Protege PRT-CTRL-SE User manual

Protégé® SE Integrated System Controller

Installaon Manual

PRT-CTRL-SE

PENDING

The specicaons and descripons of products and services contained in this manual were correct at the me of prinng. Integrated Control Technology Limited

reserves the right to change specicaons or withdraw products without noce. No part of this document may be reproduced, photocopied, or transmied in any

form or by any means (electronic or mechanical), for any purpose, without the express wrien permission of Integrated Control Technology Limited. Designed and

manufactured by Integrated Control Technology Limited. Protégé® and the Protégé® Logo are registered trademarks of Integrated Control Technology Limited. All

other brand or product names are trademarks or registered trademarks of their respecve holders.

Copyright © Integrated Control Technology Limited 2003-2010. All rights reserved.

Table of Contents

1.0 Welcome ............................................................................................................................2

2.0 Protégé®System Management Suite ..................................................................................3

2.1 Protégé® Modules............................................................................................................... 3

3.0 Mounng ...........................................................................................................................4

4.0 Connecons........................................................................................................................5

4.1 Cabinet Enclosure Tamper Switch ....................................................................................... 5

4.2 Earth Ground Connecon.................................................................................................... 5

4.3 AC Power ............................................................................................................................. 6

4.4 Baery Backup .................................................................................................................... 7

4.5 Baery Charge Current Seng ........................................................................................... 8

4.6 Status Indicator ................................................................................................................... 9

4.7 Encrypted Module Network ................................................................................................ 9

4.8 Telephone Dialer................................................................................................................ 11

4.9 Expansion Connector......................................................................................................... 12

4.10 Ethernet 10/100 Network Interface ................................................................................ 13

5.0 Door Access Control..........................................................................................................14

5.1 Card Reader Connecon.................................................................................................... 14

5.2 Mulple Wiegand Card Reader Connecon ...................................................................... 15

5.3 Door Contact Connecon .................................................................................................. 16

5.4 Lock Output Connecon .................................................................................................... 17

5.5 Programming the Onboard Reader................................................................................... 18

6.0 Inputs...............................................................................................................................19

6.1 Zones................................................................................................................................. 19

6.2 Resistor Value Opons....................................................................................................... 20

6.3 Trouble Zones .................................................................................................................... 21

7.0 Programmable Outputs ....................................................................................................22

7.1 Bell/Siren PGM Outputs .................................................................................................... 22

7.2 PGM 3/4 Outputs .............................................................................................................. 23

7.3 Reader PGMs..................................................................................................................... 23

8.0 Hardware Conguraon ...................................................................................................24

8.1 Conguraon Switch......................................................................................................... 24

8.2 Defaulng a Controller...................................................................................................... 25

9.0 LED Indicators...................................................................................................................26

9.1 Status LED ......................................................................................................................... 26

9.2 Fault Indicator ................................................................................................................... 26

9.3 Charge/Test Indicator........................................................................................................ 26

9.4 Auxiliary OK Indicator........................................................................................................ 26

9.5 AC OK Indicator ................................................................................................................. 26

9.6 5V Isolated Power Indicator .............................................................................................. 26

9.7 Bell 1/Bell 2 Indicators ...................................................................................................... 27

9.8 Network RX/TX Indicators ................................................................................................. 27

9.9 Ethernet Link Indicator ...................................................................................................... 27

9.10 100Mb Indicator.............................................................................................................. 27

9.11 R1/R2 Data Indicators ..................................................................................................... 27

9.12 Online Indicator............................................................................................................... 27

10.0 Mechanical Diagram .........................................................................................................28

11.0 Mechanical Layout............................................................................................................29

12.0 System Capacies .............................................................................................................30

13.0 Technical Specicaons ....................................................................................................31

13.1 Current and Validaon Example 1................................................................................... 32

13.2 Current and Validaon Example 2................................................................................... 33

13.3 Current and Validaon Example 3................................................................................... 34

14.0 Ordering Informaon........................................................................................................35

15.0 Warranty ..........................................................................................................................36

