Prostat PRF-930 User manual

User Manual

PRF-930

POWDER RESISTANCE FIXTURE

Page

I. Introducon & Descripon 4

II. Fixture Component Descripons 4

III. Resistance Measurement Procedure 6

IV. Disassembly & Cleaning 11

VWarranty 15

General Specicaons 16

Copyright © 2011 by Prostat® Corporaon. All rights reserved. Printed in the United States of America. No part of this

manual may be used or reproduced in any manner whatsoever without wrien permission. For informaon contact

Prostat Corporaon, 1072 Tower Lane, Bensenville, IL 60106 USA

Prostat is the registered trademark of Prostat® Corporaon

The PRF-930 Powder Resistance Fixture measures the

bulk resistance of powder and granulated materials.

Test material is placed in the cavity between the mea-

surement plates. Once a measurement has been made

in ohms, a xture calculaon, or correcon factor, con-

verts the resistance measurement to volume resisvity

in ohm-cm. The PRF-930 provides the most accurate

measurements when used with a precision wide range

resistance instrument, such as the Prostat PRS-801

Resistance System, or equivalent laboratory system.

For guarded plate measurements use an instrument

ground reference.

The PRF-930 Powder Fixture meets requirements of “Technical Recommendaons of Naonal Instute

of Occupaonal Safety and Health JNIOSH-TR-No. 42 (2007) Recommendaons for Requirements for

Avoiding Electrostac Hazards in Industry 2007”

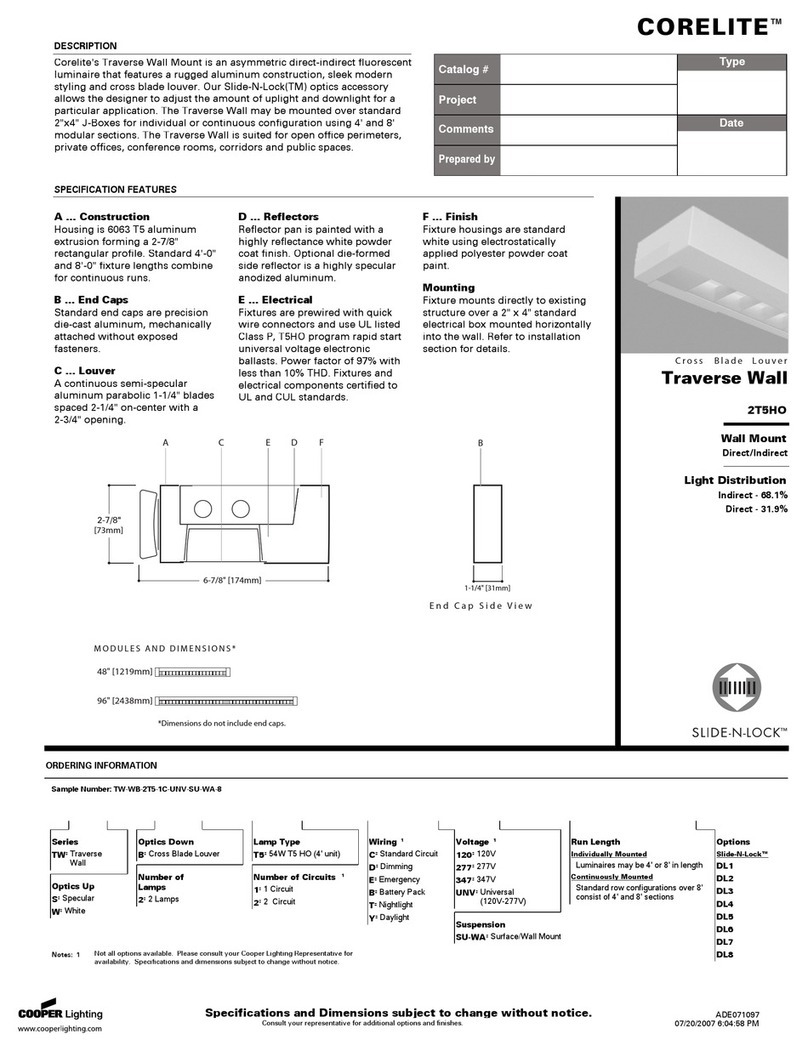

A. Acrylic Frame

An electrically insulave acrylic frame provides structural support and precise posioning of the

two measurement plates.

