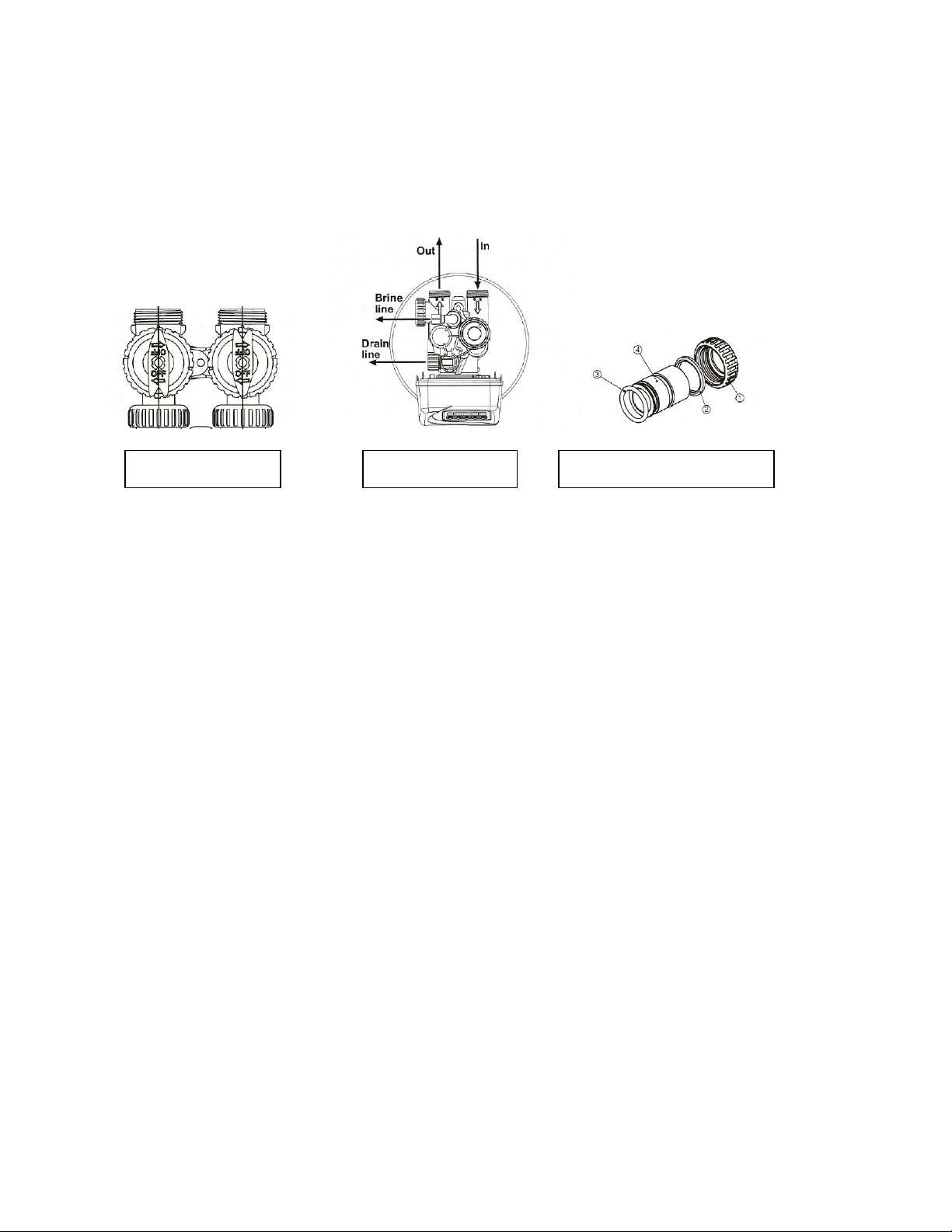

valve. Align the insert connection ends with o’ring seals and

nuts to the inlet and outlet connections of the control valve.

Hand tighten the nuts. DO NOT OVERTIGHTEN THE NUT!