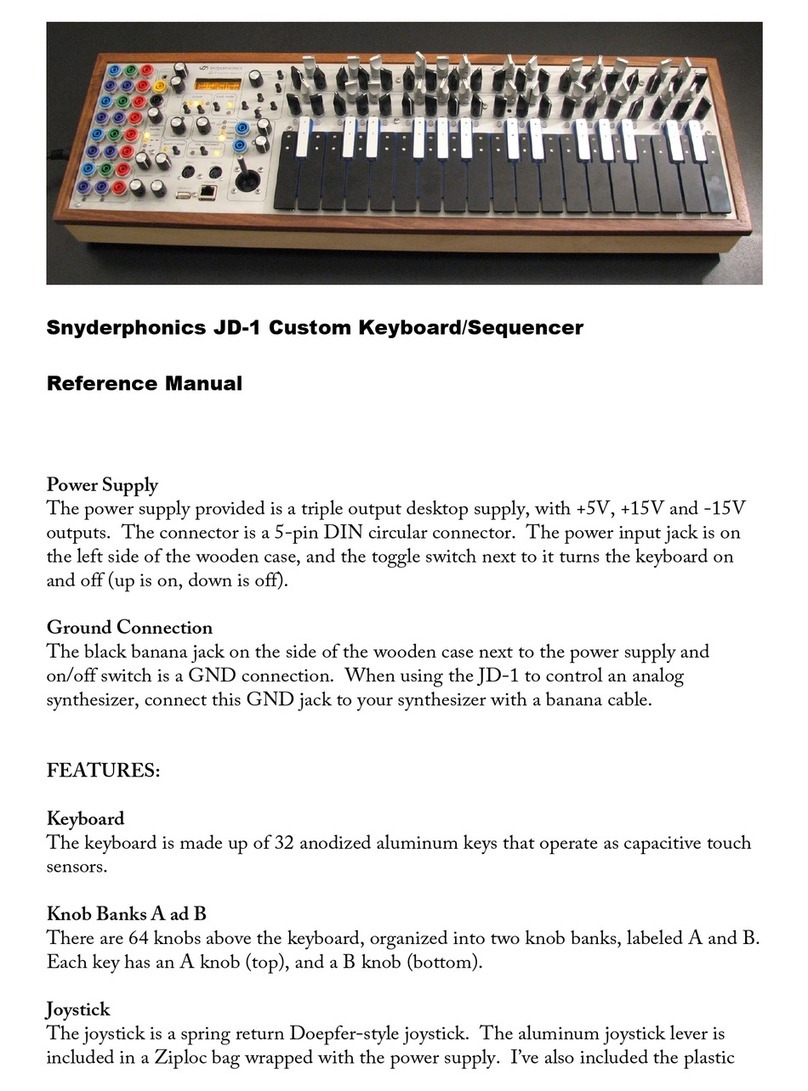

1.0 Welcome!

Thank you for purchasing the Protégé® SE Integrated System Controller by Integrated Control

Technology. The Protégé® System is an advanced technology security system specically designed

to enhance the funconality of condominium and apartment security with exible local monitoring

and osite communicaon.

The Protégé® SE Integrated System Controller is the central processing unit of the Protégé® System.

The Protégé® SE Integrated System Controller communicates with all system modules, stores all

conguraon and transacon informaon, process’s all system communicaon and reports alarms

and system acvity to a monitoring staon or remote computer.

Flexible module network architecture allows large numbers of modules to be connected to the

RS-485 Module Network. Up to 250 modules can be connected to the Protégé® SE Integrated

System Controller in any combinaon to the network up to a distance of 900m (3000).

The current features of the Protégé® SE Integrated System Controller include:

• Internal industry standard 10/100 Ethernet

• 32 Bit advanced RISC processor with 2MB RAM and 4MB ash

• 16x high security monitored zone inputs

• NIST Cered AES 256 Bit Encrypon

When receiving the Protégé® SE Integrated System Controller you should nd the kit contains the

items listed below. The kit type is clearly labelled on the packaging and will tell you what your kit

contains. Please note that if you do not have the correct contents contact your distributor

immediately.

• Protégé® SE Integrated System Controller

• Protégé® SE Integrated System Controller Quick Start Guide

• 6x nylon spacers

• 36x 1K ohm resistors

• Red/black baery backup wires

• 2x Diode 1N4007 1A 400V (Axial)

For more informaon on the Protégé® SE Integrated System Controller and other Integrated Control

Technology products please login to www.incontrol.co.nz.

!Indicates a warning or advisory message relang to the secon or locaon.

?Indicates a hint or suggeson that relates to the secon or locaon.

