Advanced MxPro 5 User manual

Specifications:

Models, Sales Order Parts:

Mxp-547 Pager Interface Card

Mxp-547-BX Pager Interface (Boxed)

Applications / Limitations:

For use with Pager Systems compliant to ESPA 4.4.4 protocol

If a printer is also required, fit an internal Mxp-512 printer assembly.

Compatibility:

A new PC configuration program (MxPager) is provided for configuring the pager interface.

The interface has been compatibility tested with Multitone pager systems.

The Mxp-547 can be installed on the chassis plate in the medium, large and deep panels.

The Mxp-547-BX can be used with all Mx-5000 Series panels.

Item

Specification Details

Power supply

15-30V DC (e.g. Wired from panel 24V auxiliary supply)

Supply current

50mA (typical at 24V DC).

Temperature

-5°C to 50°C

Humidity

95% Humidity (non condensing)

Dimensions

PCB: 85mm H x 105mm W x 15mm D

Enclosure: 218mm H x 300mm W x 45mm D

Panel Interface

RS232 Galvanically (Opto) isolated

Pager Interface

RS232 Galvanically (Opto) isolated

Fault Input

Non-monitored / Monitored (10K EOL, 470R active)

Maximum № of Pagers

250

Maximum № of Groups

50

Maximum № of Pagers

per Group

8

Event Types Supported

Fire Alarm, Test Alarm, Plant Alarm, Pre-Alarm, Fault, and Disablement

As our policy is one of constant product improvement the right is therefore reserved to modify product specifications without prior notice

www.acornfiresecurity.com

www.acornfiresecurity.com

3

Table of Contents Page

1INSTALLATION..............................................................................................................................................4

1.1 FITTING THE CARD IN A PANEL..................................................................................................................4

1.2 MOUNTING THE BOXED VERSION...............................................................................................................4

1.1 STATUS INDICATIONS................................................................................................................................5

1.1.1 Heartbeat LED Indicator ....................................................................................................................5

1.1.2 RS232 Activity LEDS .........................................................................................................................5

1.2 WIRING TO THE PAGER INTERFACE............................................................................................................5

2CONFIGURATION..........................................................................................................................................6

2.1 GENERAL CONFIGURATION OPTIONS.........................................................................................................7

2.1.1 General Options.................................................................................................................................7

2.1.2 Retransmission ..................................................................................................................................7

2.1.3 Text Cuts............................................................................................................................................8

2.2 PAGER INTERFACE COMMUNICATIONS SETTINGS.......................................................................................9

2.3 PAGER EVENTS........................................................................................................................................9

2.4 PAGER GROUPS.....................................................................................................................................10

2.5 SHIFT TIMES...........................................................................................................................................10

2.6 PAGER ZONES........................................................................................................................................11

2.7 UPLOAD COMMUNICATIONS ....................................................................................................................11

3FAULT CODES.............................................................................................................................................12

