6.2.2. Variable Tracking Ratio Mode, Constant

Voltage Operation.

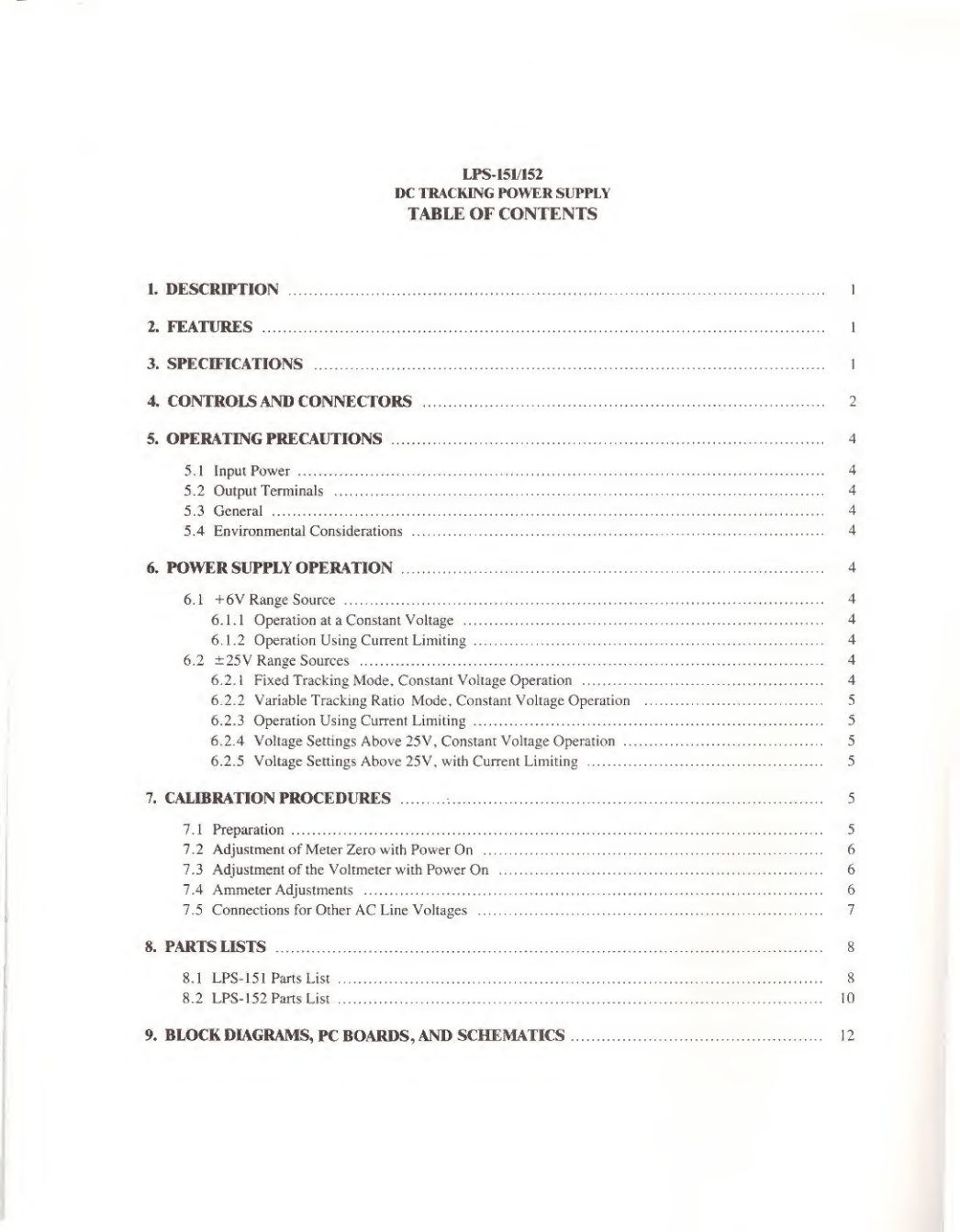

a. Push the +25V METER selector button (3).

b. Ensure that the TRACKING RATIO selector switch (7)

is in the VARIABLE position.

c. Turn the CURRENT controls (12) and (14) to their fully

clockwise positions.

d. Turn the REFERENCE/-^ 25V control (6) to the desired

positive voltage,

e. Push the TRACKING —25V METER selector button (4).

f. Using the TRACKING RATIO control (9), set the

—25 Vsource to the desired negative voltage.

