ELCOS CEM-120 User manual

ELCOS SRL - Parma - CEM-120 – PROG – EN 1

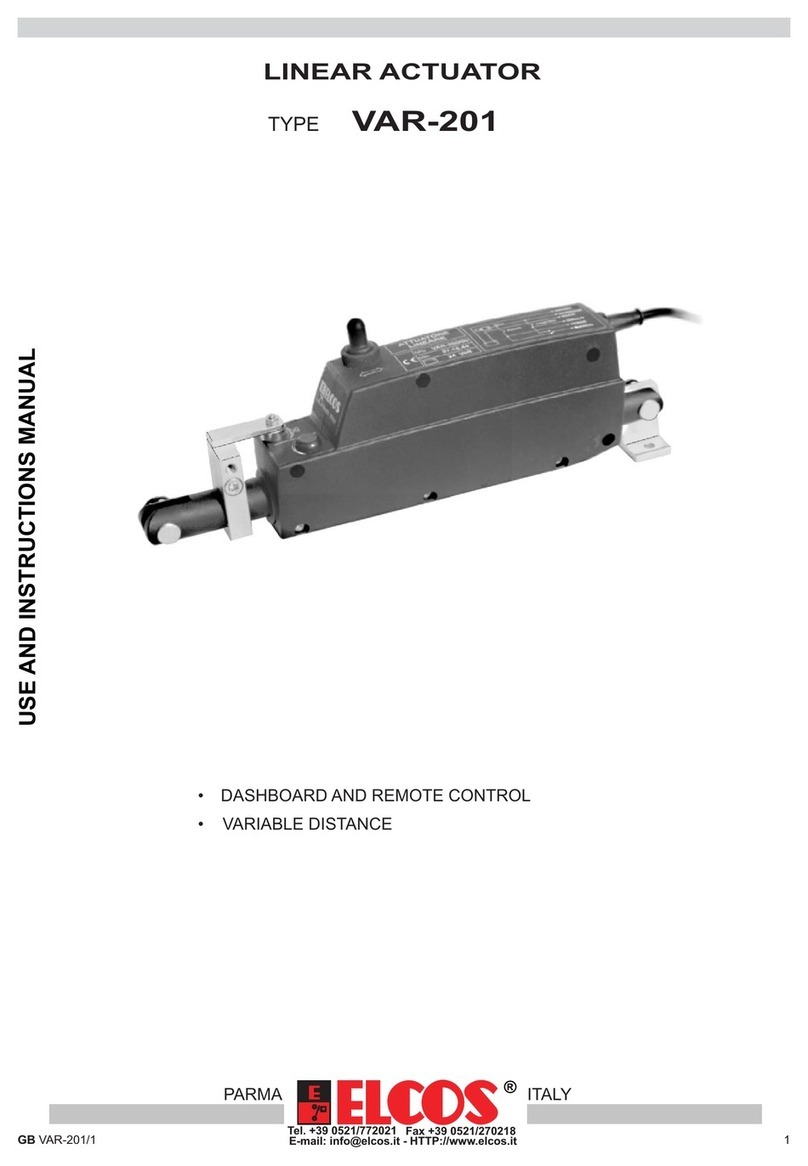

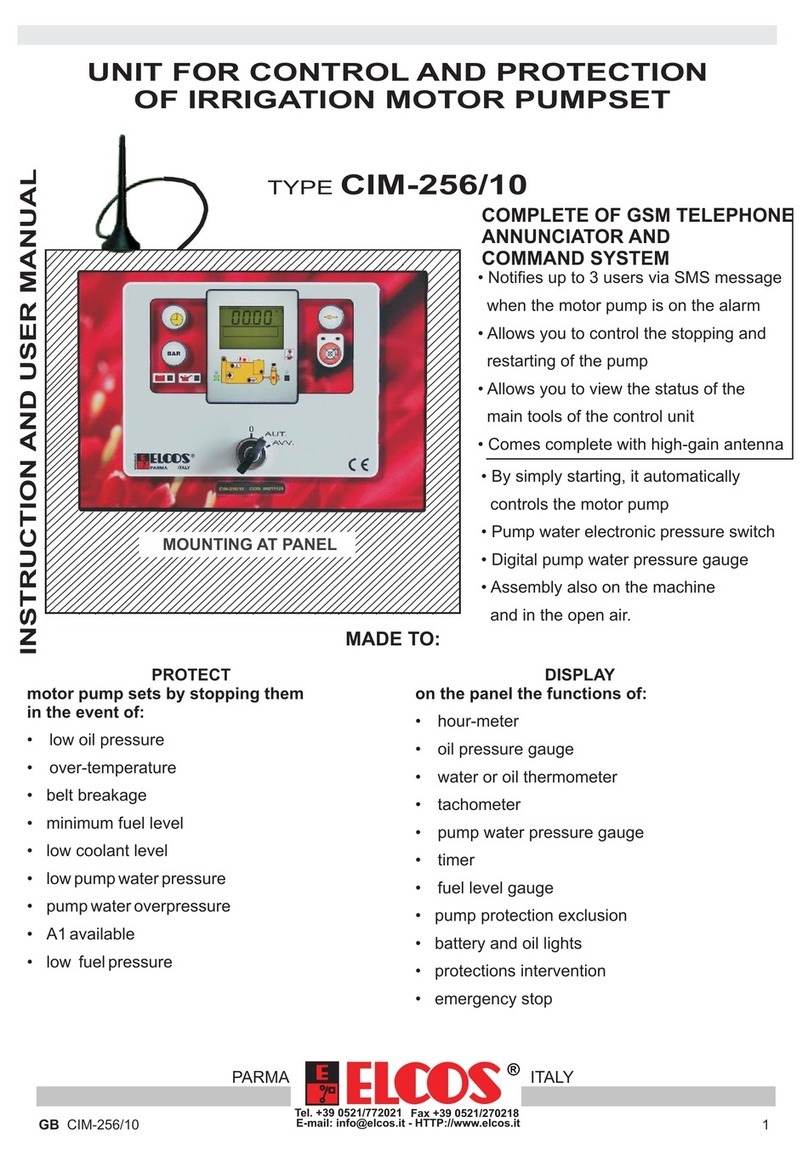

COMBINED CONTROL UNIT FOR CONTROLLING AN INDEPENDENT

GENERATOR SET AND IRRIGATION MOTOR PUMP

TYPE CEM-120

RESERVED FOR THE

MANUFACTURER

TECHNICAL PROGRAMMING OPERATIONS MANUAL

ELCOS SRL - Parma - CEM-120 – PROG – EN

2

REPLACING THE CONTROL UNIT

TRANSFER OF PROGRAMMING OPERATIONS

MEMORY

Press and

wait for

completion of the

transfer.

Check that the

memory

is inserted

correctly.

WARNING

THE TYPE AND REVISION

OF THE TWO CONTROL

UNITS MUST BE THE

SAME.

Before replacing the control unit, we advise transferring all the programming settings to the new control

unit; if this operation is not carried out, the new control unit will operate with the factory programming

settings. In this case, it is necessary to carry out programming of the current transformer.

PROCEDURE

TO BE CARRIED OUT WITH ENGINE STOPPED

AND CONTROL UNIT NOT POWERED

NEW CONTROL UNIT CONTROL UNIT TO BE REPLACED

Remove the

memory and

eliminate it

MEMORY

Supply power to the control unit

The following is read on the display

or

or

Repeat the procedure

It is possible to transfer the programming operations of a standard control unit onto several memories.

We advise you not to exceed fty transfers.