www.acornfiresecurity.com

www.acornfiresecurity.com

4

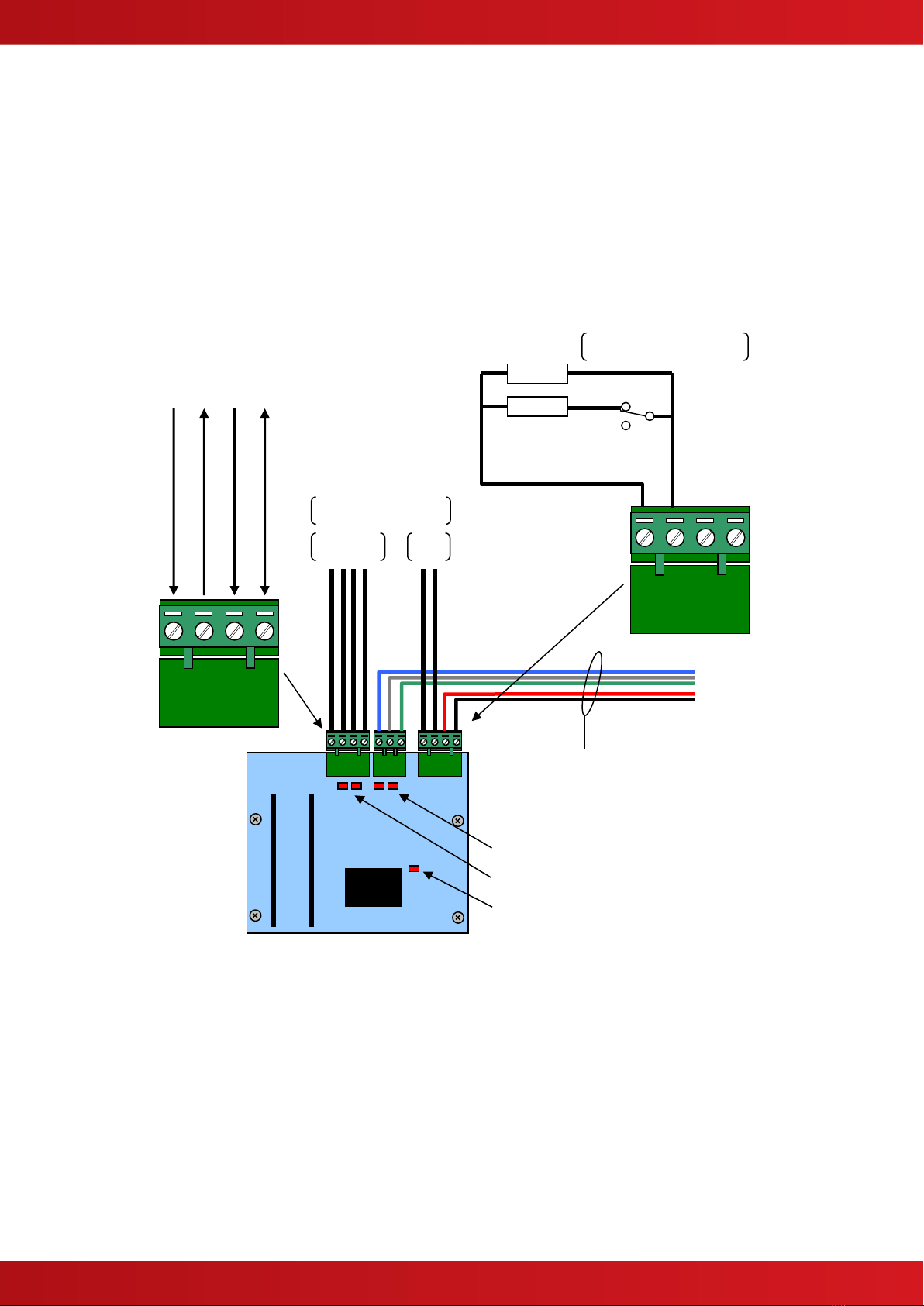

1 Installation

1.1 Fitting the Card in a Panel

Mount the card to the pillars on the chassis plate using the four M3 screws supplied.

Connect 24V DC supply from the AUX output to the connections on the Pager Interface.

OBSERVE POLARITY!

Connect the RS232 serial connection between the base card and the Pager Interface.

Connect: TX –RX,

RX –TX

GND –GND

1.2 Mounting the Boxed Version

The enclosure dimensions and fixing

points are shown in the diagram

opposite.

Connect 24V DC supply from the AUX

output to the connections on the Pager

Interface.

OBSERVE POLARITY!

Connect the RS232 serial connection

between the base card and the Pager

Interface.

Connect: TX –RX,

RX –TX

GND –GND

Run the cabling in rigid conduit or use

fire rated cable. Note: Maximum

distance of 3m (10ft) between the FACP

and the interface.

WARNING: HIGH VOLTAGE INSIDE

DO NOT REMOVE COVER

No Serviceable Parts Inside

Pager Interface

Base Card

RS232 Wiring

DC PWR Wiring

226mm

35mm

17mm

172mm

Cable Anchor

Points x2

Earth Termination

Points x4

Back Box Fixing

Points x4

Pager

Comms

Pager

Fault

Power

IN

Comms

IN

Recommended

Knockout Usage

Pager Interface

www.acornfiresecurity.com

www.acornfiresecurity.com

5

1.1 Status Indications

Status indications are provided on the card to show operation of the interface.