MATERIAL TEST CAVITY

POWER PLATE

(Test Voltage)

MEASUREMENT PLATE

(Current Sensing)

ACRYLIC FRAME

5

Rev. A / January 2010

PRF-930 Advanced Powder Fixture

Once assembled in the acrylic frame, the two plates form a cavity that becomes the material test

area. Powder substances are loaded into the xture completely lling the test cavity. A test volt-

age is applied to the power plate and current through the material is sensed on the measure-ment

plate.

B. Measurement Plate

The PRF-930 concentric measurement plate assembly

consists of a center plate with a diameter of approxi-

mately 2.4 cm (0.945 inch), having a surface area of 4.5

cm2 (0.7 in2). The center plate is separated from the

measurement guard plate by a virgin Teon™ insert

(Figure 3).

When installed in the acrylic xture the center plate is

posioned directly against the test material. The center

plate connects to the resistance instrument using the

Black receptacle on the plate’s outer surface (Figure 4).

The measurement guard plate connects to the instru-

ment’s ground reference using the Green receptacle on

the outer measurement plate assembly.

C. Power Plate

Power is applied to the material under test by the

xture’s power plate. Connecon to the power plate is

made using the Red connector (Figure 5). Test voltage

is applied to material under test by contact with the

power plate’s inner surface.

Power Plate

Outer Surface

Power Plate

Inner Surface

Power Connecon

6Rev. A / January 2010

PRF-930 Advanced Powder Fixture

The resistance measurement and resisvity calculaon procedure includes the following Steps:

• Filling the xture cavity with material for tesng

• Connecng the xture to a resistance instrument for measurement

• Making a material measurement in

• Consider variables eecng resistance measurements

• Calculang Volume Resisvity of the test material in ohm-cm

A. Filling the Fixture Cavity

Before using the xture be sure it is clean and properly assembled. (See “Disassembly & Cleaning”,

below.) The volume of the xture is approximately 15 cm3. Depending on material characteriscs

approximately 1.0 tablespoon will be required to completely ll the xture cavity. Place the mate-

rial in the PRF-930 and compress it lightly.

Material compression should be limited to the degree that represents the material’s use, transport

or storage condions. This is subjecve and best determined by personnel most experienced with

the material process and applicaons. In any event, do not compress the material to an extreme

degree beyond that which the material experiences under ordinary condions.

Follow material manufacturer or supplier’s safety precauons, procedures and han-

dling recommendaons when tesng any material.

1. Level the material at the top surface of the xture. (Figure 6)

7

Rev. A / January 2010

PRF-930 Advanced Powder Fixture

2. Be sure the wipe excess material from the top of the acrylic frame

B. Fixture Connecons

Three connecons to a precision, wide range resistance system (Figure 7) are required for accurate

measurements:

1. Connect the instrument’s test voltage (power) lead, usually from the Posive (+) terminal to

the Red connecon mounted on the xture’s power plate.

2. Connect the instrument’s current sensing lead, usually the Negave (-) terminal, to the Black

center plate recepcal.

Negave (-)

Terminal

Instrument Ground

Reference

Posive (+)

Terminal

3. Connect the instrument’s ground reference to the Green guard plate recepcal

C. Making the Resistance Measurement

The PRF-930 complies with the fundamental requirements of measuring bulk resistance of pow-

dered and granulated materials. Actual procedures and specied condions may vary between

test methods cited by standards bodies in dierent countries. The PRF-930 was designed in accor-

dance with the Recommended Pracce for Protecon against Hazard arising out of Stac Electric-

ity in General Industrie, published by The Naonal Instute of Industrial Safety, Japan, Technical

Recommendaon No. RIIS-TR-87-1. Other naonal commiees may be examining similar methods

for these measurements.

Center Plate

Connecon

Guard Plate

Connecon

Power Plate

Connecon

8Rev. A / January 2010

PRF-930 Advanced Powder Fixture

For illustrave purposes, the following procedure is based on resistance measurement protocol

developed by the Electrostac Discharge Associaon (ESDA) Standards Commiee, which is based

in Rome, New York, USA. Use other recommended measurement protocol when suitable and avail-

able.

