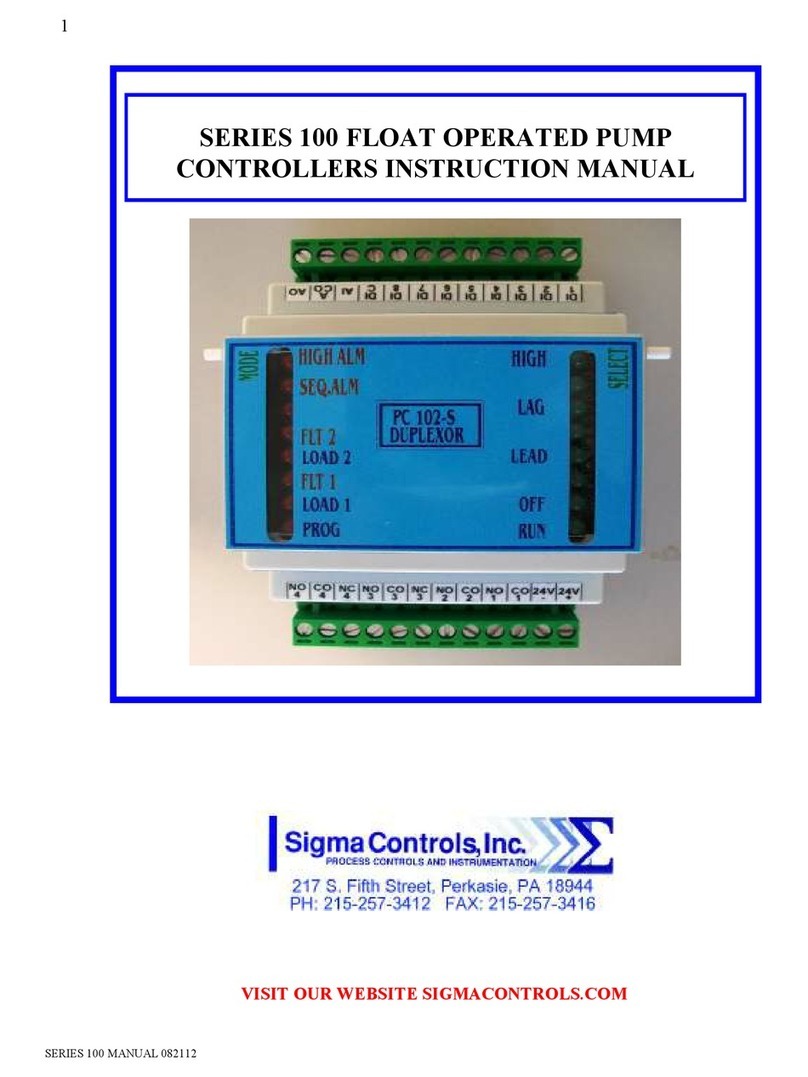

Sigma Controls MYRIAD QLC User manual

Table of contents

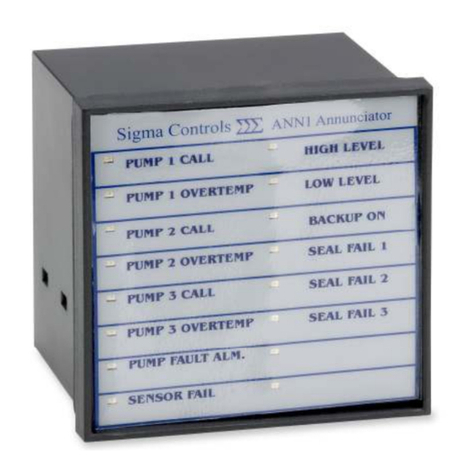

Other Sigma Controls Controllers manuals

Popular Controllers manuals by other brands

Lasermet

Lasermet ICS-7-OEM instruction manual

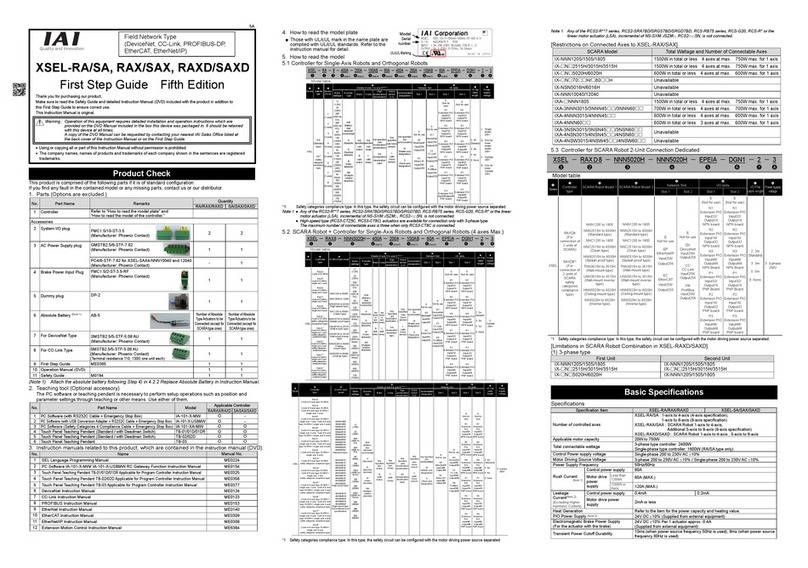

IAI

IAI XSEL-RA First step guide

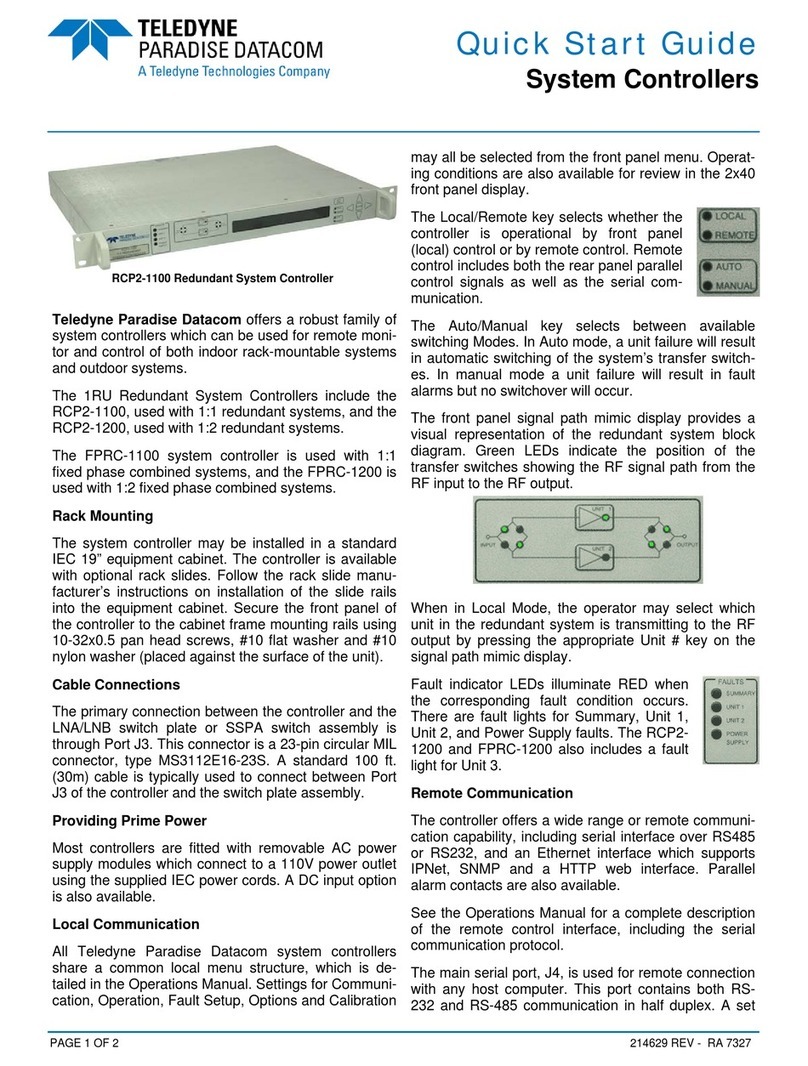

Teledyne

Teledyne RCP2-1100 quick start guide

S&S Northern

S&S Northern Merlin 1000VW+ Installation & operation manual

