Proval A210 Series User manual

PROVAL A210-211-212-213-Series

Rack and Pinion Pneumatic Actuators

Installation, Operation and Maintenance Manual

ϮϭϬͲϮϭϭͲϮϭϮͲϮϭϯ^ĞƌŝĞƐ

d>ϯϭϮϭϬͲ/KDE

ŽŶƚĞŶƚƐ

:ƵůϮϬϭϲ

dĂďůĞ ŽĨ ŽŶƚĞŶƚƐ/

Table of Contents

Section 1: Before You Start

ϭϭ

Installation, Operation and Maintenance Reference Documents......................1

ϭϮ

Warehouse Storage .................................................................................................................1

ϭϯ

On-Site Storage.................................................................................................................2

Section 2: Introduction

Ϯϭ

Identification ..........................................................................................................................3

ϮϮ

Intended Use..............................................................................................................................4

Ϯϯ

Specifications.....................................................................................................................4

Section 3: Product Code

ϯϭ

Configuration code for a default actuator ..................................................................6

Section 4: Installation

ϰϭ

Before You Start..................................................................................................................7

ϰϮ

Failure Modes .........................................................................................................................7

ϰϮϭ

Valve Rotation..........................................................................................................7

ϰϮϮ

Position After Failure.............................................................................................8

ϰϯ

Principles of Operation .......................................................................................................8

ϰϯϭ

Solenoid Valve.............................................................................................................8

ϰϯϮ

Ingress Protection (IP) rating...........................................................................9

ϰϯϯ

Double-Acting Actuators .............................................................................. 10

ϰϯϰ

Spring-Return Actuators................................................................................11

ϰϰ

Actuator Assembly Codes .............................................................................................. 12

ϰϱ

Actuator to Valve Installation........................................................................................13

ϰϲ

Mounting of control and feedback accessories....................................................... 15

ϰ

Recommended Tubing Sizes.......................................................................................16

Section 5: Mechanical Stroke Adjustment

ϱϭ

Travel Stop Adjustment ...................................................................................................... 18

ϱϭϭ

Double-Acting Actuators .............................................................................. 18

ϱϭϮ

Spring-Return Actuators................................................................................18

Section 6: Maintenance

ϲϭ

General...........................................................................................................................................20

ϲϮ

Repair..............................................................................................................................................20

ϲϮϭ

Spring-Return actuator ..................................................................................20

ϲϮϮ

Recommended Spare Parts ........................................................................ 20

ϮϭϬͲϮϭϭͲϮϭϮͲϮϭϯ^ĞƌŝĞƐ

d>ϯϭϮϭϬͲ/KDE

ŽŶƚĞŶƚƐ

:ƵůϮϬϭϲ

dĂďůĞ ŽĨ ŽŶƚĞŶƚƐ/

Section 7: Decommission (Out of Service)

ϭ

Before You Start...............................................................................................................22

Ϯ

Removing the actuator from the valve .....................................................................23

Section 8: Disassembly

ϴϭ

Removing End Caps..........................................................................................................25

ϴϮ

RemovingSpringCartridges(Spring-Return).....................................................26

ϴϯ

Removing of Limit Stop.....................................................................................................27

ϴϰ

Removing Pistons..............................................................................................................27

ϴϱ

Removing Pinion ...............................................................................................................28

ϴϲ

Cleaning the Body .........................................................................................................28

Section 9: Reassembly

ϵϭ

Grease Instructions ........................................................................................................30

ϵϮ

Reassembly of the pinion................................................................................................31

ϵϯ

Reassembly of the pistons..............................................................................................32

ϵϰ

Reassembly and settings of the limit stops.............................................................34

ϵϱ

Reassembly of the end caps...........................................................................................34

ϵϱϭ

Double-Acting actuators...............................................................................34

ϵϱϮ

Spring-Return actuators ................................................................................36

ϵϲ

Basic function and Air Leak Test...........................................................................................38

Section 10: Troubleshooting

ϭϬϭ

Mechanical Problems .......................................................................................................39

