Prozone PZ7 User manual

T.O3 NATURAL TECHNOLOGY

Reduces Chemical Usage,

Improves Sanitation

Produces Crystal Clear Water

Prozone Water Products: 2610 6th Street SW ·Huntsville, AL 35805 ·256-539-4570 ·www.prozoneint.com

Copyright 2007

PZ7

Ozone Generator Systems

INSTALLATION GUIDE and

OPERATION MANUAL

- Residential Pools up to 40,000 Gallons

20352-1

2

IMPORTANT SAFETY INSTRUCTIONS

Read and Follow All Safety Instructions

WARNING: Disconnect all power to pool equipment prior to installation, maintenance,

or removal of the PZ7.

WARNING: Do not permit children to operate this product

WARNING: To avoid risk of electric shock, fire, or injury, service should only be performed

by a qualified pool service professional.

WARNING: Installation must be performed in accordance with the National Electric Code

and any applicable local or state installation codes.

WARNING: When mixing acid with water, ALWAYS ADD ACID TO WATER, NEVER

WATER TO ACID.

SAVE THESE INSTRUCTIONS

PZ7

• Read and be familiar with this manual before installing or operating your new PZ7.

• Voltage must be determined before unit is installed.

• Replace damaged cord immediately.

• Do not bury cord.

• Connect only to a properly grounded, grounding type receptacle.

• Install at least 5 feet from the inside wall of the pool using non-metallic plumbing. The ozone generator is to be

located one foot above the maximum water level to prevent water from contacting electrical equipment. Install to

provide drainage of compartment for electrical components.

• Wear safety glasses when drilling and tapping holes for installation of unit.

WARNING: Short term inhalation of high concentrations of ozone and long term inhalation of low concentrations of ozone

can cause serious harmful physiological effects. Do not inhale ozone gas produced by this device.

NOTE: The instructions in this document provide general installation guides. Consult your dealer for specific installation instructions.

Additional information is available at www.prozoneint.com. Check system for any visible shipping damage. If damage has occurred,

contact the delivery company and your dealer immediately. Before beginning installation, please turn to the Installation Kit Inventory

Section and verify that all listed parts are on hand.

Tools Needed: Power Drill with 7/8” hole saw, Screw Driver, Pliers, Knife

PZ7

Installation

3

INTRODUCTION TO OZONE

The Prozone system produces ozone when air is drawn across a special high-energy vacuum ultraviolet (VUV) lamp, converting some air to

ozone. A venturi injector is inserted on the return line, by-passing water back into the return line of the pool which creates suction that draws

the ozone into the venturi, mixing the bubbles as the water returns to the pool. It is operated automatically by connecting the Prozone system

directly to the circulation pump or plugging into a timer. A check valve is employed to prevent water back up in the event of system failure. A

siphon loop is recommended for added backpressure resistance. The system should run 8-12 hours per day for good results; 24 hours per day

for optimum water clarity and minimum chemical usage.

Although ozone is mainly thought of as a sanitizer, it acts primarily as an oxidizer in the pool environment. In a typical pool, using chlorine only,

up to 90 percent of the chlorine may be used up in reactions unrelated to disinfection. The byproducts of these reactions are combined chlorines.

Combined chlorines are the cause of eye irritation, odor, and the other unpleasant side effects of chlorination. When ozone is used, it oxidizes a

large portion of the contaminants (usually referred to as bather load) which results in the formation of combined chlorines. The result is that more

chlorine is available for disinfection and less chlorine is required to maintain the pool. Ozone also provides some disinfection, but an ozone

residual cannot be established, so the use of chlorine or bromine is always recommended. Baquacil may also be used in conjunction with the

Prozone system for water sanitation. Refer to the Baquacil manual for shocking instructions.

PREPARING FOR INSTALLATION

1.

2.

3.

4.

5.

Check for and correct all leaks in plumbing.

Balance the pH.

Backwash the filter on retrofit installation.

Shock the pool. The use of Calcium Hypochlorite is recommended, or hydrogen peroxide if Baquacil is used.

CAUTION: Make sure voltage is the same as prescribed on the side of the Prozone Ozone Generator.