6. Locate the tail piece kit that is packaged with the control valve.

The standard tail piece kit is 1” copper with optional 1” PVC or ¾”

copper kits available as a special order. Each tail piece,

o’ring, split ring and nut is presassembled at the factory. Align a

tail piece assembly to the bypass valve threaded inlet and insert

until the nut can be tightened. Hand tighten the nut because

excessive tightening will damage the assembly. REPEAT THE

PROCEDURE FOR THE OUTLET CONNECTION.

Service and Drain Piping:

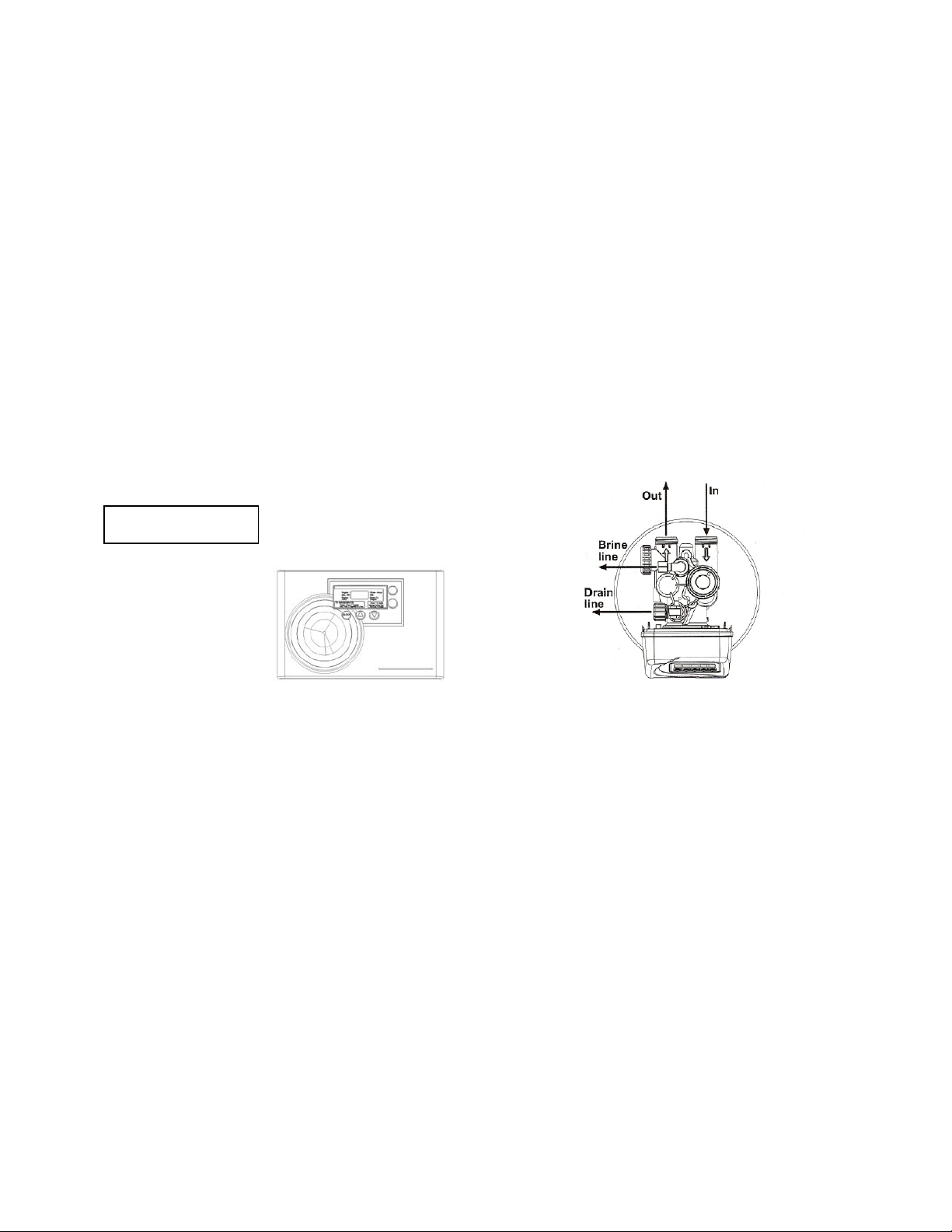

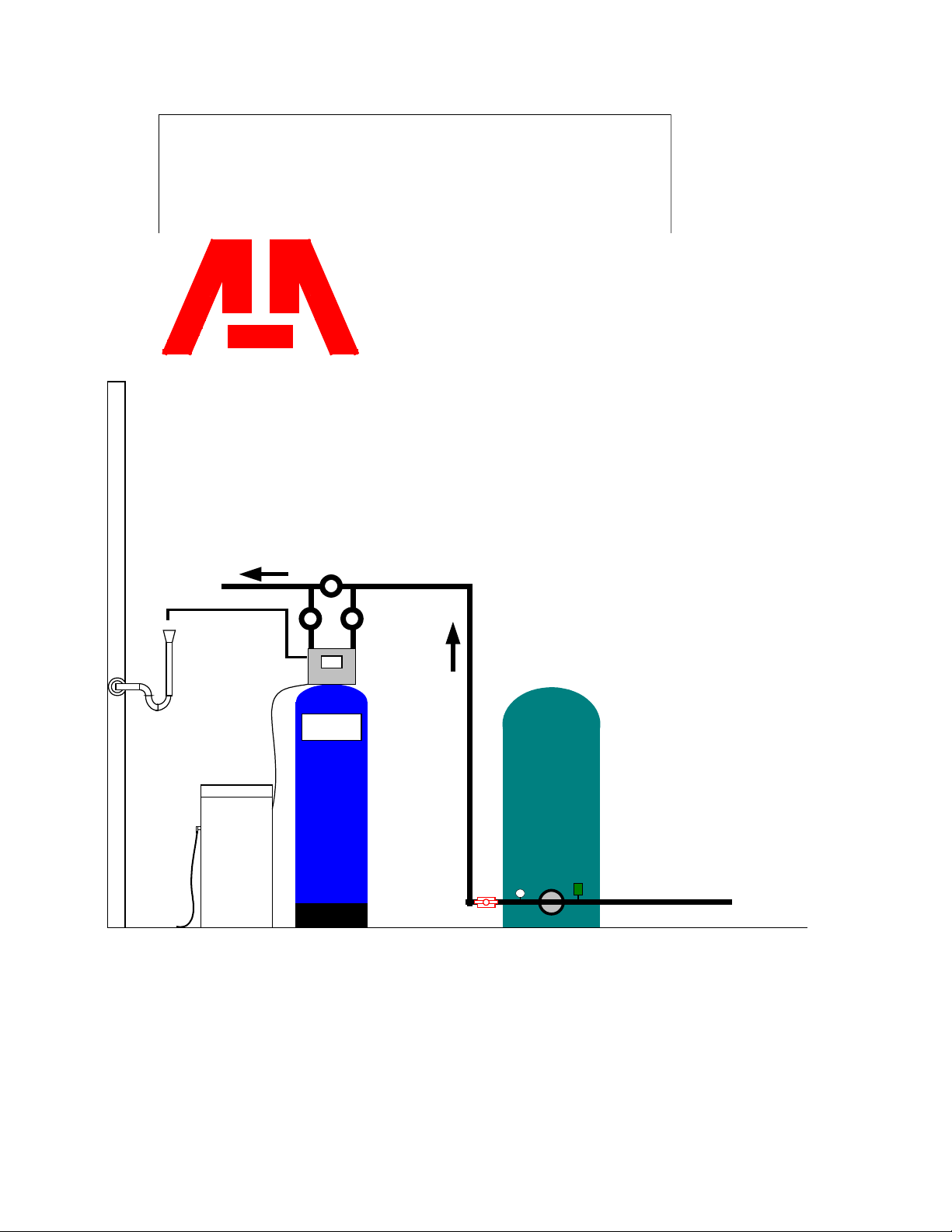

1. Pipe water softener into the service lines .The inlet and outlet

connections of the control valve are 1” copper or PVC and are

located on the back of the valve body. As you face the timer the inlet

is on the right and the outlet is on the left. Always follow local

plumbing codes when installing our water treatment equipment.