1.1.1 Heartbeat LED Indicator

The Heartbeat LED will normally flash at a rate of 1Hz (once per second) to indicate that the card is

operating.

1.1.2 RS232 Activity LEDS

LED2: RS232 RX –Lit when data is received from the fire panel.

LED1: RS232 TX –Lit when data is transmitted to the fire panel.

LED10: RS232 RX –Lit when data is received from the pager.

LED9: RS232 TX –Lit when data is transmitted to the pager.

1.2 Wiring to the Pager Interface

The Serial Interface follows the standard RS232 interface connections. Run the cabling in rigid conduit or use

fire rated cable. Note: Maximum distance of 3m (10ft) between the Interface and the Pager.

Connect the TX terminal of the interface to the RX (RXD-Receive) input of the pager.

Connect the RX terminal of the interface to the TX (TXD-Transmit) output of the pager.

Connect the GND terminal of the interface to the 0V or GND terminal of the pager.

Pager Interface

Power and Data to FACP

RS232

I/F

Fau

lt

Interface to the ESPA

Pager System

GND (Ground)

RX (Receive from Pager)

TX (Transmit to Pager)

CTS (Clear to Send from Pager)

+24

V

0V

10K

470R

Fault Input Arrangement

Monitored Input

LED –Heartbeat

LED –RS232 to PAGER

LED –RS232 to FACP

www.acornfiresecurity.com

www.acornfiresecurity.com

6

If required, the CTS terminal of the interface can be connected to the DTR output of the pager if this is provided.

Using the MxPager program, the fault input can be configured as monitored (used) / non-monitored (unused)

and can be inverted to provide compatibility with Normally Open (Inverted) or Normally Closed fault relay output

contacts.

The diagram above shows the EOL arrangement for the monitoring of the relay output contacts. The diagram

shows the normally closed condition.

2 Configuration

The MxPager software is used to configure the operation of the unit.

The program uses the standard RS232 upload / download lead supplied with the PC-NET-003 PC CONFIG

software for connecting the PC to the Pager Interface.

The software is supplied on a CD. To install the software onto the PC, insert the CD and the program should

auto-run. Follow the on-screen prompts to install the software.

If the auto-run feature is disabled or does not run, select START, RUN and enter D:\setup.exe where D: is the

drive letter of your CD drive.

To run the program, select Start, All Programs, Advanced Electronics, MxPager.

The program will open up with a new (blank) configuration file. The screen is as follows:

Use the normal windows “New, Open and Save” functions to create / open a file via

either the “File” menu or the buttons.

The tree view on the left shows the list of configurable options.

The active view on the right shows the parameters and functions that can be changed for the option selected.

Additional buttons are available and are context sensitive and are

grouped into common functions as follows.

a) Add / Delete / Edit pager addresses

b) Connect to / Disconnect from / Upload to target pager interface.