The Table below summarizes the levels that are recommended by The Association of Pool and Spa Professionals

(APSP). It is important to maintain these levels in order to prevent corrosion or scaling and to ensure maximum enjoyment

of the pool. Test your water periodically. Take a water sample in to be professionally tested by a Pool and Spa

Professional at least once a month. See our web site for more information on Basic Pool Water Chemistry.

pH 7.2 – 7.6

Alkalinity 80 – 120 ppm

TDS < 1,000

Cyanuric Acid 30 – 70 ppm

Free Chlorine 0.5 – 1.5 ppm

Calcium Hardness 60 – 400 ppm

Metals 0 ppm

Nitrates / Phosphates < 30 ppm

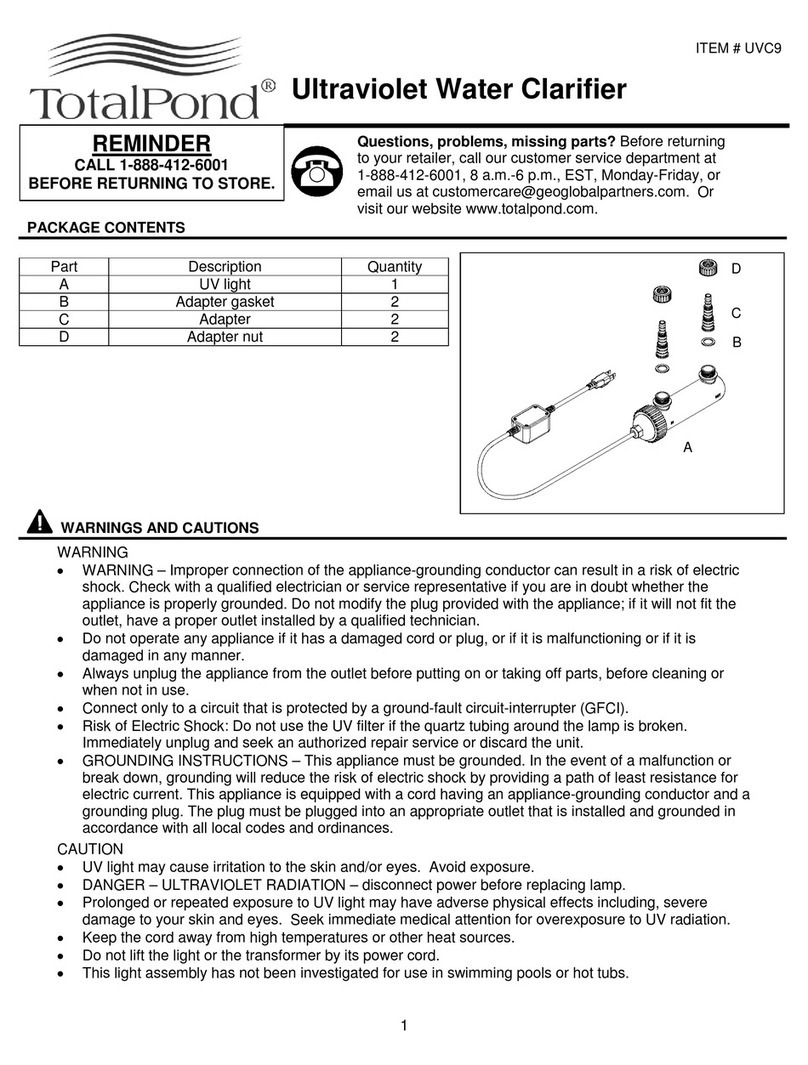

SADDLE CLAMP ASSEMBLY

Note: For 2” pipe, do not use 1-1/2” adapters

and gasket and turn Bushings so small end

points toward Injector (for Entrance)

or PVC Pipe (for Exit).

For bypass Entrance, (before Ball Valve)

Using 1-1/2” pipe, Assemble:

Venturi Injector (Note direction)

Saddle Clamp Top & Bottom

Top & Bottom Adapters

Bushing (Note direction)

Gasket

Screws (2)

Nuts (2)

For bypass Exit, (after Ball Valve)

Using 1-1/2” pipe, Assemble:

PVC Pipe

Saddle Clamp Top & Bottom

Top & Bottom Adapters

Bushing (Note direction)

Gasket

Screws (2)

Nuts (2)

Venturi Injector

(600002)

Screw (2)

(201863)

Saddle Clamp Top

(201155-4)

Saddle Clamp Bottom

(201155)

Bushing

(201155-5)

Top Adapter

(201155-2)

Bottom Adapter

(201155-3)

Gasket

(400076)

7/8” Dia. Hole

1/4-20 Nut (2)

(20703)

PVC Pipe

(20314)

Screw (2)

(201863)

Saddle Clamp Top

(201155-4)

Saddle Clamp Bottom

(201155)

Bushing

(201155-5)

Top Adapter

(201155-2)

Bottom Adapter

(201155-3)

Gasket

(400076)

7/8” Dia. Hole

1/4-20 Nut (2)

(20703)

4

PZ7

Saddle Clamp Installation

CAUTION: Make sure the voltage is the same as prescribed on the side of the Prozone ozone generator. Overvoltage will void

customer warranty.