ϭϬϮ

Pneumatic Problems ........................................................................................................40

ϭϬϯ

Electrical Problems............................................................................................................41

Section 11: Parts List and Spare Parts Recommendations

ϭϭϭ

Exploded View and Parts List......................................................................................42

AppendixA: Spring load removal

ϭ

Spring load relief ................................................................................................................43

Appendix B: Tool & Torque Table

»

Table B-1 End cap bolts .........................................................................................45

»

Table B-2 Bottom Flange .........................................................................................45

»

Table B-3 NAMUR (VDE/VDI 3845) flanges.......................................................46

»

Table B-4 Limit stop dimensions..........................................................................46

»

Table B-5 Recommended circlip pliers................................................................46

/ŶƐƚĂůůĂƚŝŽŶKƉĞƌĂƚŝŽŶĂŶĚDĂŝŶƚĞŶĂŶĐĞ DĂŶƵĂů

d>ϯϭϮϭϬͲ/KDE

^ĞĐƚŝŽŶϭĞĨŽƌĞzŽƵ ^ƚĂƌƚ

:ƵůϮϬϭϲ

ĞĨŽƌĞzŽƵ^ƚĂƌƚ

ϭ

Section 1: Before You Start

This section explains:

•

Base safety procedures

•

Where to find detailed information relating safety.

•

Storage guidelines.

Installation, adjustment, putting into service, use, assembly, disassembly and

maintenance

of the pneumatic actuator must be performed by qualified personnel.

Failure to follow the above guidelines will void warranty.

Actuator must be isolated both pneumatically and electrically before any (dis)assembly

starts. Before mounting or (dis)assembly, the actuator consults the relevant sections of

this manual.

ϭϭ

Installation, Operation and

Maintenance Reference Documents

Before you start, read the following documents:

•

All chapters in this manual.

•

Safety Guide (Document No. TL.32.A210-SG.EN).

Failure to read the Safety Guide will void the warranty.

Not following the instructions of the Safety Guide can lead to failure of the product and

harm to personnel or equipment.

ϭϮ

Warehouse Storage

•

All actuators should be stored in a clean, dry warehouse, free from excessive

vibration and rapid temperature changes.

•

All actuators should not be stored directly to the floor surface - it must be placed

in racks/shelves or use a pallet.

^ĞĐƚŝŽŶϭĞĨŽƌĞzŽƵ^ƚĂƌƚ

:ƵůϮϬϭϲ

/ŶƐƚĂůůĂƚŝŽŶ KƉĞƌĂƚŝŽŶ ĂŶĚDĂŝŶƚĞŶĂŶĐĞ DĂŶƵĂů

d>ϯϭϮϭϬͲ/KDE

Ϯ

ĞĨŽƌĞzŽƵ^ƚĂƌƚ

ϭϯ

On-Site Storage

•

All actuators should be stored in a clean, dry warehouse, free from excessive

vibration and rapid temperature changes.

•

Prevent moisture or dirt from entering the actuator. Plug or seal both

air

connection ports.

Failure to follow the above guidelines (Warehouse and On Site Storages) will void warranty.

EKd/

/ŶƐƚĂůůĂƚŝŽŶKƉĞƌĂƚŝŽŶĂŶĚDĂŝŶƚĞŶĂŶĐĞ DĂŶƵĂů

d>ϯϭϮϭϬͲ/KDE

^ĞĐƚŝŽŶϮ/ŶƚƌŽĚƵĐƚŝŽŶ

:ƵůϮϬϭϲ

/ŶƚƌŽĚƵĐƚŝŽŶ

ϯ

Section 2: Introduction

This section explains:

•

How to identify the received product,

•

The intended use of the product

•

Construction details

•

Actuator specifications

Ϯϭ

Identification

The A210-211-212-213 Series Rack and Pinion actuators are available as double-acting or

spring-return versions. 15 models are available, ranging from 9 Nm to 3500 Nm (80 to

31000 lbf.in)

nominal torque output.