Example:

CONTROL UNIT A

(STANDARD) CONTROL UNITS B - C - D TO BE UPDATED

Remove the

memory

and insert it

in the new control

unit

If, during normal

operation, the

fault is activated

the memory is no

longer used.

To reset press

ABC D

CONTROL UNIT STAND BY

After 30 seconds of inactivity, the control unit enters STAND BY and completely switches off all the

notications (led and display).

To exit STAND BY, press one of the buttons.

RESTORATION OF FACTORY PROGRAMMING OPERATIONS OF THE PROGRAMMING OPERATIONS:

ENGINE, GENERATOR AND PROGRAMMABLE TIMES

Disconnect the battery power supply to the control unit (we suggest opening the protection fuse).

Supply power to the control unit again, simultaneously press (within 8 sec.)

the three buttons, wait for the following to be written on the display:

STANDARD PROGRAMMING.

1. Switch off the power to the control units.

2. Remove the memory from control unit A.

3. Remove the memory from control unit B.

4. Insert memory B in control unit A.

5. Supply power to control unit A.

6. The following message is displayed.

“UPDATE THE CONTROL UNIT?”.

7. Press the STOP button.

8. The following message is displayed

“SAVE DATA IN MEMORY?”

9. Press the START button.

10. The following message is displayed

“END OF TRANSFER”.

11. Switch off the power to control unit A.

12. Remove memory B from control unit A.

13. Insert memory B in control unit B.

14. Supply power to control unit B.

15. The following message is displayed

“UPDATE THE CONTROL UNIT?”.

16. Press the START button.

17. The following message is displayed “END OF

TRANSFER”.

18 Repeat from point 3 for memories C and D.

UPDATE THE

CONTROL UNIT?

END OF

TRANSFER

ERROR IN

TRANSFER

MEMORY NOT

INSTALLED

ERROR

MEMORY

ELCOS SRL - Parma - CEM-120 – PROG – EN 3

Press to select: PROGRAMMING SETTINGS. TO EXIT THE

PROGRAMMING MODE.

To exit the

programming mode

select

- MAN

- AUT

- OFF

(led off)

TECHNICAL

PROGRAMMING

LANGUAGE

CHOICE

USER

PROGRAMMING

CHOICE OF

FUNCTIONS

RESET

PREVENTIVE

MAINTENANCE

PROGR. SETTING

OF PUMP

TEMP. PROBE

PROGRAMMING

CHOICE OF

TRANSMITTERS

PRESS. PROBE

PROGRAMMING

SWITCHING OFF

INSTRUMENTS

FUEL FLOAT

OHM VALUES

CHOICE OF

AMPEROM. TRANSF.

AVAILABLE

ANOMALY

ANOMALIY

LOG

MOD BUS GSM

PARAMETERS

PROGRAMMABLE

TIMES

ENGINE

PROGRAMMING

GENERATOR

PROGRAMMING

see

page

4

5

6

8

8

15

17

16

18

17

18

18

18

19

20

19

20

12

13

14

14

15

9

10

7

Stopping systems.

G.S. frequency.

Weekly automatic test.

Battery voltage.

Procedure for:

Resetting of kilowatt-hour.

Resetting of starting failures count.

Access to preventive maintenance.

Deletion of expired maintenance.

Preheating.

Start-up.

Pause.

Stop.

Cooling.

Battery undervoltage.

Battery overvoltage.

Overtemperature warning.

Overtemperature.

Fuel reserve.

Fuel nished.

G.S. undervoltage.

G.S. voltage present.

G.S. overvoltage.

G.S. underfrequency.

G.S. overfrequency.

Adjustment of running engine threshold,

tachometer and overspeed.

Signal coming from

the charging alternator.

Pump water overpressure (differential).

Programming of the ohmic values of the temperature transmitter.

Choice of already programmed temperature and pressure transmitters.

Choice of already programmed fuel oat.

Programming of the ohmic values of the pressure transmitter.

Procedure for switching instruments on and off.

Procedure for deleting the switching off.

Programming of ohmic values of fuel oat.

Procedure for choosing the A. T.

Programming of times, polarity, possibility to stop.

Fault message.

Faults that have occurred.

Complete reset of the log.

GSM connection. Card address. Programming of telephone numbers. Baudrate. Code for resetting

cyclic maintenance by mobile phone, Fault SMS..

Italian English French Spanish

German Portuguese

TECHNICAL PROGRAMMING OPERATIONS

RUNNING ENGINE

SETTINGS

ACCESS TO PROGRAMMING MODE

Start delay after closing of the call.

Stop delay after opening of the call.

Time for connection of the general alarm.

Weekly self-test duration.

Insufcient intervention time or pump water overpres-

sure.

G.S. voltage.

Choice of number of ammeters.

G.S. protection devices in manual mode.

Input 41.

Fault information.

Choice of unit of measurement.

Signal coming from the pick-up..

Signals coming from the generator.

Low oil pressure warning.

Charging alternator fault.

Number of starting attempts.

G. S. start with battery with low charge.

Choice of radiator uid level probe.

Engine warming.

G.S. overload warning.

G.S. overload.

G.S. does not supply power.

G.S. asymmetry out of range.

Resetting of start-up count.

Change of indicated hours.

PRESS TO DISPLAY THE

REQUIRED PROGRAMMING

PRESS (10”)

SIMULTANEOUSLY

TO DISPLAY TECHNICAL

PROGRAMMING SETTINGS.

19 Procedure for switching functions on and off.

Procedure for deleting the switching off.

SWITCHING OFF

FUNCTIONS

ELCOS SRL - Parma - CEM-120 – PROG – EN

4

CHOICE OF LANGUAGE. The preset language is Italian, the selectable languages are: ENGLISH-FRENCH-GERMAN-

SPAIN-PORTUGUESE.

SELECT

LANGUAGE

ENGLISH

ENGLISH

Press to select

the language.

Press and wait for

the system to write

PROGRAMMED

Press to

display.

CHOICE OF LANGUAGE

ELCOS SRL - Parma - CEM-120 – PROG – EN 5

STOPPING

SYSTEMS

G.S.

VOLTAGE

BATTERY

VOLTAGE

WEEKLY AUTOMATIC

TEST

GENERATOR

FREQUENCY

ENERGIZED IN

STOP MODE

SINGLE-PHASE

24 V

ON

50 Hz

ENERGIZED IN

RUN MODE

THREE-PHASE

12 V

OFF

60 Hz

ENERGIZED IN

RUN MODE

THREE-PHASE

12 V

OFF

50 Hz

WEEKLY AUTOMATIC TEST. When the WEEKLY AUTOMATIC TEST ON programming is nished, the generator set

immediately executes the test cycle.

GENERATOR FREQUENCY.

Press to choose.

Press to choose.

Press to choose.

Press to choose.

Press to choose.

Factory setting

Factory setting

Factory setting

Factory setting

Factory setting

READ BEFORE USING THE CONTROL UNIT

CHOICE OF FUNCTIONS

Press to

display.

Press to

display.

Press to

display.

Press to

display.

Press to

display.

Press and wait for

the system to write

PROGRAMMED.

Press and wait for

the system to write

PROGRAMMED.

Press and wait for

the system to write

PROGRAMMED.

Press and wait for

the system to write

PROGRAMMED.

Press and wait for

the system to write

PROGRAMMED.

ELCOS SRL - Parma - CEM-120 – PROG – EN

6

CHOICE OF FUNCTIONS

PROTECTION

IN MANUAL

CHOICE OF NUM.