1. Connect material lled xture to resistance measurement system as discussed above.

2. Energize the instrument in accordance with manufacturer’s instrucons.

3. Select Test Voltage of 10 volts

4. Start the instrument’s TEST sequence where test voltage is applied to the xture.

5. If indicated resistance is less than 1.0x106 ohms, record the measurement aer a steady state

value has been reached

6. If indicated resistance at 10 volts is greater than 1.0x106 ohms, stop the test

7. Reset the test voltage to 100 volts

8. Start the TEST sequence and apply 100 volts to the xture for the instrument’s electricaon

period, or unl a steady state value has been reached.

Or use the test voltage and electricaon period required by the applicable standard

test method or procedure

9. Record the measurement in ohms

D. Variables Eecng Resistance Measurements

Several factors will eect resistance measurements, including:

• Temperature

• Humidity

• Material Compression

• Material Moisture Content

• Test Voltage

• Instrumentaon Electricaon Period

• Material Composion

• Other factors depending on condions and material characteriscs

Repeatability between measurements, and reproducibility between laboratories are eected by all

of these variables. One must understand the eect of resistance measurement variables to avoid

confusion and misunderstandings between dierent test results.

Increased ambient humidity or material moisture will reduce the resistance measurement, that is:

cause the material to appear more conducve. Lower humdiy, reduces material moisture con-

tent, which increases indicated material resistance. High test voltage may (1) “boil” o moisture,

or (2) change the material’s electrical characteriscs. Idenfy and record all the apparent variables

in your measurement situaon to provide validity, repeatability and reproducibility to your mea-

surements.

9

Rev. A / January 2010

PRF-930 Advanced Powder Fixture

To enhance repeatability of successive measurements allow the meaterial to rest between mea-

surements. One general guideline is recording the electricaon period required for a steady state

measurement and then add one minute to the measurement me to calculate the minimum rest

period between measurements. For example, if 1 minute is used to obtain a steady state measure-

ment – plus 1 minute – the rest me between measurements of the same sample is 2 minutes. On

the other hand, if a steady state measurement is obtained in 15 seconds, the total minimum me

between measurements is 1 minute 15 seconds. Typically, materials will be precondioned at de-

ned temperature and relave humidity for 48 hours or more, and measured in the same environ-

ment using dened procedures to reduce the eect of ambient variables.

E. Calculang Volume Resisvity (ohm-cm)

Resistance is a measurement, whereas Volume Resisivity is a calculaon based on (1) a resistance

measurement, (2) xture dimensions and, (3) material thickness. To convert resistance measure-

ments in ohms obtained with the PRF-930 to volume resisvity () in ohm-cm, we use the follow-

ing equaon to convert the resistance measurement to resisvity.

Where,

R = Resistance obtained from the material measurement in ohms

A = Area of the xture’s center plate in cm2

d = Distance in cm between the measurement and power plates.

The relaonship of A divided by d is oen re-

ferred to as a in cm (CF), which is mulplied

by the measured resistance to obtain resisvity. (See

, below)

Exact xture dimensions can be obtained during xture clean-

ing using the measurement procedures described below. When

the xture is disassembled, and aer it is cleaned, measure the

concentric center plate with a micrometer as shown in Figure 8,

at right.

The center plate area A is calculated using the equaon:

Where p is approximately 3.1416 and r is the radius of the cen-

ter plate, which is one-half the plate diameter. The distance d

between plates is measured with a micrometer (Figure 9) aer

the xture is reassembled. The measurement is made at the

center point of the measurement plates, midway between the

acrylic frame vercal supports.

dbe

10 Rev. A / January 2010

PRF-930 Advanced Powder Fixture

While the correcon factor (CF) for each xture is inially determined by Prostat before shipment, tem-

perature, humidity, handling and use may slightly modify xture dimensions. Assuming your xture is typi-

cal of the one pictured here, you can conrm dimensions and correc-on factor, described below.