The A210-211-212-213 Series-Series uses standardized interfaces for solenoid, switchbox

or positioner

mounting (VDI/VDE3845; NAMUR). The valve interface is equipped with

an insert in the pinion bottom that allows both ISO5211 or DIN3337 mounting.

The springs in the spring-return version allow a fail action in case of loss of air supply

pressure (Fail-to-Close or Fail-to-Open).

As from size PA032 and PA040 double-acting versions have flat end caps to reduce

actuator length and internal air volume.

Figure 1 Identification

ϭ

Top auxilliaries interface (VDI/VDE 3845; NAMUR)

Ϯ

Solenoid interface (VDI/VDE 3845; NAMUR)

ϯ

Valve interface with ISO5211, DIN 3337 patterns and insert drive

ϰ

Spring-return actuators: - with springs

ϱ

Double-acting actuators: - no springs

ϰ

ϱ

ϭ

Ϯ

ϯ

^ĞĐƚŝŽŶϮ/ŶƚƌŽĚƵĐƚŝŽŶ

:ƵůϮϬϭϲ

/ŶƐƚĂůůĂƚŝŽŶ KƉĞƌĂƚŝŽŶ ĂŶĚDĂŝŶƚĞŶĂŶĐĞ DĂŶƵĂů

d>ϯϭϮϭϬͲ/KDE

/ŶƚƌŽĚƵĐƚŝŽŶ

ϰ

ϮϮ

Intended Use

The A210-211-212-213 Series Rack and Pinion actuators are intended for the automation

and operation of quarter-turn valves like Butterfly, Ball and Plug valves.

Rack and Pinion actuators can also be used to operate dampers or any other quarter-turn

applications.

Ϯϯ

Specifications

Table 1. Pressure Range

Actuator

T

ype

Pressure

Double-Acting

0.2 to 8.3 barg (2.9 to 120 psig)

Spring-Return

6 to 8.3 barg (87 to 120 psig), with maximum spring set

3 to8.3 barg(43.5 to 120 psig), reduced spring quantity

Table 2. Operating Media

Actuator

T

ype

Operating Media

Double-Acting and Single-Acting

Air, dry or lubricated and inert gases

Dew point at least 10K below ambient temperature

For sub-zero applications, take appropriate measures

Mentioned pressure levels are"gauge pressures".

Gauge pressure is equal to absolute pressure

minus atmospheric pressure.

Table 3. Temperature Range

Actuator

T

ype

T

emperature

Standard

-20°C to +80°C (-4°F to +176°F)

Option: Low Temperature

-40°C to +80°C (-40°F to +176°F)

Option: High Temperature

-20°C to +10°C (-4°F to +°F)

/ŶƐƚĂůůĂƚŝŽŶKƉĞƌĂƚŝŽŶĂŶĚDĂŝŶƚĞŶĂŶĐĞ DĂŶƵĂů

d>ϯϭϮϭϬͲ/KDE

^ĞĐƚŝŽŶϮ/ŶƚƌŽĚƵĐƚŝŽŶ

:ƵůϮϬϭϲ

Introduction 5

Table 4. Air Consumptions of Actuators(Lt/Stroke)

Counter Clockwise Rotation

(CCWR)

Air supplied through

port B forces the piston

towards each other causing

the pinion to rotate clock

wise while air is being

exhausted through port A

Air supplied through port

A forces the piston away

from each other causing

the pinions to rotate

counter clockwise while

air is being exhausted

through port B.

Clockwise Rotation (CWR)

Air supplied through port B

forces the piston towards

each other causing the

pinion to rotate counter

clockwise while air is being

exhausted through port A.

Air supplied through port

A forces the piston away

from each other causing

the pinions to rotate

clockwise while air is being

exhausted through port B.

The Proval actuators typically operate counter clockwise to open and clockwise to close. The direction of pinion rotation

(CCW to CW) can be reversed changing the orientation of pistons as shown in the picture above.