AMMETERS

INPUT

41

INDICATION

OF ANOMALIES

CHOICE OF UNIT

OF MEASUREMENT

WITHOUT

STOP

ONE AMMETER

L2

INHIBITION OF

PROTECTION

NUMERIC

CODE

WITH

STOP

AMMETERS

L1 L2 L3

PROTECTION

AVAILABLE

WRITTEN

INDICATION

WITH

STOP

AMMETERS

L1 L2 L3

PROTECTION

AVAILABLE

WRITTEN

INDICATION

BAR

°C

CHOICE OF NUMBER OF AMMETERS. It is possible to choose: three ammeters or one

ammeter, with the current transformer connected on phase L2.

INPUT 41

Input 41 can be used in two ways:

1) Fully programmable available protection input (times, polarity, possibility to

stop and message describing the fault)

or

2) Disabling of control unit protection devices, when the input is connected to ground only the following

protection devices remain active: OVERSPEED, OVERFREQUENCY and EMERGENCY. The

remaining protection devices are switched off.

Press to choose.

Press to choose.

Press to choose.

Press to choose.

Press when the arrow is next

to the unit of measurement

to be changed.

Factory setting

Factory setting

Factory setting

Factory setting

Factory setting

kPa

°F

Press to

display.

Press to

display.

Press to

display.

Press to

display.

Press to

display.

Press and wait for

the system to write

PROGRAMMED.

Press and wait for

the system to write

PROGRAMMED.

Press and wait for

the system to write

PROGRAMMED.

Press and wait for

the system to write

PROGRAMMED.

Press and wait for

the system to write

PROGRAMMED.

ELCOS SRL - Parma - CEM-120 – PROG – EN 7

SIGNALS COMING FROM THE CHARGING ALTERNATOR

RUNNING ENGINE THRESHOLD, TACHOMETER, OVERSPEED AND UNDERSPEED ADJUSTMENTS

ADJUSTMENTS WITH CHARGING ALTERNATOR FREQUENCY (W)

TACHOMETER ADJUSTMENT

SIGNALS COMING FROM THE GENERATOR

SIGNALS COMING FROM THE PICK-UP MAGNETIC TRANSDUCER (control unit terminals 63 - 64)

ADJUSTMENT OF RUNNING ENGINE THRESHOLD

Normally no adjustment needs to be carried out, but if it is necessary to carry it out: stop the engine.

Choose the voltage threshold coming from the charging alternator (terminal D+).

Adjustment range 3 to 12 (12V) 6 to 24 (24V). Factory setting 7V (14V).

Factory setting 7V, 14V.

OVERSPEED ADJUSTMENT

RUNNING ENGINE

THRESHOLD 66

RUNNING ENGINE

THRESHOLD RPM

OVERSPEED

7 V

600 RPM

7 V

600 RPM

1860 RPM

1860 RPM

Decreases Increases

Press to choose the voltage thresh-

old.

Press to choose at how many revs

you want to disable the starter motor.

Adjustment range 300 to 4000 RPM.

Press to choose the

overspeed threshold.

Adjustment range 1530 to 5100 RPM.

Press to

display.

Factory setting

Factory setting

Factory setting

Threshold

NECESSARY PROGRAMMING

(With terminal 65 of the control unit

connected)

ADJUSTMENT OF RUNNING ENGINE AND OVERSPEED

with signals coming from the W of the charging alternator (control unit terminal 65)

PICK-UP (control unit terminals 63-64)

ADJUSTMENT OF RUNNING ENGINE THRESHOLD - rst carry out tachometer adjustment

Normally no calibration needs to be carried out, but if it is necessary to carry it out: stop the engine.

Run the engine at a costant and known rpm value

(for example by means of a portable revolution counter).

Run the engine at a costant and known rpm value

(for example by means of a portable revolution counter).

• ADJUSTMENT OF RUNNING ENGINE THRESHOLD no adjustment

• TACHOMETER ADJUSTMENT see page 5 ADJUSTMENT OF TACHOMETER WITH GENERATOR FREQUENCY

• OVERFREQUENCY ADJUSTMENT - see page 12 GENERATOR OVERFREQUENCY

TACHOMETER ADJUSTMENT

NECESSARY PROGRAMMING

(With terminals 63-64 of the control

unit connected)

PICKUP CALIBRAT.

3,000 RPM

Press and wait for the system to

write PROGRAMMED.

To stop press button

PICKUP CALIBRAT.

PRESS START

With this signal do not connect terminal 65

Setting

with control unit

connected to D+

(control unit

terminal 66)

of the

pre-excitation

alternator.

Setting with

control unit

connected to

the W

(control unit

terminal 65)

of the pre-exci-

tation alternator

or to the

yellow wire

of the perma-

nent magnet

alternator.

Press to

display.

Press to

display.

Press and

wait for the

system to write

PROGRAMMED.

Press to

display.

Press and

wait for the

system to write

PROGRAMMED.

Press and

wait for the

system to write

PROGRAMMED.

Start the engine

whit the button .

PICKUP CALIBRAT.

3000 RPM

PROGRAMMING

Set the rpm of the engine

read on the portable

tachometer.

Factory setting

RPM/W CALIB.

PRESS START

Press to

display.

Start the engine

whit the button .

RPM/W CALIB.

3000 RPM

Set the rpm of the engine

read on the portable tacho-

meter.

RPM/W CALIB.

3000 RPM

Press and wait for the system to

write PROGRAMMED.

To stop press button

Factory setting

ELCOS SRL - Parma - CEM-120 – PROG – EN

8

MAINTENANCE

NOT EXPIRED

RESET

KILOWATT HOUR?

RESET STARTING

FAILURES?

RESET STARTUP

COUNTER?

MODIFY

HOUR METER

DELETE

MAINTENANCE 1?

0 s

RESET

KILOWATT HOUR?

RESET STARTING

FAILURES?

RESET STARTUP

COUNTER?

1 2 3 4 5h

DELETION OF EXPIRED MAINTENANCE OPERATIONS

RESETTING OF KILOWATT-HOUR.

RESETTING OF COUNT OF FAILURES TO START.

RESETTING OF START-UP COUNT.

CHANGE OF INDICATED HOURS.

When you change the value of the hour meter the preventive maintenance programming must be done again.

To delete press

simultaneously and wait for

PROGRAMMED to be written.

To reset press simultaneously and wait for

programmed to be written.

To reset press simultaneously

and wait for programmed to be written.

To reset press simultaneously

and wait for programmed to be written.

To reset press simultaneously

and wait for programmed to be written.

The warning light goes out when all

the expired maintenance operations are

deleted.

Press to

display.

Press to

display.

Press to

display.

Press to

display.

PREVENTIVE MAINTENANCE

CHANGE RESETTING OPERATIONS

The control unit manages three xed time notications and a cyclic notication. Notications 1, 2 and 3 are for a xed

time and trigger only once, when the hour meter reaches the programmed value. Notication number 4 is cyclic and triggers after

the programmed hours and whole multiples of them. The request for maintenance is indicated: by the ashing of the hour meter,

the intermittent switching on of the yellow warning light and the message on the display.

Example 1: Notication 4 is programmed to 100. The notication triggers after 100, 200, 300, 400 ... hours.

Example 2: Notication 1 is programmed to 100. The notication triggers at 100 hours, and never triggers again.

The factory value for all the notications is zero. The maintenance operations are programmed by the G.S. manufacturer during

testing. The maximum value is 59999 hours.

