Provill BTP-2100E User manual

U

Us

se

er

r

M

Ma

an

nu

ua

al

l

Barcode Printer

PROVILL TECHNOLOGY Co., Ltd.

M

Mo

od

de

el

l:

:

B

BT

TP

P-

-2

21

10

00

0E

E

BTP-2100E USER MANUAL

Declaration

Information in this document is subject to change without notice. PROVILL

Technology Co., Ltd. (Hereinafter referred to as “PROVILL”) reserves the right to

improve products as new technology, components, software, and firmware become

available. If users need the further data about these products, please feel free to

contact our market department or your local distributor.

No part of this document may be reproduced or transmitted in any form or by any

means, electronic or mechanical, for any purpose without the express written

permission of PROVILL.

Copyright

This manual was published in 2008 and PROVILL owns the copyright.

Made in China.

Version: 1.0.

Trademark

Our registered trademark

Safety warning

Caution: Must comply with warning to avoid bodily harm or damage to

device.

Notice: Provides important information and prompts for printer

operation.

Warning

This is a class A product. In a domestic environment this product may cause radio

interference in which case the user may be required to take adequate measures.

Quality Certification

(DNV)ISO9001:2000

EMC and Safety Standards Applied

- 1 -

BTP-2100E USER MANUAL

- 2 -

CONTENT

General Safety Information .................................................... 1

Overview ............................................................................... 2

Outline................................................................................ 2

Package content .................................................................. 2

Printer mount ...................................................................... 3

Connect with power adapter.................................................. 3

Connect communication cable ............................................... 3

Printer operations ................................................................. 4

Apperance and parts ............................................................ 4

Main modules ...................................................................... 5

LEDs and keys .................................................................... 5

Loading paper ..................................................................... 8

Assembling the ribbon ........................................................ 10

Starting the printer ............................................................. 11

Installing the driver ............................................................ 13

Printer adjustment................................................................15

THP pressure adjustment.................................................... 15

Sensor position adjustment................................................. 15

Printer common parameter adjustment ................................. 17

Cleaning THP .................................................................... 20

Cleaning sensors ............................................................... 20

Cleaning the platen ............................................................ 20

LEDs and buzzer status...................................................... 22

The printout quality issue ................................................... 23

Appendix..............................................................................24

BTP-2100E USER MANUAL

- 3 -

Appendix 1 Technical specifications ................................... 24

Appendix 2 Self-test page................................................... 28

Appendix 3 Print and paper out position ............................... 30

Appendix 4 Communication interface ................................... 31

Appendix 5 Paper load guide in peel-off mode ...................... 33

BTP-2100E USER MANUAL

General Safety Information

Before installing and using the printer, please read the following items

carefully.

Safety Labels

The THP (THP) is calorific and its temperature is high when

printing or just after the operation, so please don’t touch it and

its peripherals for safety purpose.

Due to the static, please don’t touch the surface of THP and

connecting parts to keep it from damages.

Caution

zInstall the printer on a flat and stable place.

zReserve adequate space around the printer so that the operation and maintenance

can be performed conveniently.

zKeep the printer far away from water source and do not expose the printer to direct

sunlight, strong light and heater.

zDo not use or store the printer in a place exposed to heat of fire, moisture and

serious pollution.

zDo not place the printer on a place exposed to vibration and impact.

zNo dew condensation is allowed to the printer. In case of such condensation, do

not turn on the power until it has completely gone away.

zConnect the AC adaptor to an appropriate earthing outlet. Avoid sharing a single

outlet with large power motors and other devices that may cause voltage

fluctuation.

zDisconnect the AC adapter when the printer is deemed to spare for a long time.

zDon’t spill water or other electric materials into the printer. In case that this

happens, turn off the power immediately.

zDo not allow the printer to start printing when there is no recording paper in,

otherwise the THP and platen roller will be damaged.

zTo ensure print quality and normal lifetime, use recommended paper and ribbon or

materials with same quality.

zTurn off the printer before connecting or disconnecting interfaces connectors to

prevent control board from damages.

zSet the print darkness to a lower grade as long as the print quality is acceptable.

This will help to keep the THP durable.

zDo not disassemble the printer without permission of a technician, even for

repairing purpose.

zKeep this manual carefully at hand for ready reference.

- 1 -

BTP-2100E USER MANUAL

Overview

Outline

BTP-2100E/2200E/2300E printer has a smart appearance and high

performance, which is an ideal label printer for office use. It can apply to

real-time label printing, label batch printing, transport and commercial label

printing, other receipt printing for railway, airport, bus station, etc.

This product can connect with the peripheral equipments via serial or other

interfaces, at the same time it can provide common drivers for the operation

systems as WINDOWS95/98/2000/NT4.0/XP and a software package based

on DLL.

zThermal / thermal transfer printing.

zLow noise and high-speed thermal printing.

zEasy and quick paper load.

zUse 32 bit hi-speed micro-processor.

zUse Auto-suitable control of heat history and temperature.

zUse new THP which has long lifetime and hi-quality of printout.

zSupport continuous paper, label paper, marked paper and

perforated paper.

