!

system are properly connected to one another and operate properly without any mutual interferences, as well as if they conform to effective

standards:

- EN 361 – for fall protection body harness;

- EN 354, EN 355, EN 353-1, EN 353-2, EN 360, EN 362 – for connectors and energy absorbing components;

- EN 795 – for anchoring points (solid construction elements);

- EN 341 – for emergency and rescue equipment;

!The length of camping device of the fall from height protection system has to be taken into consideration every time, as it influences directly the

distance travelled during the fall arrest action,

!One should pay special attention to some elements connected to the clamp that can deteriorate its strength characteristics, such as connecting

the clamp with broad belts,

!The AZ 300 device has been designed to protect a single person only,

!The AZ 300 device cannot be used to secure lifting or lowering of loads,

!The system used to protect user against fall from height must include fall protection equipment reducing the pulling force, acting on the user

while arresting the fall, to maximum value of 6kN (e.g. fall safety energy absorber with lanyard or retractable fall arrester).

Every time before using the fall protection system that includes the scaffold scissors clamp, one is obliged to verify if all the elements of the

4

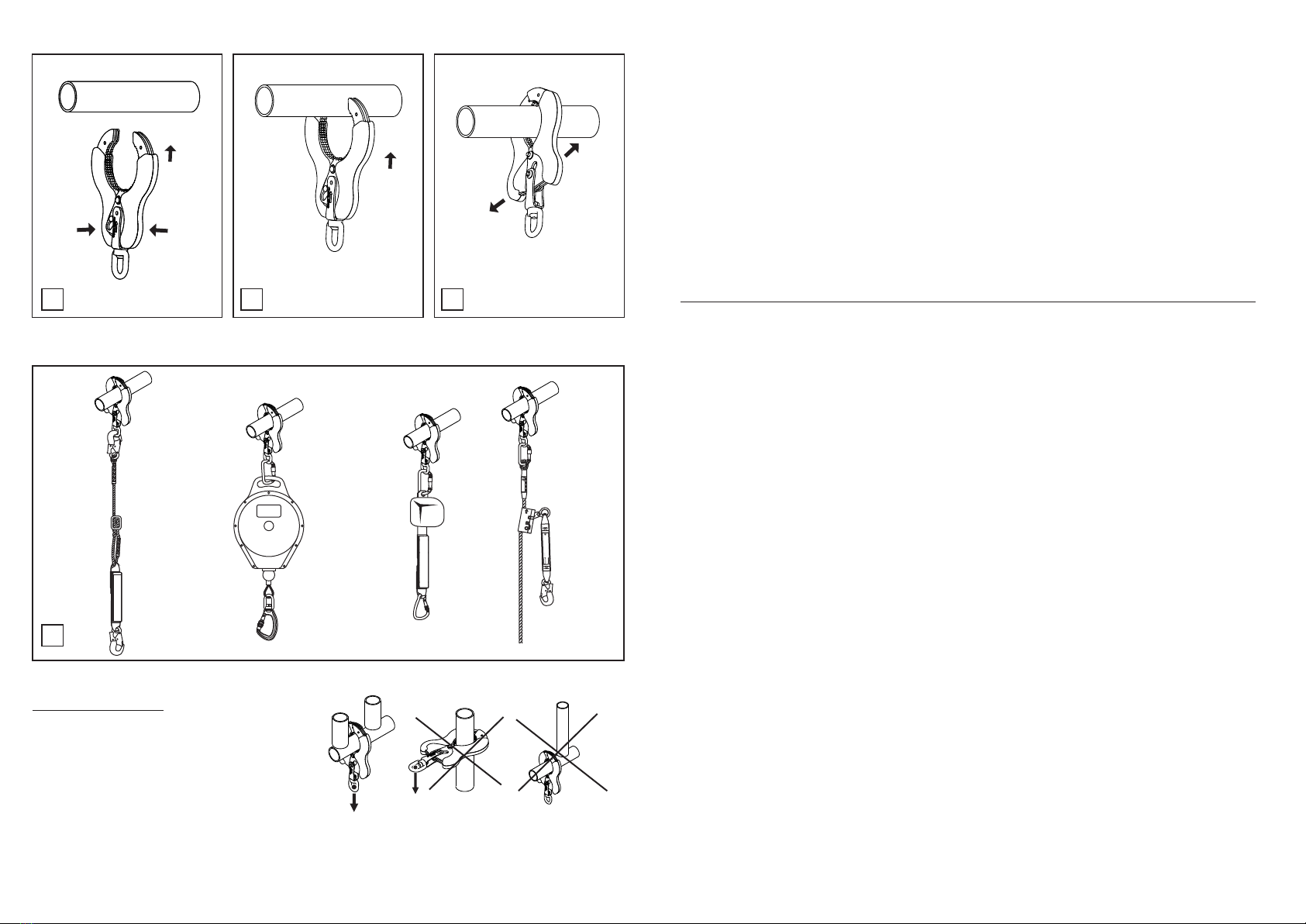

Connect the energy absorbing / connecting element to the snap hook (e.g. energy absorber with lanyard, retractable fall arrester, working lanyard, or

rope grab).