Model PA 32 PA 40 PA 52 PA 63 PA 75 PA 83 PA 92 PA 105 PA 125 PA 140 PA 160 PA 190 PA 210 PA 240 PA 270

Opening (Lt) 0,03 0,06 0,12 0,21 0,30 0,43 0,64 0,88 1,4 2,2 3,2 5,4 6,8 9 14

Closing (Lt) 0,04 0,08 0,16 0,23 0,34 0,47 0,73 0,95 1,6 2,5 3,7 5,9 7,5 11 17

B A

B A

B AB A

^ĞĐƚŝŽŶϯWƌŽĚƵĐƚŽĚĞ

:ƵůϮϬϭϲ

/ŶƐƚĂůůĂƚŝŽŶ KƉĞƌĂƚŝŽŶ ĂŶĚDĂŝŶƚĞŶĂŶĐĞ DĂŶƵĂů

d>ϯϭϮϭϬͲ/KDE

WƌŽĚƵĐƚ ŽĚĞ

ϲ

Section 3: Product Code

This section explains:

•

How to create the configuration code for a default actuator.

•

How to create the configuration code for an actuator with added integral options.

End-Cap Color

Body Finish

Seal Material

ISO Flange Connection

Rotation Direction

Spring Type

PinionMaterial

Stem Connection Size

Valve Stem Connection

Type

Size

Acting Type

Series

Type

Type

PA Pneaumatic Actuator

Valve Stem Connection Type

Y Double Square

D Diagonal Square

K Parallel Square

SDoubleD

Spring Type

N/A Double Acting

A5

B6

C7

D8

E9

F10

G11

H12

Series

0A210

1A211

2A212

3A213

4A214

Stem Connection Size

09 9mm

11 11mm

14 14mm

17 17mm

22 22mm

27 27mm

36 36mm

46 46mm

xx Upon Request

Acting Type

D Double Acting

S Spring Return

Size

10 032

15 040

20 052

25 063

30 075

35 083

40 092

45 105

50 125

55 140

60 160

65 190

70 210

75 240

80 270

Rotating Direction

C Open/Clockwise

W Open/Counterclockwise

ISO Flange Connection

AF3

B F3/F5

C F3/F5/F7

D F5/F7

E F7/F10

F F10/F12

G F14

H F16

IF4

JF4/F7

Pinion Material

G Galvanized

P Stainless Steel

N Nickel Plated

Stem Connection Size

A9mm

B 11mm

C 14mm

D 17mm

E 22mm

F 27mm

36 36mm

46 46mm

xx Upon Request

Seal Material

N NBR

V Viton

WϬ^ϱϬϮϮ',t Ez'

/ŶƐƚĂůůĂƚŝŽŶKƉĞƌĂƚŝŽŶĂŶĚDĂŝŶƚĞŶĂŶĐĞ DĂŶƵĂů

d>ϯϭϮϭϬͲ/KDE

^ĞĐƚŝŽŶϰ/ŶƐƚĂůůĂƚŝŽŶ

:ƵůϮϬϭϲ

/ŶƐƚĂůůĂƚŝŽŶ

Section 4: Installation

This section explains:

•

The actuator rotation direction.

•

In which position the actuator will end after a failure.

•

Principles of operation:

Ͷ

Solenoid operation

Ͷ

Double acting and Spring return operation

•

Assembly codes.

•

Actuator to valve assembly.

ϰϭ

Before You Start

In case of an air or electrical failure, it is important to know the behavior of the actuator.

Before mounting the actuator on a valve, consult the following sections below.

ϰϮ

ActuatorRotationDirection

ϰϮϭ

Valve Rotation

For the following paragraphs we assume that valves rotate as indicated in figure 3.

Figure 3 Normal valve rotation

The valve is closed

after

a clockwise

rotation.

The valve is open after

a counterclockwise rotation.

