Promation Engineering P1 A P Series User manual

Table of contents

Other Promation Engineering Controllers manuals

Promation Engineering

Promation Engineering P7-24PN4-DC User manual

Promation Engineering

Promation Engineering P1-12VN4 AC User manual

Promation Engineering

Promation Engineering P2-120N4-RC User manual

Promation Engineering

Promation Engineering P1.A Series User manual

Promation Engineering

Promation Engineering P2 Series User manual

Promation Engineering

Promation Engineering P1 A P-XOV Series User manual

Promation Engineering

Promation Engineering P1.A Series User manual

Promation Engineering

Promation Engineering P7-120PN4-HR User manual

Promation Engineering

Promation Engineering P2-120PN4-HR User manual

Popular Controllers manuals by other brands

AudioCodes

AudioCodes Mediant 3100 Quick setup guide

Mitsubishi Electric

Mitsubishi Electric FX3U-4DA installation manual

Balluff

Balluff SmartVision BAE PD-VS-014-05 user manual

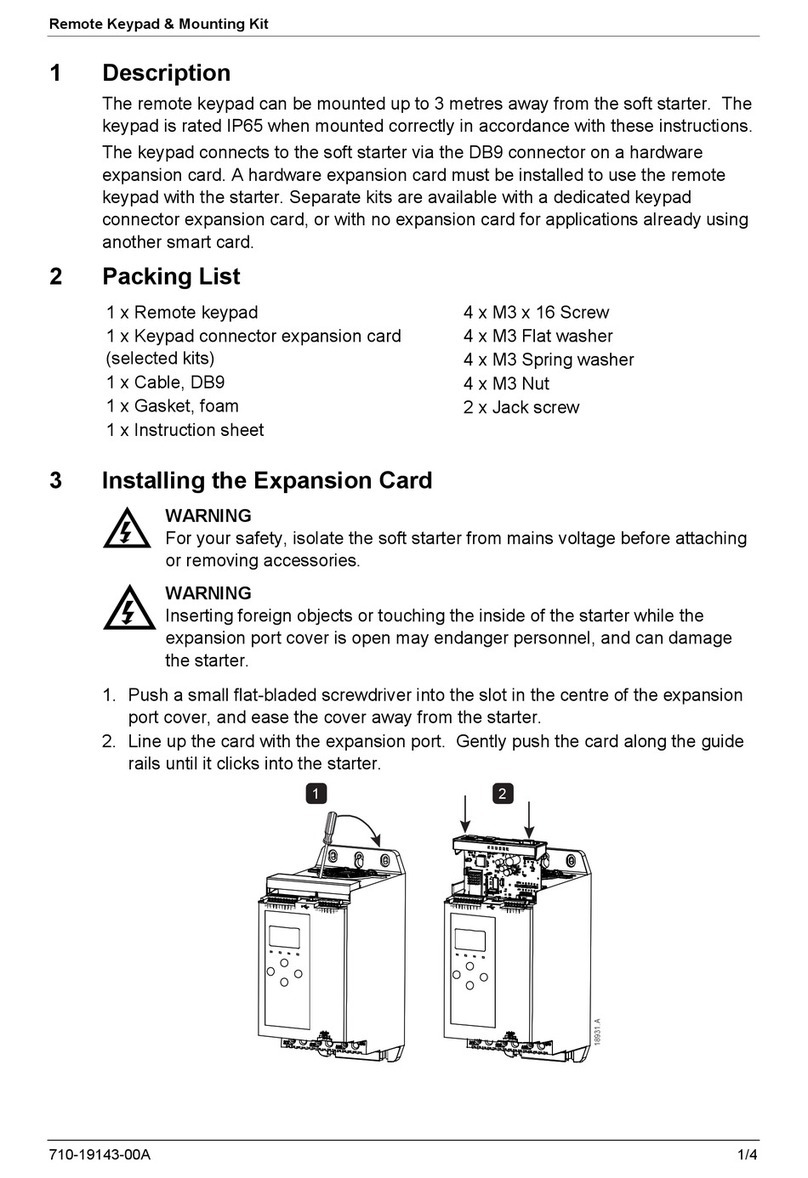

SOFTSTARTUK

SOFTSTARTUK LV-AP manual

Muller Elektronik

Muller Elektronik DRILL-Control Installation and operating instructions

Tech Controllers

Tech Controllers i-2 user manual

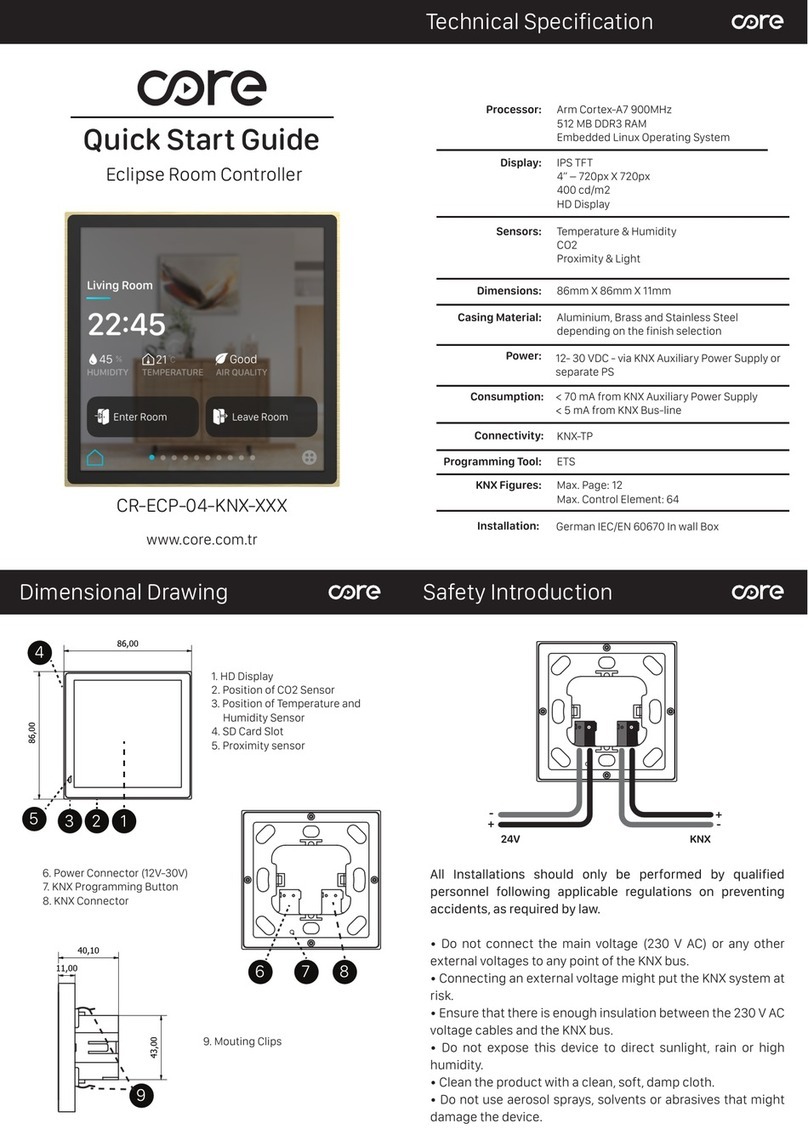

Core

Core Eclipse CR-ECP-04-KNX Series quick start guide

Daikin

Daikin BRC1H61W installation manual

Fuji Electric

Fuji Electric PXZ Series Operation manual

GEM

GEM 4242PTAZ Assembly instructions

IBM

IBM SAN Volume Controller 2145-CG8 Hardware installation guide

controlair

controlair 1227 Installation, operation and maintenance instructions