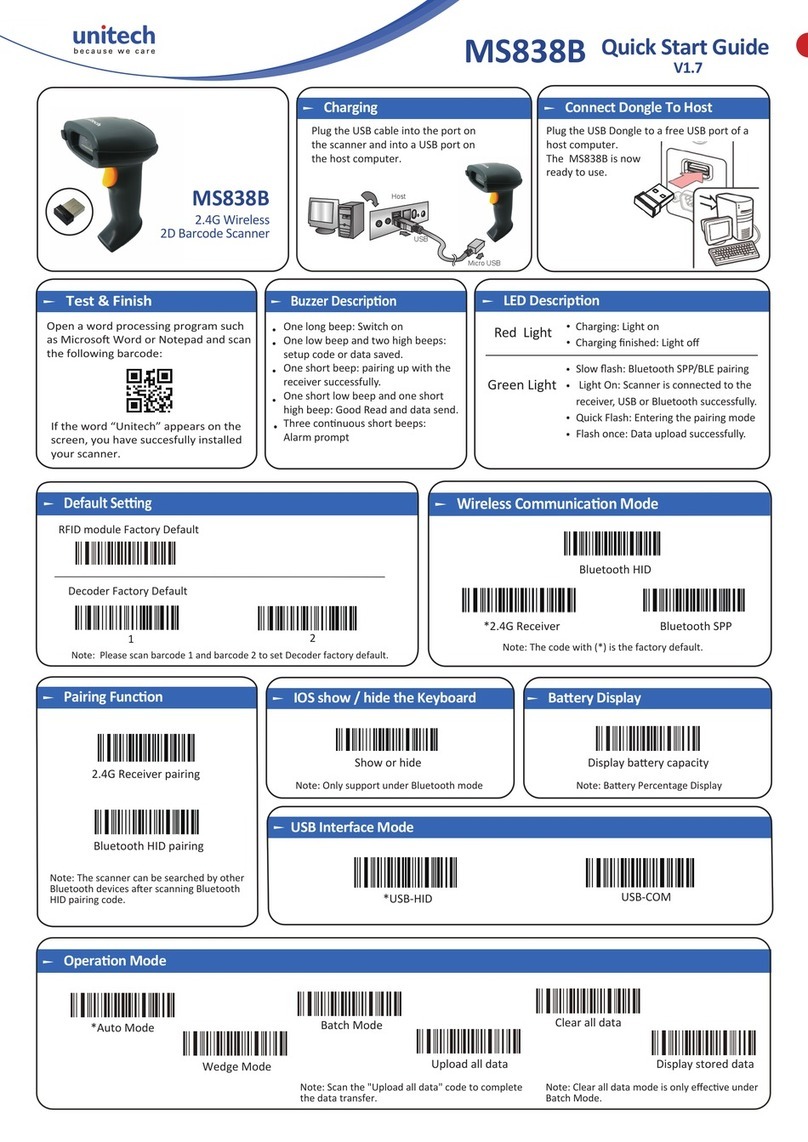

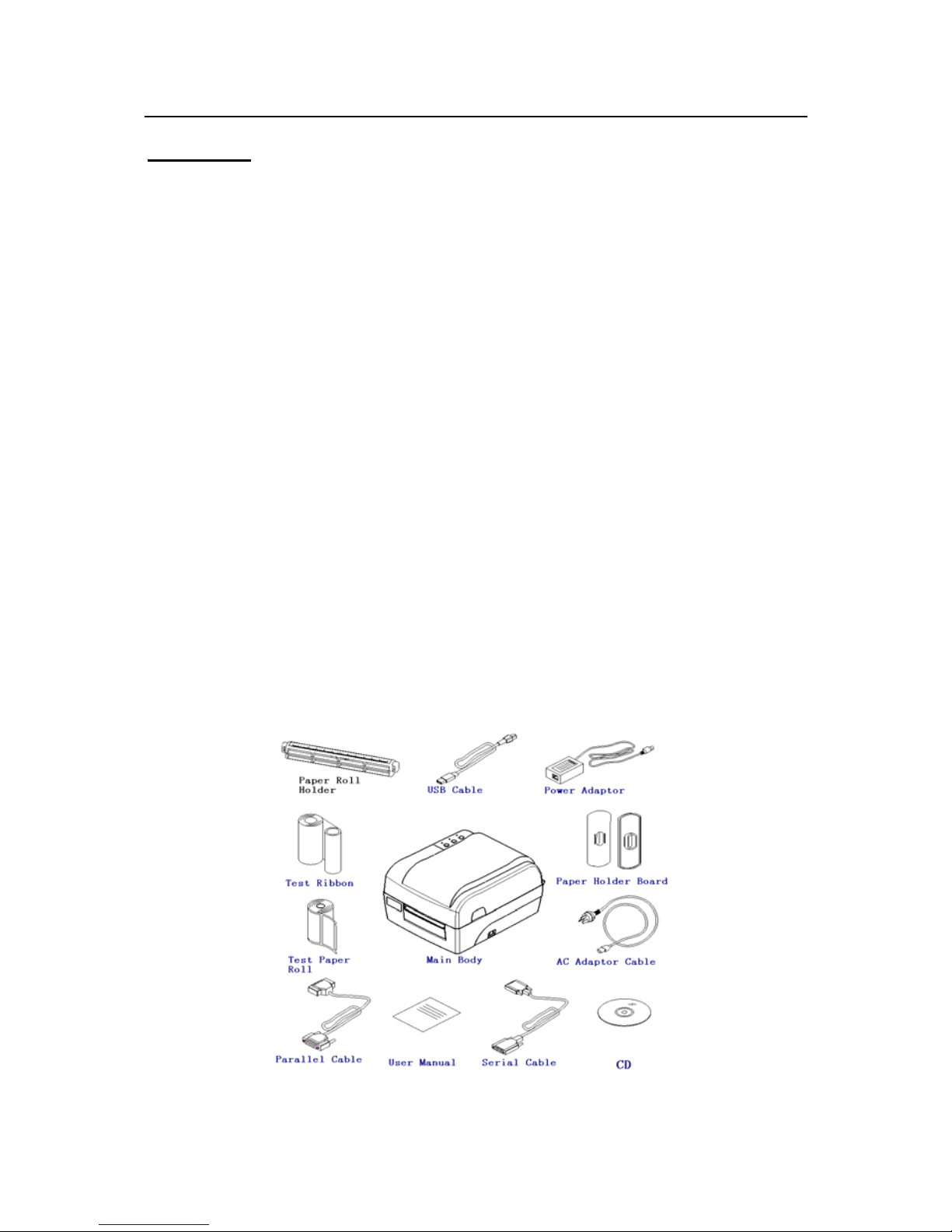

Package content

Unpacking the printer carton and refer to the packing list to check parts as

below (include all parties in figure 1.1, of which Serial cable or USB cable shall

be used depending on corresponding interface type). If any part is short or

damaged, please contact with our distributor or manufacturer.