[TEXT] Bold text enclosed in brackets is used to show a secon number or address of

a programmable opon or informaon on programming shortcut sequences.

Italics Italic text shows a reference to a secon, page, manual or website.

2

2.0 Protégé® System Management Suite

The Protégé® System Management Suite applicaon is a Windows®™ based Integrated Access

Control and Alarm Management System designed for any conguraon from single site, single

Protégé® SE Integrated System Controller applicaons up to global mul-naonal corporaons

using mulple site, mulple Protégé® SE Integrated System Controller installaons.

Product Code Descripon

PRT-SMGT-ENT Protégé® System Management Suite Enterprise Edion

PRT-SMGT-PRO Protégé® System Management Suite Professional Edion

PRT-SMGT-STN Protégé® System Management Suite Standard Edion

PRT-SMGT-1U Protégé® System Management Single Client License Edion

2.1 Protégé® Modules

The Protégé® System can be expanded to accommodate large numbers of modules using the

encrypted RS-485 Network. Modules that are currently available are listed below. Visit

www.incontrol.co.nz for the latest Protégé® Module and product informaon.

Product Code Descripon

PRT-CTRL-SE Protégé® SE Integrated System Controller

PRT-CTRL-LE Protégé® LE Integrated System Controller

PRT-TLCD Protégé® Touchscreen Keypad

PRT-ATH1 Protégé® Temperature and Humidity Sensor

PRT-KLCD Protégé® Alphanumeric LCD Keypad

PRT-ZX16-PCB Protégé® 16 Zone Input Expander

PRT-ZXS16-PCB Protégé® Standard 16 Zone Input Expander

PRT-PX16-PCB Protégé® 16 PGM Output Expander

PRT-PXS16-PCB Protégé® Standard 16 PGM Output Expander

PRT-RDM2-PCB Protégé® Mini 2 Reader Expander

PRT-RDS2-PCB Protégé® Standard 2 Reader Expander

PRT-RDI2-PCB Protégé® Intelligent 2 Reader Expander

PRT-RDE2-PCB Protégé® Ethernet 2 Reader Expander

PRT-ADC4-PCB Protégé® Analog Input Expander

PRT-DAC4-PCB Protégé® Analog Output Expander

PRT-COMM Protégé® RS-232 Serial Communicaon Interface

PRT-PX16-DRI Protégé® 16 Input Desnaon Reporng Interface

PRT-PSU-5I Protégé® Intelligent 5 Amp Power Supply

PRT-HIO Protégé® Hi-O Network Door Control Module

3

3.0 Mounng

The Protégé® SE Integrated System Controller is supplied as a PCB only (Printed Circuit Board). It

is recommended that the gear plate style enclosures be used where possible, as this provides the

best mounng and installaon soluon as well as the required cable entry and

terminaon space.

When installing the Protégé® SE Integrated System Controller ensure that there is adequate

clearance around all sides of the cabinet enclosure and air ow to the vents of the enclosure are

not restricted.

It is recommended to install the Protégé® SE Integrated System Controller in a locaon that will

facilitate easy access for wiring. It is also recommended that the Protégé® SE Integrated System

Controller is installed in electrical rooms, communicaon equipment rooms, closets or in an

accessible area of the ceiling.

Step 1

Insert the plasc standos in to the locaons to mount the PCB board.

Step 2

Calculate the locaon and posion of the cabinet enclosure and mark the holes for the keyhole

points in the top le and right locaons. This will allow you to screw in the screws and then hang

the box on them adjusng the locaon to suit.

Step 3

Ensure a solid xing point and screw in the two screws. Before ghtening the top screws insert the

tamper bracket in the slot provided on the right side of the cabinet enclosure.

Step 4

Fix the cabinet enclosure securely using the remaining mounng holes on the boom le, right

and centre of the cabinet enclosure.

Step 5

If you are extending the Protégé® SE Integrated System Controller by the addion of a

communicaons module or memory interface insert the 4 extended nylon standos through the

rear of the Protégé® SE Integrated System Controller.

Step 6

Insert the PCB in to the cabinet enclosure and mount using the plasc standos inserted during

step 1.

!

It is recommended to install the cabinet enclosure when the circuit board is not

installed on the plasc standos as this will reduce the risk of damage caused by

debris during the installaon.

