mengverwarmingscircuits

PROMATIC CMP25-2

Régulateur de vanne mélangeuse pour circuits de chauffage

PROMATIC CMP25-2

ENG

5

INTRODUCTION

PROMATIC CMP25-2 controller is a modern designed, microprocessor-driven device

made with digital and SMT technology.

It is intended to control mixing heating circuit with radiator or surface heating systems.

CMP25-2 features multi-chanel program timer for time-dependent room heating.

CMP25-2 controllers can be connected to network and operate as uniform control system

for multi heating circuits.

For initial setup see Initial controller setup, page 9!

Weather compensated controller for mixing heating circuits

PROMATIC CMP25-2

ENG

6

CONTENTS

USER MANUAL

CONTROLLER DESCRIPTION..................................................................................8

Controller appearance.................................................................................................8

Operation mode indication ..........................................................................................8

INITIAL SETUP OF CONTROLLER...........................................................................9

Procedure of initial setup.............................................................................................9

MAIN DISPLAY AND NAVIGATION ........................................................................11

Main display description and design..........................................................................11

Description of symbols shown on display..................................................................11

Symbols for operation mode..............................................................................11

Symbols for user functions ................................................................................12

Symbols for temperature ans data overview .....................................................12

Symbols for protection functions .......................................................................13

Symbols for communication of controllers in network........................................13

Symbols for notice and warnings.......................................................................13

Basic screen navigation ............................................................................................14

Locking / unlocking the screen ..................................................................................14

Display for help, notices and warnings......................................................................15

ENTRY AND NAVIGATION THROUGH THE MENU ...............................................16

Menu structure and description .................................................................................17

Temperture settings ...........................................................................................20

User functions ...................................................................................................21

Operation mode .................................................................................................22

Time programs ...................................................................................................23

Basic settings ............................................................................................................26

Data Overview...........................................................................................................27

SERVICE SETTINGS MANUAL

SERVICE SETTINGS................................................................................................28

Basic parameters ......................................................................................................28

Heat curve..........................................................................................................30

Service parameters ...................................................................................................32

Floor drying parameters ............................................................................................35

Factory settings.........................................................................................................36

ENG

7

INSTALLATION MANUAL

CONTROLLER INSTALLATION ..............................................................................37

Installation onto mixing valve ....................................................................................37

Controller's electric connection..................................................................................39

Connection of mains...........................................................................................39

Connection of sensors, room units and BUS......................................................39

Connection of digital room unit DD2+.................................................................40

Connection of room sensor ................................................................................40

Marking and installation of temperature sensors ................................................41

Operation mode by sensor failure ......................................................................42

Expanding the system on multiple heating circuits.............................................42

HYDRAULIC AND ELECTRIC SCHEMES...............................................................44

TECHNICAL DATA...................................................................................................47

DECLARATIONS AND STATEMENTS....................................................................48

Conformity with standards and directives..................................................................48

Disposal of old electrical & electric equipment ..........................................................48

ENG

8User manual

USER AND SETTINGS MANUAL

CONTROLLER DESCRIPTION

OPERATION MODE INDICATION

CONTROLLER APPEARANCE

1 2

Graphic display with touch panel.

Button - Esc, Help.

Illuminated button:

green - closing of mixing valve

red - opening of mixing valve

2

1

ENG

9 User manual

INITIAL SETUP OF CONTROLLER

Controller PROMATIC CMP25-2 is equipped with innovative solution “EASY START” for

easy setup with the help of setup wizard.

When you connect the controller to the power supply

for the first time or by reset, the software version is

shown. Next, the setup wizard runs.

PROCEDURE OF INITAL SETUP

On screen appears picture for selecting the display orientation.

Press icon where letter Ais normally readable.

After selecting proper display orientation, press button to confirm your selection.

STEP 1 - DISPLAY ORIENTATION

Press icon which indicates the proper direction ( ) of mixing valve opening.

After selecting proper valve opening direction, press button to confirm your selection.

STEP 2 - OPENING OF THE MIXING VALVE

OR

ENG

10User manual

RESET

Switch off power supply of the controller. Hold button and switch on

power supply. Controller resets and runs initial setup.

Press icon which indicates your language.

After selecting proper language, press button to confirm your selection.

STEP 3 - LANGUAGE SELECTION

Select scheme for controller operation.

Confirm your selection with button .

STEP 4 - HYDRAULIC SCHEME

Selected hydraulic scheme, screen orientation direction, rotation direction

and language can be at any time changed in service settings or with reset of

controller!

Press buttons and to set requested heat curve

steepness. Confirm your selection with button .

Heat curve steepness is detailed described on pages 30

and 31.

STEP 5 - HEAT CURVE STEEPNESS

OR

ENG

11 User manual

MAIN DISPLAY AND NAVIGATION

All important data of controller operation are shown on the graphic LCD display which is

intended also for setting the controller.

