Prozeda BDC 102 User manual

BDC 102

Microprocessor-controlled control unit for solar thermal systems

IMPORTANT

Before installing and using this device, you must read through the

instructions carefully.

Failure to observe the instructions and safety information contained in

these installation and operating instructions will void the guarantee for

the device described/installed.

STORE THESE INSTRUCTIONS IN A SAFE PLACE.

31.01.2007

1328BED001-10B-E

Installation and Operating Instructions

Installation and Operating Instructions

BDC 102 1328BED001-10B-E Status 01/07

- 2 -

Table of contents

1SAFETY INSTRUCTIONS 3

2SYMBOLS AND ABBREVIATIONS 5

3DEVICE DESCRIPTION 6

3.1 Usage 6

3.2 Device features 6

3.3 Layout diagram 6

4OVERVIEW OF DEVICE COMPONENTS 7

5DEVICE INSTALLATION 7

6ELECTRICAL CONNECTION 8

6.1 230V connection 8

6.2 Connection of temperature sensor 8

6.3 Replacing the fuse 8

7COMMISSIONING 9

8OPERATION / INDICATORS 10

8.1 Adjustment of control values 10

8.2 Indicators 10

9REGULATOR FUNCTIONS 11

10 RECTIFICATION OF FAULTS 11

10.1 Indicated faults (display): 11

10.2 Faults that are not indicated 12

11 TECHNICAL DATA 13

12 RESISTANCE TABLE PT1000 SENSOR 13

iSubject to change without notice

Installation and Operating Instructions

BDC 102 1328BED001-10B-E Status 01/07

- 3 -

1 SAFETY INSTRUCTIONS

This control unit must be disconnected from the mains before any installation

and wiring work is carried out.

This device may only be opened, connected and commissioned by trained

personnel. In so doing, the

relevant safety regulations, especially VDE 0100

must be adhered to.

•Prior to any installation or wiring

work on the electric motors, always

fully disconnect the device from the

operating voltage and ensure that the

mains supply cannot be reactivated.

Never mix up the connections for the

protective safety low voltage area

(sensor, flow meter) with the 230 V

connections. This could result in

damage and hazardous voltages to the

device itself and to the attached sensors

and devices.

•Solar thermal systems can become very

hot. There is a risk of being burnt. Take

care when installing the temperature

sensor.

•Install the BDC 102 in such a way that

no excessive operating temperatures

(>50°C) result, e.g. as a result of heat

sources.

•BDC 102 is not protected against

splashing and dripping. You should

therefore install it in a dry location.

•If there are signs of damage to the

control unit, cables or attached pumps

and valves, the systems must not be

operated.

•Check whether the materials used for

the piping, thermal insulation, pumps

and valves are suitable for the

temperatures that will occur in the

system.

If you have any questions concerning your solar thermal system or your control unit, please

contact your installer or supplier for advice.

Installation and Operating Instructions

BDC 102 1328BED001-10B-E Status 01/07

- 4 -

2 SYMBOLS AND AB BREVIATIONS

Warning!

This symbol indicates potential dangers

Warning: 230 Volts

This symbol indicates risk to life through high voltages.

•List

iInformation on operation/special features

Instructions/procedure

?Test/check

Installation and Operating Instructions

BDC 102 1328BED001-10B-E Status 01/07

- 5 -

3 DEVICE DESCRIPTIO N

3.1 Usage

BDC 102 is a microprocessor-controlled,

temperature difference regulator for

controlling the functions of solar thermal

systems with one storage cylinder and one

collector.

The control unit is for use in dry rooms,

indoors and in private homes, business and

commercial premises.

The control unit may be used only as a

solar control unit. If used in other scenarios,

the installer must check whether the

standards and safety regulations stipulated

for the area of use are met.

Use of the device in ways other than that

intended by the manufacturer requires the

approval of the manufacturer, failing which

the guarantee shall not apply.

3.2 Device features

BDC 102 is characterised by the following features:

•Compact design

•Minimal installation work

•2 LED “power-on” indicators

•Monitoring of operation

•Adjustable temperature regulator

value

•Pump block protection

•Installation protection

3.3 Layout diagram

The layout diagram for the BDC 102 control

unit is shown below. This control can be

used in similar systems that function in the

same way. This diagram is not a complete,

hydraulic circuit diagram.

Picture 1

storage

cylinder

collector array

Installation and Operating Instructions

BDC 102 1328BED001-10B-E Status 01/07

- 6 -

4 OV E R V I E W O F DE V I C E C O M PO N ENTS

No.: Function

1 Connection to supply voltage

2 Connection to solar circuit pump (A1)

3 Connection to collector sensor (T1)

4 Connection to storage cylinder

sensor (T2)

5 Adjustment of maximum storage

cylinder temperature TSPmax

6 Green light for “Mains”:

device is connected to power supply

Green light for “Pump”:

7 Red light for “Fault”

8 Fuse

5 DEV I C E INS T AL L AT I O N

The BDC 102 may be installed only in dry rooms where there is no risk of

explosion. Installation on a flammable base is not permitted.