www.acornfiresecurity.com

www.acornfiresecurity.com

7

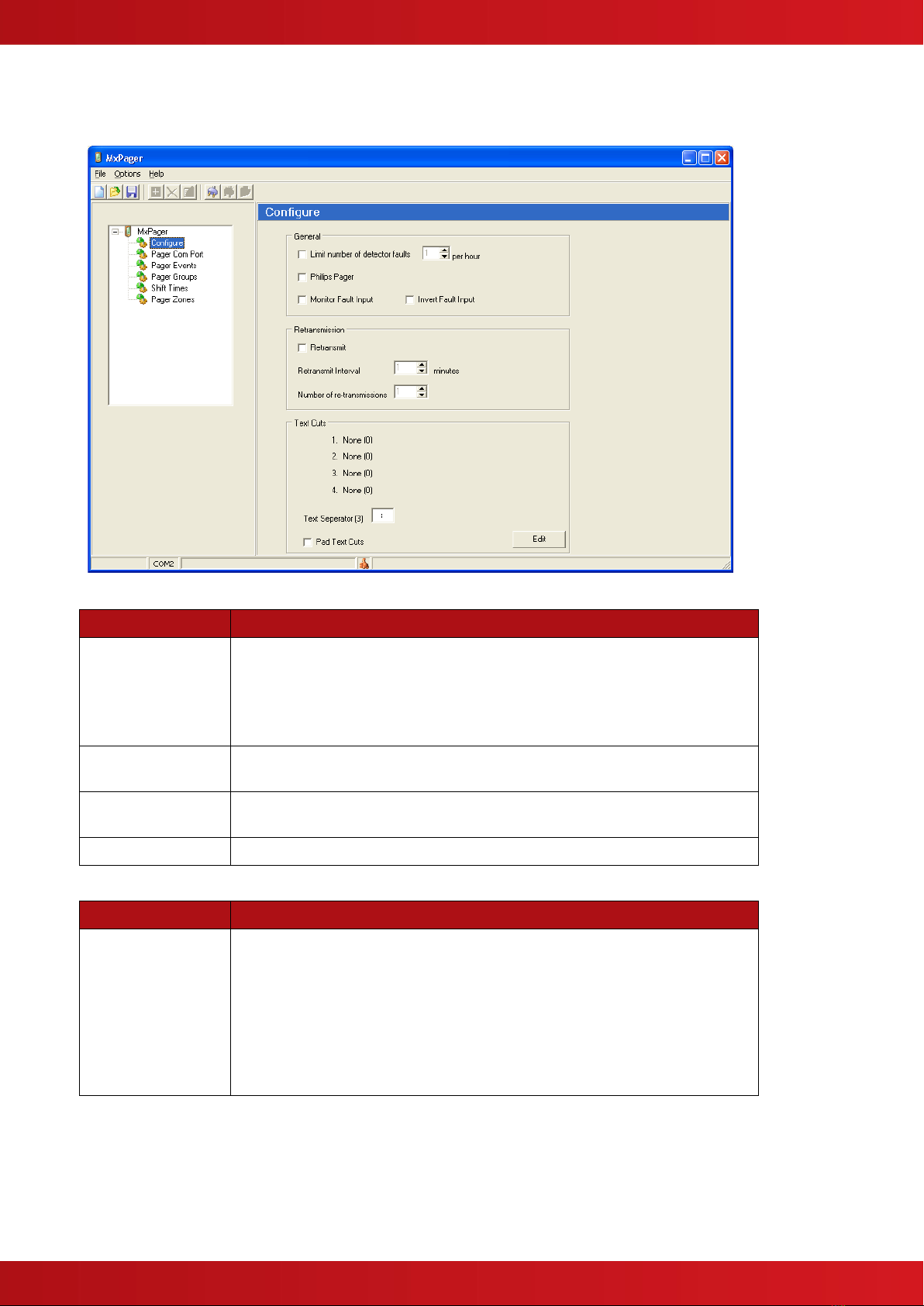

2.1 General Configuration Options

The general configuration options provide a set of specific settings to configure the interface to the type of pager

in use and how the pagers are to be notified with information. The default (new) screen is shown below:

2.1.1 General Options

Item

Description

Limit number of

detector faults

This can be used to prevent a large number of faults, say due to a loop

failure, swamping the pager system.

Unticked, the interface will report all faults as they occur.

To restrict the number of possible fault messages, tick the box and then

set the number of fault per hour in the range 1 –250.

Philips pager

Tick this box if the pager is specifically a Philips pager system. Leave

unticked for all other pager systems.

Monitor Fault Input

Tick this box to utilise the fault input circuit. Leave unticked to ignore the

fault input circuit.

Invert Fault Input

Tick this box to Invert the signal and monitor NO relay contacts.

2.1.2 Retransmission

Item

Description

Retransmit

Unticked, the interface will report all events only once as they occur.

Tick the box to retransmit the events more than once.

Set the retransmit interval in the range 1 –30 minutes. Set the number of

retransmissions in the range 1 –255.