Figure 1.1

- 2 -

BTP-2100E USER MANUAL

Printer mount

The printer should be placed on the flat table surface where water,

moisture or dust should be prevented. When mounting it, the slanting

extent shall not exceed 15°.

Connect with power adapter

1) Be sure that printer power switch is off.

2) Connect one end of AC power cable to power adapter, then put another

end of power adapter into power adapter socket at the back of the

printer.

3) Put another end of AC power cable into 220V power socket.

Notice: If the printer is idle for a long period, please disconnect the

power.

Connect communication cable

1) Be sure the printer power switch is off.

2) Put communication cable into matched interface and fix it in using clip

spring or screw of the plug.

3) Connect another end of communication cable to the host.

Notice: Please do not connect or disconnect Serial and Parallel cable

with power on!

- 3 -

BTP-2100E USER MANUAL

Printer operations

Apperance and parts

1—Bottom cover

2—Top cover 3—Left cover

4—Key 5—LED

6—Power switch

7—Peel-off turnplate

8—Tear-off bar

9—Scale Label

10—Platen holder

11—Ribbon holder

12—THP pressure knob

13—Ribbon baffle

14—Ribbon rewinding shaft

15—Ribbon output shaft

16—Paper guide

17—Paper roll holder

18—THP cover

19—Manual ribbon bushing

20—THP lift-up button

21—Ribbon block

22—Locking hook

23—Paper guide block

24—Platen

25—Reflection sensor

26—Sensor top cover

27—Transmission sensor

28—Transmission sensor cover

29—THP

30—Ribbon turn wheel

- 4 -

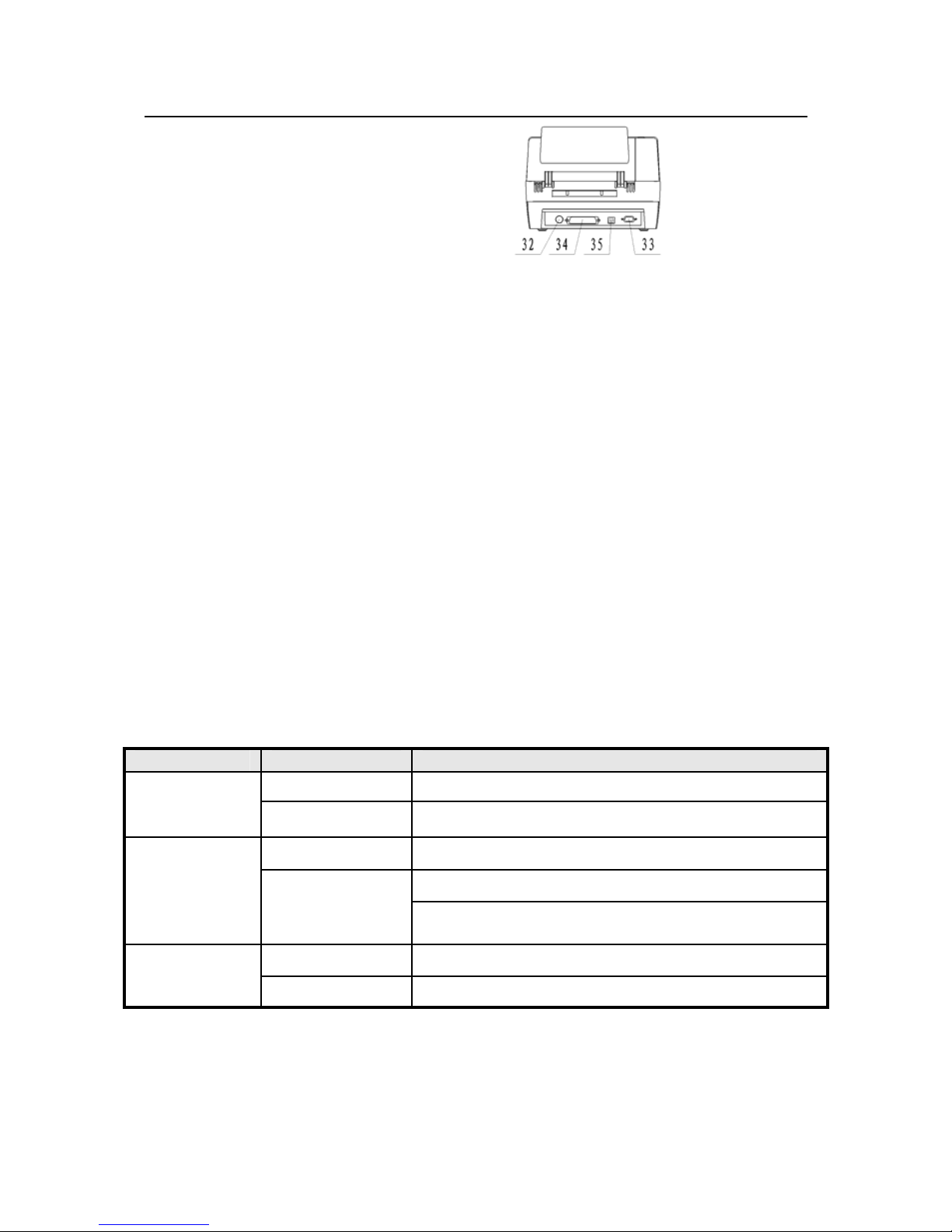

BTP-2100E USER MANUAL

31—THP micro-switch

32—Power adaptor interface

33—Serial interface

34—Parallel interface

35—USB Interface

Main modules

1) Keys and LEDs(4, 5)

Indicate the printer status and execute its print functions.