Body / End-Cap Finish

A RAL.9005 Piano Black L RAL.9010 Glossy White

B RAL.9005 Matte Black M RAL.1006 Glossy Yellow

C RAL.2004 Glossy Orange N RAL.9006 Glossy Dark Gray

D RAL.7035 Glossy Light Gray V White Anodized

E RAL.3000 Glossy Red Y Black Anodized

F RAL.6026 Glossy Green Z PTFE

G RAL.5005 Glossy Blue S 1 AISI304 Stainless Steel

H RAL.5018 Glossy Turquoise S 2 AISI316 Stainless Steel

J RAL.5015 Glossy Light Blue S 3 AISI305 Stainless Steel

K RAL.9007 Glossy Silver

^ĞĐƚŝŽŶϰ/ŶƐƚĂůůĂƚŝŽŶ

:ƵůϮϬϭϲ

/ŶƐƚĂůůĂƚŝŽŶ KƉĞƌĂƚŝŽŶ ĂŶĚDĂŝŶƚĞŶĂŶĐĞ DĂŶƵĂů

d>ϯϭϮϭϬͲ/KDE

ϴ

/ŶƐƚĂůůĂƚŝŽŶ

ϰϮϮ

Position After Failure

The position of the actuator after a failure depends on the:

ϭ

Principle of operation (see paragraph 4.3)

Ϯ

Assembly codes (see paragraph 4.4)

ϯ

Kind of failure. Refer to the table below.

Table 5. Position After Failure

ϰϯ

Principles of Operation

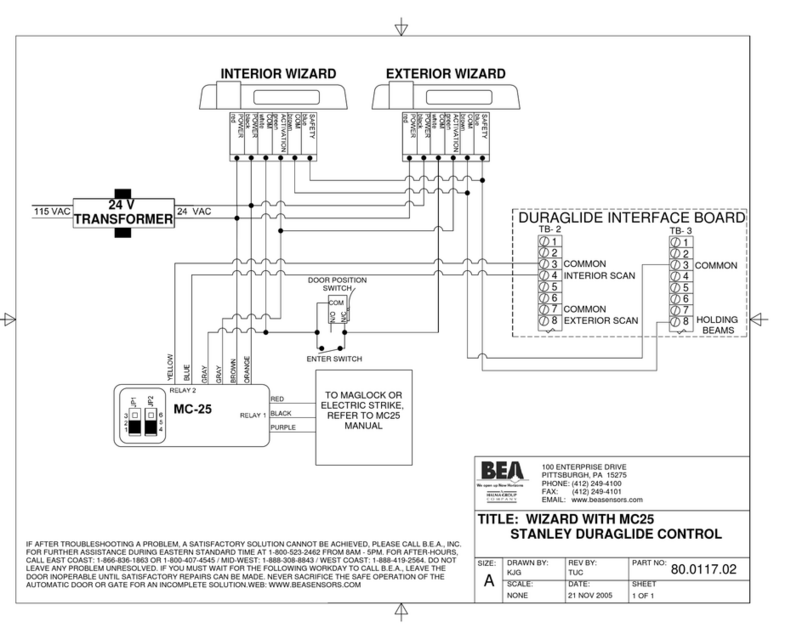

ϰϯϭ

Solenoid Valve

All actuators can be either piped with solid or flexible tubing with the solenoid valve

mounted remotely from the actuator or by mounting a VDI/VDE 3845 (NAMUR)

designed

solenoid valve DIRECTLY onto the NAMUR mounting pad on the side of the

actuator

Figure 4 Typicalsolenoidoperation

Spring-Return Operation Double-Acting Operation

&

:

:

/ŶƐƚĂůůĂƚŝŽŶKƉĞƌĂƚŝŽŶĂŶĚDĂŝŶƚĞŶĂŶĐĞ DĂŶƵĂů

d>ϯϭϮϭϬͲ/KDE

^ĞĐƚŝŽŶϰ/ŶƐƚĂůůĂƚŝŽŶ

:ƵůϮϬϭϲ

/ŶƐƚĂůůĂƚŝŽŶ

ϵ

The table below represents the cycle time (operating time) per different Actuator sizes:

Table 6. Operating Speed

Cycle time in seconds

Actuator

size

Spring-Return(12springs) Double-Acting

0°-90°

90

°

-0

°

0°-90°

90°-0°

PA32

N/A N/A 0.5 0.4

PA40

N/A N/A 0.55 0.47

PA52

2.66 0.44 0.6 0.53

PA63

2.74 0.52 0.66 0.58

PA75

2.83 0.61 0.72 0.64

PA83

3.01 0.74 0.83 0.73

PA92

3.26 0.79 1 0.86

PA105

4.36 1.08 1.35 1.3

PA125

4.68 1.22 2.4 1.79

PA140

4.84 1.65 2.5 2.1

PA160

5.83 3.4 3.93 2.6

PA190

8.5 4.5 4.55 3.45

PA210

17 4.84 5.5 4.35

PA240

18.4 6.14 8.4 8.33

PA270

24.9 12.54 10.9 8.53

PA300

31.6 16.54 15 14.9

Operating time is average with actuator under load and solenoid valve fitted.

Test conditions:

ϭ

Solenoid with flow capacity: 0.6 m

3

/hr

Ϯ

Pipe diameter: 6mm

ϯ

Medium:

clean air

ϰ

Supply pressure: 5.5 bar (80psi)

ϱ

Load: with average load

ϲ

Stroke:

90°

Temperature: Room temperature

ϰϯϮ

Ingress Protection (IP) rating

A210-211-212-213 Series actuators are IP66/IP67 rated. In case of IP66 or IP67

requirements, take

precautions that comply with the IP66/IP67 requirements to prevent

moisture or dust from

entering the actuator through the open air exhaust port(s), either

directly on the actuator

or at the exhaust ports of the connected solenoid valve.

We recommend to connect tubing to the exhaust(s) and lead this into a dry and dust free

area, or to use check valves in the exhaust.

^ĞĐƚŝŽŶϰ/ŶƐƚĂůůĂƚŝŽŶ

:ƵůϮϬϭϲ

/ŶƐƚĂůůĂƚŝŽŶ KƉĞƌĂƚŝŽŶ ĂŶĚDĂŝŶƚĞŶĂŶĐĞ DĂŶƵĂů

d>ϯϭϮϭϬͲ/KDE

ϭϬ

/ŶƐƚĂůůĂƚŝŽŶ

ϰϯϯ

Double-Acting Actuators

The operating principle, as explained here, is applicable for actuators with assembly code

W (direct acting).

•

Applying supply pressure to port A will move the pistons outward to the

"Open"

position of the valve.

•

Applying supply pressure to port B will move the pistons inward to the

"Close"

position of the valve.

•

For assembly codes C, the operating principle is reversed (reverse acting).

Figure 5

Double-Acting Operation

Outward Stroke

Inward Stroke

B A

/ŶƐƚĂůůĂƚŝŽŶKƉĞƌĂƚŝŽŶĂŶĚDĂŝŶƚĞŶĂŶĐĞ DĂŶƵĂů

d>ϯϭϮϭϬͲ/KDE

^ĞĐƚŝŽŶϰ/ŶƐƚĂůůĂƚŝŽŶ

:ƵůϮϬϭϲ

/ŶƐƚĂůůĂƚŝŽŶ

ϭϭ

ϰϯϰ

Spring-Return Actuators

The operating principle, as explained here, is applicable for actuators with assembly code

C (direct acting).

•

Applying supply pressure to port A will move the pistons outwards to the

"Open"

position of the valve.

•

Venting the supply pressure from port A will cause the springs to move the

pistons inwards to the "Close" position of the valve.

•

For assembly codes W, the operating principle is reversed (reverse acting).

Figure 6

Stroke Movements

Outward Stoke

Inward Stroke

^ĞĐƚŝŽŶϰ/ŶƐƚĂůůĂƚŝŽŶ

:ƵůϮϬϭϲ

/ŶƐƚĂůůĂƚŝŽŶ KƉĞƌĂƚŝŽŶ ĂŶĚDĂŝŶƚĞŶĂŶĐĞ DĂŶƵĂů

d>ϯϭϮϭϬͲ/KDE

ϭϮ

/ŶƐƚĂůůĂƚŝŽŶ

ϰϰ

Actuator Assembly Codes

Figure 7 Assembly Code - Double-Acting

Assembly code: W Assembly code: C

= Standard, Counterclockwise-to-Open = Reverse, Clockwise-to-Open

= Fail-to-Close = Fail-to-Open

B

A

A

B

Pinion

Pistons

B A B A

Pistons

A = Rotation when central air chamber is pressurized.