ACCESS TO PERIODIC PROGRAMMING

PREVENTIVE

MAINTENANCE 1

500h

NO STOP

500h

NO STOP

Decreases Increases

Press when the arrow is

next to the value to be

increased

STOP, when the maintenance has expired

it enables the general alarm and prevents

subsequent start-ups. NO STOP, enables

the general alarm for 10 seconds.

Press to

display.

Press again to change the number

of the maintenance operation 1 - 2 -3 -4 (cyclic)

Factory setting

Example

Zero hours of preventive

maintenance not activated

ExPIRED MAINTENANCE OPERA-

TIONS ARE CONSIDERED FAULTS

Fault

codes

Alarms

111

Preventive

maintenance 1

112 2

113 3

114 4

1 2 3 4 5h

Press and

wait for the system

to write PROGRAMMED.

Press

to display.

Press again to change the

number of the expired

maintenance operation.

ELCOS SRL - Parma - CEM-120 – PROG – EN 9

PROGRAMMABLE TIMES

DESCRIPTION

SECONDS

ADJUSTMENT

RANGE

FACTORY

SETTING

PREHEATING TIME preheating operation time. 0 to 60 0 (off)

STARTING TIME operation time of attempt to start. 5 to 25 5

PAUSE TIME pause between attempts to start. 1 to 20 5

STOPPING TIME

Stopping system operation time after the engine running signal has disappeared.

1 to 55 20

COOLING TIME

Engine operating time between the moment of releasing the generator contactor and

operation of the stopping system.

0 to 360 120

START-UP DELAY AFTER THE CALL

With the call contact closed and the delay expired, start-up begins.

1 to 600 1

STOP DELAY AFTER OPENING OF THE CALL

On opening of the call contact and after the delay has expired, the generator contactor is

de-energized.

1 to 600 1

TIME FOR CONNECTION OF THE GENERAL ALARM

Number 350 indicates continuous operation with no time limits.

10 to 350 350

(continuous

operation)

WEEKLY SELF-TEST DURATION When the test time expires, the engine stops. 1 to 60

minutes

3 minutes

INSUFFICIENT INTERVENTION TIME OR PUMP WATER OVERPRESSURE after the

increase or lowering of pump water pressure and when this time has expired, the stopping

process begins.

0 to 300 5

PREHEATING

TIME

STARTING

TIME

PAUSE

TIME

STOPPING

TIME

0 s

5 s

5 s

20 s

0 s

5 s

5 s

20 s

PREHEATING TIME. Preheating operation time. 0 seconds, preheating off.

STARTING TIME. Operation time in the attempt to start.

PAUSE TIME. Pause between attempts to start.

STOPPING TIME. Stopping system time after the engine running signal has disappeared.

Press to change the time

Press to change the time

Press to change the time

Press to change the time

Time

Time

Time

Time

Decreases

Decreases

Decreases

Decreases

Increases

Increases

Increases

Increases

Press and wait for

the system to write

PROGRAMMED.

Press and wait for

the system to write

PROGRAMMED.

Press and wait for

the system to write

PROGRAMMED.

Press and wait for

the system to write

PROGRAMMED.

Press to

display.

Press to

display.

Press to

display.

Press to

display.

ELCOS SRL - Parma - CEM-120 – PROG – EN

10

COOLING

TIME

DELAY AFTER

OPENING OF CALL

WEEKLY AUTOTEST

TIME

STARTUP DELAY

AFTER CALL

GENERAL ALARM

CONNECTION TIME

INTERV. TIME OF

WATER PRES.SW

120 s

1 s

3 min.

1 s

350 s

5 s

120 s

1 s

3 min.

1 s

350 s

5 s

COOLING TIME. Engine operating time between the moment of releasing the

generator contactor and operation of the stopping system.

STOP DELAY AFTER OPENING OF THE CALL.

On opening of the call contact and after the delay has expired, the generator contactor is de-energized.

WEEKLY SELF-TEST DURATION.

When the test time expires, the engine stops.

START-UP DELAY AFTER CLOSING OF THE CALL.

With the call contact closed and the delay time expired, start-up begins.

TIME FOR CONNECTION OF THE GENERAL ALARM.

Number 350 means continuous operation with no time limits.

INSUFFICIENT INTERVENTION TIME OF PUMP WATER OR PUMP WATER OVERPRESSURE.

After the increase or lowering of pump water pressure and when this time has expired, the stopping process begins.

Press to change the time

Press to change the time

Press to change the time

Press to change the time

Press to change the time

Press to change the time

Time

Time

Delay

in intervention

Delay

in intervention

Time

Delay

in intervention

Decreases

Decreases

Decreases

Decreases

Decreases

Decreases

Increases

Increases

Increases

Increases

Increases

Increases

PROGRAMMABLE TIMES

Press and wait for

the system to write

PROGRAMMED.

Press and wait for

the system to write

PROGRAMMED.

Press and wait for

the system to write

PROGRAMMED.

Press and wait for

the system to write

PROGRAMMED.

Press and wait for

the system to write

PROGRAMMED.

Press and wait for

the system to write

PROGRAMMED.

Press to

display.

Press to

display.

Press to

display.

Press to

display.

Press to

display.

Press to

display.

ELCOS SRL - Parma - CEM-120 – PROG – EN 11

BASIC TABLE OF

TECHNICAL PROGRAMMING

CODE

ANOMALIE

(ANOMALIES)

FUNCTIONS

AND PRO-

TECTION

DEVICES OF

GENERATOR

SET AND

IRRIGATION

MOTOR

PUMP

(INDICATION

ON THE

DISPLAY)

INSTANT OF

ACTIVATION

(seconds)

THRESHOLDS FOR DELAY

IN INTERVENTION

STORES THE FUNCTION

COOLING

HEATER

Stop THE INTERVENTION OCCURS

WHEN:

ALARM ADJUST-

MENT

RANGE

FACTORY

ADJUST-

MENT

ADJUST-

MENT

RANGE

FACTORY

ADJUST-

MENT

PROGRAM-

MABLE

FACTORY

SETTING

SECONDS

120 BATTERY

UNDERVOLT-

AGE

ALWAYS

ACTIVE

8 to 12(12V)

16 to 24(24V)

11 (12V)

22 (24V)

1 to 5 2 YES NO DOES NOT STOP The battery voltage remains lower than

the programmed threshold for the entire

intervention delay time.

121 BATTERY

OVERVOLT-

AGE

“12 to 18(12V)

24 to 36(24V)

16 (12V)

32 (24V)

=5 YES YES YES WITH-

OUT

STOP

The battery voltage exceeds the

programmed threshold for the entire

intervention time

123 WARNING

OF OVER-

TEMPERA-

TURE

“90 to 140°C 95°C = = YES YES YES WITH-

OUT

STOP

The temperature measured by the

transmitter exceeds the set threshold.

124 ENGINE

OVERTEM-

PERATURE

“90 to 140°C 100°C = = YES NO STOPS

125 OVERTEM-

PERATURE

DETECTED

BY THERMO-

STAT

WITH

ENGINE

RUNNING

= = = = YES NO STOP The temperature exceeds the threshold of

the thermostat. No programming is

possible.

129 FUEL RE-

SERVE.

ALWAYS

ACTIVE

0 to 99% 10% 1 to 5 1 NO NO DOES NOT STOP

The fuel level remains below the threshold

for the entire intervention delay time.

130 FUEL FIN-

ISHED “0 to 99% 1% 1 to 20 3 YES YES YES WITH

STOP

131 LOW OIL

PRESSURE

WARNING

10 AFTER

DETECTION

OF ENGINE

RUNNING

0 to 6 bar 0 to 5 bar 1 to 5 1 YES NO DOES NOT STOP

The pressure measured by the transmitter

remains lower than the programmed thresh-

old for the entire intervention delay time.