2 3

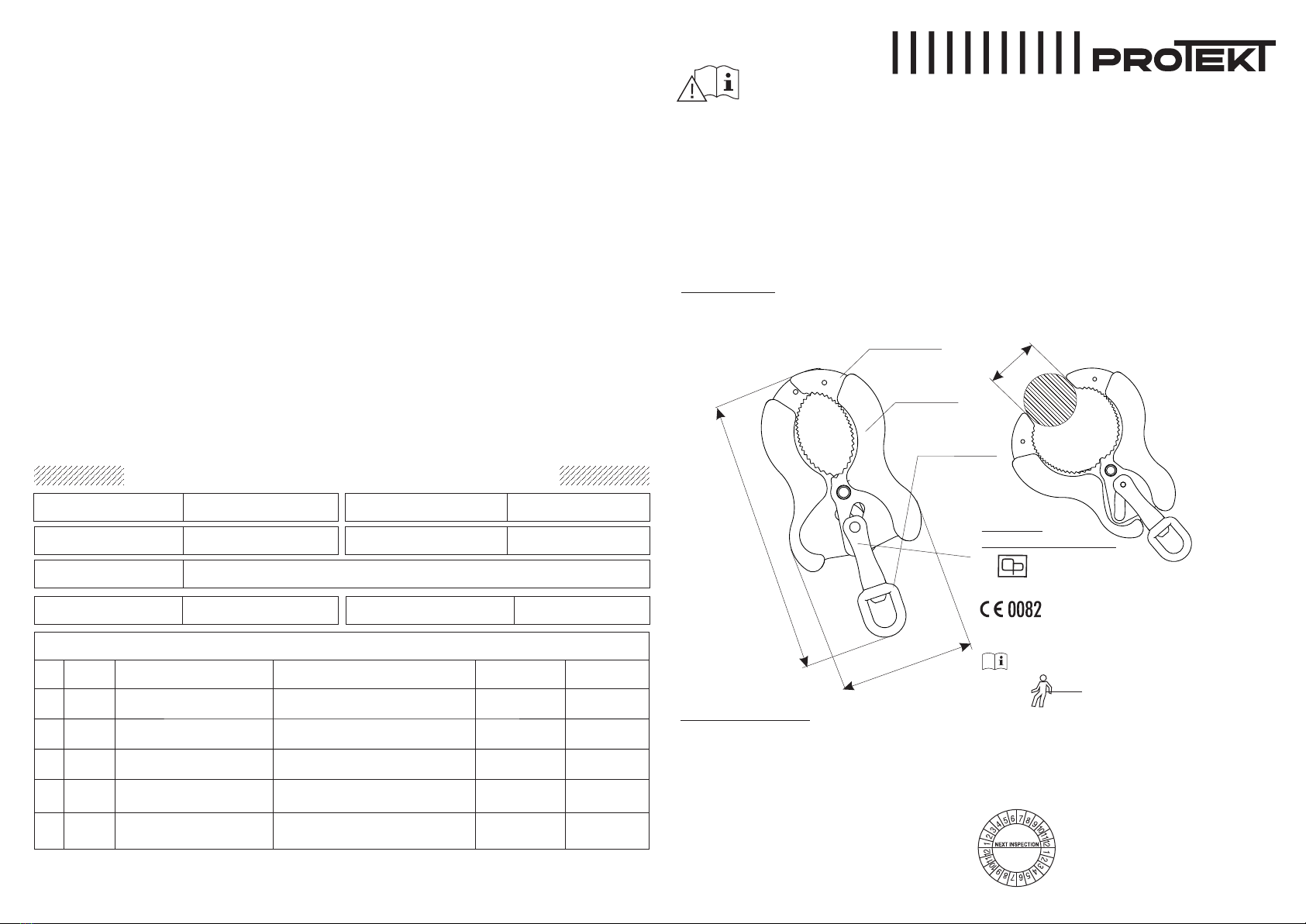

INSTALLATION OF THE DEVICE

The AZ 300 device can be installed only on horizontal pipe elements

of scaffolding static constructions. The shape and design of the

construction element must prevent the clamp from accidental

decoupling or damaging the clamp. The construction element must

be placed directly above the user. It is always required to check

whether the clamp after securing it in the construction element is

properly closed. The minimal static strength of the solid

construction must be equal to 12 kN.

!The personal protective equipment against falling from heights may be used only by people who underwent appropriate training.

!The personal protective equipment cannot be used by persons whose health condition may influence the safety of both everyday's operation and

possible rescue activities.

!The rescue plan has to be prepared and ready to implement in case the emergency situation occurs.

!

!It is strictly forbidden to modify the equipment in any aspect without prior, written consent of the manufacturer.

!Any repairs of the equipment may be performed uniquely by the manufacturer of the devices or a third party authorized to do so by the manufacturer.