7/8” Hole Saw

INSTALLATION ASSEMBLY USING

P15 SADDLE CLAMP KIT

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

Turn pump OFF.

Locate section of existing plumbing in which you choose to install the ENTRANCE leg of the bypass. Location should be in any

accessible area after the pump, but before the filter.

Install Saddle Clamp Top & Bottom, (and adapters if needed), without Bushing, (this will be used as a guide for your installation hole).

Drill a 7/8” hole through one wall of the pipe, using power drill, being careful not to drill too deep to avoid penetrating the opposite side

of the plumbing.

Locate section of existing plumbing in which you choose to install the EXIT leg of the bypass. Location should be in any accessible

area after the filter, and heater (if equipped).

Repeat steps 3 & 4.

Remove both Saddle Clamp Assemblies.

Using components listed, mount one Saddle Clamp Assembly on Entrance bypass location with the INLET side of the Venturi Injector

mounted in the Saddle Clamp Bushing, (ozone ports should be facing upward). Tighten both screws.

Using components listed, mount the other Saddle Clamp Assembly on Exit bypass location with the ½” x 3” PVC pipe mounted in the

Saddle Clamp Bushing. Tighten both screws.

Attach one end of ¾” clear hose to Venturi Injector and secure with a metal clamp. Attach other end of ¾”clear hose to ½” x 3” PVC

pipe and secure with a metal clamp.

Mount the PZ7 Ozone Generator on a wall or surface at least 1 foot above maximum water level to prevent water from contacting the

electrical equipment. Unit orientation will not affect performance.

Electrical Installation: Your Prozone PZ7 System is designed to operate on either 120 or 240 VAC, 50/60 HZ. Wire Prozone Ozone

Generator system to circulation pump switch or timer. Prozone system and circulation pump should be started simultaneously. Use

N.E.C. or local code grounding and installation procedures for swimming pool equipment.

NOTE: If your filtration system uses a Diatemateous Earth (DE) or cartridge filter, install a ¾” Ball Valve (not included) in the ¾” Hose on the

output side of the Venturi Injector as shown. This allows the bypass to be closed when back flushing or adding DE. It may be necessary to

install a Ball Valve (not included) in the main line between the Entrance and Exit of the bypass, (entire installation is moved after filter or heater

if equipped). The Ball Valve will need to be adjusted to ensure adequate flow through the bypass.

Pump

Filter Heater

Pool

Bypass

Entrance

¾” Hose

Bypass

Exit

¼” Hose

Check Valve

¾” Ball Valve

(If using a DE filter)

Venturi Injector

¼” Hose

PZ7

Cut a 6” length of ¼” Polybraid Hose and connect one end to the open ozone port (Marked #1) on the Venturi Injector and the other

end to the OUTLET side of the Check Valve, (Make sure you can blow air through the Check Valve towards the Injector port). Secure

both ends with black plastic clamps.

Connect the remaining section of ¼” Polybraid Hose to the INLET side of the Check Valve and the other end to the barb on the side of

the PZ7 Ozone Generator. Secure both ends with black plastic clamps.

5

PZ7

PVC Tees Installation

INSTALLATION ASSEMBLY USING

P11 PVC TEES KIT

CAUTION: Make sure the voltage is the same as prescribed on the side of the Prozone ozone generator. Overvoltage will void

customer warranty.

Pump

Filter Heater

Pool

Bypass

Entrance

¾” Hose

Bypass

Exit

¼” Hose

Check Valve

¾” Ball Valve

(If using a DE filter)

Turn pump OFF.

Locate section of plumbing in which you choose to install the ENTRANCE leg of the bypass. Location should be in any accessible

area after the pump, but before the filter.

Install a PVC Tee that has ¾ FPT, with the threaded portion of the Tee facing upward.

Locate section of plumbing in which you choose to install the EXIT leg of the bypass. Location should be in any accessible area

after the filter, and heater (if equipped).

Install a PVC Tee that has ¾ FPT, with the threaded portion of the Tee facing upward.

Apply Teflon tape to the threads of the (2) ¾” MPT x ¾” HB fittings, part number 20678, and screw the fittings into the (2) PVC Tees

you installed in steps 3 and 5.

Cut a 6” length of ¾” hose and connect one end to the fitting on the ENTRANCE side of the bypass, (after the pump, before the

filter), and secure with a metal clamp.

Connect the other end of the 6” hose to the INLET side of the Venturi Injector and secure with a metal clamp.

Attach one end of the remaining ¾” hose to the OUTLET side of the Venturi Injector and secure with a metal clamp.