4

5

4.0 Connecons

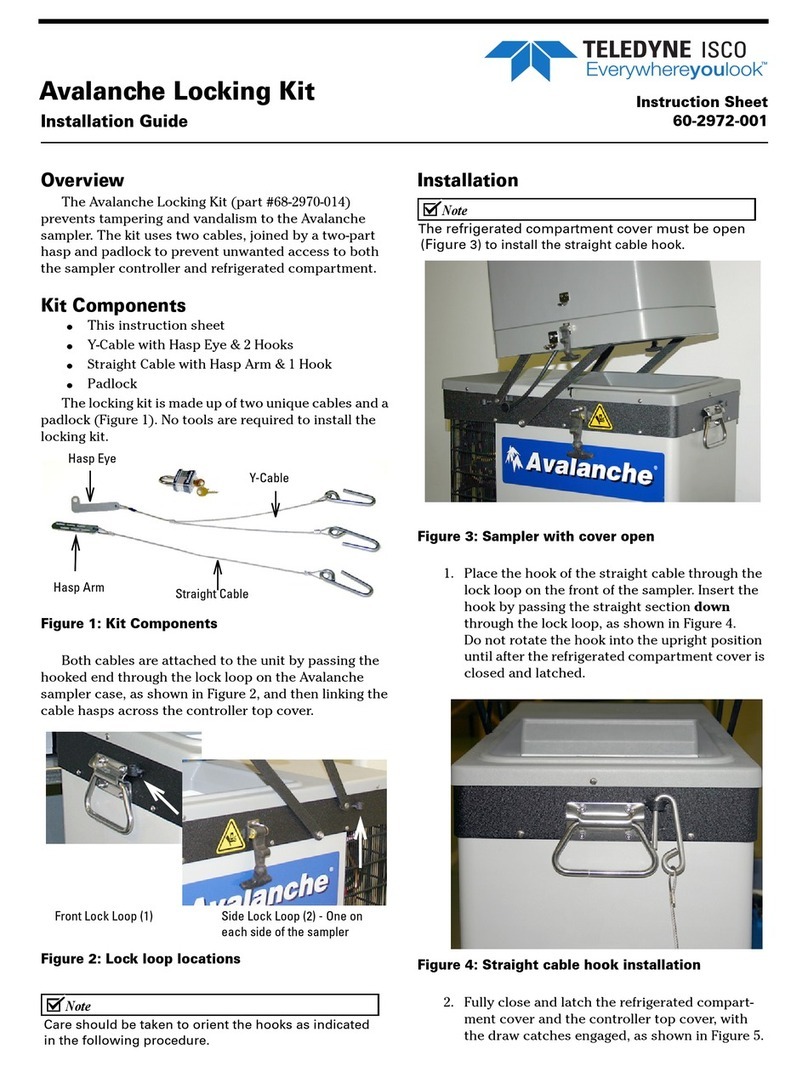

4.1 Cabinet Enclosure Tamper Switch

The cabinet enclosure tamper input signals to the monitoring staon or remote computer that an

cabinet enclosure has been opened. The tamper input switch should be mounted into the steel

bracket provided and connected to the tamper connecon terminals as shown in gure 1 below.

4.2 Earth Ground Connecon

The Protégé® SE Integrated System Controller has a connecon for earth ground. For best results a

cold water pipe should be used with a pipe wiring clamp. If a cold water pipe is not available

connect to a suitable ground connecon in the installaon. A minimum 14AWG solid copper wire

should be used from the Protégé® SE Integrated System Controller’s earth connecon point to the

clamp on the cold water pipe. If other earth clamps are present at the same connecon point

connect the clamp below the exisng units.

Figure 1 - Tamper Input Connecon

Figure 2 - Earth Ground Connecon

!

The telephone communicaon dialer contains a separate earth connecon. Do not

loop the earth connecon from the dialer to the earth of the Protégé® SE

Integrated System Controller. A separate connecon should be connected to the

same earth point.

AC AC B+ B- ST TP TP

Bracket

Ta mper Switch

AC AC B+ B- ST TP TP

6

4.3 AC Power

The Protégé® SE Integrated System Controller should be supplied by a dedicated electrical power

source rated for a minimum 10Amp load and have a dedicated circuit breaker. Do not use a switch

controlled breaker or a switched electrical point to supply electrical power. Connect the primary of

a 16VAC, 50/60Hz, 40VA transformer to the electrical circuit and run the secondary to the AC Input

on the Protégé® SE Integrated System Controller terminals.