132 LOW OIL

PRESSURE

10 AFTER

DETECTION

OF ENGINE

RUNNING

= = = IMMEDI-

ATE

YES NO STOPS The pressure is lower than the set threshold

of the pressure switch (no programming is

possible).

133 FAILURE

TO

STOP

AFTER

STOP CON-

TROL

= = = 60 YES See description on page 5 of the user

instruction manual (no programming is

possible).

135 LOW LEVEL

IN

RADIATOR

ALWAYS

ACTIVE

= = = 5

YES YES STOPS

The coolant falls below the electrode and

the intervention delay time has elapsed (no

programming is possible).

136 CHARGING

ALTERNA-

TOR FAULT

(belt break-

age)

10 AFTER

DETECTION

OF ENGINE

RUNNING

= = = 3 YES NO YES WITH-

OUT

STOP

The alternator does not charge the battery

and the intervention delay time has elapsed.

137 NUMBER OF

ATTEMPTS

TO START

(FAILURE TO

START)

ALWAYS

ACTIVE

1 to 10

START-UPS

4 START-

UPS

= = YES NO STOP See description on page 4 of the user

instruction manual.

138 G.S. START

WITH FLAT

BATTERY

ALWAYS

ACTIVE

Minimum threshold 900 to 7200 1200

(20 minutes)

NO The voltage measured on the battery remains

lower than the minimum threshold for 60

seconds (time not adjustable) the engine starts.

If during running, a call occurs, the control unit

closes the generator contactor. The engine stops

after the battery voltage remains above the

maximum threshold for the entire intervention

delay time.

12.2 to 12.7

24.4 to 25.4

12.4 (12V)

24.8 (24V)

13.5 to 14.5

27 to 29

13.6 (12V)

27.2 (24V)

Maximum threshold

139 OVER-

SPEED

“

RPM

of engine

THRESHOLD

for overspeed

=2 YES NO STOP

The speed remains higher than the

programmed threshold for at least two

seconds; causes the engine to stop.

1530

to

5100

1500

1800

3000

3600

1860 (62Hz)

2220 (74Hz)

3720 (62Hz)

4400 (74Hz)

140 FUEL FLOAT

DISCON-

NECTED

“= = = = NO DOES NOT STOP The fuel oat circuit is disconnected (no

programming is possible).

144 PICK-UP DIS-

CONNECTED

ALWAYS

ACTIVE

= = = = = DOES NOT STOP The PICK-UP circuit is disconnected. No

programming is possible.

146 PICK-UP

FAULT “= = = 1=DOES NOT STOP The PICK-UP is faulty. No programming is

possible.

220 G.S. UNDER-

VOLTAGE

10 AFTER

THE

THRESH-

OLD IS

EXCEEDED

50 to 500V ~ 335V three-

phase.

193V

single-phase

1 to 10 3 YES YES YES WITH

STOP

The generator voltage remains lower than

the programmed threshold for the entire

intervention delay time.

ELCOS SRL - Parma - CEM-120 – PROG – EN

12

BASIC TABLE OF

TECHNICAL PROGRAMMING

CODE

ANOMALIE

(ANOMALIES)

FUNC-

TIONS AND

PROTECTION

DEVICES OF

GENERATOR

SET AND

IRRIGATION

MOTOR PUMP

(INDICATION

ON THE

DISPLAY)

INSTANT OF

ACTIVATION

(seconds)

THRESHOLDS FOR DELAY

IN INTERVENTION

STORES THE FUNCTION

COOLING

HEATER

Stop THE INTERVENTION OCCURS

WHEN:

ALARM

ADJUST-

MENT

RANGE

FACTORY

ADJUST-

MENT

ADJUST-

MENT

RANGE

FACTORY

ADJUST-

MENT

PROGRAM-

MABLE

FACTORY

SETTING

SECONDS

G.S. VOLTAGE

PRESENT

ALWAYS AC-

TIVE

50 to 400V~ 355V three-

phase 205V

single-phase

1 to 600 Generator

connection to

power user

delay 7

NO DOES NOT STOP The voltage steadily remains above the programmed

threshold for the entire generator connection to power

user delay time (the generator contactor closes).

222 G.S. OVERVOLT-

AGE

After detection of

engine running

50 to 500V~ 440V THREE-

PHASE 253V

SINGLE

PHASE

0 to 10 3YES NO YES WITH

STOP The generator voltage remains higher than the

programmed threshold for the entire intervention

delay time.

223 G.S. UNDERFRE-

QUENCY

10 after the

threshold is

exceeded

45 to 60Hz 45 Hz 0 to 10 5YES YES YES WITH

STOP

The frequency of the generator remains lower than

the programmed threshold for the entire intervention

delay time.

224 G.S. OVERFRE-

QUENCY

ALWAYS

ACTIVE

45 to 74Hz 60 (50Hz)

72 (60Hz)

0 to 5 2YES NO STOPS The frequency of the generator remains higher than

the programmed threshold for the entire intervention

delay time.

225 G.S. OVERLOAD

WARNING “0 to 120%

(MAX

2400A)

47.5A

(CURR.

TRANSF. 50/5)

0 to 30 20 NO NO DOES NOT STOP

The current of the generator remains higher than

the programmed threshold for the entire intervention

delay time.

226 G.S. OVERLOAD “0 to 120%

(MAX

2400A)

50A

(CURR.

TRANSF. 50/5)

0 to 30 10 YES YES YES WITH

STOP

227 G.S. DOES NOT

SUPPLY POWER “= = 0 to 180 60

YES NO YES WITHOUT

STOP

The generator does not supply power for the entire

intervention delay time.

230 INCORRECT

G.S. PHASE

SEQUENCE

“= = = =

NO DOES NOT STOP

The connections of the mains phases are incorrect.

The generator contactor is not closed (no programming

is possible).

231 G.S. ASYMME-

TRY OUT OF

RANGE

“5 to 20% 15% 1 to 600% 15 YES YES STOPS The percentage difference of the genset voltages

remains above the programmed threshold for the

entire intervention delay time (the generator contactor

opens).

419 EMERGENCY

STOP “= = = = = NO STOP The emergency button is pressed. (No programming

is possible).

421 AVAILABLE

Fully programmable available fault, see page 20.

440 MEMORY ERROR ALWAYS

ACTIVE = = = = =

DOES NOT STOP

During normal operation the memory is no longer used.

441 MEMORY NOT

INSTALLED “= = = = = The memory is no longer recognized by the control

unit.

443 TABLE OF FUEL

FLOAT INCOR-

RECT

“= = = = =

Just one value is programmed or non-increasing or

decreasing values are programmed

446 TABLE OF

PRESS. OIL

INCORRECT

ALWAYS

ACTIVE = = = = =

447 TEMPERATURE

TABLE INCOR-

RECT

“= = = = =

444 INSUFFICIENT

WATER PRES-

SURE

After switch-

ing on

= = = 5YES YES WITH

STOP

The pump water pressure remains lower for the entire

intervention delay time.

445 PUMP WATER

OVERPRES-

SURE

The pump water pressure remains higher for the entire

intervention delay time.

449 WATER TRANS-

MITTER DISCON-

NECTED

ALWAYS

ACTIVE = = = 60 YES NO WITH

STOP

The pressure transmitter circuit is disconnected.

N. B.: all the programming settings are to be carried out with the engine stopped. FAULT CODES: ALARM 111-112-113-114 (see page 8). THE ALARM FAULT CODES

500–501 – 502 – 503 – 504 are describe in the modem attachment (B).