2. If sweat fittings are used, be sure soldering is done in such a manner

as not to allow heat to reach the control valve or bypass. (If

Schedule 80 PVC is used make sure to follow the proper primer and

solvent instructions.)

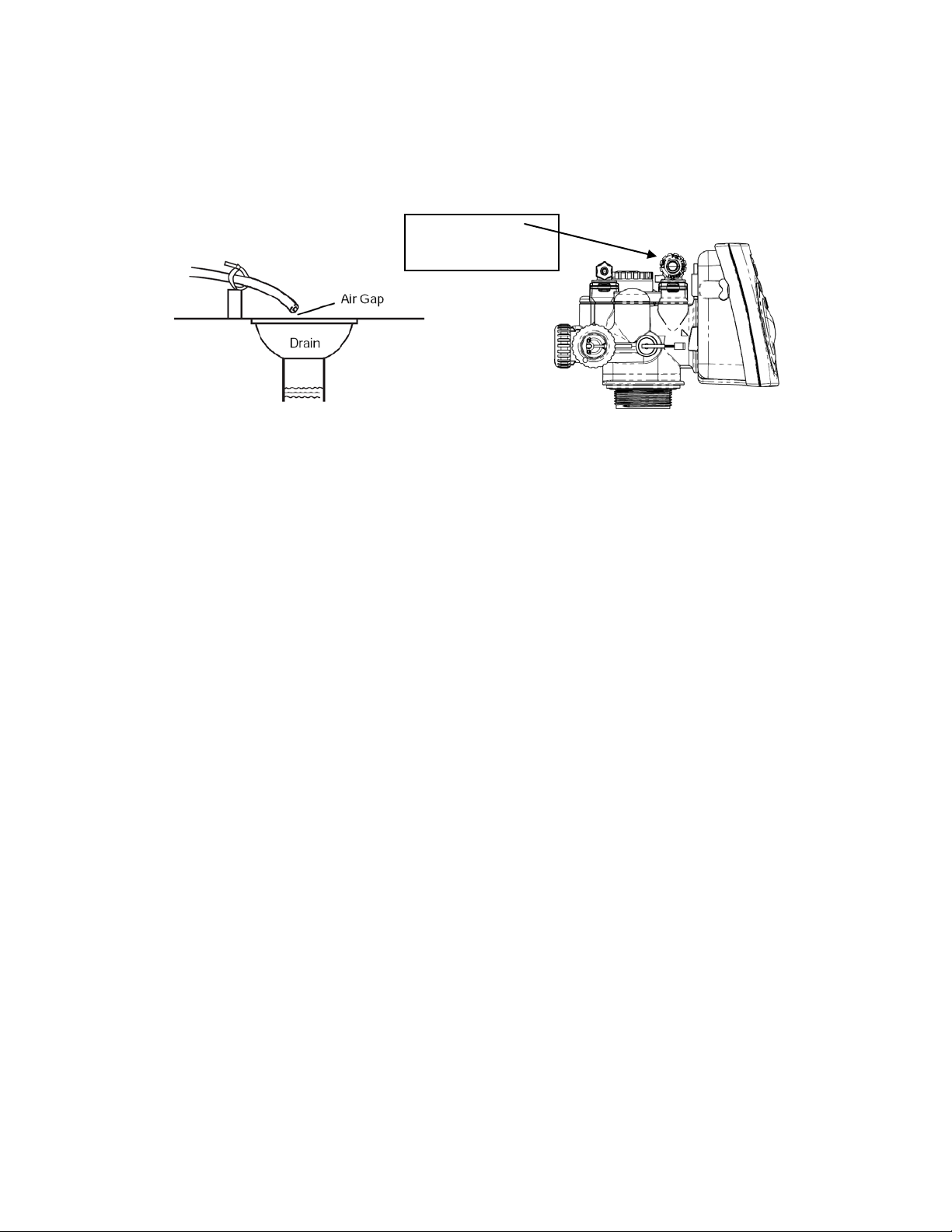

3. The drain line connection is 5/8 OD or ¾” npt and is located on the

top left of the valve as you face the timer. It is recommended you