Specic regional regulaons may allow the transformer to be mounted inside the cabinet

enclosure. In this case wire the electrical circuit to the electrical terminaon point inside the

cabinet enclosure and the secondary wires of the transformer to the AC Input on the Protégé® SE

Integrated System Controller. The earth wire should be routed to the terminal on the Protégé® SE

Integrated System Controller when using an internal transformer.

!

Terminaon of wiring to the Protégé® SE Integrated System Controller while power

is applied or the baery is connected may cause serious damage to the Protégé®

SE Integrated System Controller and will VOID ALL WARRANTIES OR GUARANTEES.

Power the unit only aer all wiring, conguraon and jumper sengs are

completed.

Figure 3 - AC Power Connecon

AC AC B+ B- ST TP TP

Transformer

Mains Input

7

4.4 Baery Backup

It is recommended that a minimum of a 4Ah baery is used as the main baery backup. From the

accessory bag provided, connect the red and black baery terminaon wires to the B+ and B-

terminals. Connect the spade terminals to the baery as shown in gure 4 below. Connecon of

the baery in reverse will not damage the Protégé® SE Integrated System Controller but will cause

the electronic baery fuse (5A fast blow) to open. Prolonged reverse connecon can cause damage

to the Protégé® SE Integrated System Controller.

The baery test procedure uses a special algorithm to prevent deep discharge and increase baery

endurance. A dynamic baery test is performed every ten minutes (default) when AC power is

present. A baery trouble zone alarm will be generated if the baery is either disconnected or

shows poor capacity. Baery fault condions will acvate the baery trouble zone.

If AC is not present the Protégé® SE Integrated System Controller will monitor the baery for a low

voltage level and will acvate the baery trouble zone. The next dynamic baery test will

occur 30 minutes aer AC power has been restored. This delay allows the baery to achieve

opmal charging during the rst 30 minutes that power has been restored to the unit. Once the

rst test is completed the dynamic tesng will return to the programmed value (default 10

minutes).

When power is rst applied to the Protégé® SE Integrated System Controller a dynamic baery test

will be performed aer 30 seconds, this allows the status and condion of the baery to be

detected. On compleon of this rst test the default tesng period of 10 minutes will be resumed,

this is a programmable seng in the Protégé® SE Integrated System Controller panel opons. The

test period can be changed as required by seng the baery test me in the Protégé® SE

Integrated System Controller Conguraon Menu.

!

Only aach standard lead acid baeries. Do not connect the baery wires or B+

and B- terminals of the Protégé® SE Integrated System Controller to any other

ancillary device (siren, lock or mag clamp etc). Connecon may cause erroneous

faults or serious damage to the Protégé® SE Integrated System Controller and will

VOID ALL WARRANTIES OR GUARANTEES.

Figure 4 - Baery Connecon

AC AC B+ B- ST TP TP

Gel Cell Backup Ba�ery

+

-

8

4.5 Baery Charge Current Seng

To congure the Protégé® SE Integrated System Controller manually for the charge current, select

the appropriate baery current limit seng using the jumpers as shown in gure 5 below.

Figure 5 - Baery Charge Jumper

Figure 6 - Jumper Locaon

350mA 700mA

9

4.7 Encrypted Module Network

The Protégé® SE Integrated System Controller incorporates technically advanced encrypted RS-485

communicaons technology. The isolated communicaons interface oers full galvanic isolaon to

prevent ground loop noise and cross phase ground dierenal. The communicaon oers superior

interference immunity. Connecon of the communicaons should be performed according to the

following diagram.

Figure 8 - Standard Communicaon Connecon

4.6 Status Indicator

The Status Output will acvate according to the status indicator on the Protégé® SE Integrated

System Controller and can be used to provide signalling or indicaon of the Protégé® SE Integrated

System Controller status outside the enclosure. The following diagrams show the connecon of an

LED indicator to the Status Output.

Figure 7 - External Status LED Connecon

AC AC B+ B- ST TP TP

1K5 OHM

LED

+AUX- Z1 COM COMZ2 Z3 Z4

NAN+ N- NB

Networt communica�ons input

from the Protégé® SE Integrated

System Controller or previous

Protégé® module

10

Figure 10 - EOL Jumper

Always connect the Protégé® SE Integrated System Controllers NA and NB terminals to the NA and

NB terminals of the expansion devices and keypads. The N+ and N- must go to a 12V power supply

source as shown in gure 9 below.