F. Center Plate Area:

1. Measure center plate diameter (Figure 8): 2.4 cm

2. Divide center plate diameter by 2 to obtain its radius: 1.2 cm

3. Calculate center plate area A:

G. Correcon Factor:

1. Measure the distance d between the power plate and measurement plate as shown in Figure

9. Assume the measurement is 0.95 cm

2. Divide the area A by the distance d to obtain the correcon factor:

Converng Resistance (ohm) to Resisvity (Ohm-cm):

As we discussed above, the equaon for converng resistance to resisvity is

11

Rev. A / January 2010

PRF-930 Advanced Powder Fixture

Here, the area A of the center plate is divided by the distance d between plates to obtain the correcon

factor (CF) in cm. In our example above the correcon factor is 4.76 cm. We simply mulply the correc-

on factor (cm) by the material’s measured resistance (ohm) to obtain volume resisvity in ohm-cm. The

table below shows four examples:

Instrument Measure-ment (ohm) x Correcon Factor (cm) = Calculated Resis-vity (ohm-cm)

5.5 x 1044.76 2.62 x 105

7.5 x 1074.76 3.57 x 108

6.3 x 1094.76 3.00 x 1010

9.5 x 1011 4.76 4.52 x 1012

Aer use, the PRF-930 should be cleaned before storing. There are several reasons to clean the xture im-

mediately aer use:

• Prevent contaminaon of future measurements by previous material residue

• Insure the xture performs at its opmum resistance range, which is approximately 1 to greater

than 1.0x1013 ohm.

• Prevent degradaon of the xture acrylic materials due to crazing, which ulmately weakens the

frame.

Cleaning consists of:

1. Emptying the xture of test materials

2. Disassembly

3. Cleaning the measurement plate assemblies, which is a dierent procedure from Cleaning the

acrylic frame

A. Empty the Fixture:

Dry powder and granulated materials can simply be poured from the xture and should be disposed of

in an appropriate manner. In situaons where the material is non-toxic or harmful, small amounts of

residue can be blown from the xture using low pressure compressed air as may be allowed in the using

environment. Avoid tapping the xture against a hard surface to knock materials out of the xture as this

may cause xture misalignment. Once emped, another sample of the same material may be loaded and

tested.

Before measuring dierent materials, the xture should be disassembled and cleaned.

12 Rev. A / January 2010

PRF-930 Advanced Powder Fixture

Dispose of materials in a safe and appropriate manner as recommended by the mate-

rial’s supplier. Use cauon whenever applying compressed air for cleaning purposes.