After the TRACKING RATIO control (9) has been set,

turning the REFERENCE/F25V control (6) will cause

the —25V source to change its voltage with respect to

the +25V source by the established ratio,

g. Press the REFERENCE ~'“25V METER selector button

(3).

h. The load may now be connected to the supply.

6.2.3. Operation Using Current Limiting

a. Set the CURRENT controls (i2) and (14) to their fully

counterclockwise positions,

b. Set the ±25V sources to the desired voltage by using

one of the procedures above. Disregard the step involv-

ing turning the current controls fully clockwise.

c. Ensure that the REFERENCE +25V METER selector

button (3) is pressed in.

d. Short circuit the COM and +25V terminals (10) and

(11). The voltmeter will indicate zero volts.

e. Set the +0.5A (-1- 1Aforthe EPS- 152) CURRENT con-

trol (12) to the desired level of current limiting as indi-

cated on the AMMETER (23). Rotating the CURRENT

control (12) clockwise raises the current limit setpoint.

f. Remove the short circuit from the COM and +25V ter-

minals (10) and (11).

g. Press the TRACKING —25V METER selector button

'(4),

h. Short circuit the COM and —25V terminals (10) and

(13). The voltmeter will indicate zero volts,

i.Set the -0.5A(-IAfor the LPS- 152) CURRENTcon-

trol (14) to the level of current limiting desired as indi-

cated on the AMMETER (23). Rotating the CURRENT

control (14) clockwise raises the current limit setpoint.