Figure 9 - Network Power Connecon

?

The diagram above shows a power connecon taken from the Auxiliary Power

Outputs on the Protégé® SE Integrated System Controller’s zone terminals. It is

recommended to only use this connecon for smaller systems where limited power

is required. For larger installaons use a separate power supply.

NAN+ N- NB

NAN+ N- NB

NAN+ N- NB

+AUX-Z13 COMCOMZ14Z15 Z16

Protégé® SE Integrated System

Controller or module supplying

power to networke d devices

AUX power from Module or

external power supply

Next modules

on network

EOL OFFEOL ON

?The EOL (End Of Line) jumper seng must be set in the on posion for the rst and

last expansion device only.

!

The 12V N+ and N- Communicaon Input must be supplied from only one point.

Connecons from more than one 12V supply may cause failure or damage to the

units supplying power.

11

4.8 Telephone Dialer

The Protégé® SE Integrated System Controller provides the ability to communicate alarms and

upload/download informaon with remote systems using the onboard 2400bps modem. The

telephone line can be connected directly to the Protégé® SE Integrated System Controller using the

onboard telephone connecon terminals.

Figure 11 - Telephone Line Connecon

!

It is recommended that the earth connecon for the telephone and main power

supply (refer to the secon Earth Ground Connecon on page 5) earth be run

separately and should be terminated on the cold water pipe or similar grounding

point within the installaon.

R1iT1i T1o R1o

Te lco line �p and ring input

Te lco line out

Cold water earth pipe

12

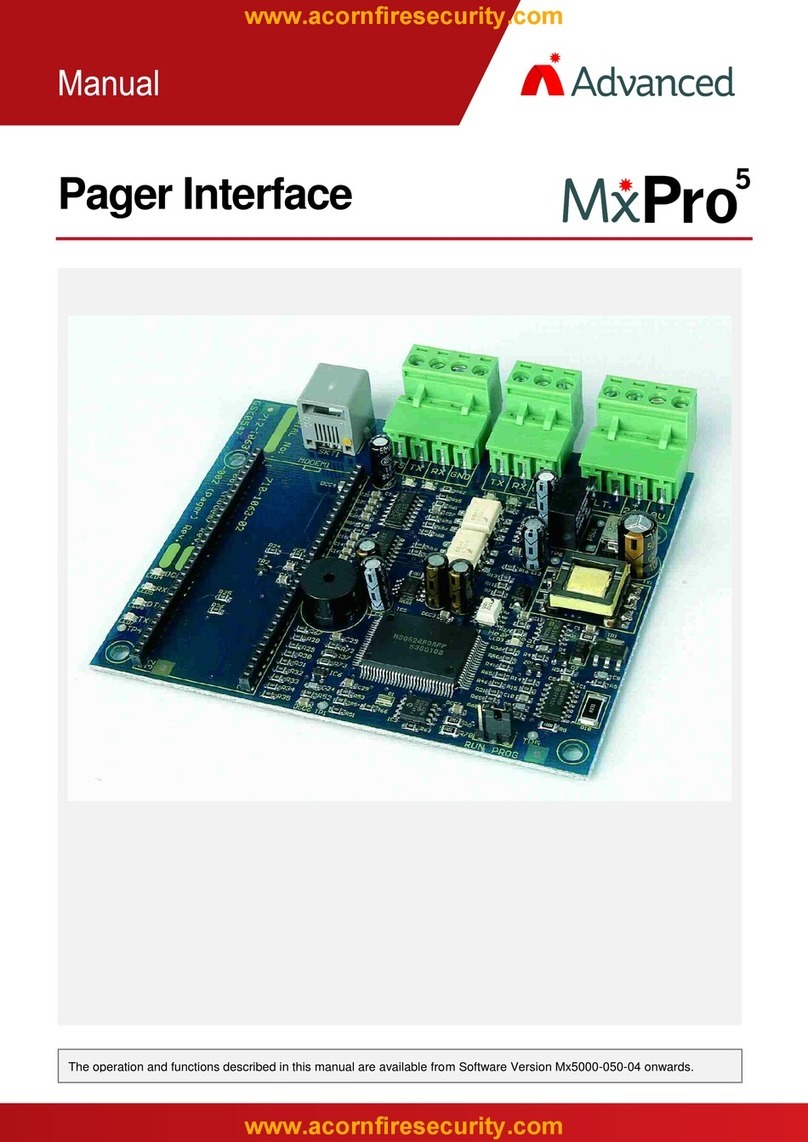

4.9 Expansion Connector

The Protégé® SE Integrated System Controller has an onboard expansion connector that is used to

connect serial communicaon, memory and special funcon interface devices. Connect the

interface card to the Protégé® SE Integrated System Controller as shown in the following diagrams.