!The personal protective equipment cannot be used outside of the scope it is designed to.

!The personal protective equipment is considered individual and can be used by a single person only.

!Before use one is obliged to check if all the elements of the equipment that composes the fall protection system are working together flawlessly. All the

connections and fittings are to be checked periodically in order to eliminate the risk of accidental loosening or disconnecting.

!In case the operation of any given element of the fall protection set is disturbed by other element(s)'s operation, it is strictly forbidden to use the set.

!Every time before using the personal protective equipment it is required to thoroughly check its condition in order to identify and eliminate any

malfunctions.

!While performing the inspection one has to verify all the elements of the equipment, paying special attention to any possible damages, excessive

wear, corrosion, abrasions, cuts and malfunctioning. Special care needs to be taken while examination of the following elements:

- buckles, adjustment elements, anchoring (connecting) points, webbing, seams and loops, in case of body harnesses and positioning belts;

- connecting loops, webbing, seams, casing and connecting elements, in case of energy absorbers;

- lanyard, loops, thimbles, connectors and adjustment elements, in case of lanyards and fibre-made guides;

- lanyard, wires, clamps, loops, thimbles, connectors and adjustment elements, in case of lanyards and steel guides;

- lanyard or webbing, proper operation of winding and blocking mechanism, casing, energy absorber and connectors in case of retractable fall

arresters;

- device body, proper sliding movement along the guide and correct operation of blocking mechanism, rollers, screws and bolts, connectors and

safety energy absorber, in case of rope grabs;

- load carrying body, rivets, main clamp, proper operation of blocking mechanism, in case of connectors (snap hooks).

!At least once a year, after each 12 months of using the personal protective equipment it has to be withdrawn from use in order to perform thorough

periodical inspection. The examination can be executed by a person responsible for periodical inspections of the personal protective equipment in a

company who received appropriate training. The periodical inspections can be also performed by the manufacturer of the equipment or other

company or entity authorized by the manufacturer. All the components of the equipment are to be precisely checked and special attention must be

paid to any signs of possible damages, excessive wear, corrosion, abrasions, cuts and malfunctioning (see preceding point). In case of complicated

and complex design of the equipment, such as in case of retractable fall arresters, the periodical inspections can be done only by the manufacturer or

other company or entity authorized by the manufacturer. After the inspection is completed the date of the following examination will be defined.

!Regular equipment inspections are basic requirement for maintaining proper condition of the equipment and user safety that depends on proper and

accurate operation and reliability of the equipment.

!Readability of all the markings on the protective equipment is to be verified during the periodical inspection (device parameters).

!All the information concerning the safety devices (name, serial number, data of purchase and first use, user's name, repairs and periodic inspections

related information, as well as withdrawal from operation) have to be included in equipment identity card issued with a device. The company using the

equipment is held responsible for the consistency and completeness of the date in the equipment identity card. It is being filled in by a person

responsible for personal protective equipment in the company. Any personal protective equipment without issued and completed equipment identity

card cannot be used.

!Should the equipment be sold outside of its country of origin, the supplier is obliged to issue user's manual with information related to maintenance,

periodic inspections and repairs in an official language of the country equipment is to be used.

!The personal protective equipment has to be withdrawn from use immediately if any doubts concerning its condition or proper operation arise. The

equipment may be used again only after performing thorough examination of the devices by the manufacturer followed by the written permission to

use it again.

!The personal protective equipment has to be withdrawn from use and disposed (permanently destroyed) if it was used during fall arrest incident.

Being suspended in PPE (e.g. arresting a fall), beware of suspension trauma symptoms. To avoid symptoms of suspention trauma, be sure that the

proper rescue plan is ready for use. It is recommended to use trauma relief straps.

1

USP BLOCMAX

EN 353-2

Nr kat.: AC 010

Data

produkcji:

DOPUSZCZONE DO STOSOWANIA WYŁĄCZNIE Z LINAMI f14 mm

Numer

urządzenia:

Przed zastosowaniem

zapoznać się dokładnie

z instrukcją użytkowania

POLAND

93-403 Łódź

ul. Starorudzka 9

tel/fax: (0 42) 683 03 21

(0 42) 683 03 22

LINA ROBOCZA

USP BLOCMAX-RORIP

CORRECT

The required free space between the working are and the ground level (or other elements situated below the working place) must be defined by the fall

from height protection system being used and should depend on equipment being used (fall arresting device, safety lanyard, etc.). The minimum

distance of the free space below the working point is evaluated as the sum of lengths of particular components of the fall protection system plus an

additional 1m safety margin. The required free space distance below the working place must be verified against the user's manual of the fall protection

system to be used.

INCORRECT

Hold the grip of the clamp with one hand Push the hand grip until the full spread

of the clamp, then secure the clamp

on the element.

Release the hand grip, enabling the device

to automatically secure on the bar.

MAIN RULES FOR USING THE PERSONAL PROTECTIVE EQUIPMENT AGAINST FALLING FROM HEIGHTS

max.

12 kN