BATTERY

OVERVOLTAGE

BATTERY

UNDERVOLTAGE

16 V

NO STOP

11 V

2 s

16 V

NO STOP

11 V

2 s

BATTERY OVERVOLTAGE. By factory default, the protection device is programmed not to cause a stop. Non-adjustable intervention delay of 5 sec.

Press when the arrow is

next to the parameter to be modied.

Press when the arrow is

next to the parameter to be modied.

Threshold

Threshold

Stop

of engine

With Stop

NO STOP

Increases

Without Stop

STOP

Decreases

Delay

in intervention

ENGINE PROGRAMMING SETTINGS

BATTERY UNDERVOLTAGE. Does not stop the engine.

Press to

display.

Press to

display.

Press and wait for

the system to write

PROGRAMMED.

Press and wait for

the system to write

PROGRAMMED.

ELCOS SRL - Parma - CEM-120 – PROG – EN 13

Factory

setting

NORMAL

OPERATION

REVERSED

OPERATION

NORMAL

OPERATION

NORMAL

OPERATION

REVERSED

OPERATION

CHOICE OF RADIATOR FLUID LEVEL PROBE.

DESCRIPTION

CHOICE OF PROBES

CHOICE OF PROBES

CHARGING ALTERN.

ANOMALY

NUMBER OF STARTUP

ATTEMPTS

OIL PRESSURE LOW

WARNING

START WITH

FLAT BATTERY

RADIATOR

LEVEL PROBE

NO

FUEL

95°C

NO STOP

NO STOP

100°C

PROGRAM ONE LEVEL AT A TIME

ENGINE OVERTEMPERATURE WARNING.

CHARGING ALTERNATOR FAULT. It is possible to program the stop; by factory default it is programmed to stop.

NUMBER OF ATTEMPTS TO START. 10 attempts to start can be programmed. (Failure to start).

LOW OIL PRESSURE WARNING. (The pressure measured by the pressure transmitter). This is programmed as notication and does

not stop the engine. (The low pressure detected by the pressure switch causes the engine to stop).

STARTING OF GENERATOR SET WITH BATTERY WITH LOW CHARGE. (With control unit in automatic mode). Starts or stops the

generator set depending on the voltage measured at the battery terminals.

FUEL RESERVE. Does not stop the engine.

FUEL FINISHED. It is possible to program the stop; by factory default it is programmed to stop.

OVERTEMPERATURE.

Press when the arrow is

next to the parameter to be modied

Press when the arrow is

next to the parameter to be modied

Press when the arrow is

next to the parameter to be modied.

Press when the arrow is

next to the parameter to be modied

Press when the arrow is

next to the parameter to be modied

Press to choose.

Press when the arrow is

next to the parameter to be modied

Press when the arrow is

next to the parameter to be modied

Press and wait for

the system to write

PROGRAMMED.

THIS IS

DISPLAYED

ON THE DISPLAY

THIS IS

DISPLAYED

ON THE DISPLAY

Press to

display.

Stop

of engine

Delay

in intervention

Delay

in intervention

Delay

in intervention

Stop

of engine

Stop

of engine

Decreases

Number

of attempts

Increases

INTERVENTION DUE TO ENGINE OVERTEMPERATURE. The temperature is measured by the (TEMPERATURE) TRANSMITTER and is

programmable. The protection device can be set on two levels and intervenes when these are exceeded. The warning level is

programmed only as notication, the other level is programmed to stop the engine (the overtemperature is also detected by the

thermostat that always causes the engine to stop).

Threshold

Threshold

Minimum threshold Maximum threshold

Threshold

Threshold

STOP

RADIATOR

CORE

IN THE ABSENCE OF

LIQUID, REMOVESTHE

GROUND SIGNAL

THE CONTROL UNIT IS

PROGRAMMED FOR

NORMAL OPERATION

RADIATOR

CORE

IN THE ABSENCE

OF LIQUID,

ACTIVATESTHE

GROUND SIGNAL

• FUEL

RESERVE (10%)

• FUEL

FINISHED (1%)

95°C/203°F

NO STOP

100°C/212°F

1%

3 s.STOP

0.5Bar/500Kpa

1 s

12.4Volt 13.6

1200 s 12.4Volt 13.6

1200 s

0.5Bar

1 s

1%

3 s STOP

Press to

display.

Press to

display.

Press to

display.

Press to

display.

Press to

display.

Press to

display.

Press and wait for

the system to write

PROGRAMMED.

Press and wait for

the system to write

PROGRAMMED.

Press and wait for

the system to write

PROGRAMMED.

Press and wait for

the system to write

PROGRAMMED.

Press and wait for

the system to write

PROGRAMMED.

Press and wait for

the system to write

PROGRAMMED.

Press and wait for

the system to write

PROGRAMMED.

Press to

display.

OVERHEATING

WARNING

OVERHEATING

ENGINE

44

ELCOS SRL - Parma - CEM-120 – PROG – EN

14

GENERATOR PROGRAMMING

GENERATOR UNDERVOLTAGE. The protection device is activated when the generator voltage steadily stays higher than the

programmed value for 10 seconds. The preset threshold is 335V with intervention delay of 3 seconds.

GENERATOR VOLTAGE PRESENT. The generator contactor closes when the voltage steadily

remains above the programmed threshold for the entire generator connection to power user delay time.

GENERATOR UNDERFREQUENCY.

By factory default, the protection device is switched off. To activate it, you must program an intervention frequency

different from 0 Hz. The protection device is activated when the generator frequency steadily stays higher than the

programmed value for 10 seconds.

GENERATOR OVERFREQUENCY.

The factory set threshold is 60 Hz, suitable for 50 Hz systems. In the event of

OVERFREQUENCY, the engine is stopped. The stop is not programmable.

GENERATOR OVERVOLTAGE. It is factory programmed to stop.

G.S.

UNDERVOLTAGE

G.S. VOLTAGE

PRESENT

G.S.

UNDERFREQUENCY

G.S.

OVERFREQUENCY

G.S.

OVERVOLTAGE

Press when the arrow is

next to the parameter to be modied

Press when the arrow is

next to the parameter to be modied

Press when the arrow is

next to the parameter to be modied

Press when the arrow is

next to the parameter to be modied

Press when the arrow is

next to the parameter to be modied

Press and wait for

the system to write

PROGRAMMED.

Delay

in intervention

Delay

for connection

Delay

in intervention

Delay

in intervention

Delay

in intervention

Stop

of engine

Stop

of engine

Stop

of engine

Without stop

STOP

Without stop

STOP

Without stop

STOP

Without stop

STOP

With stop

NO STOP

With stop

NO STOP

With stop

NO STOP

With stop

NO STOP

Threshold

Threshold

Threshold

Threshold

Threshold

355 V

7 s

45 Hz

5 s STOP

60 Hz

2 s

440 V

3 s STOP

355 V

7 s

335 V

3 s STOP

335 V

3 s STOP

45 Hz

5 s STOP

60 Hz

2 s STOP

440 V

3 s STOP

Press to

display.

Press to

display. Press and wait for

the system to write

PROGRAMMED.

Press to

display. Press and wait for

the system to write

PROGRAMMED.

Press and wait for

the system to write

PROGRAMMED.

Press to

display.

Press and wait for

the system to write

PROGRAMMED.

Press to

display.

ELCOS SRL - Parma - CEM-120 – PROG – EN 15

GENERATOR OVERLOAD WARNING.

