PROTENT MODUL 4000 User manual

MANUAL

PRO-TENT MODUL 4000

PRO-TENT 5000

Pro-Tent MODUL 4000 1,5 x 1,5 / 2 x 2 / 3 x 1,5 / 3 x 2 / 4 x 2 /3 x 3 / 4,5 x 3 / 6 x 3 m

Pro-Tent 5000 3 x 3 / 4,5 x 3 / 6 x 3 m

Important points to note

• Pro-Tent tent systems have been designed for temporary

outdoor use to provide protection from sun and rain.

• Pro-Tent tent systems should not be exposed to extreme

weather conditions such as storms, snowfall or hail. In wind

and rain, the Pro-Tent tent systems must be secured with

our weight plates and/or tensioning ropes and tent pegs.

• Bear in mind that the colouring of the synthetic fabric may

fade over time as a result of UV radiation.

• Never fold up the fabric roof when it is damp. It is bestto lay

it loosely over the frame in a dry room.

• Pro-Tent tent systems have been released for delivery by our

quality assurance department and marked "awless in work-

manship and function". If you still have reason to complain

about this product, please contact your local sales oce

immediately.

Product warranty

We grant a 5-year warranty, starting from the day of sale for

the folding construction of the Pro-Tent tent systems. During

this time, our warranty covers the following (upon presenta-

tion of the purchase receipt):

• The free replacement of defective parts due to quality

defects on the part of the manufacturer, including labour

Further claims within warranty processing with the Pro-Tent

tent systems cannot be asserted. Defects that occur as a

result of not complying with these instructions are excluded

from the warranty in all cases.