DISPLAY DESCRIPTION AND DESIGN

1

2

Operation

mode

Active user functions

Temperature

overview

and other

data

Time and date

T1= 21°C

T2= 5°C T3= 45°C

T4= 65°C

Notifications

and warnings

Room unit

Temperature

overview

Screen

unlocking

Key

Esc

Time and date Screen

unlocking

Indication of mixing valve

and pump operation

Notifications

and warnings

SYMBOLS FOR OPERATION MODE

DESCRIPTION OF SYMBOLS SHOWN ON THE DISPLAY

Symbol Description

Heating mode

Cooling mode

Room heating according to program timer - day temperature

Room heating according to program timer - night temperature

Heating according to the set-point day temperature

Heating according to the set-point night temperature

Switch off

Manual operation

ENG

12User manual

SYMBOLS FOR USER FUNCTIONS

Symbol Description

Party

Eco

Holiday

Floor drying is active

Automatic switchover to summer mode

Heating with constant stand pipe temperature is active

Remote activation

Boost heating

SYMBOLS FOR TEMPERATURE AND DATA OVERVIEW

Symbol Description

Measured temperature

Calculated or set-point temperature

Indoor (Room) temperature

Outdoor temperature

Stand-pipe temperature

Return-pipe temperature

Boiler temperature

Mixing valve - closing (flashing indicates trend for closing)

Mixing valve - opening (flashing indicates trend for opening)

Circulation pump

T1, T2, T3, T4

TR

TA

TQ

Temperature measured on sensor T1, T2, T3 or T4.

Temperature measured on room unit DD2+.

Outdoor temperature, acquired t BUS connection.

Boiler temperature, acquired from BUS connection.

- day of drying

- drying duration (days)

ENG

13 User manual

1

2

SYMBOLS FOR COMMUNICATION OF CONTROLLERS IN NETWORK

Symbol Description

Devices, connected to the communication line COM1

First (1) or second (2) room unit DD2+ is connected

Independent controller - not connected to bus

First controller in bus connection

Last controller in bus connection

Rank of controller and BUS connection COM1/COM2

Intermediate controller in bus connection

SYMBOLS FOR PROTECTION FUNCTIONS

Symbol Description

Liquid fuel boiler overheating protection

Frost (indoor) protection

SYMBOLS FOR NOTICE AND WARNINGS

Symbol Description

Notice

In case of exceeding the maximum temperature or activation of

protection function, the controller indicates the event with flas-

hing symbol on the display. If the maximum temperature is no

longer exceeded or if the protection function is turned off, a

lited symbol indicates a recent event.

Press to open the screen to check notifications.

Warning

In the event of sensor failure, bus or com connection error, the

controller indicates the failure with flashing symbol on the

display. If the issue is resolved or no longer present, a lited

symbol indicates a recent event.

Press to open the screen for warnings.

ENG

14User manual

Button Function of button

Screen unlocking / locking

Help

Menu entrance

Move to next data

Move forward / backward in menu or data

Increasing / decreasing the data value

Confirmation

Confirmation and return to the previous menu or selection

If you want to change the controller settings or overview the operation data. Press the

button to unlock the screen.

The screen is automatically locked 60 s after the last key is pressed.

LOCKING/UNLOCKING THE DISPLAY

BASIC SCREEN NAVIGATION

ENG

15 User manual

Delete warnings

By pressing this button all sensors that are not connected will be deleted from

the list of failures.

Note:

Failures of sensors that are required for controller operation can not be

deleted.

First unlock the screen by pressing the button . Press button to open the

screen for help, notices and warnings is opened.

Short manual

Short manual for use of the controller.

Controller version

Overview of controller type and software version.

Notices

List of exceeding the maximum temperatures and activated protection functi-

ons. By pressing the buttons and move through the list of notifi-

cations. Press to exit the list.

Warnings

The list of sensors failures and other components.

By pressing the buttons and move through the list of warnings.

Press to exit the list.

DISPLAY FOR HELP, NOTICES AND WARNINGS

Available posibilities:

ENG

16User manual

If menu features more than one full screen of selections, press button to

move on the next screen or button to move to the previous screen.

To unlock the screen press button . To enter the menu press button .

ENTERY AND NAVIGATION THROUGH THE MENU

1

2

1

2

To move around the menu, press icons displayed on the screen.