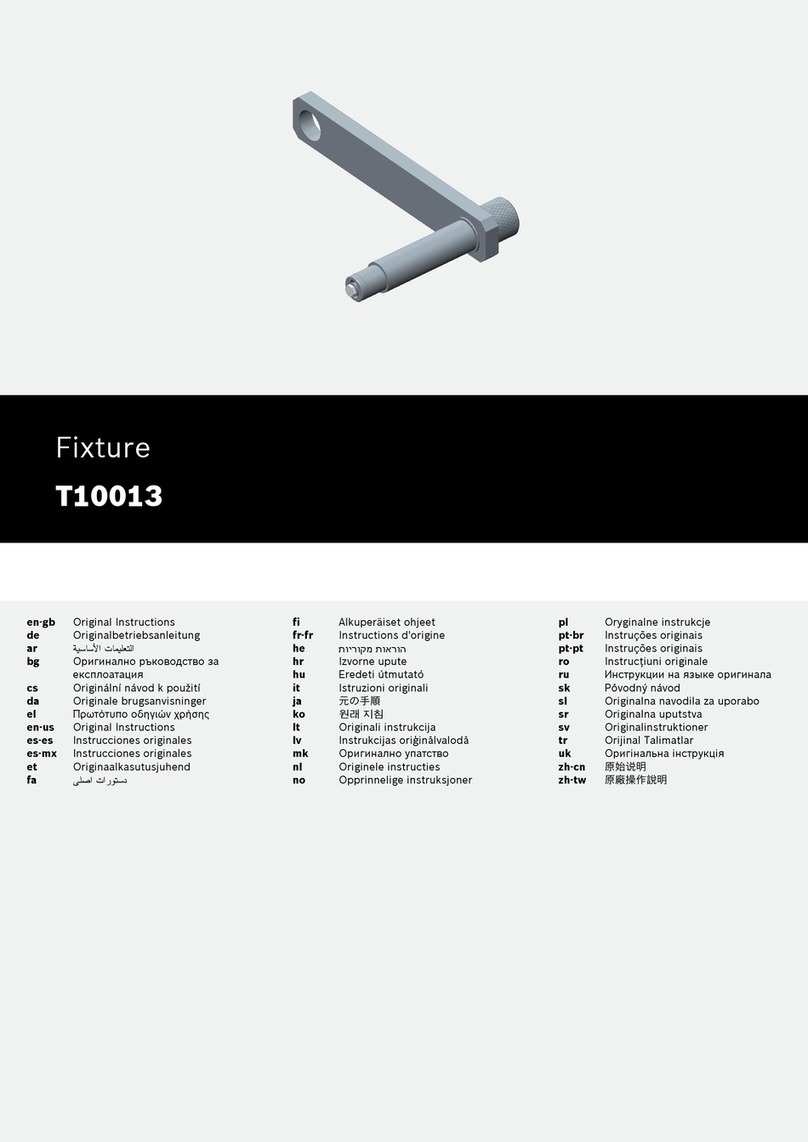

B. Disassembly

The xture plates are mounted in the acrylic frame us-

ing 8 at head, socket machined screws. The four long

1 inch (25 mm) screws are used to mount the plates

to the boom of the acrylic frame, and the shorter ⅝

inch (16 mm) screws, hold the plates against the ver-

cal frame segments. To disassemble the xture, simply

remove the eight screws with the wrench provided.

(Figure 10)

C. Cleaning Fixture Metal Plates

The metal plates can be wiped free of material dust,

then cleaned with a 70% soluon of iso-propyl alcohol

(IPA) and dislled water. The plate should then be thor-

oughly dried with a clean, low linng cloth or ssue as

shown in Figure 11.

Do not use this alcohol soluon on the acrylic

frame assembly. The alcohol will damage the

material and cause “crazing”, which appears as

small cracks that seriously weaken the assembly.

Cleanliness of the measurement assembly Teon separator and center plate are crical to xture accu-

racy.

The alcohol soluon may be used only to clean the metal and Teon xture materials.

Do Not use alcohol on the acrylic frame assembly.

13

Rev. A / January 2010

PRF-930 Advanced Powder Fixture

Be sure to remove any visible parcles and wash the Teon

separator twice with the IPA soluon, then dry with the pro-

vided micro ber cloth. Allow the xture to air dry aer clean-

ing for an addional 15 minutes before using the xture for

measurements. Use the same cleaning procedure for the power

plate. (Figure 12)

Noce the edges of the metal plates. Flanges are machined

around three sides of the plates. These special edges are to en-

sure proper alignment when mounng the plates in the acrylic

xture. Be sure to clean the alignment edge anges so they are

free of parcles.

When cleaning the metal plates, avoid touching the material

contact surfaces. Human contact will transfer nger oils to the

test surfaces, which are unnecessary contaminants.

D. Cleaning the Acrylic Frame

The machined acrylic frame must be cleaned carefully. or cleaners containing

alcohol or ammonia as these soluons will cause “crazing” resulng in many hairline cracks and

weaken the assembly. Once the metal plates are removed, brush any parcles from the frame us-

ing the supplied brush. Use a coon swab where necessary to remove stubborn contaminants

If necessary, wash the acrylic xture free of contaminants with clean water, rinse one or more

mes, then allow to air dry or carefully wipe with a low linng cloth.

Reassembly of PRF-930 Fixture

When preparing to reassemble the xture, note the three alignment anges on each metal plate.

These edges are designed to t into the recessed groove surrounding the plate mounng loca-

ons. Their funcon is to insure proper alignment and minimize plate movement.

Posion the plates such that they are placed in the acrylic frame with edge alignment anges

seated in the frame’s recessed grooves. (Figure 15 & 16) Insert two long 1 inch machine screws

14 Rev. A / January 2010

PRF-930 Advanced Powder Fixture

into the boom of the frame and thread them into the measurement plate. Do not ghten the

screws; simply install them to hold the plate into posion.

Install the ⅝ inch screws through the vercal segment of the frame and thread into the meas-ure-

ment plate. Tighten screws to snug, just to “nger ght”.

The alcohol soluon may be used only to clean the metal and Teon xture materials.