AREAS OF APPLICATION

2

PRO-TENT MODUL 4000 / 5000

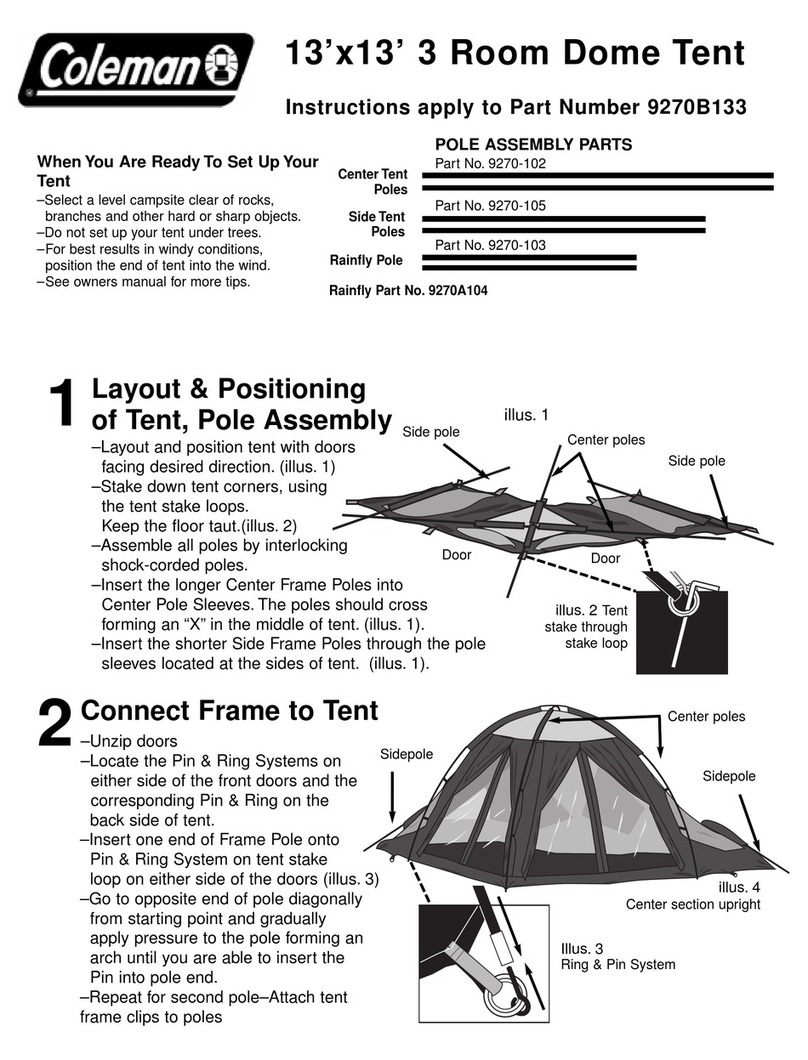

a) 1 aluminium frame

b) 1 carrier bag

c) 2 wheels for mounting on the bag

d) 1 Torx key

e) 1 adapter bar pliers

f ) 1 assembly instructions

g) 1 tensioning set

Remove the wheels from the storage compartment. Screw the wheels into the angle plate on both sides as far

as they will go in the thread.

WHEEL ASSEMBLY

SCOPE OF DELIVERY

a) c)b)

d)

e)

Video transport bag

2 3

PRO-TENT MODUL 4000 / 5000

The Pro-Tent folding tent can be assembled comfortably by

two people. Many steps should be carried out at the same

time. This generally applies to the entire assembly and dis-

mantling process.

Step 1:

Open the buckle at the bottom of the bag. Open the zip of the transport bag,

which is now accessible, as far as it will

go. Use your foot to push the wheels

and the angle plate mounted on them

away from the frame.

Remove the bag from the side of the

frame and store it safely until you need

it again.

Grasp the frame on the outer proles.

Lift the frame slightly. Open the frame

by stepping backwards and spreading

your arms at the same time.

ASSEMBLY

Assembly video

It is best to always

grasp the frame on the

shorter side of the tent -

i.e. on the 3m side of a

6 x 3m tent.

TIP

4

ASSEMBLY

Step 2:

Hold the frame below the middle pivot point by the cross

struts. This is the optimal handling position for opening the

frame. Lift the frame slightly and open it by stepping back

only so far that the gable pole extends about 10 cm.

When positioning

the fabric roof, the

gable pole should only

be extended by

about 10 cm.

TIP

Tensioning

loops

The corners of the fabric roof

are easily recognisable by the

sewn-on tensioning loops. After

the rst assembly, the roof can

remain in place. However, never

store the tent in the transport

bag when it is damp.

TIP

Step 3:

Throw over and x the four corners of the fabric roof to

the outer legs.

4 5

ASSEMBLY

Step 4:

Fasten the velcro straps on the inside of the roof corners

tightly underneath the plastic connector around the leg.

Make sure that the reinforcement ap is placed symmetrically

and without creases around the leg beforehand.

Step 5:

Fixing the roof gable to the protection cover: Push the recess/

slot on the fabric sleeve through the tongue on the prole

cover. Tighten the sleeve rmly using the velcro strap.

6

ASSEMBLY

Step 7:

To engage the roof struts, the plastic gliders must be pushed

out over the top push buttons of the corner legs. This applies

equally to any centre legs if installed.

Tip: Grasp the lower roof strut and push it from above with

your free hand.

Upper push

button

Plastic glider

Step 6:

Grasp the frame again below the middle pivot point at the

cross struts, lift slightly and open the frame by stepping

backwards until the roof begins to stretch.

6 7

ASSEMBLY

Step 8:

Easy tightening of the fabric roof by using the velcro straps.

To do this, pull the roof panel down a little rst.

Push button spring in the upper leg

(locking of the gliders)

Height compensation

for uneven terrain

1.

End position2.

1.

2.

Step 9:

Now pull out all the legs to the end position (2).

Functional explanation of how to engage the legs

Extend the leg: To do this, raise

the leg slightly and only then

pull it out with your foot.

TIP

8

ASSEMBLY

DISMANTLING

1. Loosen all velcro straps on the roof panel.

2. Press the red push button release below the plastic gliders

on each leg. This unlocks the roof frame.

3. Release the push button and retract the legs.

4. Grasp the frame above the middle pivot point on the roof

proles, lift slightly and push together again by stepping

forward but do not close completely to prevent jamming.

5. Push the frame together completely at the upper corners.

6. The frame can now be stowed in the mobile transport bag

together with the roof, which should be smoothed out a

little beforehand. To do this, open the bag completely and

place it sideways over the frame with the fabric roof. Pull

the bag down and slide the angle plate between the

wheels under the plastic gliders of the frame. Then close

the zip and the buckle. Finally the belt must be pulled tight

to ensure safe transportation.