B = Rotation when end cap air chambers are pressurized.

All views are from above. Pistons are shown in inward position.

Pinion

/ŶƐƚĂůůĂƚŝŽŶKƉĞƌĂƚŝŽŶĂŶĚDĂŝŶƚĞŶĂŶĐĞ DĂŶƵĂů

d>ϯϭϮϭϬͲ/KDE

^ĞĐƚŝŽŶϰ/ŶƐƚĂůůĂƚŝŽŶ

:ƵůϮϬϭϲ

/ŶƐƚĂůůĂƚŝŽŶ

ϭϯ

ϰϱ

Actuator to Valve Installation

Actuator must be isolated pneumatically and electrically before any (dis)assembly starts.

Stay away from moving parts to prevent serious injuries. When test cycling the actuator

and valve assembly by applying pressure to the A or B port, be aware that there are

moving

parts like pinion top, actuator to valve coupling and the valve- blade, ball, plug,

etc.

The actuator is designed to be installed, commissioned and maintained using generic

tools like wrenches, Allen keys and screwdrivers. For the removal of inserts, a special

extractor

tool can be supplied on request.

During assembly to the valve, do not hit with hammer on pinion top. This can damage

the pinion top washer and cause premature failure.

Before mounting the actuator on the valve or valve bracket, be sure that both

the actuator and the valve are in the same closed or open position.

Refer to appendix B, Tool and Torque tables, for using the right size tool

Table 7. Tool Table

Symbol

T

ool

Symbol

T

ool

Wrench – All types and sizes.

Metric and Imperial

Allen key

Circlip Pliers

ϭ

Remove handle nut, handle, lock washer, and etc. from the valve if required.

Ϯ

Visually check to make sure the valve is CLOSED.

Figure 9 Valvehandle removal

^ĞĐƚŝŽŶϰ/ŶƐƚĂůůĂƚŝŽŶ

:ƵůϮϬϭϲ

/ŶƐƚĂůůĂƚŝŽŶ KƉĞƌĂƚŝŽŶ ĂŶĚDĂŝŶƚĞŶĂŶĐĞ DĂŶƵĂů

d>ϯϭϮϭϬͲ/KDE

ϭϰ

/ŶƐƚĂůůĂƚŝŽŶ

ϯ

When required, check if the insert drive (23) is mounted. If not, use a plastic mallet

and tap slightly until the reducer square is in the required position.

Be sure that the insert is mounted at 90° or 45°. It is possible to mount the insert

turned 22.5°. This way the valve will not open or close the right way.

Figure 10 InsertdriveInstallation

Parallel

square

Diagonal

square

Flat head

Double square

ϰ

Install the bracket to the valve flange. Tighten all bolts and nuts and apply

the correct torque.

Figure 11 BracketInstallation

/ŶƐƚĂůůĂƚŝŽŶKƉĞƌĂƚŝŽŶĂŶĚDĂŝŶƚĞŶĂŶĐĞ DĂŶƵĂů

d>ϯϭϮϭϬͲ/KDE

^ĞĐƚŝŽŶϰ/ŶƐƚĂůůĂƚŝŽŶ

:ƵůϮϬϭϲ

/ŶƐƚĂůůĂƚŝŽŶ

ϭϱ

ϱ

Install the actuator to the bracket. Tighten all bolts and apply the correct

torque

(refer to Table 8).

Table 8. Bottom flange torque values

Actuator Size

ISO Pattern

T

orque (Nm)

T

orque (lbf.ft)

T

hread Min. Max.

T

hread

Min.

Max.