7. CALIBR,

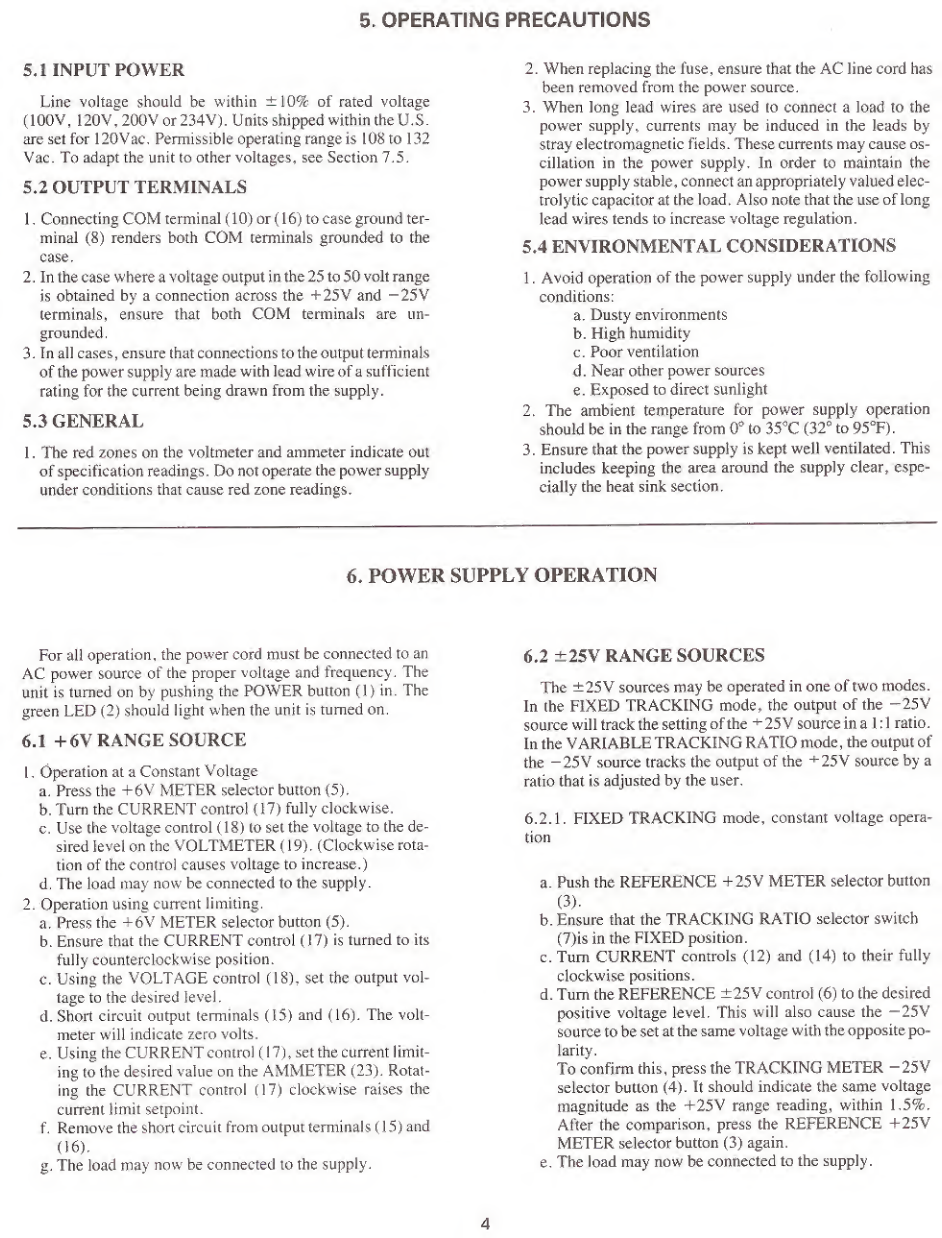

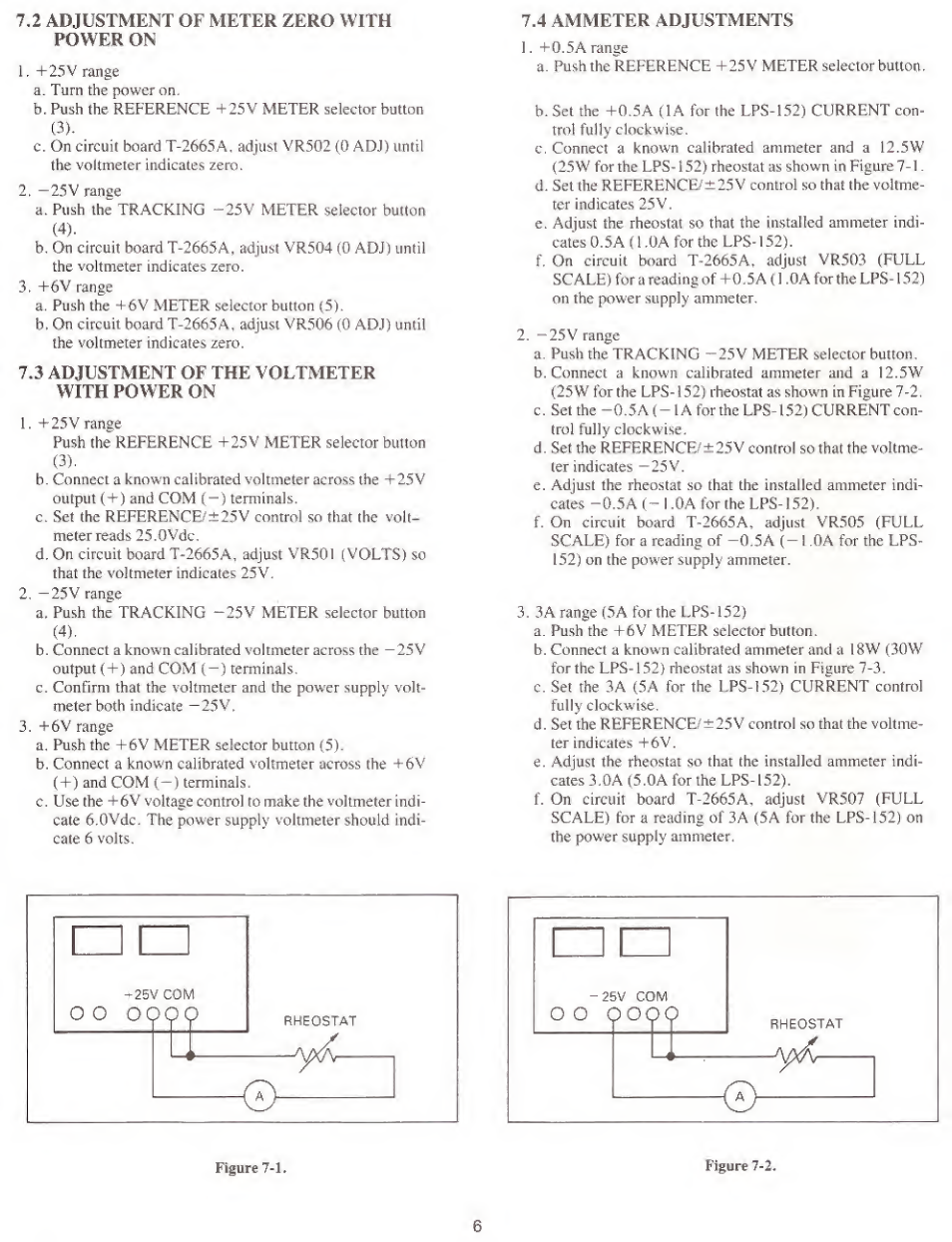

The following instructions detail the calibration of the

meters and voltage outputs for the LPS- 151/152 power sup-

ply, Also included are transformer tap changing directions so

that the ptiwer supply may be used with aline voltage other

than 120Vac,

7

A

PREPARATION

I.Adjustment of Meter Mechanical Zero.

a. Turn the powder supply off and allow one minute for all

capacitors to discharge.

b. On the voltmeter, turn the zero adjust screw (20) so that

the pointer indicates exactly zero.

c. When the pointer is at zero, rotate the screw asmall

amount in the opposite direction to the direction it was

last turned in step bto relieve movement tension.

j. Remove the short circuit from the COM and -25V ter-

minals (10) and (13).

k. Press the REFERENCE +25V METER selector button

(3).

l. The load may now be connected to the supply.

6.2.4. Voltage Settings Above 25V, Constant Voltage

Operation

.

Used together, the ±25V sources will produce amaximum

output of 50V. However, in this mode the 6V output

may not be used.

a. Press the REFERENCE -^25V METER selector button

(3).

b. Set CURRENT controls (12) and (14) to their fully

clockwise position.

c. Ensure that the TRACKING RATIO selector switch

(7)is in the FIXED position.

dTurn the REFERENCE/F25V control (6) such the the

voltmeter (18) indicates one -half of the desired voltage

value. Remember that the voltmeter will only indicate

one-half of the voltage value between the ±25V output