For conguraon informaon refer to the Protégé® Reference Manual and the Installaon

Instrucons provided with the interface device.

When installing the daughter board ensure that the plasc mounng hardware provided is

correctly inserted from the rear of the Protégé® SE Integrated System Controller. Pay aenon to

the key locaon of the 40 Way Connector.

Figure 12 - Expansion Connector and Mounng Hole Locaon

Figure 13 - Connecon and Mounng

!

Power to the Protégé® SE Integrated System Controller must be turned o when

connecng any hardware or system device to the Protégé® SE Integrated System

Controller. Failure to do so may damage the Protégé® SE Integrated System

Controller and expansion device.

!If the Protégé® SE Integrated System Controller is used with the expansion

connector ed then the second onboard reader port becomes unavailable.

13

4.10 Ethernet 10/100 Network Interface

The communicaon between the Protégé® System and the Protégé® SE Integrated System

Controller uses a 10/100 Ethernet network operang the TCP/IP protocol suite. The IP address of

the Protégé® SE Integrated System Controller can be congured using the LCD Keypad

Terminal. The default IP address is set to a stac IP address of 192.168.1.2 with a subnet mask of

255.255.255.0. These IP address sengs are commonly used for internal networks.

When installing an Ethernet connecon the Protégé® SE Integrated System Controller should be

interfaced using a standard segment (<100m in length) and should be connected to a suitable

Ethernet hub or switch.

Temporary direct connecons can be used for onsite programming by connecng directly to the

computer Ethernet port.

?

Installing the Protégé® SE Integrated System Controller on an acve network

requires knowledge of the conguraon and structure for the network. Always

consult the network or system administrator and ask them to provide you with a

xed IP address that can be assigned to the Protégé® SE Integrated System

Controller.

!

When the IP address has previously been set and is not known you are able to set

conguraon DIP switch 3 (Secon 8.0) which on power up of the Protégé® SE

Integrated System Controller will congure the IP address to 192.168.111.222 this

will allow access to the conguraon ulity to change or review the programmed

IP Address.

Figure 14 - Ethernet 10/100 Switch Hub Connecon

Figure 15 - Ethernet 10/100 Direct Connecon

14

5.0 Door Access Control

The Protégé® SE Integrated System Controller provides Access control funconality onboard

without the requirement for addional hardware. With 2 Access controlled Doors built in, the

exibility of the Protégé® System as expanded even further.

The Protégé® SE Integrated System Controller allows the connecon of 2x Wiegand devices to

control 2 doors (Entry or Exit Only) or can be congured in Mulplex Mode to allow 4x Wiegand

devices controlling 2 doors giving the exibility of Entry and Exit readers.

5.1 Card Reader Connecon

The following diagrams show the connecon of standard Wiegand Reader with the Protégé® SE

Integrated System Controller controlling an Access Door in Entry or Exit mode (2 Doors, 2 Readers).

!

The shield connecon on the card reading device that is connected to the

Protégé® SE Integrated System Controller port should not be connected to a AUX-

or 0V connecon. Do not join the shield and black wires at the card reading device.

The shield should not be connected to any shield used for isolated communicaon.

Always refer to the card reader manufacturer for detailed installaon guidelines.

The beeper output on the Protégé® SE Integrated System Controller provides

diagnosc informaon to the end user and installer when access is denied or the

unit is operang oine.

Figure 16 - Card Reader Connecon

+AUX-Z9COM COMZ10Z11 Z12 L1D0 D1 BZ

SHIELD*

* See Te xt

N/R = Not Required

N/R

N/R

RED

BLACK

GREEN

WHITE

ORANGE

BROWN

YELLOW

BLUE

!If the Protégé® SE Integrated System Controller is used with the expansion

connector ed then the second onboard reader port becomes unavailable.

