Proportion-Air PS-400 User manual

INPS400

09/24/04 N.K.

PS-400

Power Supply

DESCRIPTION

The PS-400 power supply is designed for use

with Proportion-Air’s line of electronic pressure

regulators. In addition to being a DC power

supply, it has a signal conditioning circuit which

is designed to accept a DC voltage signal and

either amplify or attenuate it as well as offset it

for specific applications. The circuit is also ca-

pable of inverting the signal by repositioning

two jumpers.

♦ Designed for use with Proportion-Air valves

♦ Input power 110 or 220 VAC

♦ Provides DC power and signal conditioning

♦ Gain and Offset adjustment of DC voltage

♦ Capable of inverting DC voltage signal

♦ Safety fuse protected

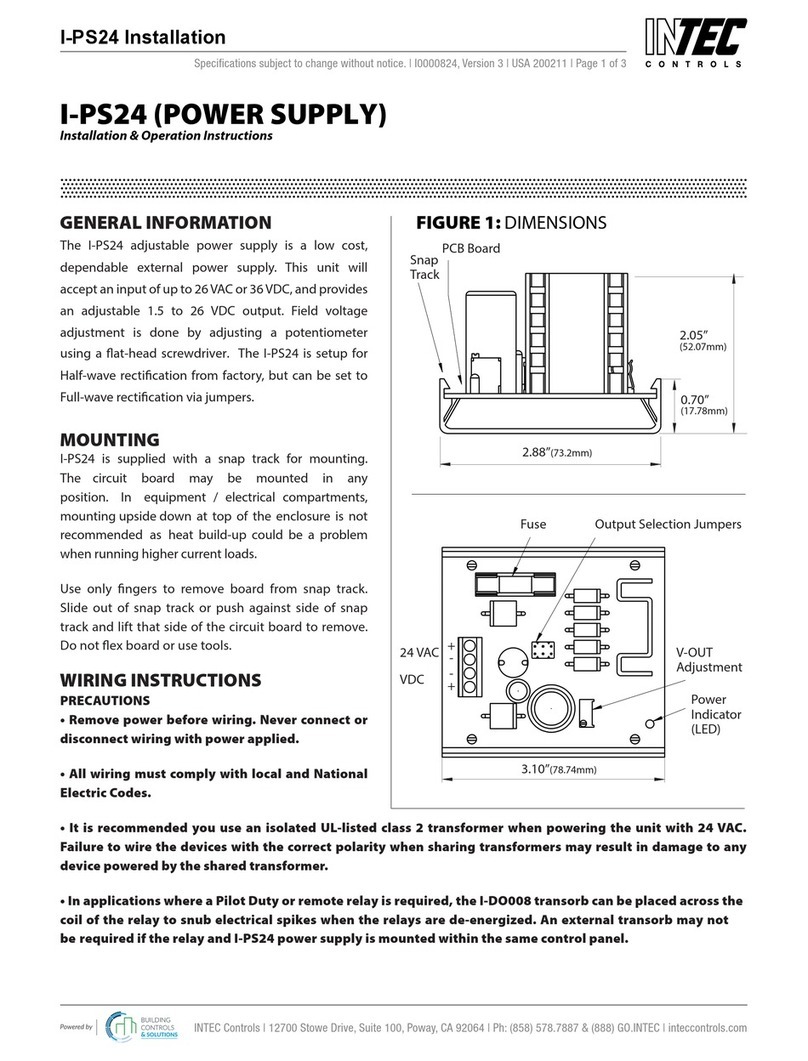

DIMENSIONS

Input Power 110 VAC

220 VAC ( both at 50-60 HZ)

Regulated Output Power 15 VDC at 600 mA (fused)

+/- 0.75 VDC

Physical 8-32 threaded standoffs

Weight

Net. Weight: 0.50 lbs. (0.23 Kg)

Shipping Weight: 0.75 lbs. (0.34 Kg)

Operating Temperature 32° to 158°F (0° to 70°C)

SPECIFICATIONS

HOW TO ORDER

PS - 400 - 110

Model Series

110 = 110 VAC

220 = 220 VAC

Input power

Terminal Function / Description

AC 110 or 220 VAC connection

AC 110 or 220 VAC connection

COM DC power and signal common

+15V Regulated +15 VDC @ 600mA max

Connected to next terminal

Connected to previous terminal

+15V Regulated +15 VDC @ 600mA max

V IN Input to the signal conditioner

V OUT Output of the signal conditioner

Courtesy of CMA/Flodyne/Hydradyne ▪Motion Control ▪Hydraulic ▪Pneumatic ▪Electrical ▪Mechanical ▪(800) 426-5480 ▪www.cmafh.com

INPS400

09/24/04 N.K.