Push button release

8 9

DISMANTLING

SIDE WALLS

3. Slide two adapter strips over the

piping cord on each of the outer two

fabric sections.

Note: In addition to the side wall, four adapter strips (a) are in-

cluded in each carrying bag - 2 per lower leg. The grooves of the

upper leg are continued downwards with the adapter strips. In

this way, the piping cord sewn into the outside of the side wall

is securely guided and held from top to bottom in the leg.

a)

1.

2.

3.

2. Open zips as far as possible. Pull the

two outer, narrow pieces of fabric

into the groove of the upper legs

and velcro them to the inner roof

panel at the top.

Side wall

1. Attach the side wall horizontally

between the two legs to the inner

roof panel.

Video assembly

side wall

10

ACCESSORIES/SIDE WALLS

Removing the side wall

1. Press the adapter strips of the side

wall together at the lower end and

screw them out of the groove of the

leg from the bottom upwards at the

side. Alternatively, the adapter strip

pliers can be used for this purpose.

2. Open the zips about halfway down

the lower leg. Pull the narrow piece

of fabric out of the grooves in the

leg, velcro it to the top of the roof

panel and close the zips.

3. Loosen the velcro on the upper edge

of the side wall across the entire

width. To do this, hold the foot and

head ends of the side wall with one

hand each; it is best to tear velcro

away from the roof panel with a

helper and fold it up immediately

without it touching the ground.

4. Then press the four strips into the

groove of the lower legs and align

them with the lower edge. Then

close the zips again.

4.

10 11

ACCESSORIES/SIDE WALLS

Cross-connectors

1. Pull the top edge with the piping

of the half-height side wall into the

cross-connector, align the connec-

tor at the height of the side wall

between the two legs and lock it in

their prole grooves. To do this, close

the eccentric screws using a Torx key

(approx. 1/2 turn).

2. Open the zips until the two outer

pieces of fabric can be comfortably

pulled into the groove of the upper

legs.

3. Pull in two adapter strips on each of

the two outer fabric pieces and align

them with the lower edge . Then

press the four strips into the groove

of the lower legs. Then close the zips

again.

1.

2.

3.

4. Video assembly

Inside cabins

4. Optionally, a cross connector or tele-

scopic connector can be inserted into

the lower edge of the side wall. This

provides additional transverse stability

and the visually perfect nish.

The inside of the side

wall is easily recognisable

by the sewn-on label with

the serial number.

TIP

12

ACCESSORIES/CROSS-CONNECTORS

Optional legs Pro-Tent MODUL 4000

Optional legs can be inserted at each connection node. These

allow you to subdivide rooms in the module size of 1 m 1.5 m

or also to assemble inside cabins. Attaching additional cross-

connectors or side walls also signicantly increases the stability

of the entire frame.

Attach the optional stand leg to the outside of the frame

(1-4): Push the adapter into the leg with the push button facing

downwards (1) and snap it into the top hole of the leg (2). Insert

the leg with the adapter through the lower 3-piece connector

into the upper 3-piece connector (3). Then pull out the lower leg

to the end position (4).

Attach the optional leg below the gable (5-8): Push the

adapter into the leg with the push button facing downwards

(5) and snap it into the second hole of the leg (6). Remove

the prole cover on the 4-piece connector and place it in the

storage compartment of the transport bag. Insert the leg with

the adapter into the gable (7). Then pull out the lower leg to

the end position (8).

7. 8.

1. 2. 3. 4.

5. 6.

12 13

ACCESSORIES/OPTIONAL LEGS

Optional legs Pro-Tent 5000

Optional legs can be inserted at each connection node. These

allow you to subdivide rooms in the module size of 1.5 m or also

to assemble inside cabins. Attaching additional cross-connectors

or side walls also signicantly increases the stability of the entire

frame. In contrast to the optional Pro-Tent MODUL 4000 support

leg, which only requires one adjustable adapter, the Pro-Tent

5000 has two separate optional support legs for the 3-piece

connector and 4-piece connector.