NOTE: If the condition persists and if a pager address has been assigned

to the ALL CALL Group, then the interface will send a message to the ALL

CALL pager address after all normal retransmissions have occurred. This

will be sent after the programmed retransmit interval.

www.acornfiresecurity.com

www.acornfiresecurity.com

8

2.1.3 Text Cuts

The information to be sent to the pager can be configured

to specific system information and / or user text.

Some pagers have limited display capability.

To accommodate this restriction, the text can be further

cut to send only part of the available message so that a

composite message can be built up from various sources.

Up to four text cuts can be defined.

Note: Text cuts are from the beginning of the available

string. For example, the zone text can be up to 32

characters in length. Applying a text cut of 6 will mean

that the first six characters of the string are sent to the

pager. (i.e. “Ground Floor West” would be sent as

“Ground”).

Press the EDIT button and a pop-up screen will be shown

as opposite:

Click on one of the available text types and using the

mouse pointer, drag this down to one of the text cut

fields.

Build up the message order and then determine the

length (cut) of each string to be built in to the full

message.

User text can be entered / typed into the boxes to the

right of the item.

For example:

The pager is to be sent a message in the format:

FIRE/FAULT/ALARM –ZONE0001 –ZONE TEXT (16

characters)

The example screen image opposite shows the settings

required.

The maximum length of each item is detailed in the table

below.

Item

Maximum Length

Device Text

26

Zone Text

32

Event Text

16

Point Address

12

Event Time

8

Zone Number

4

User Text

16

NOTE: The Pager interface automatically strips off any

“spaces” after the text characters and only sends the

actual text characters.

For example: The text <LIBRARY ROOM > is sent as <LIBRARY ROOM>

If The PAD TEXT CUTS option is ticked then these trailing “space” characters are included in the message.

