9

Components Quantity Packing Figure№ Marking

Test-object 1bag 1b, 2 —

Sleeve gaskets of the combination

magnetic scanner 2bag —

Polyethylene bag 1box —

Transportation packaging 1 — —

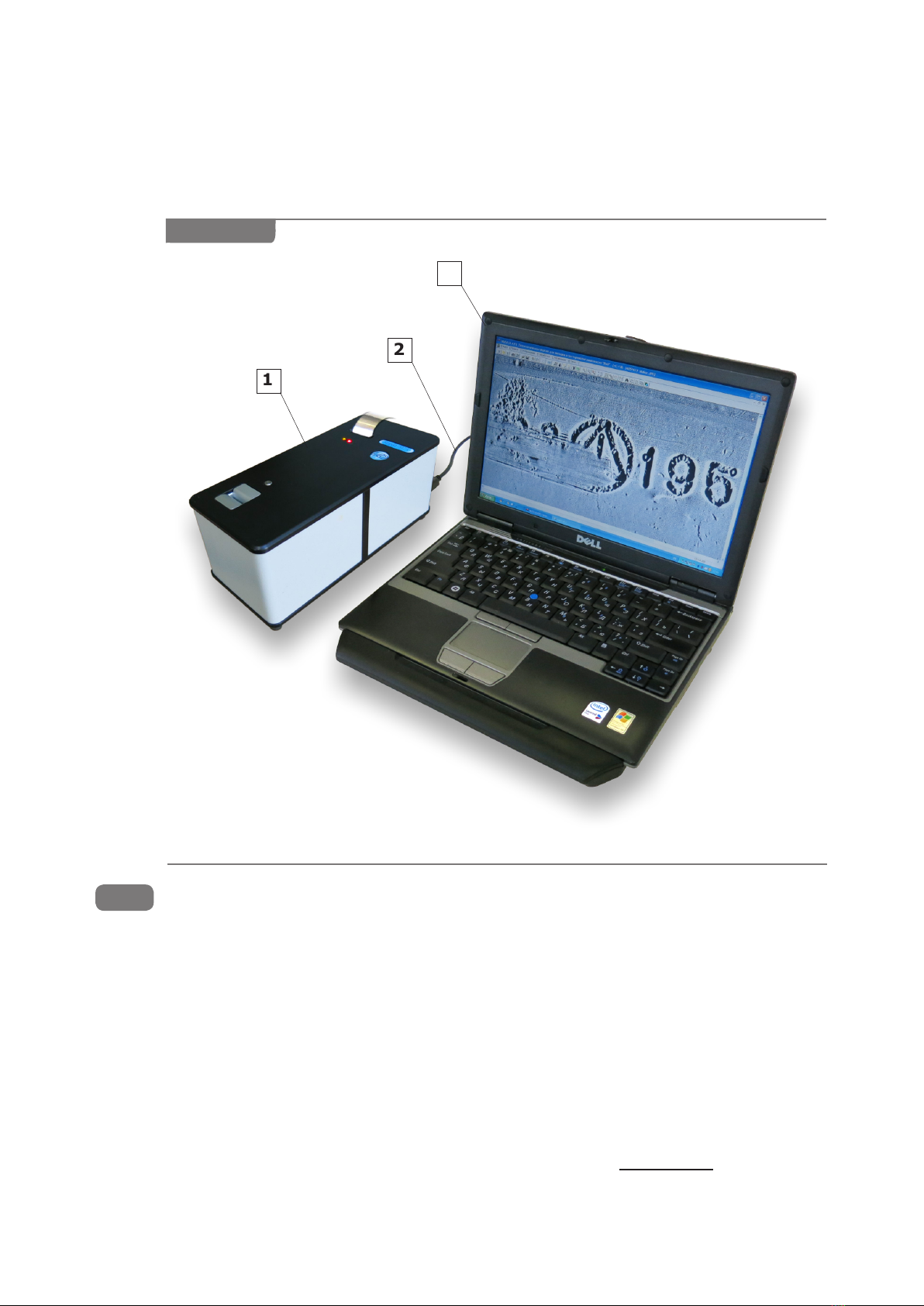

Regula 7517A

serial #,

year of

production

** — supplied optionally.

CongurationandOperation

Regula 7517A is a set of hardware components and software products. The device allows

examining objects using different methods.

Examination starts with magnetic copying (making a magnetogram = magnetic copy) of

the ferromagnetic object surface. The magnetic copying accessories set (MCAS) contains

various kinds of magnetic scanners which locally magnetize the object, excite its magnetic

stray elds and copy them to the intermediate exible magnetic carrier (magnetic tape) without

removing the lacquer–and-paint coating. The eddy-current scanner (supplied optionally) is

used for investigating internal stresses in ferromagnetic objects and for examining the surface

of aluminum objects.

The magnetogram is loaded into the USB device for magneto-optical visualization

(MOV USB device) where information about object’s surface layer is scanned. The MOV USB

device combines two functional components: optic-mechanical block and block of electronics.

The optic-mechanical block (OMB) contains a magneto-optical visualizer which converts

magnetic stray elds of a magnetic copy into an image and a special tape drive mechanism

which moves the magnetic copy relative to the visualizer.

A magnetic copy is loaded into the tape drive where it is automatically detected and

introduced into the tape drive tract. Then it is scanned step-by-step by a sensor designed

on the basis of a magneto-optical crystal. Magneto-optical visualization of magnetograms of

the examined object is based on Faraday magneto-optical effect which occurs in crystalline

lms of Bi-containing ferrite garnets.

Light distribution obtained as a result of visualization is received by the sensitive element

of the video camera and is converted into a digital TV signal which is further processed and

examined with the help of PC software.

Step-by-step input of images into a PC allows making automatic panoramic stitching of a

digital image from several sub-shots.

The block of electronics manages OMB resources (electric drive, inductor, illuminator,

video camera and indicators).

The PC operates the MOV USB device via special software. The PC displays newly obtained

and stored examination data which are processed, examined and documented.

Peripherals (supplied optionally) extend examination possibilities of the device by applying

additional methods and means of investigation.

The device operates together with the following peripherals:

zUSB device for optical input,

zmagnetic powder visualization device,

zeddy-current probe,

zelectrochemical etching device.

Basic functions of NUCA (EYER) software:

zoperating USB devices,

zinput and processing of images,

zautomatic program correction and panoramic stitching of MOV frames,

zimage scaling and rotation,

zcomparison of images,

zmeasurements of linear and angular sizes,

zsaving and printing of image les as illustrations to the photo charts.

Table1(continued)

1.1.4