Attach the optional stand leg to the outside of the frame

(1-3): Insert the leg (1) through the lower 3-piece connector into

the upper 3-piece connector (2). Then pull out the lower leg to

the end position (3).

Attach the optional leg below the gable (4-6): Remove the

prole cover on the 4-piece connector and place it in the storage

compartment of the transport bag. Insert the leg (4) with the

adapter into the gable (5). Then pull out the lower leg to the end

position (6).

5.4. 6.

2.1. 3.

For inserting the

optional legs, always

raise the frame

(end position).

TIP

14

ACCESSORIES/OPTIONAL LEGS

SECURING YOUR TENT IN WIND AND RAIN

Please ensure that the tent is well secured according to

the prevailing weather conditions. Use the tensioning set

supplied for this purpose. Depending on your requirements,

additional 12.5 kg weight plates can be stacked on top of the

existing weight plates and/or 50 l water weights can also be

used to secure the tent on hard surfaces.

To make your tent as secure as possible, you should tension

your folding tent in a way that makes most sense with regard

to physics. The tensioning ropes should lead away from all

four corners of the folding tent at an angle of approx. 45

degrees. Flaps are provided at the corners of the fabric roof

for this purpose.

CAUTION: The tensioning ropes must not be too tightly

fastened. Tension only with moderate force so that the ropes

do not sag. If it is windy, you must check from time to time

whether the tensioning ropes and pegs are still holding rm -

and readjust them if necessary or set the pegs again.

Note: Tensioning is particularly eective and ecient be-

cause it not only keeps your folding tent in place in windy

conditions, but also prevents too much movement from

aecting your folding pavilion, which in the worst case could

damage the construction.

Weight plate hexagonal (12.5 kg)

The modular hexagonal weight plate with a weight of 12.5 kg is

mainly used when a Pro-Tent folding tent needs to be secured

with a lot of weight. Securing the folding tent with sucient

ballast is indispensable, especially if there are no possibilities for

tensioning it.

This weight plate can easily be stacked in up to six layers and

thus applies up to 75 kg of ballast onto a single folding tent leg.

For example, an 8 x 4 m folding tent with six legs can be secured

with up to 450 kg using weight plates. Only the rst weight plate

needs a xing bolt to connect the legs of the folding tent with

the lowest weight plate.

Water weight (50 litres)

The water weight is an additional way of securely tensioning an

aluminium folding tent when being used outdoors. It is used as

an alternative to tensioning the tent with the professional ten-

sioning set. The water weight can be used to increase safety in

strong winds - or when using pegs is not possible or prohibited.

The water weight is made of PVC and is cylindrical. Its diameter

and height are both 40 cm. Its capacity is about 50 litres. Two

twist locks allow easy and quick lling of the water weight with

water as well as uncomplicated emptying. Two handles on the

side make it easy to grab and carry.

The tent is secured

using the tensioning

set included in the

scope of delivery.

Optionally, and to

make handling even

easier, a matching

quick tensioning

set is available see

illustration.

45°

14 15

SECURING IN WIND AND RAIN

PROTENT AG

Zelt- und Messebau-Systeme

Neuhofstrasse 10

8630 Rüti

Schweiz

Tel.: +41 (0) 55 220 28 00

info@pro-tent.ch

www.pro-tent.ch

PROTENT GmbH

Zelt- und Messebau-Systeme

Im Brühl 1

65589 Hadamar-Ndz.

Deutschland

Tel.: +49 (0) 6433 946668-0

info@pro-tent.de

www.pro-tent.de

05/2023

This manual suits for next models

3

Table of contents

Other PROTENT Tent manuals

Popular Tent manuals by other brands

Zempire

Zempire PRONTO 10V2 instruction manual

Outwell

Outwell BLOSSBURG 380 AIR instruction manual

TentCraft

TentCraft GYBE FUSION PANEL Setup instructions

Westfield

Westfield TRAVEL SMART Series quick start guide

Tentandtable.com

Tentandtable.com Premium Pole Tent 20' x 20' Assembly instructions

Zempire

Zempire Adventure Series instructions