The casing of the BDC 102 is designed for surface mounting.

Picture 2

1 5

6

7

8

2 3

4

Installation and Operating Instructions

BDC 102 1328BED001-10B-E Status 01/07

- 7 -

6 ELEC T R I C AL C O N NECTI ON

You must observe the safety instructions in chapter 1

Do not carry out wiring work when the device is connected to

the electricity supply!

6.1 230V connection

The control unit is supplied with electricity as soon as it is connected to the mains supply. The

pump is connected using a terminal screw on the control unit.

The device must be opened in order for it to be wired up.

6.2 Connection of temperature sensor

The BDC 102 operates with accurate platinum temperature sensors of type PT1000.

The terminal screws for the temperature sensors allow simple attachment.

Installation/wiring of temperature sensor:

Install the sensors at the requisite places

on the collector (T1) and the storage

cylinder (T2). In so doing, ensure good

temperature transmission and, if

necessary, use a thermally conductive

paste.

Attach the cable to the control unit. The

cables of the temperature sensors can

be extended. For lengths up to 15 m, a

cross-section of 2 x 0.5 mm² is required;

for lengths up to 50 m, a cross-section of

2 x 0.75 mm² is necessary. For lengths

exceeding 10 meters, a shielded cable is

recommended. Sensor cables must not

be laid parallel to 230 Volt power cables

as these can cause faults.

To protect the collector sensor within the

control unit, the use of a lightning

protection device (accessories) is

recommended.

Connect the collector sensor to the

terminals labelled T1. There is no need

to observe a particular polarity (see page

6, figure 2).

Connect the storage cylinder sensor to

the terminals labelled T2. There is no

need to observe a particular polarity (see

page 6, figure 2).

6.3 Replacing the fuse

The device is protected against overload

and short circuit by means of a switching

output with a fine-wire fuse. The fuse is

located in the top left part of the casing in

the green mount.

If the fuse is defective, e.g. if none of the

lights glow when the control unit is

connected - you can replace the fuse with

an identical one.

Only prescribed fuse types may be used:

fine-wire fuse 5 mm x 20 mm 2A/T (2A current, surge-proof version)

Installation and Operating Instructions

BDC 102 1328BED001-10B-E Status 01/07

- 8 -

7 COM M I S S I O N I NG

Commission your control unit in the following sequence:

?Are the collector and storage cylinder sensors

correctly mounted

?Has the correct sensor type been selected

(PT1000)?

Yes No

Select and install the correct sensor

?Is the power cable for the pump connected

correctly to the pump and the control unit?

Yes No

Connect the cables correctly

If the pump is powered directly via a mains

cable: does the pump work?

Yes

Unplug the mains cable

No

Unplug the mains plug

Test the pump cable,

test the pump

Reconnect the pump to the control unit

?Are the sensor cables for the collector and

storage cylinder sensors correctly connected to

the relevant control unit terminals?

Yes No

Connect sensors correctly

With the mains supply switched off, connect the

control unit and then switch on the mains supply

(e.g. via a safety fuse):

?Does the green “Mains” light lights up

Yes No

Test the fuse on the device

Check the fuse protection on the

mains

?Does the “Fault” light flash

No Yes

Rectify fault as described in section 9

If the “Pump” light lights up, check whether the

pump is working.

Yes No

Rectify fault as described in section 9

Control unit is ready for use. If necessary:

carry out settings for TSPmax*

Write down your settings:

Date TSPmax

°C

°C

* TSPmax: maximum

temperature storage cylinder

* TSPmax:

Installation and Operating Instructions

BDC 102 1328BED001-10B-E Status 01/07

- 9 -

8 OP E R AT I O N /IN D I C AT O R S

8.1 Adjustment of control values

Adjustment of maximum storage cylinder temperature TSPmax

This setting determines the maximum temperature that the storage cylinder may reach. This

value is set using the TSPmax adjustment knob such that the arrow points to the required

temperature. Values between 20°C and 95°C are possible.

The low values are intended primarily for operation of swimming pool heating systems.

For hot water storage cylinders, values of between 60°C and 90°C are usual.

A temperature of 80°C is preset at the factory.

8.2 Indicators

The operating status and potential faults are indicated by two lights. For easier identification, a

pump symbol is shown next to the green LED and a warning symbol next to the red

LED.