www.acornfiresecurity.com

www.acornfiresecurity.com

9

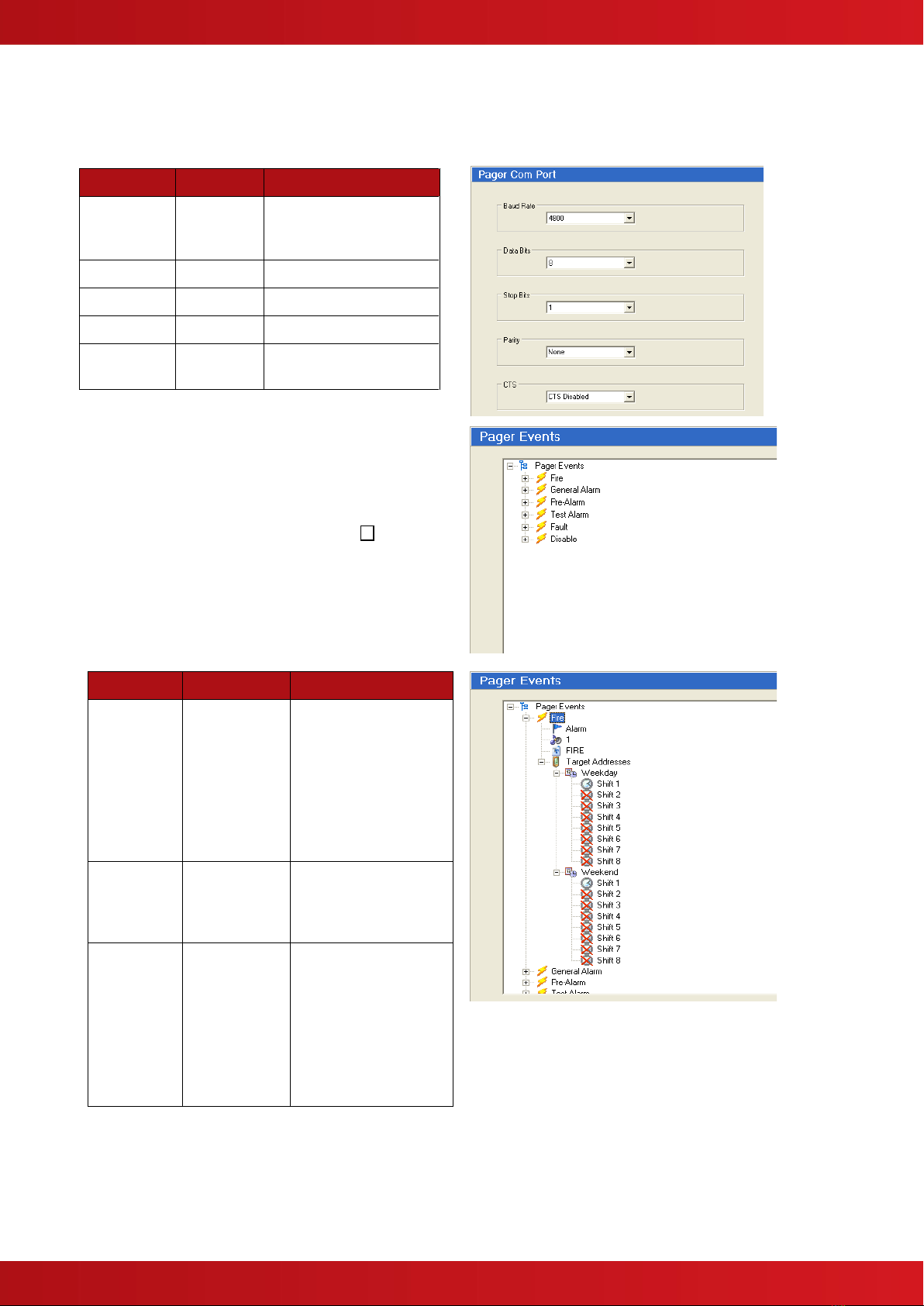

2.2 Pager Interface Communications Settings

The serial interface can be configured to the settings of the pager system. Refer to the pager system

documentation for further details on the settings required.

The table below shows the options available.

Item

Default

Options

Baud Rate

4800

600, 1200, 2400,

4800, 9600, 19200,

38400 and 57600

Data Bits

8

7, 8

Stop Bits

1

1, 2

Parity

None

None, Odd, Even

CTS

Disabled

Disabled, Enabled,

Switched

2.3 Pager Events

In the pager events option, it is possible to determine

to which pagers each type of event should be sent

and to configure some basic event parameters.

The active window shows and event tree with all of

the possible event types.

To configure an event type, click on the + symbol to

expand the tree.

The Basic options are described in the table below.

Right click on the item to edit its setting.

Item

Default

Options

Flag

Fire = Alarm

Alarm, Plant

Alarm, Pre-

Alarm and

Fault = High

Disable and

Enable =

Normal

Alarm

High

Normal

Beep

Code

1

0 –9 Refer to the

pager documentation

to see if it supports

this option.

Text

Fire

Alarm

Plant Alarm

Pre-Alarm

Fault

Disable

Enable

Up to 16 characters

–this text is used in

the “Event Text”

string –see the

section on Text Cuts.

There can be up to 8 shifts per day for

both weekdays and for weekend days.

Shifts that are not configured are crossed

out.

www.acornfiresecurity.com

www.acornfiresecurity.com

10

Right Click on a shift to add a pager –a text entry box is

displayed. Enter the address of the pager to which these

messages should be sent either directly in the box or select from a

drop down list by clicking the down arrow button.

The list presented includes all defined individual

pagers and pager groups currently unused

in this shift.

For confirmation, the zone ranges assigned to the pager (if defined)

are shown alongside the pager number. For example, Pager 12

opposite is assigned to Zones 1-25 and 110-233.

Pager Addresses can be up to four (4) digits in length and can consist

of the numbers 0-9, the characters A-F or a wild card (*)

character. For example, these could be –1, 09, A1, B1F, 9010 or A1*D

(i.e. A10D to A1FD).

NOTE: Addresses “1”, “01”, “001” and “0001” are not the same pager.

A combination of up to three (3) individual addresses or groups can be assigned to a shift.

2.4 Pager Groups

To simplify event programming, pagers can be

assigned to pager groups. A group can consist

of up to eight (8) individual pager addresses.