2) Power switch(6)

Turn off the power when pressing “O”, and turn on the power

when pressing “-”.

3) Paper holder(17)and Paper guide(16)

Hold paper roll and prevent it sliding in paper outlet.

4) Paper guide block(23)

Prevent paper sliding in paper outlet.

5) Reflection sensor(25)

Verify black mark paper, check it available or position it.

6) Transmission sensor(27)

Verify label paper, check it available or position it.

7) THP micro-switch(31)

Check THP open or closed status.

LEDs and keys

LEDs functions

LED name Status Explanation

Always light Printer is in standby status

Power LED

(Green)Flash Printer is busy(process commands)

Always Off Printer is in standby status

Printer enters pause status

Stop LED

(Yellow)Always light Wait and confirm label is taken away in

tear-off/peel off mode

Always Off Printer is in standby status

Error LED

(Red)Flash Printer has error

Table 2.1

- 5 -

BTP-2100E USER MANUAL

- 6 -

Keys functions

Keys Functions Explanation

Feed paper

In standby status, press down “Feed” key, the

printer feeds one label for non-continuous

paper. The printer feeds paper until releasing

the key for continuous paper.

feed

key

Print self-test page

Turn on the power and press “feed” key until

buzzer sounds, then the printer starts to print

a self-test page.

In standby status, press down “Pause” key,

the printer enters pause status. When

pressing down “Pause” again, the printer

shall be back to standby status.

Pause Press down “Pause” key in printing, then the

current print job shall pause. When pressing

down “Pause” key again, the printer shall

continuous last print job.

Confirm label is

taken away

In tear-off/peel-off mode, after the printer

shall print a label and stop without paper

sensor, the light shall be on. User presses

down “Pause” to confirm label taken away.

then printer shall retract paper and start to

print next label.

Pause

key

Paper checkout

Turn on the power and press down “Pause”

until buzzer sounds, the printer shall feed

paper and verify paper.

Cancel print job

First press “Pause” key to stop current print

job, then press “Pause” key to cancel the

print job.

Remove error This key is used to remove printer error and

recover printer standby status

Cancel

key

Enter default Serial

communication

Turn on the power and press down “Cancel”

key until buzzer sounds, then the printer

enters default serial mode.(9600, N, 8, 1,no

Auto paper load)

Table 2.2

LEDs and Buzzer

1) Buzzer sounds shortly under following cases:

zWhen the printer is turned on or reset with software

successfully.

zErase FLASH successfully.

zDownload character set, bitmap to FLASH successfully.

BTP-2100E USER MANUAL

2) Printer error information, buzzer and LEDs:

Error

information Buzzer sound LED

THP lift-up

Wrong command

functions

Paper end

Serial

communication

error

Paper checkout

error

THP voltage /

temperature

abnormal

Ribbon is used

out

System error

Flash

Table 2.3

Key-configuration functions

The printer can print the configuration content and execute the

parameter configuration using keys and LEDs’ status.

Serial interface and Parallel interface are standard interfaces of printer,

RS-232 interface is standard Serial interface, Centronics parallel

interface accords with IEEE1284. User can also choose USB interface

to replace Parallel interface.

1) Simple Parameter Settings

Key Key Function LEDs Status

FEED+

PAUSE

Press “FEED” and “PAUSE”, release after the

buzzer sound once, start to print simple

parameter setting menu and enter simple

parameter setting mode.

Three LEDs flash

alternately.

Press “FEED” first to confirm the change of the

paper type after entering the simple mode. Power LED flashes

FEED

Continue to press “FEED” to switch among

label paper, label mark paper, continuous

paper.

Different

compounding of the

three LEDs means

different setting.

Press “PAUSE” to confirm changing the type of

print after entering the simple mode. PAUSE LED flash.

PAUSE

Continue to press “PAUSE” to switch print

mode between thermal print and thermal

transfer print.

Different

compounding of the

three LEDs means

different setting.

- 7 -

BTP-2100E USER MANUAL

Press “CANCEL” first to confirm the change of

Auto. Paper Feed after entering the simple

mode.

Error LED flash

CANCEL

Continue to press “CANCEL” to switch between

Auto. Paper Feed mode and non-auto paper

feed mode.

Different

compounding of the

three LEDs means

different setting.

FEED+

CANCEL

Press “FEED” and “CANCEL” to save the

modified parameter and exit the simple

parameter setting mode and back to standby

status.

Power LED always

light.

Table 2.4

2) Complex Parameter Settings

Key Key Functions LED Status

PAUSE+

CANCEL

Press “PAUSE” and “CANCEL”, release

after the buzzer sound once, start to print

complex parameter setting menu and

enter complex parameter setting mode.

POWER LED always

light.

STOP LED not light.

ERROR LED always

light.

FEED

Press “FEED” to turn the main menu

content withershins or change parameter

of current menu item.

POWER LED flashes

once.

PAUSE

Press “PAUSE” to print current setting

items to be changed. After that, press

“PAUSE” to print the changed setting

items and back to the first item of the

setting menu.

STOP LED flashes

once.

CANCEL

Press “CANCEL” and turn main menu

content items deasil or change the

parameter of current menu item.

ERROR LED flashes

once.

FEED+

CANCEL

Press “FEED” + “CANCEL” to save the

changed parameter and exit complex

setting mode, then back to standby

status.

POWER LED always

light.

Table 2.5

Loading paper

1) Push up the top cover with two hands according to the arrows in figure

2.1 and open it.