Attach other end of ¾” hose to the fitting on the EXIT side of the bypass, (after the filter/heater), and secure with a metal clamp.

PVC Tee PVC Tee

Venturi Injector

¼” Hose

PZ7

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

Mount the PZ7 Ozone Generator on a wall or surface at least 1 foot above maximum water level to prevent water from contacting the

electrical equipment. Unit orientation will not affect performance.

NOTE: If your filtration system uses a Diatemateous Earth (DE) or cartridge filter, install a ¾” Ball Valve (not included) in the ¾” Hose on the

output side of the Venturi Injector as shown. This allows the bypass to be closed when back flushing or adding DE. It may be necessary to

install a Ball Valve (not included) in the main line between the Entrance and Exit of the bypass, (entire installation is moved after filter or heater

if equipped). The Ball Valve will need to be adjusted to ensure adequate flow through the bypass.

Cut a 6” length of ¼” Polybraid Hose and connect one end to the open ozone port (Marked #1) on the Venturi Injector and the other

end to the OUTLET side of the Check Valve, (Make sure you can blow air through the Check Valve towards the Injector port). Secure

both ends with black plastic clamps.

Connect the remaining section of ¼” Polybraid Hose to the INLET side of the Check Valve and the other end to the barb on the side of

the PZ7 Ozone Generator. Secure both ends with black plastic clamps.

Electrical Installation: Your Prozone PZ7 System is designed to operate on either 120 or 240 VAC, 50/60 HZ. Wire Prozone Ozone

Generator system to circulation pump switch or timer. Prozone system and circulation pump should be started simultaneously. Use

N.E.C. or local code grounding and installation procedures for swimming pool equipment.

6

PZ7

Inventory Lists & Troubleshooting

INSTALLATION KIT INVENTORY

TROUBLESHOOTING GUIDE

PROBLEM PROBABLE CAUSE REMEDY

Loose wiring Check all wiring connections

No power to unit Check voltage compatibility

Check power source

No light from Prozone unit

Defective lamp or other internal component Return unit to dealer

Excessive back pressure Check for kinks or clogs in hose or plumbing

Leak in fitting Replace fitting

No bubbles from injector or

no evidence of ozone in pool

Filter not working Check filter

Water in Ozone Generator Check Valve failure Verify Check Valve in Venturi is operating properly

Water chemistry out of balance Check readings and balance accordingly

Total Dissolved Solids (TDS) level too high Refer to dealer for proper water testing

Cloudy water; foamy water; scum

Filter not working Clean or replace filter

NOTE: Cloudy water may occur when the ozone generator is started. Filter and backwash as necessary.

P15 Saddle Clamp Installation Kit

P11 PVC Tees Installation Kit

Description

Part Number

Quantity

684 Venturi Injector

600002

1

Plastic Clamp ½”

20185

4

Metal Clamp 1¼”

20067

2

Polybraid Hose ¼”

20260

72”

Clear Vinyl Hose ¾”

20264

96”

Check Valve

20214

1

PVC Pipe ½” x 3”

20314

1

Screw # 8 x ¾” PPSMS

20109

4

Saddle Clamp, Outer Top

201155-4

2

Saddle Clamp, Outer Bottom

201155

2

Saddle Clamp, Inner Top

201155-2

2

Saddle Clamp, Inner Bottom

201155-3

2

Saddle Clamp Gasket

400076

2

Saddle Clamp Bushing

201155-5

2

Screw #14 x 1½” PPMS

201863

4

Nut ¼-20

20703

4

Description

Part Number

Quantity

684 Venturi Injector

600002

1

Plastic Clamp ½”

20185

4

Metal Clamp 1¼”

20067

4

Polybraid Hose ¼”

20260

72”

Clear Vinyl Hose ¾”

20264

96”

Check Valve

20214

1

PVC Fitting 2” SL x ¾” FPT

201095

2

PVC Fitting 2” SP x 1½” SL

201114

4

PVC Fitting ¾” MPT x HB

20678

2

Screw # 8 x ¾” PPSMS

20109

4

This manual suits for next models

1

Table of contents

Popular Water Dispenser manuals by other brands

Wellsys

Wellsys WS 15000 user manual

Master Water Conditioning

Master Water Conditioning MCA Series Installation and operation manual

Honeywell

Honeywell HWBAP1073 Series owner's manual

Water Control Corporation

Water Control Corporation BrassMaster Plus TurfMaster Installation and operation manual

Kenmore

Kenmore ULTRASOFT 625.3888 owner's manual

East Midlands Water

East Midlands Water Harveys Block Salt installation instructions