FM15_P28 HV PN7 (-TS) Ver I_052217

Page 4

101414

P213 Class Div Label 15 101414.ai

Label 810-10168 is

accurate 12/02/14.

Label 810-10174 is

accurate 12/02/14.

PEI Explosion Proof Product

(aluminum bolt on tag)

CAUTION: To reduce the risk of ignion

of hazardous atmospheres,

disconnect the equipment

from the supply circuit before

opening. Keep assembly ghtly

closed when in operaon.

WARNING:To reduce the risk of

ignion of hazardous atmospheres, an

appropriately cerfied sealing fing,

cable gland or plug must be

directly connected to the enclosure.

Class I, Division 1, Groups C, D

Class II,Division 1,Groups E,F,G

Class III; T6

Ex d IIB Gb T6; Ex tb IIIC T85°C Db

Class I, Zone 1, AEx d IIB Gb T6

Zone 21, AEx tb IIIC T85°C Db

CAUTION: To reduce the risk of ignion of hazardous atmospheres, disconnect the

equipment from the supply circuit before opening. Keep assembly

ghtly closed when in operaon. WARNING:To reduce the risk of

ignion of hazardous atmospheres, an appropriately cerfied sealing

fing, cable gland or plug must be directly connected to the enclosure.

ATTENTION! Pour réduire le risque d’inflammaon des atmosphères dangereuses,

démontez l’équipement du circuit d’approvisionnement avant de l’ouvrir. Maintenez

l’assemblage bien fermé lors de l’ulizaon. MIS EN GARDE! Pour réduire le risque

d’inflammaon des atmosphères dangereuses, un joint d’étanchéite, un

presse-étoupe ou une prise dûment cerfié doit être lié à l’encastrement.

CAUTION: To reduce the risk of ignion of hazardous atmospheres, disconnect the

equipment from the supply circuit before opening. Keep assembly

ghtly closed when in operaon. WARNING:To reduce the risk of

ignion of hazardous atmospheres, an appropriately cerfied sealing

fing, cable gland or plug must be directly connected to the enclosure.

ATTENTION! Pour réduire le risque d’inflammaon des atmosphères dangereuses,

démontez l’équipement du circuit d’approvisionnement avant de l’ouvrir. Maintenez

l’assemblage bien fermé lors de l’ulizaon. MIS EN GARDE! Pour réduire le risque

d’inflammaon des atmosphères dangereuses, un joint d’étanchéite, un

presse-étoupe ou une prise dûment cerfié doit être lié à l’encastrement.

Class I,Division 1,Groups C, D

Class II,Division 1,Groups E,F,G

Class III; T6

Ex d IIB Gb T6; Ex tb IIIC T85°C Db

Class I, Zone 1, AEx d IIB Gb T6

Zone 21, AEx tb IIIC T85°C Db

Class I, Division 1, Groups C, D

Class II, Division 1, Groups E,F,G

Class III; T6

Class I: 7 point Arial Bold, 7 point leading, tracking -40%

CAUTION: To reduce the... Calibri 6.5pt Bold and Regular

Tracking set at -25%, leading 6pt except above WARNING (leading at 8pt)

This size tag is 78mm (3.0709”) wide X 35mm (1.378”) high X .016 inch thick

Corner radii 6.35mm (.25”)

Part Number assigned: 810-10168

No hyphenation.

Standard size tag should be easier to fabricate.

Two tags, one without zone information for temporary use.

Needs remaining French warning text.

Needs French text checked for clarity/accuracy of language.