Select the group required and Right Click to

“Add” a pager address. A text entry box is

displayed. Either enter the number of the pager

to which these messages should be sent

directly in the box or select from a drop down list

by clicking the down arrow button.

The list presented

includes all defined

individual pagers

currently unused in

this group.

2.5 Shift Times Up to eight shifts can be

defined for weekdays and for

weekend days. As default, each

day is defined as one shift.

Right Click on the blue bar and click

“Add” to add a shift.

Click on the boundary between the

two shifts and drag the

boundary to the required time.

Shifts can be defined in five-

minute intervals.

Repeat the process to define the number of shifts and the shift

times required for both weekdays and weekend days.

www.acornfiresecurity.com

www.acornfiresecurity.com

11

2.6 Pager Zones

Each Pager Address must be configured to define

from which zones the events will be sent to the pager.

This can be used to prevent unnecessary or unwanted

events being sent to all pagers or it can be used to define

only those zones that are relevant to a specific person.

For example, a nurse pager can be configured to cover

only those zones concerned with the hospital wards

covered by the nurse.

Up to two ranges can be defined.

Right Click in the table or on a specific address to Add /

Delete / Edit and entry.

A new pop-up dialogue box is shown.

Define the new pager number and address ranges as

required. See example below.

If only one address

range is required,

then use “Zonal Range 1” only.

The maximum zone range is 1 –2000.

2.7 Upload Communications

To upload the configuration data to the pager interface, first unplug the

cable from the base card and plug in the upload / download lead as

shown opposite.

Click on the “Connect to Target” button and when

communications is established, click on the “Upload” button to transfer the

data.

On completion, remove the upload / download lead and re-fit the lead

from the base card.

Pager Interface

www.acornfiresecurity.com

www.acornfiresecurity.com

12

3 Fault Codes

The following table lists the possible fault conditions reported on the Panel LCD and their meaning. The list is in

descending order of priority.

Item

Description

DEVICE MISSING

The pager interface is not responding to the panel communications.

Check power and serial communications connections to the interface.

Check that the Heartbeat LED on the interface is flashing.

CORRUPT DATA

The communications between the panel and the pager is being affected.

Check the serial communications connections to the interface.

PROGRAM FAIL

The pager interface has detected a checksum error in its operating

program.

Re-flash the operating program into the interface using the MxFlasher

Tool.

CONFIG. FAIL

The pager interface has detected a checksum error in its configuration

data.

Power down the interface then reapply power. Re-configure the interface

using the MxPager Tool with the configuration settings.

NOT READY

The pager interface has either never been configured or is not fully

configured.

This could occur if the RS-232 lead is disconnected during a

configuration upload.

Re-configure the interface using the MxPager Tool with the configuration

settings.

CPU RESET

The pager interface has just powered up or has been reset due to a

watchdog timer. This will not normally appear on the display but may

appear in the log.

DEVICE FAULT

The pager interface cannot establish communications with the ESPA

Paging system.

Check the serial communications connections between the interface and

the ESPA Pager system.

OPEN CIRCUIT

There is an open circuit condition on the Fault Input wiring.

Check the connections between the interface and the ESPA Pager

system including the EOL resistor.

SHORT CIRCUIT

There is a short circuit condition on the Fault Input wiring.

Check the connections between the interface and the ESPA Pager

system including the EOL resistor.

INPUT FAULT

The Fault Input is in its active condition indicating a fault condition from

the ESPA Pager system.

Check the ESPA Pager system.

NOTE: The input can be configured with an “Invert” property. Check that

the correct configuration has been used for this input’s required

operating properties.

Normal

The interface and the Fault Input are in their normal operating condition.

NOTE: Transmission to the Pager Interface is prevented whilst the panel is in COMMISSION mode. This is to

prevent the paging of unwanted / spurious messages whilst commissioning / testing the panel.

www.acornfiresecurity.com

www.acornfiresecurity.com

Other manuals for MxPro 5

2

This manual suits for next models

2

Table of contents

Other Advanced Recording Equipment manuals