LED Display colour Meaning

Green LED

“Mains” Continuous green

light Control unit is switched on

Green LED

“Pump” Flashing green

light Pump is switched on

Red LED “Fault” Continuous red

light

No circulation, although pump is switched

on, or system protection

Red LED “Fault” Red flashing light Error on collector or storage cylinder

sensor

Please observe the specifications laid down by the manufacturer of the storage

cylinder

Installation and Operating Instructions

BDC 102 1328BED001-10B-E Status 01/07

- 10 -

9 REG UL ATO R F U N CTI O N S

Temperature difference control

The BDC 102 regulates the difference in

temperature between the collector and the

storage cylinder:

If the collector temperature is more than 7K

higher than that of the storage cylinder, the

pump is switched on.

If the collector temperature falls below the

value: storage cylinder + 3K, the pump is

switched off.

The pump is always switched off if the

storage cylinder temperature is higher than

the value set for TSPmax.

Sensor monitoring

The two temperature sensors and their

connecting cables are monitored for

interruption and short circuit. A defective

sensor is indicated by a flashing “Fault”

light. An incorrect sensor type is generally

also indicated as a “short circuit” or

“interruption”.

Monitoring of circulation

Whilst the system is operating, the control

unit checks (pump = “on”), whether, with the

pump switched on, the difference in

temperature between the collector and the

storage cylinder exceeds the amount of

60°C+7K for 30 minutes. If this occurs, a

fault – continuous red light – is displayed.

Pump block protection

If the solar thermal system is not in use due

for example, to continuous bad weather, the

solar circuit pump can “seize”. To prevent

this from happening, the control unit

switches the pump on for 30 seconds at 10-

day intervals.

Installation protection

If the collector temperature exceeds 120°C,

the control unit switches off the solar circuit

pump. The pump is switched on again at

105°C, equivalent to a hysteresis of 15K.

10 RECT I FI C AT I O N OF F AULTS

There are basically two kinds of system

fault:

•Faults that are recognised by the control

unit and which it can therefore indicate

•Faults that cannot be indicated by the

control unit

10.1 Indicated faults (display):

These faults are indicated by means of the red “Fault” LED. The frequency with which a light

flashes within a space of a few seconds indicates a specific error number. The possible

corresponding error sources are listed in the following table:

Installation and Operating Instructions

BDC 102 1328BED001-10B-E Status 01/07

- 11 -

Fault indication Possible causes Action

Flashes once •Interruption in the

cable to the collector

sensor

•Sensor defective

Check cables

Check sensor resistance value,

replace sensor if necessary

Flashes twice •Short circuit in the

cable to the collector

sensor

•Sensor defective

Check cables

Check sensor resistance value,

replace if necessary

Flashes three times •Interruption to the

cable to the storage

cylinder sensor

•Sensor defective

Check cables

Check sensor resistance value,

replace sensor if necessary

Flashes four times •Short circuit in the

cable to the storage

cylinder sensor

•Sensor defective

Check cables

Check sensor resistance value,

replace if necessary

Light permanently on

No circulation:

•Air in the system

•Error in pump

connection

•Pump defective

•Pump has seized

Installation protection

De-aerate the system

Check the pump connection

Replace the pump

Ensure the pump is running

Collector temperature >= 120°C, wait

until the temperature has fallen below

105°C

10.2 Faults that are not indicated

Faults and errors that are not displayed can

be tested using the following table and

possible causes and sources of error

identified. If, based on the description, fault

rectification is not possible, please contact

the supplier or installer of the system.

Error Possible causes Action

No display function •No 230V power supply

Switch on or connect the control unit

Check domestic fuse box for

connection

•Fuse within device is

defective

Test fuse, replace with new, type

2A/F fuse if necessary.

Test 230V components for short

circuit

•Device defective Contact the supplier

Green LED “pump” light

blinks, but pump does not

work

•Connection to pump

interrupted.

•Pump has seized.

•No power supply to

switching output.

Test cable to pump

Ensure the pump is running

Control unit defective. Contact

supplier.