Do Not use alcohol on the acrylic frame assembly.

Install the power plate opposite the measurement plate in the same manner. As before, align the

edge anges with the recessed groove (Figure 17). Install the screws and make them just snug – do

not over ghten screws.

Improper Handling & Cleaning Causes Damage &

Voids Product Warranty.

Power Plate Connecon Flange & Recess Groove

15

Rev. A / January 2010

PRF-930 Advanced Powder Fixture

If cleaned with alcohol, acrylic will “craze”. Crazing is degradaon of the acrylic polymer in ap-pearance

and strength (Figure 18). Over ghtening screws could cause cracking of acrylic (Figure 19).

Prostat Corpoaon Warranty

Prostat Corporaon expressly warrants that for a period of one (1) year from the date of purchase, that

Prostat instruments will be free from defects in material (parts) and workmanship (labor). If Prostat re-

ceives noce of such defect during the warranty period, Prostat will replace at its expense such parts that

it determines to be defecve. Any defecve part must be returned to Prostat postage prepaid with proof

of purchase date.

Warranty Exclusions – THE FOREGOING EXPRESS WARRANTY IS MADE IN LIEU OF ALL OTHER PRODUCT

WARRANTIES, EXPRESS AND IMPLIED, INCLUDING MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE, WHICH ARE SPECIFICALLY DISCLAIMED. The express warranty will not apply to defects or dam-

age due to accidents, neglect, misuse, alteraons, operator error, or failure to properly maintain, clean, or

repair products. Limit of Liability – in no event will Prostat or any seller be responsible or liable for special,

incidental, or consequenal losses or damages, under any legal theory including but not limited to con-

tract, negligence, or strict liability.

Fulllment by Prostat of its express warranty obligaons described above will be purchaser’s exclusive

remedy and will be Prostat’s and seller’s limit of liability for any breach of warranty or otherwise.

16 Rev. A / January 2010

PRF-930 Advanced Powder Fixture

Basic Descripon: Acrylic frame xture with opposing power and concentric ring measurement

plates for resistance measurement of small volumes of powder and

granulated materials. Correcon Factor (CF) is used to convert bulk

resistance measurement to volume resisvity in ohm-cm.

Upper Resistance Limit: Nominal 1.0x1014 ohms ±20% @ 500 Volts, 71oF (21.7oC), 18% Rh, Clean,

empty xture. Note that most resistance measure-ments are made at 100

volts and below.

Material Capacity: Approximately 1.0 Tablespoon (US) (15 cm3)

Correcon Factor (CF)

to Ohm-cm: Based on:

Where,

ρ = Volume Resisvity in ohm-cm

R = Resistance obtained from the material measurement in ohms

A = Area of the xture’s center plate in cm2

d = Distance in cm between the measurement and power plates.

and,

ρ = R (CF)

Where,

ρ = Volume Resisvity in ohm-cm

R = Resistance obtained from the material measurement in ohms

CF = Correcon Factor (Area [A] of the xture’s center plate in cm2 divided

by Distance [d] in cm between the measurement and power plates.

Typical CF Range 4.6 cm to 4.9 cm, Typical 4.75 cm

Approximate

Fixture Dimensions: Note: Dimensions vary slightly from xture to xture as they are hand pol

ished and assembled. Temperature and humidity will aect xture

dimensions. Approximate dimensions as follows:

W 2.36 in (60 mm) x D 1.25 in (32 mm) x H 2.25 in (57 mm)

Approximate

Fixture Weight: 12.35 oz (250 gm)

17

Rev. A / January 2010

PRF-930 Advanced Powder Fixture

18 Rev. A / January 2010

PRF-930 Advanced Powder Fixture

19

Rev. A / January 2010

PRF-930 Advanced Powder Fixture

Specicaons are subject to change without noce.

All Prostat trademarks and trade names are the property of Prostat Corproaon.

All other trademarks and trade names are the property of their respecve companies.

PROFESSIONAL STATIC CONTROL PRODUCTS

Prostat Corporaon

Corporate Headquarters • 1072 Tower Lane • Bensenville, IL 60106 • 630-238-8883 • Fax: 630-238-9717 • 1-855-STATIC1 • www.prostatcorp.com

Other manuals for PRF-930

1

Table of contents