Needs final internal approval

Needs CSA approval

Used in IOM

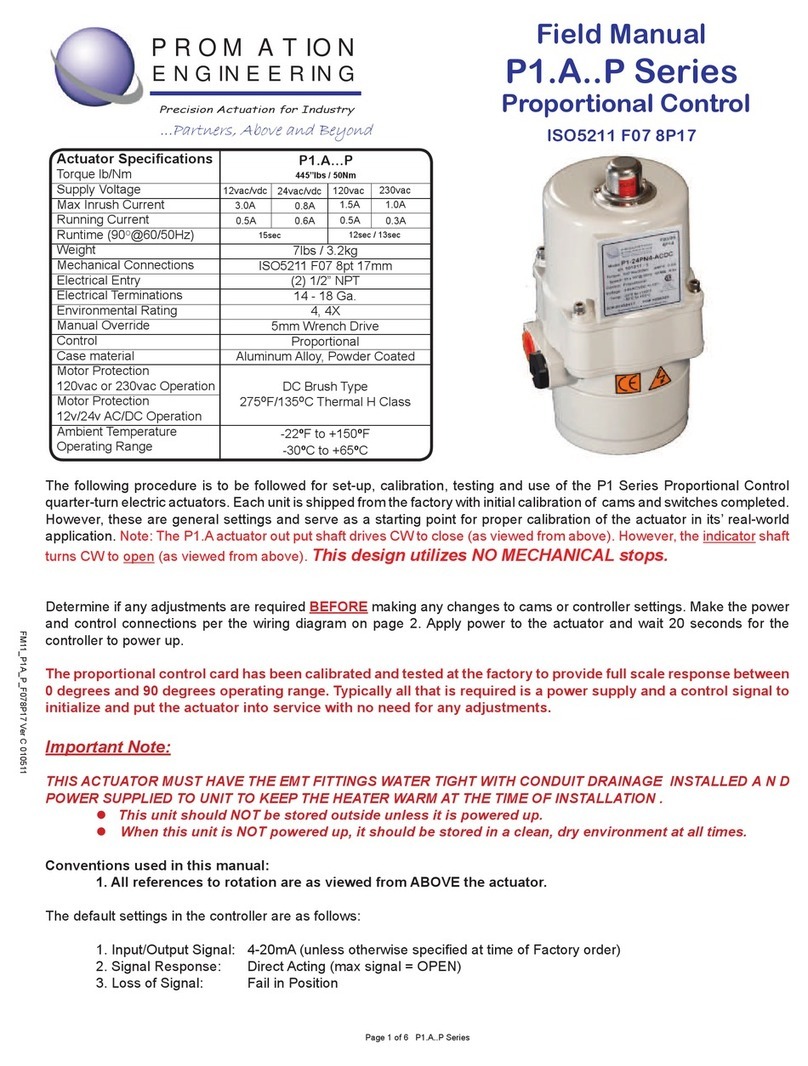

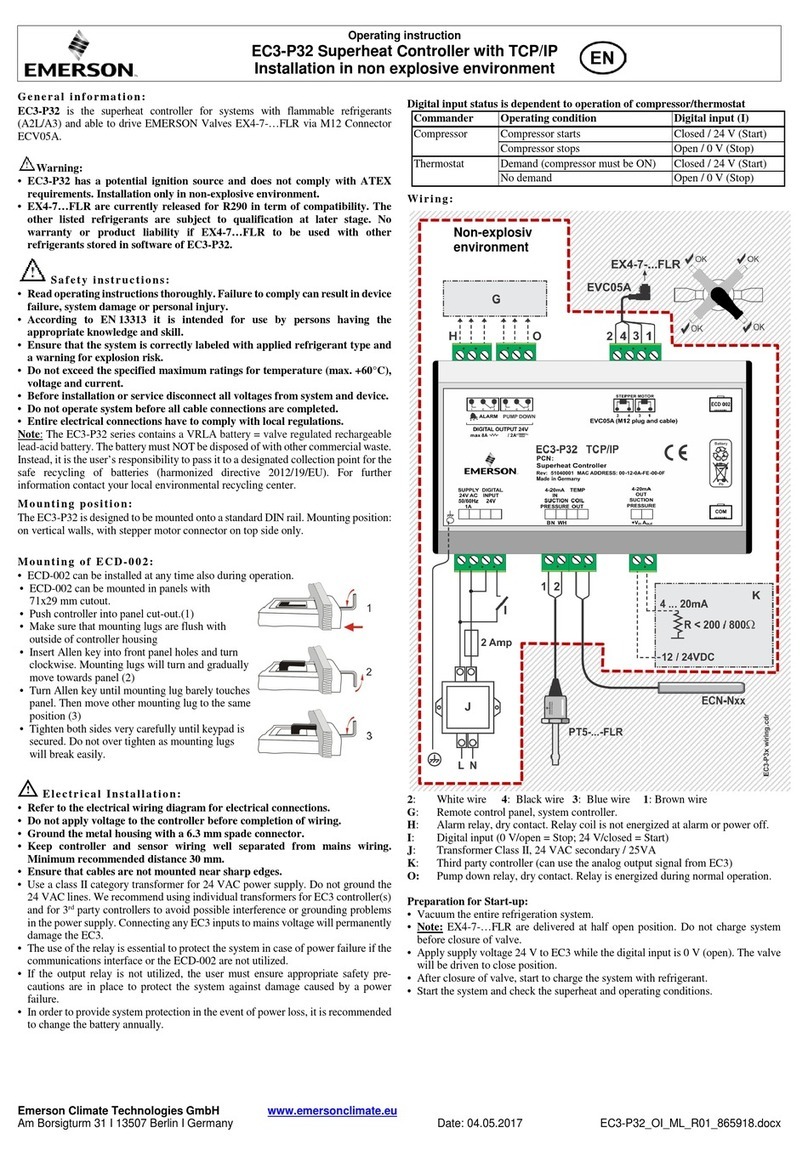

Product mounting, set up, and installation notes speci c to Hazardous Location Actuators.

Operation and maintenance of a hazardous location actuator is the same as for an ordinary location actuator with

the following amendments:

1. ONLY install a hazardous location actuator in a

hazardous location for which the actuator was

designed. The actuator is clearly marked with the

classification for which it was designed and tested.

2. Mount, calibrate, and test actuators only during non-

hazardous conditions.

3. Do NOT operate in ambient temperatures above +125° F

(+52° C).

4. Do NOT, under any circumstances, remove the cover of the actuator while in a

hazardous location with power still present inside the actuator. This could cause

ignition of a hazardous atmosphere.

5. After removal of the cover care must be taken not to scratch, chip, or deform

the mating surfaces of the cover and base of the actuator (see photos at right).

Deformation to these surfaces negates the hazardous location rating of this

actuator and the actuator should be removed from hazardous location service.

6. Mating surfaces of the cover and base must be cleaned before replacing cover.

When replacing the actuator cover, carefully align the two pins (non-removable)

embedded in the lower housing with the corresponding holes in the top housing.