Installation and Operating Instructions

BDC 102 1328BED001-10B-E Status 01/07

- 12 -

11 TECHN I C AL D AT A

Housing

Material 100% recyclable ABS casing for surface-mounte

d

installation

Dimensions(H x W x D) in mm, weight 80 x 80 x 52; approx. 180 g

Protection class IP65 in accordance with VDE 0470

Electrical values

Operating voltage AC 230 Volt, 50 Hz, -10...+15%

Internal device fuse Micro-fuse 5 x 20mm 2A/surge-proof

Radio interference level N in accordance with VDE 0875

Terminals for sensors Cross-section max. 0.75 mm² fine-strand/single-strand

Temperature sensor / temperature

range

PTF6 - 25°C - 200°C

PT1000, 1000 kΩat 0°C

Testing voltage 4 kV 1 min in accordance with VDE 0631

Switching output 230 V∼/ 2 A / approx. 230 VA for cos ϕ= 0.7 – 1.0

Operating temperature 0 ... + 50°C

Storage temperature -10 ... + 65°C

Regulator functions Temperature difference regulator

Maximum storage cylinder temperature

Adjustable from approx. 20°C to 95°C

Temperature difference Temp. difference at which pump switches on 7K

Temp. difference at which pump switches off 3K

Pump block protection function Every 10 days

Sensor monitoring Interruption and short circuit

System monitoring Circulation, system protection

12 RESI ST ANCE TAB L E PT1000 S E NSO R

The correct function of the temperature sensor can be checked against the following

temperature resistance table, using a resistance measurement device:

Temperature in °C Resistance (Ohms) Temperature in °C Resistance (Ohms)

-30 882 60 1232

-20 921 70 1271

-10 960 80 1309

0 1000 90 1347

10 1039 100 1385

20 1077 120 1461

30 1116 140 1535

40 1155 200 1758

50 1194

Manufacturer of BDC 102 control unit devices: PROZEDA GmbH.

Table of contents

Other Prozeda Controllers manuals

Popular Controllers manuals by other brands

Lennox

Lennox M0STAT61Q-1 Installation & operation instructions

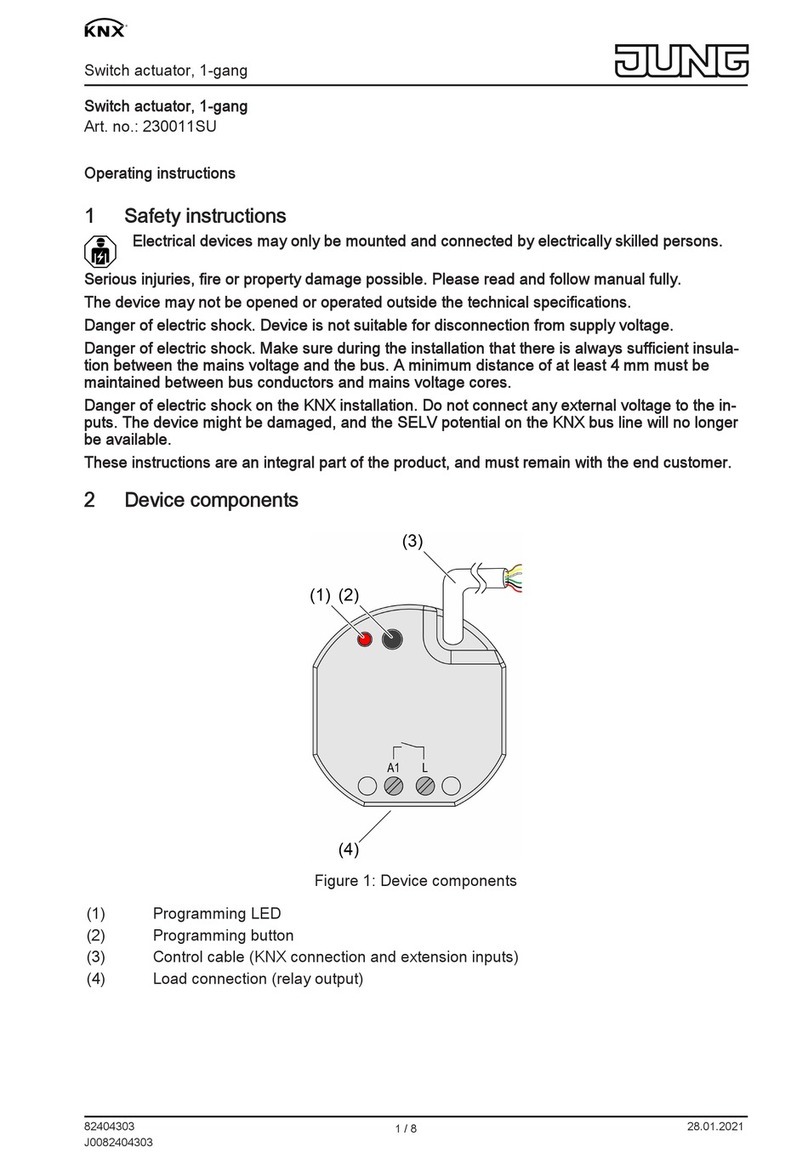

Jung

Jung KNX 230011 SU quick start guide

Dexter Laundry

Dexter Laundry DX Series Service manual

Verasys

Verasys ZEC410 installation instructions

AccuTherm

AccuTherm US-5461P-ACCU1 instruction manual

Kohzu Precision

Kohzu Precision KOSMOS series user manual