PUMP WATER OVERPRESSURE. Factory setting: differential 2 bar.

It is possible to program: the differential is adjustable 1-1.5-2-2.5-3-3.5. For a working pressure between 1 and 4 bar, the

overpressure differential is xed at 1 bar.

GENERATOR OVERLOAD.

GENERATOR DOES NOT SUPPLY POWER.

The generator does not supply power for the entire intervention delay time.

GENERATOR ASYMMETRY OUT OF RANGE. Asymmetry percentage higher than the set threshold.

This unbalance is the increase and decrease of the voltage of two phases compared to the voltage of another phase.

GENERATOR OVERCURRENT. The protection device can be set on two levels and intervenes when these are exceeded.

It does not replace the overload switch. The warning level acts only as notication, whereas the other level can be

programmed to stop the engine.

For example, if transformer 100/5 is chosen, the factory setting of the overcurrent triggers the intervention at 100A, but only when

the current transformer withstands this current.

PUMP PROGRAMMING

G.S. OVERLOAD

WARNING.

DIFFERENTIAL

OVERPRESSURE

G.S.

OVERLOAD

G.S.

DOES NOT SUPPLY

G.S. ASYMMETRY

OUT OF LIMIT

Press when the arrow is

next to the parameter to be modied

Press when the arrow is

next to the parameter to be modied

Press when the arrow is

next to the parameter to be modied

Press when the arrow is

next to the parameter to be modied

Press to choose

Delay

in intervention

Delay

in intervention

Stop

of engine

Stop

of engine

Decreases

Decreases

Without stop

STOP

Without stop

STOP

Increases

Increases

With stop

NO STOP

With stop

NO STOP

Threshold

Threshold

Percentage

...A

20 s STOP

2.0 BAR

...A

10 s STOP

60 s NO STOP

15%

15 s

...A

20 s

3.5 BAR

...A

10 s STOP

60 s NO STOP

15%

15 s

Press and wait for

the system to write

PROGRAMMED.

Press to

display.

Press to

display. Press and wait for

the system to write

PROGRAMMED.

Press and wait for

the system to write

PROGRAMMED.

Press to

display.

Press to

display. Press and wait for

the system to write

PROGRAMMED.

Press and wait for

the system to write

PROGRAMMED.

Press to

display.

ELCOS SRL - Parma - CEM-120 – PROG – EN

16

CHOICE OF ALREADY PROGRAMMED TEMPERATURE AND PRESSURE TRANSMITTERS

CHOICE OF

TEMP. TRANSM.

CHOICE OF

PRESSURE TRANSM..

TTAO/402.

TTAO/403.

VEGLIA

VDO/120.

VDO

JCB 1707.

VDO/150.

VDO/29/10

LOMBARDINI.

BERU

LOMBARDINI

PROGRAMM.

F 16173

PROGRAMM.

Press to

choose

Factory setting

Press to

choose

TABLE OF ALREADY PROGRAMMED PRESSURE TRANSMITTERS

0

BAR

1

BAR

2

BAR

3

BAR

4

BAR

5

BAR

6

BAR

7

BAR

8

BAR

9

BAR

OHM

TPO/403 270 251 203 157 114 79 52

VDO 10 50 85 119 152

VDO/29/10 9 38 57 77 99 114 134 149 164 180

Fitted on

engine:

Lombardini

10 31 52 71 90 107 124 140 156 170

Press to

display

choice of

pressure

transmitters.

Press and wait for

the system to write

PROGRAMMED

PROGRAMMABLE

PRESSURE

TRANSMITTER

Press and wait for

the system to write

PROGRAMMED

PROGRAMMABLE

TEMPERATURE

TRANSMITTER

Press to

display

choice of temperature

transmitters.

Factory setting

TABLE OF ALREADY PROGRAMMED TEMPERATURE TRANSMITTERS

25°C 50°C 70°C 80°C 85°C 90°C 95°C 100°C 120°C 130°C

OHM

TTAO/402 896 365 196 145 127 110 97 85 53

VDO/120 548 287 95 69 59 51 44 38 22 17

VDO/150 498 323 183 113 96 83 73 62 37 29

BERU 1100 567 395 319 278 227 165

VEGLIA 708 399 245 210 175 153 130 75 59

JCB 1707 503 200 105 78 67 59 51 45

Fitted on

engine:

Lombardini

927 322 155 112 96 83 71 62 36 29

F 16173

Fitted on

engines:

AIFO

834 436 322 280 243 213 187 113 89

ELCOS SRL - Parma - CEM-120 – PROG – EN 17

PROGRAMMING OF THE OHMIC VALUES OF THE TEMPERATURE AND PRESSURE TRANSMITTERS

(PROBES)

WARNING: It is necessary to program at least 2 values (to obtain good precision in the control of temperature

and pressure, we recommend programming at least 4 values).

If just one value is programmed or non-monotone values are programmed, the fault is detected.

OIL TEMP. TABLE

NOT CORRECT OR

OIL TEMP. TABLE

NOT CORRECT .

25 °C

- - - OHM 1 BAR

- - - OHM

3 BAR

155 OHM

90 °C

110 OHM

Example

Example

°C BAR

25 50 70 80 85 90 95 100 120 130 0.0 1 2 3 4 5 6 7 8 9

WRITE THE RESISTIVE VALUES

OHM

TEMPERATURE TRANSMITTERS PRESSURE TRANSMITTERS

Decreases Increases Decreases Increases

By factory default, the control unit is set for pressure and temperature transmitters TYPE TPO/403 (Pressure),

TTAO/403 (Temperature). It is possible to program 10 resistive values, corresponding to the characteristic curves of

other temperature and pressure transmitters.

PROGRAMMING OF CORRESPONDENCE

TECHNICAL PROGRAMMING

Press to

display.

Press and hold

and wait for the

system to write

PROGRAMMED.

Press

briey

to display the

programming settings

carried out.

Press to

display.

Press and hold

and wait for the

system to write

PROGRAMMED.

Press briey

to display the

programming settings

carried out.

TEMPERATURE TRANSMITTERS

TO BE PROGRAMMED

PRESSURE TRANSMITTERS

TO BE PROGRAMMED

ELCOS SRL - Parma - CEM-120 – PROG – EN

18

PROCEDURE FOR SWITCHING INSTRUMENTS AND FUNCTIONS ON AND OFF

Instruments and functions can be switched on or off using the following procedures.

KVOLTAMMETER

ENGAGED

OFF KVOLTAMMETER

W

Press to choose.

Press to

display.

Factory setting

MANAGEMENT

OF FUEL W

PROGRAMMABLE

FLOAT

FUEL

To program or change

the already programmed values, see

FUEL FLOAT PROGRAMMING

EXAMPLE

EXAMPLE

SWITCHING OFF OF INSTRUMENTS

(See above procedure)

Measurements produced by the

control unit CEM-120

FACTORY PROGRAMMING

SETTINGS

ON OFF

WATTMETER •

VARMETER •

VOLTAMMETER •

POWER FACTOR METER •

KILOWATT-HOUR •

TACHOMETER •

THERMOMETER •

OIL PRESSURE GAUGE •

PROGRAMM.

CHOICE OF ALREADY PROGRAMMED FUEL FLOAT

VEGLIA

VDO

DATCON

W

Press

to choose.

FLOAT LEVEL IN

TANK

OHM

VEGLIA

(factory setting)

FULL 0

FREE 300

VDO FULL 150

FREE 0

DATCON FULL 37

FREE 240

CHOICE OF

FUEL FLOAT

CHOICE OF FUEL FLOAT. The control unit is programmed for a oat with rheostat, suitable for

FUEL LEVEL indication.