Fully seat the cover before tightening the cover bolts to avoid damaging the cover.

7. After securing the cover back onto the actuator there should be NO gaps larger

than 0.003 in. (0.08mm) between the cover and the base of the actuator. This can

be checked by a 0.003 in. thick by 1/2 in. wide feeler gauge which may not enter

between the two faces more than 1/8 of an inch.

8. All electrical connections must be to national, state, and local codes and in

accordancewithhazardouslocationspecificationsforwhichthisactuatoristo

be used.

9. Reducers,glands,and/orconduitmustbeappropriatelycertifiedtobeusedin

hazardous locations.

10. Toreducetheriskofignitionofhazardousatmospheres,anappropriatelycertified

sealingfitting,cableglandorplugmustbedirectlyconnectedtotheenclosure.

11. Anunusedconduitportmustbesealedwithanappropriatelycertifiedthreaded

blanking plug.

12. Under certain extreme circumstances, the non-metallic parts incorporated in the

enclosure of this equipment may generate an ignition-capable level of electrostatic

charge. Therefore the equipment shall not be installed in a location where the

external conditions are conducive to the build-up of electrostatic charge on such

surfaces. In addition, the equipment shall only be cleaned with a damp cloth.

Plate found on actuator

Mating Surfaces

(refer to note 5, 6)

Alignment pins/holes

(refer to note 6)

Feeler Gauge (refer to note 7)

Page 1 P2/3 HV-PN7 Series

Hazardous Location Actuators