Lutron Electronics

Lutron Electronics Homeworks QS seeTouch HQWIS-NB-NONE installation instructions

Stober

Stober SD6 Series Commissioning instructions

Distech Controls

Distech Controls DA-016N024PX installation instructions

AQUARAY

AQUARAY MultiControl operating instructions

Johnson Controls

Johnson Controls TEC2245-4 installation instructions

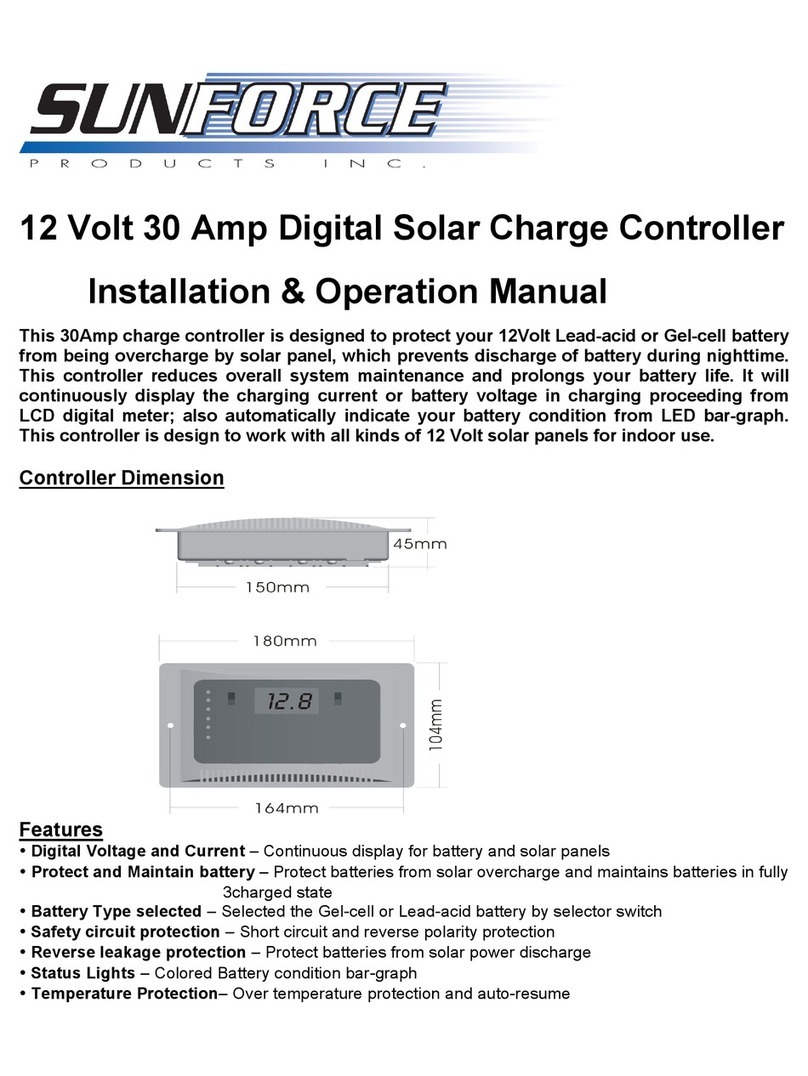

Sunforce

Sunforce 12 Volt 30 Amp Digital Solar Charge... Installation & operation manual

Circuitron

Circuitron TC-1 quick start guide

Microsensor

Microsensor MPM Series Operation manual

cashco

cashco D Installation, operation & maintenance manual

Covaris

Covaris S220 Service note

Autonics

Autonics TN Series product manual

Schnick-Schnack-Systems

Schnick-Schnack-Systems Long Distance Controller user guide

PIETRO FIORENTINI

PIETRO FIORENTINI REVAL 182 Technical manual

Grundfos

Grundfos Fire RS Installation and operating instructions