MANAGEMENT OF FUEL W

It is possible to program the use of a

oat with contact that closes to

ground when there is no fuel.

PROGRAMMING OF OHMIC VALUES OF FUEL FLOAT

It is possible to program 10 resistive values,

corresponding to the characteristic curves

of other oats.

PROGRAMMING OF CORRESPONDENCE

FLOAT TO BE PROGRAMMED

50%

- - - OHM

50%

- - - OHM

OHM

0% 10 20 30 40 50 60 70 80 90 100%

WRITE THE RESISTIVE VALUESWRITE THE RESISTIVE VALUES

Decreases Increases

WARNING: It is necessary to program

at least 2 values (to obtain good

precision in the control of the fuel, we

recommend programming at least 4 values).

If just one value is programmed or

non-monotone values are programmed, the

fault is detected

.

INCORRECT

FUEL FLOT TABLE

OHM

Press briey

to display

the programming

carried out.

Press to

display the function and the

instrument to be switched off.

Press to

display.

Press and wait for

PROGRAMMED to be

displayed.

Press and wait for

PROGRAMMED to be

displayed.

Press and hold

and wait for the

system to write

PROGRAMMED.

ELCOS SRL - Parma - CEM-120 – PROG – EN 19

SWITCHING OFF OF FUNCTIONS (See procedure on previous page)

ON OFF

•

MAN MODE (MANUAL)

AUT MODE (AUTOMATIC) •

OFF MODE (LOCKED) •

BATTERY UNDERVOLTAGE •

BATTERY OVERVOLTAGE •

OVERTEMPERATURE WARNING •

ENGINE OVERTEMPERATURE (Measured by the temperature transmitter) •

LOW OIL PRESSURE WARNING •

FAILURE TO STOP •

START WITH FLAT BATTERY •

G.S. UNDERVOLTAGE •

G.S. OVERVOLTAGE •

G.S. UNDERFREQUENCY •

G.S. OVERLOAD WARNING •

G.S. OVERLOAD •

G.S. DOES NOT SUPPLY POWER •

INCORRECT G.S. PHASE SEQUENCE •

G.S. ASYMMETRY OUT OF RANGE •

STAND BY •

PICK UP DISCONNECTED •

SENDING OF SMS AT EACH START AND STOP - an SMS message is sent for each automatic

start-up or stop •

SMS ON CHANGING TO AUT MODE •

SMS ON CHANGING TO OFF MODE •

SMS ON RESETTING CYCLIC MAINTENANCE - see description in modem attachment (B) •

SMS ON FAULT RESET •

CHARGING ALTERNATOR - for this switching off, also release the deector and carry out the

procedure described on page 5; see ADJUSTMENT OF TACHOMETER WITH GENERATOR

FREQUENCY (switching off to be avoided, incomplete engine running detection)

•

GENERAL ALARM - switching off is possible when this intervenes to warn of an imminent

automatic start-up except for a call start-up. It cannot be switched off when the intervention is caused

by a fault.

•

12 24

VOLT

CHOICE OF CURRENT TRANSFORMER

It is possible to select current transformers from 30/5 up to 2000/5.

EXAMPLE

Press

to choose the value of the current

transformer.

AMP. TRANSFORMER

50/5

AMP. TRANSFORMER

100/5

G.S. OVERLOAD

WARNING

G.S.

OVERLOAD

95A

100A

PROGRAMMED

AUTOMATIC CALIBRATION (A. C.)

• GENERATOR OVERLOAD WARNING

• GENERATOR OVERLOAD

After the A. C. is programmed, the thresholds are automatically

adjusted.

The WARNING threshold is set at 95%,

the overload threshold is set at 100% of the nominal value of the

A. C.

To change the thresholds manually, refer to page 15

Press and wait for

the system to write

FAULT LOG

To reset press

simultaneously and

wait for the system

to write PROGRAMMED.

ANOMALIES

OCCURRED N 12 h1501 20-05-

2014 17:30

LOW OIL

PRESSURE

RESET

LOG?

Press to

display.

Number

(progressive)

of faults

that have occurred

Date

Hour

meter

of engine

Time

Decreases Increases

(Example) COMPLETE RESET OF THE LOG

RESET

LOG?

The data of the last 100 faults that have stopped the engine are collected.

Press to

display.

ELCOS SRL - Parma - CEM-120 – PROG – EN

20

HOW TO WRITE

Press to move the cursor

- Press to write

- Press and hold until a segment

is deleted

press and hold to delete completely

(1)

(1)

(1)

(1)

(1)

EXAMPLE

(can be set from 0 to 60 s)

PROGRAMMING OF AVAILABLE FAULT

MOD BUS GSM PARAMETERS

POLARITY

ACTIVATION

INTERVENTION

DELAY

MEMORY

Press

to change the functions and the

intervention delay.

ANOMALY

TEXT

THE NEW DESCRIPTION OF THE FAULT IS NOT TRANSLATED.

STOP NO STOP

NOT

STORED

POLARITY

ACTIVE AT GROUND

ALWAYS

ACTIVE

0 s

STOP

STORED

POLARITY

ACTIVE OPEN

ACTIVE

RUNNING

(1) FACTORY

SETTINGS

NOTE the interventions always

activate the general alarm.

Press and wait for

PROGRAMMED to be

displayed.

BOARD

ADDRESSES

BAUDRATE

CONNECTION

WITH

1

9600 BPS

MOD Bus

1

9600 BPS

MOD Bus

BAUDRATE. Select 4800/9600/14400/19200/28800/34400.

Programming of telephone numbers of users to be notied when the machine is in alarm condition. See "Sending SMS messages" in the MODEM manual

CARD ADDRESS. Up to 9 cards (control units) can be addressed.

SERIAL PORT RS232. MOD BUS - GSM - MODEM -

Select GSM 9600 bps to activate the connection with the telephone number to be notied when the G.S. is in alarm condition.

Press when the arrow is

next to the parameter to be modied.

Press when the arrow is

next to the parameter to be modied.

Factory programming setting

Factory programming setting

Factory programming setting

Factory programming setting

Or

GSM

MODEM

- 2 - 3

Or

TELEPHONE 1

TELEPHONE 1

333 TELEPHONE 1

333123456

Cursor No. of user

Example

Mobile phone number

Press to

move the cursor.

Press to

write the number.

CODE FOR RESETTING OF CYCLIC MAINTENANCE: with your mobile phone, write 006 or SERVICE.

Press and wait for

the system to write

PROGRAMMED.

Press and wait for

the system to write

PROGRAMMED.

Press and wait for

the system to write

PROGRAMMED.

Press to choose.

Press to choose.

Press to

display.

Press to

display.

Press and wait for

the system to write

PROGRAMMED.

Press and wait for

the system to write

PROGRAMMED.

Press to

display.

Press to

display.

Press to

display.

FAULT

SMS

33

FAULT SMS. Number of times a fault SMS will be sent in the event that no “OK” reply is received : 0 to 10.

Table of contents

Other ELCOS Controllers manuals

Popular Controllers manuals by other brands

SEW-Eurodrive

SEW-Eurodrive DHF41B manual

Charles

Charles T1 installation guide

CNC4PC

CNC4PC PLASMA THC-3 user manual

Carel

Carel ir33+ VCC Series quick start guide

Watts Industries

Watts Industries Tekmar tekmarNet2 House Control 400 Quick setup guide

RTK

RTK CIRCOR REact60E Series Installation and operating instructions