32

F03

M6

4.5 5 10-24UNC

3.3

3.7

40, 52

F03 inner pattern

M5

2.0 3.0 10-24UNC

1.5

2.2

F05 oute

r

pattern

M6

4.5 5.0

1/4"-20

3.3

3.7

63, 75, 83, 92

F05 inner pattern

M6

4.5 5.0

1/4"-20

3.3

3.7

F07 oute

r

pattern

M8

10.5 12.5

5/16"-18

7.7

9.2

105, 125

F07 inner pattern

M8

10.5 12.5

5/16"-18

7.7

9.2

F10 oute

r

pattern M10

21.0 24.5

3/8"-16

15.5

18.1

140, 160

F10 inner pattern M10

21.0 24.5

3/8"-16

15.5

18.1

F12 oute

r

pattern M12

34.5 43.0

1/2"-13

25.4

31.7

190, 210, 240, 270,

300

ϲ

When required, mount or adjust the visual indicator (22).

Figure 12 Indicator mounting

"In Line mounting" "Across Line mounting"

ϰϲ

Mounting of control and feedback accessories

Solenoid valve and or switch boxes can now be mounted to the actuator. Check

the instructions as shipped with these components for installation, operating

and

maintenance instructions.

We recommend to test-cycle the complete assembly to check correct operation.

^ĞĐƚŝŽŶϰ/ŶƐƚĂůůĂƚŝŽŶ

:ƵůϮϬϭϲ

/ŶƐƚĂůůĂƚŝŽŶ KƉĞƌĂƚŝŽŶ ĂŶĚDĂŝŶƚĞŶĂŶĐĞ DĂŶƵĂů

d>ϯϭϮϭϬͲ/KDE

ϭϲ

/ŶƐƚĂůůĂƚŝŽŶ

ϰ

RecommendedTubingSizes

In case the solenoid valve is mounted remotely (i.e. in a central solenoid cabinet) and in

order to supply sufficient flow of air supply to the actuator, the following tubing sizes are

recommended.

Table 9. Tubing Sizes

Actuator size

Runs up to

Runs over to

1.2 meters 4 feet 1.2 meters

4 feet

32, 40, 52, 63, 75,

83, 92

6 mm

1/4 inch

6 mm

1/4 inch

105, 125, 140,

160

6 mm

1/4 inch

8 mm

5/16 inch

190, 210, 240,

270, 300

6 mm

1/4 inch

10 mm

3/8 inch

/ŶƐƚĂůůĂƚŝŽŶKƉĞƌĂƚŝŽŶĂŶĚDĂŝŶƚĞŶĂŶĐĞ DĂŶƵĂů

d>ϯϭϮϭϬͲ/KDE

^ĞĐƚŝŽŶϰ/ŶƐƚĂůůĂƚŝŽŶ

:ƵůϮϬϭϲ

/ŶƐƚĂůůĂƚŝŽŶ

ϭ

Section 5: Mechanical Stroke Adjustment

This section explains:

•

What the mechanical stroke adjustment is.

•

What the factory settings are.

•

How to adjust the travel stops.

A210-211-212-213 Series actuator sizes 32 to 300 have two stroke adjustment stops for

adjusting

accurately the stroke of the actuator/valve assembly in open and closed

position.

The smallest actuator, size 32, have limit stops on end-caps.

The factory setting of the stroke is 90°. Most quarter-turn valve applications will not

require

readjustment of these settings.

If required, the stroke can be adjusted by means of two-stroke adjustment bolts.

Figure 13 Factory Setting

Size 32 - 1 60 Size 190 - 300

10° -5°

10° -3°

90°

95°

90°

93°

90°

90°

This manual suits for next models

3

Table of contents

Popular Controllers manuals by other brands

DigitaLinx

DigitaLinx DL-UHDILC owner's manual

Disaster Area Designs

Disaster Area Designs SMARTClock Gen3 user manual

Siemens

Siemens RVP200 installation instructions

Johnson Controls

Johnson Controls ZFR1810 installation instructions

Industrial Indexing Systems

Industrial Indexing Systems LMC-400 user guide

Eaton

Eaton Greengate RC3 installation instructions