2) Press down Print-head lift button. After ribbon holder is lift, turn it at the

angle shown as below (stop it until a slight sound “pa” is prompted) (see

figure 2.2).

- 8 -

BTP-2100E USER MANUAL

Figure2.1 Figure2.2

3) Load a paper roll on paper roll holder and add one paper roll guide

on each side of paper roll.

4) Drop paper roll on the paper holder to the paper room, then pull out the

front end of the paper and put it in the print path flatly, and also release

the paper guide to hold it. (See figure 2.3)

Figure2.3 Figure2.4

5) Paper roll has two sizes of I/D: 25mm (1 inch) and 38mm (1.5 inch).

When paper roll ID is different, the loading method of paper holder

into paper room will be different. Operation method is as below

(See figure 2.5 and figure 2.6).

- 9 -

Figure2.5 Figure2.6

BTP-2100E USER MANUAL

Notice:

zThe print side should be upside. If it is the marked paper, please

put black mark downwards.

zThe front end of paper roll should be in the middle of the platen as

possible as it can. This could be positioned with the mark of peel-off

plate(see figure 2.4).

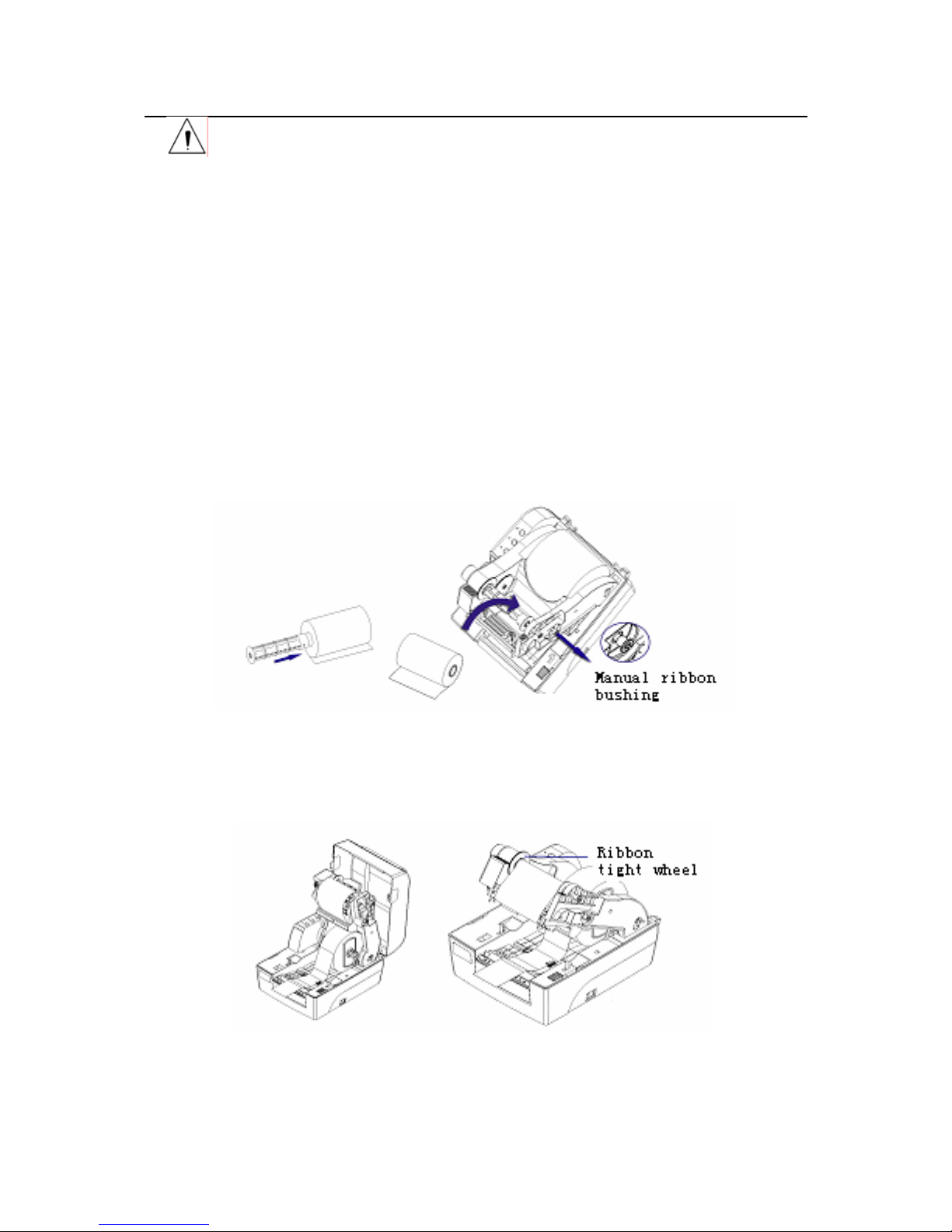

Assembling the ribbon

1) Pull the manual bushing of ribbon output shaft slightly, then take off

ribbon output shaft and put it into ribbon core axis according to the arrow

in the figure as below. (See figure 2.7)

2) Lift up the ribbon holder at about 30°(When a slight sound “pa” is

prompted, the ribbon holder shall keep this position). Pull the manual

bushing out slightly until the ribbon output shaft is at the original position,

then release the manual bushing. The mount of ribbon output shaft is

finished. (See figure 2.8)

Figure 2.7 Figure 2.8

3) Put the ribbon front around the bottom of THP and rewind it on the ribbon

retraction shaft (see figure 2.9). Turn ribbon wheel to tight it up (the

loaded paper roll and ribbon see figure 2.10).