terminals (11)and (13).

e. The load may now be connected to the supply. The

maximum current available at 50V is OJA (1 .OA with

the LPS- 152).

6.2.5. Voltage Settings Above 25V with Current Limiting.

a. Set the CURRENT controls (12) and (14) to their fully

counterclockwise positions.

b. Set the +25V sources for above 25V operation by using

the procedure above. Disregard the step involving turn-

ing the current controls fully clockwise.

c. Ensure that the REFERENCE +25V METER selector

button (3) is pressed in.

d. Shon circuit the +25V and -25V terminals (II) and

(13). The voltmeter will indicate zero volts.

e.Set the F0. 5A(+1Afor the LPS- 152) CURRENTcon-

trol (12) to the desired level of current limiting as indi-

cated on the AMMETER (23). Rotating the CURRENT

control (12) clockwise raises the current limit setpoint.

f. Remove the short circuit from the F25V and —25V ter-

minals (1 i) and (13).

g. The load may now be connected to the supply.

PROCEDURES

d. On the ammeter, turn the zero adjust screw (22) so that

the pointer indicates exactly zero.

e. When the pointer is at zero, rotate the screw asmall

amount in the opposite direction to the direction it was

last turned in step dto relieve meter movement tension,

2. Initial Control Settings

Set the front panel controls to the positions indicated.

VOLTAGE F6V (18) full counterclockwise

CURRENT controls (12), (14), (17) .full counterclockwise

REFERENCE ±25V (6) full counterclockwise

TRACKING RATIO selector (7) HXED

REFERENCE F25 METER selector (3) pushed in

5