15

5.2 Mulple Wiegand Card Reader Connecon

When operang the Protégé® SE Integrated System Controller in Mulple Reader mode the

Protégé® SE Integrated System Controller allows the connecon of 4 Wiegand reading devices

controlling two doors each with Entry/Exit readers.

When connecng Wiegand readers in Mulple Reader mode the secondary reader that is

connected will have all connecons wired to the same port as the primary card reader with the

DATA 1 connecon wired to the opposite reader connecon DATA 1 input.

!

The shield connecon on the card reading device that is connected to the

Protégé® SE Integrated System Controller port should not be connected to a AUX-

or 0V connecon. Do not join the shield and black wires at the card reading device.

The shield should not be connected to any shield used for isolated communicaon.

Always refer to the card reader manufacturer for detailed installaon guidelines.

The reader that is mulplexed in to the alternate reader port will operate as the

exit reader and the normal reader connecon should be programmed to operate as

the entry reader.

Figure 17 - Mulple Wiegand Card Reader Connecon

+AUX-Z9COM COMZ10Z11 Z12 L1D0 D1 BZ L2D0 D1 BZ

SHIELD

RED

BLACK

GREEN

WHITE

BROWN

ORANGE

YELLOW

Entry Reader

Exit Reader

BLUE

SHIELD

RED

BLACK

GREEN

WHITE

BROWN

ORANGE

YELLOW

BLUE

*

* See T e xt

N/R = Not Required

N/R

N/R

*

N/R

N/R

16

5.3 Door Contact Connecon

The Protégé® SE Integrated System Controller allows the connecon of up to 4x contacts for

monitoring and controlling access control doors. Each zone on the reader expander can be used

for the door funcon that is automacally assigned and as a normal zone input on the system. The

following example shows the connecon of a normally closed door posion monitoring contact to

monitor the Open, Closed, Forced and Alarm condions of the door.

The zones 9-12 and 13-16 can operate as either general purpose zone inputs or as onboard reader

inputs. If used as general purpose zone inputs then make sure that these input are not dened in

the onboard reader set up.

Figure 18 - Door Contact Connecon

Zone Access Control Funcon Default Seng

Zone 9 Door Contact, Port 1 Door Contact, Port 1

Zone 10 REX Input, Port 1 REX Input, Port 1

Zone 11 Bond Sense, Port 1 General Purpose Zone

Zone 12 REN Input, Port 1 General Purpose Zone

Zone 13 Door Contact, Port 2 Door Contact, Port 2

Zone 14 REX Input, Port 2 REX Input, Port 2

Zone 15 Bond Sense, Port 2 General Purpose Zone

Zone 16 REN Input, Port 2 General Purpose Zone

+AUX- Z9 COM COMZ10 Z11 Z12

N.C Zone Contact

1K 1K Door Contact

N.O Zone Contact

1K 1K REX

N.C Zone Contact

1K 1K Bond Sense

N.O Zone Contact

1K 1K REN

!

When connected the REX Input can be programmed to operate regardless of the

Door Contact State. The REX Input can also be programmed to recycle the door

alarm me to prevent nuisance alarms when the door is held open to permit longer

entry.

17

5.4 Lock Output Connecon

The Protégé® SE Integrated System Controller provides a connecon for 2x electric strike locks with

full monitoring of the lock circuit for tamper and over current/fuse blown condions. The door lock

monitoring can be disabled if it is not required.

?

When using a door with an Entry and Exit Reader, the lock output should be

connected to Bell 1, and enable the swap lock opon for the second reader input to

allow the reader LED’s to display the correct status.

!

Exceeding the maximum current on the controller outputs is not recommended.

Ensure the devices connected to the outputs are within the limits as detailed in the

Technical Specicaons secon on page 31.

!

As indicated in gure 19 the Lock Outputs are shared with the Bell/Siren funcons.

You are able to select another output for the Lock Control (P3 or P4) if the

Bell/Siren funcon is required.

!

To use the lock outputs in conjuncon with the Onboard Reader module the Lock

PGM for the Door associated with the Reader Port must be congured to be the

desired Lock Output on the Controller. By default this is not congured.

Figure 19 - Lock Output Connecon

B1+ B1- B2+ B2- P3 P4

+

-

1N4007 Diode

12VDC Electric

Locking Device

Table of contents