Figure 2.9 Figure 2.10

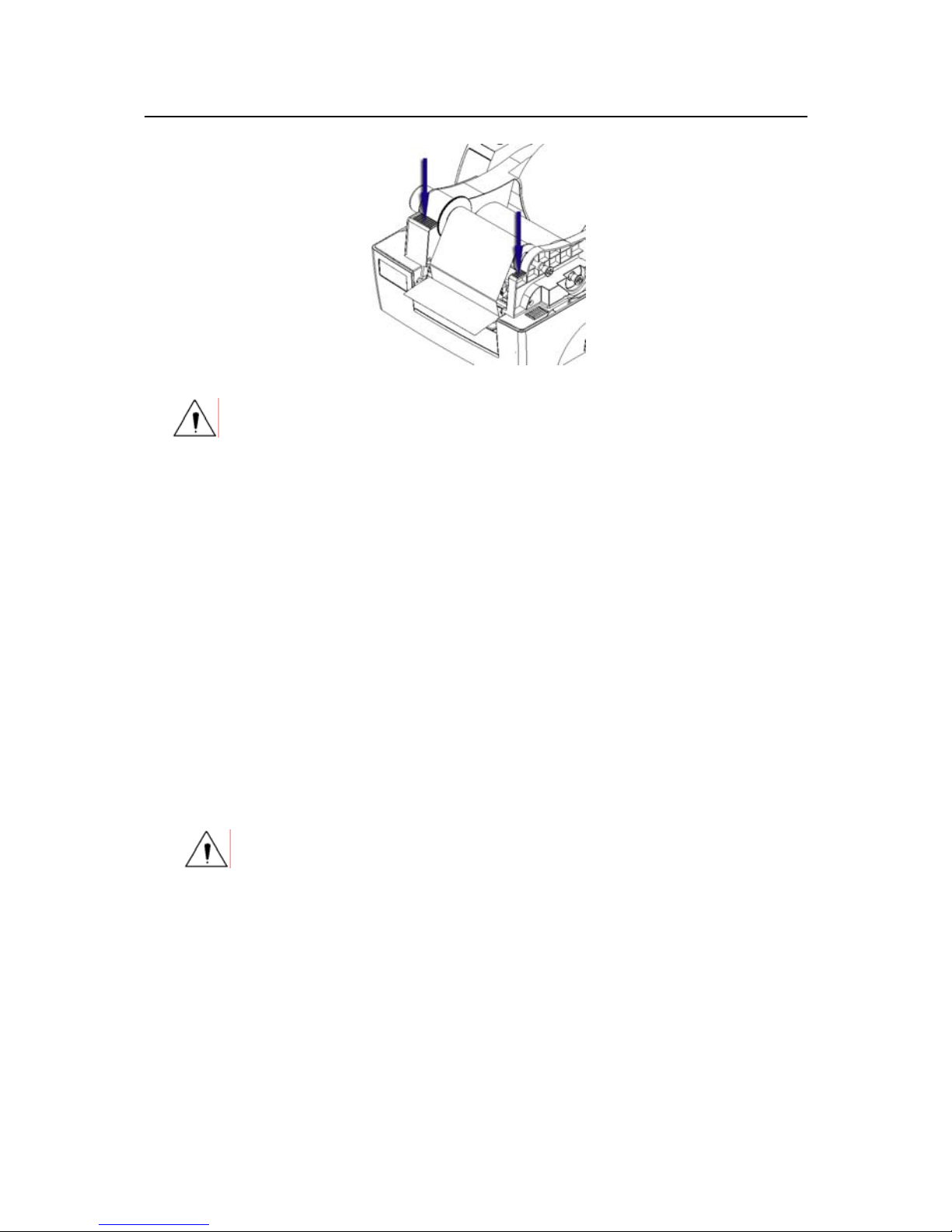

4) Press down the ribbon holder until it is locked, then close the top cover

- 10 -

BTP-2100E USER MANUAL

(see figure 2.11).

Figure 2.11

Notice:

zSelect the print mode: To select thermal transfer mode, you

need to mount ribbon. To select thermal mode, no need to

mount ribbon.

zIn normal condition, ribbon width should be bigger than the

paper width.

zDuring this mount, the ribbon should not be cockled or

damaged.

Starting the printer

Turn on the printer and self-test

1) Be sure that power adapter and communication cable are connected,

then turn on the printer power switch.

2) The printer starts self-test. After this self-test, buzzer shall sound one

time.

3) If the printer sets the media type as non-continuous paper and allows

Auto paper load, it shall automatically load paper to the print position.

Notice: If the printer cannot start or work normally, please contact

with our distributors or manufacturer.

Print a self-test page

The self-test page includes the printer configuration sample and TPH

test sample.

1) Turn off the printer power and load the media. Hold down “Feed”

key and turn power switch to “-” until the buzzer gives one sound.

The printer shall feed paper and print a self-test page after

releasing “feed” button. (Self-test page sees appendix 1).

2) The configuration describes the current settings of the printer.

- 11 -

BTP-2100E USER MANUAL

3) THP test page can show if the THP status is in good status.

Set paper type

Before the print, set the paper type in driver correctly and pay attention

to the relation between paper type and sensor in paper load. Select

paper type according to the table as below:

Paper type in the

driver Actual paper type Sensor type

Continuous paper Continuous strip paper Reflection sensor

Non-continuous marked paper Reflection sensor

Non-continuous Perforated

paper

Black mark paper

Non-continuous edge-gap

paper

Reflection sensor

Label Non-continuous label paper Transmission sensor

Table 2.6.1

Checkout mark

A Manual checkout function

1) Turn off the printer.

2) Load the media properly.

3) Hold down “Pause” key and turn power switch to “-” position.

After the buzzer gives one sound, release “Pause” key, the printer

shall feed paper and start the checkout.

4) If checkout is successful, the printer enters standby status. If it fails,

the printer shall alert, then please check:

¾If media is loaded correctly.

¾If paper type loaded is consistent with current paper type of

the printer (via a self-test page printed)

Notice:

In the following cases, the media needs to be verified before the

print:

It is the first time to mount and use the printer.