PROPORTION-AIR, INC.

BOX 218 MCCORDSVILLE, IN USA 46055

PHONE: (317)335-2602 FAX: (317)335-3853

Adjustments

Inverting/Non Inverting: For normal operation insure the jumpers are in the normal position. For a inverted signal output,

place the jumpers in the inverted position.

Gain and Offset potentiometers: The gain potentiometer allows you to either amplify or attentuate the electrical signal. The

offset potentiometer allows you to control the DC offset of the signal.

Setting gain and offset potentiometers (non-inverting unit):

1. Place a voltage equivalent to the lowest expected signal voltage on the V IN connection.

2. Adjust the offset for the desired output voltage.

3. Place a voltage equivalent to the highest expected signal voltage on the V IN connection.

4. Adjust the gain for the electrical desired output signal.

5. Repeat steps 1-4 above to verify calibration.

Setting gain and offset potentiometers (inverting unit):

1. Make sure the normal settings are already calibrated.

2. Place a voltage equivalent to the lowest expected signal voltage on the V IN connection.

3. Measure and record the output signal voltage.

4. Place a voltage equivalent to the highest expected signal voltage on the V IN connection.

5. Adjust the span such that the desired output voltage swing is obtained.

6. Place a voltage equivalent to the lowest expected signal voltage on the V IN connection.

7. Adjust the offset to achieve the desired output voltage.

Calibrating an inverting unit Example

In this example, we want to convert a 0 to 10 Vdc signal into a +5 to –5 Vdc signal.

1. While the two jumpers are at the normal setting, verify the voltmeter reads 0 Vdc at 0 Vdc input and 10 Vdc at 10 Vdc

input. If the setting do not match, calibrate potentiometers based on the above section titled “ Setting gain and offset

potentiometers (non-inverting unit)“.

2. Move the two jumpers located above the terminal strip from normal to inverted position.

3. Input a 0 Vdc signal.

4. Turn the offset potentiometer counterclockwise until voltmeter reads 5 Vdc.

5. Input a 10 Vdc signal.

6. Turn the gain potentiometer counterclockwise until your voltmeter shows –5 Vdc output.

7. Turn the offset potentiometer until your voltmeter shows 0 Vdc

8. The unit is calibrated. We recommend to go through the range and insure the desired results are obtained.

Proportion-Air products are warranted to the original purchaser only against defects in material or workmanship for one (1) year from the date of manufac-

ture. The extent of Proportion-Air's liability under this warranty is limited to repair or replacement of the defective unit at Proportion-Air's option. Propor-

tion-Air shall have no liability under this warranty where improper installation or filtration occurred.

All specifications are subject to change without notice. THIS WARRANTY IS GIVEN IN LIEU OF, AND BUYER HEREBY EXPRESSLY

WAIVES, WARRANTIES OR LIABILITIES, EXPRESS, IMPLIED OR STATUTORY, INCLUDING WITHOUT LIMITATION ANY OBLI-

GATION OF PROPORTION-AIR WITH REGARD TO CONSEQUENTIAL DAMAGES, WARRANTIES OF MERCHANTABILITY, DE-

SCRIPTION, AND FITNESS FOR A PARTICULAR PURPOSE.

............................................................................................................................................................................................................

WARNING: Installation and use of this product should be under the supervision and control of properly qualified personnel in order to avoid the risk of

injury or death.

Courtesy of CMA/Flodyne/Hydradyne ▪Motion Control ▪Hydraulic ▪Pneumatic ▪Electrical ▪Mechanical ▪(800) 426-5480 ▪www.cmafh.com