T1= 21°C

T2= 5°C T3= 45°C

T4= 65°C

T1= 21°C

T2= 5°C T3= 45°C

T4= 65°C

ENG

17 User manual

MENU STRUCTURE AND DESCRIPTION

TEMPERATURE SETTINGS

Day temperature

Night temperature

USER FUNCTIONS

Party

Eco

Holiday

Deactivation of function

OPERATION MODE

Time program operation mode

Day temperature operation mode

Night temperature operation mode

Switch OFF

Heating or cooling operation mode selector

Manual operation mode

Time program 1

Time program 2

Time program 3

Time program 4

TIME PROGRAMS

ENG

18User manual

BASIC SETTINGS

User language

Time and date

DISPLAY SETTINGS

Duration of active display illumination and menu autoexit

Intensity of active display illumination

Intensity of inactive display illumination

Contrast

DATA OVERVIEW

Diagrams of measured temperatures for last week

Diagrams of measured temperatures for last day

Special service data

CONTROLLER PARAMETERS

Basic settings

Settings for heating circuit

Settings for heat source

SERVICE PARAMETERS

Basic settings

Settings for heating circuit

Settings for heat source

ENG

19 User manual

PRAMETERS FOR FLOOR DRYING

FACTORY SETTINGS

Reset of all controller parameters

Reset of time programs

Reset of all controller settings and restart of initial setup

Save user settings

Load user settings

ENG

20User manual

TEMPERATURE SETTINGS

Day temperature

Night temperature

Use buttons and to set the temperature.

Confirm and return to the previous screen by pressing button .

Use buttons and to set the temperature.

Confirm and return to the previous screen by pressing button .

Table of contents

Languages:

Other Promatic Controllers manuals

Popular Controllers manuals by other brands

Danfoss

Danfoss VLT HVAC Drive FC 102 Programming guide

Eaton

Eaton Crouse-Hinds Flex-Station EDS Series Installation & maintenance information

Girard Systems

Girard Systems GC1146C INSTALATION AND PROGRAMMING GUIDE

HIMA

HIMA HIMatrix MI 24 01 manual

Renesas

Renesas mPD98431 user manual

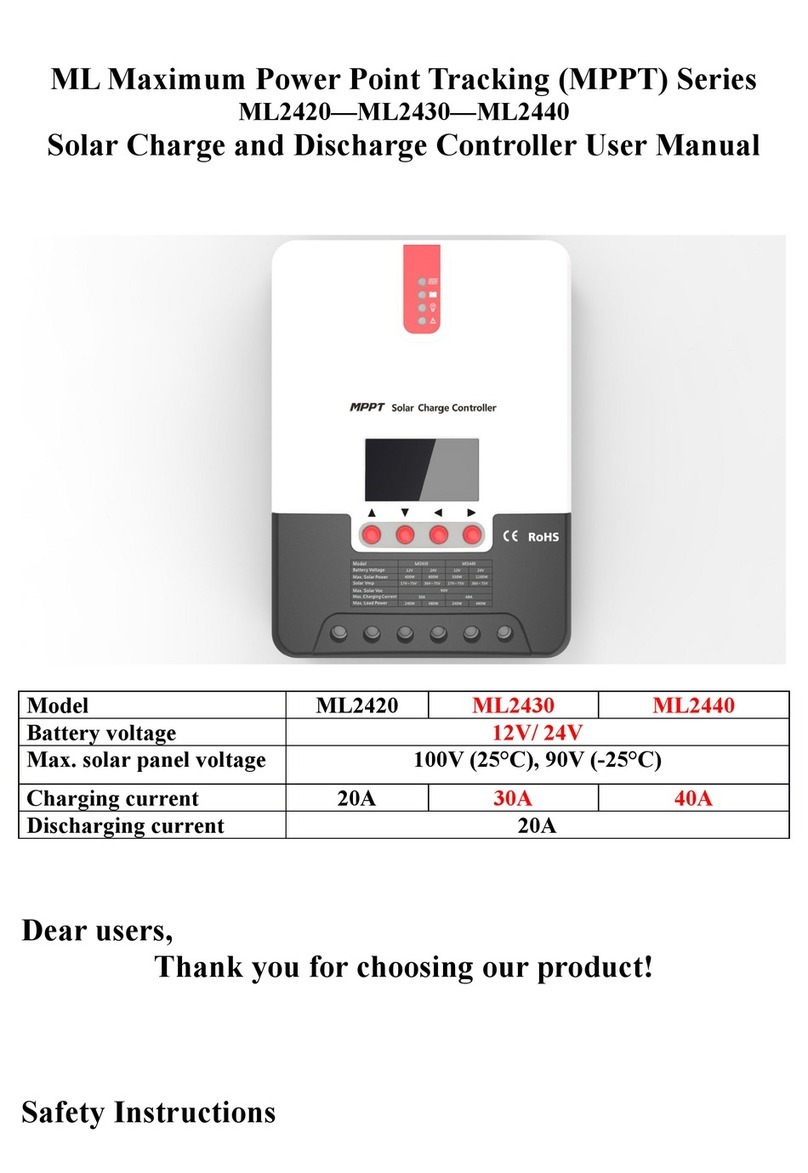

WATTUNEED

WATTUNEED ML Series user manual