The printer is used again after a long idle time.

Replace new type of paper roll.

First time to use it after cleaning the sensor.

Fails to identify marks in effect during the print.

Operation environment of the printer is changed greatly.

B Auto Checkout functions

Before starting the print job, the printer shall compare the parameter

set by customers with current parameter of the printer to decide if it

shall initiate the checkout with the process as below:

- 12 -

BTP-2100E USER MANUAL

1) Set paper type and page length correctly in the printer driver.

2) Send the print job. When the printer identifies that Auto checkout is

needed, the printer shall feed two or three labels for checkout. It

shall enter pause status after success. After pressing pause key,

the printer shall exit pause status and print.

3) If the checkout fails, the printer shall alarm:

¾Please confirm if loaded paper is same with the one

selected in the printer properties. If they are different,

please correct and print it again. The printer shall restart

Auto checkout..

¾If the settings are correct and Auto checkout still fails,

please refer to manual checkout operation.

Notice:

¾Only when the printer checkout is correct, it can work

normally.

¾After following the steps above and cleaning the sensor, it

still fail to find out the failure reason of printer checkout,

please contact with maintenance people!

Installing the driver

The drive supports the operation system as Windows98,

WindowsNT4.0, Windows 2000, Windows XP, Windows

server 2003, which is stored in the disk packed with printer. You also

can download the driver from our website www.newbeiyang.com.cn.

The installation method of the driver:

1) Run “Setup.exe” in the driver package and read the license

agreement carefully. If you accept all the clauses in this Agreement,

please click “I Accept” and then click “Next” button.

2) Choose the type and name of printer to be installed. If you want to

set this printer as the default printer, please select “setting the

printer as default printer” button, then click “next”.

3) Choose the method of installation, then click “next” button.

4) Choose the current system type, then click “next” button.

5) Set the printer port, then the system defaults interfaces as “LPT1”.

User can execute the installation depending on the current port.

- 13 -

BTP-2100E USER MANUAL

- 14 -

Please choose “BYCOMx” for the Serial drive in Windows NT4.0 or

above (“x” equals to “1,2,3,4,5,6,7 or 8”), then click “Finish” to

end the installation.

6) Press “Yes” in the dialog box to reset computer in Windows 98.

7) If you want to use USB interface, you must install USB device

driver first, installation step as follow:

When connecting USB interface printer to the host, the system identifies

USB device automatically and pop up the driver installation guide. The

printer finds out USB device drive path and installs this driver depending

on this guide.

If you want to update the driver, please run “Uninstall.exe” in the driver

package to uninstall original driver first.

BTP-2100E USER MANUAL

Printer adjustment

THP pressure adjustment

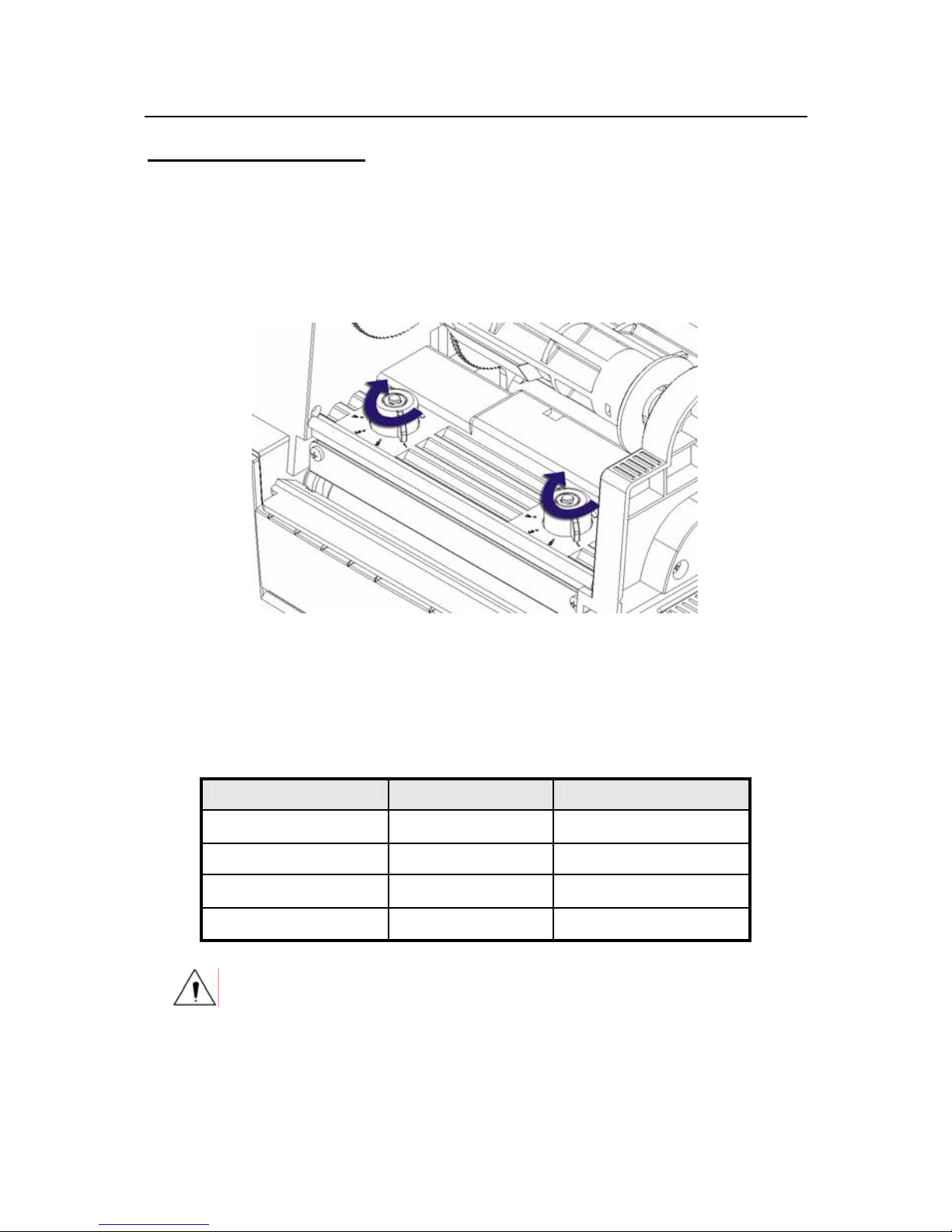

THP pressure adjustment device has two adjusting knobs each of which

has four levels indicating different THP pressures. When turning the

knob in clockwise, the THP pressure increases along with level number.

(See figure 3.1.1).

In normal print, follow the pressure level of factory default settings,

normally at level 2 or 3.

Figure 3.1.1

In following cases, you need to do the adjustment:

1) When the THP pressure in using doesn’t meet the requirement

(for example, rewinding ribbon not smoothly), turn the adjusting

knob in clockwise to increase it.

2) In using different width label for the print, different level can be

selected (only for reference, please see the table as below)

Label width Left level Right level

25mm 1 1

51mm 2 2

75mm 3 3

110mm 4 4

Notice:

It is recommended to use the THP pressure as low as

possible under the condition that the printout meets the

requirement.

Sensor position adjustment

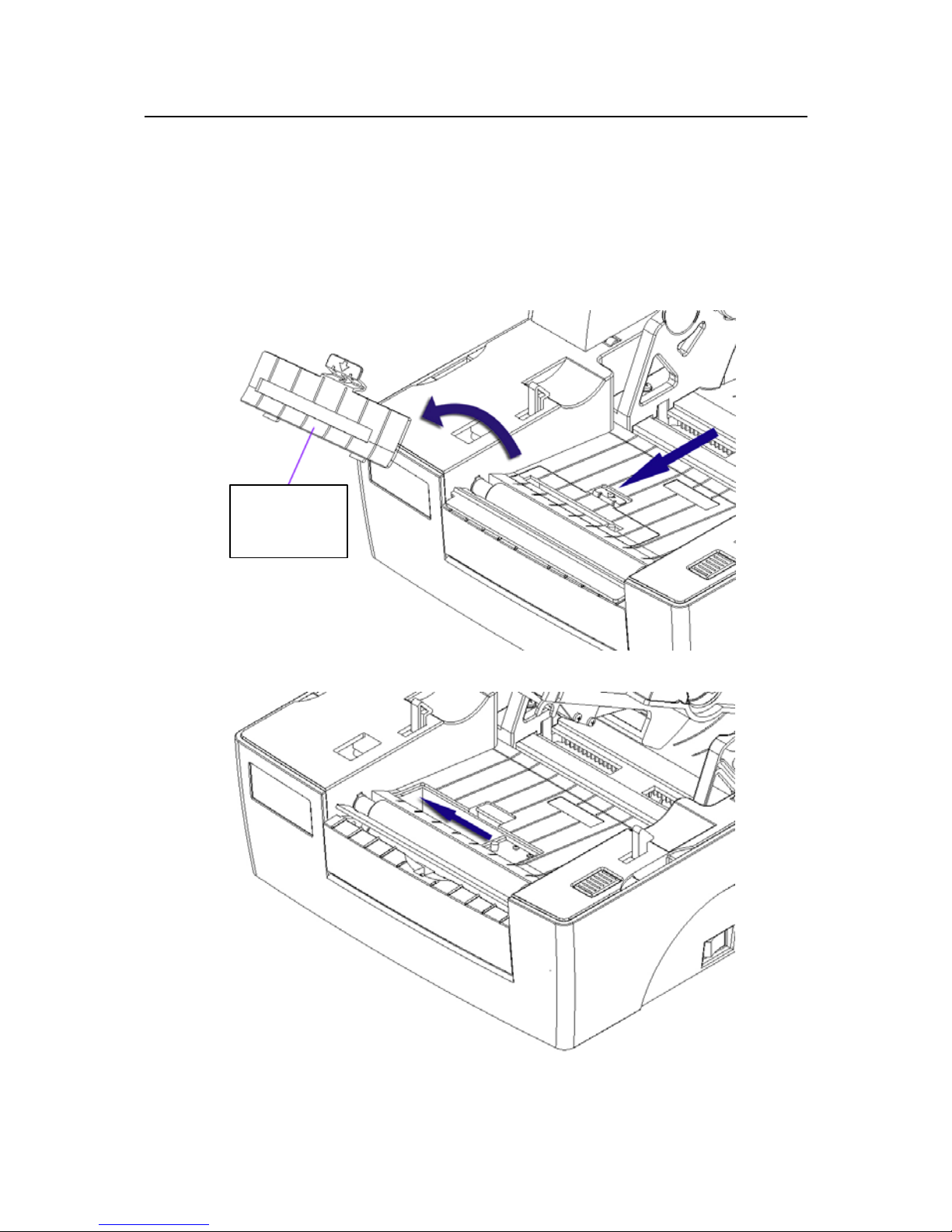

When the paper width is changed, can adjust sensor position

- 15 -

BTP-2100E USER MANUAL

according to the methods as below:

1) According to the marked position of the media, measure the

sensor position required in advance.

2) Push the latch according to the arrow on top cover, then turn

and take off top cover of the sensor (see figure 3.2.1).

3) Act on sensor latch to move the sensor to the required

position (For example: below the black mark) (see figure

3.2.2).

4) Press down top cover latch and assemble the top cover.

Top cover

of sensor

Figure 3.2.1

Figure 3.2.2

- 16 -

Table of contents