PSB 3503A1160KG User manual

Model 3503A1160KG

TRIAXIAL HIGH AMPLITUDE MEMS SHOCK ACCELEROMETER

Installation and Operating Manual

For assistance with the operation of this product,

contact the PCB Piezotronics, Inc.

Toll-free: 716-684-0001

24-hour SensorLine: 716-684-0001

Fax: 716-684-0987

E-mail: [email protected]

Web: www.pcb.com

The information contained in this document supersedes all similar information that

may be found elsewhere in this manual.

Service –Due to the sophisticated

nature of the sensors and associated

instrumentation provided by PCB

Piezotronics, user servicing or repair is

not recommended and, if attempted,

may void the factory warranty. Routine

maintenance, such as the cleaning of

electrical connectors, housings, and

mounting surfaces with solutions and

techniques that will not harm the

physical material of construction, is

acceptable. Caution should be observed

to ensure that liquids are not permitted

to migrate into devices that are not

hermetically sealed. Such devices

should only be wiped with a dampened

cloth and never submerged or have

liquids poured upon them.

Repair –In the event that equipment

becomes damaged or ceases to

operate, arrangements should be made

to return the equipment to PCB

Piezotronics for repair. User servicing or

repair is not recommended and, if

attempted, may void the factory

warranty.

Calibration –Routine calibration of

sensors and associated instrumentation

is recommended as this helps build

confidence in measurement accuracy

and acquired data. Equipment

calibration cycles are typically

established by the users own quality

regimen. When in doubt about a

calibration cycle, a good “rule of thumb”

is to recalibrate on an annual basis. It is

also good practice to recalibrate after

exposure to any severe temperature

extreme, shock, load, or other

environmental influence, or prior to any

critical test.

PCB Piezotronics maintains an ISO-

9001 certified metrology laboratory and

offers calibration services, which are

accredited by A2LA to ISO/IEC 17025,

with full traceability to SI through

N.I.S.T. In addition to the normally

supplied calibration, special testing is

also available, such as: sensitivity at

elevated or cryogenic temperatures,

phase response, extended high or low

frequency response, extended range,

leak testing, hydrostatic pressure

testing, and others. For information on

standard recalibration services or

special testing, contact your local PCB

Piezotronics distributor, sales

representative, or factory customer

service representative.

Returning Equipment –Following

these procedures will ensure that your

returned materials are handled in the

most expedient manner. Before

returning any equipment to PCB

Piezotronics, contact your local

distributor, sales representative, or

factory customer service representative

to obtain a Return Warranty, Service,

Repair, and Return Policies and

Instructions Materials Authorization

(RMA) Number. This RMA number

should be clearly marked on the outside

of all package(s) and on the packing

Service, Repair, and Return

Policies and Instructions

list(s) accompanying the shipment. A

detailed account of the nature of the

problem(s) being experienced with the

equipment should also be included

inside the package(s) containing any

returned materials.

A Purchase Order, included with the

returned materials, will expedite the

turn-around of serviced equipment. It is

recommended to include authorization

on the Purchase Order for PCB to

proceed with any repairs, as long as

they do not exceed 50% of the

replacement cost of the returned

item(s). PCB will provide a price

quotation or replacement

recommendation for any item whose

repair costs would exceed 50% of

replacement cost, or any item that is not

economically feasible to repair. For

routine calibration services, the

Purchase Order should include

authorization to proceed and return at

current pricing, which can be obtained

from a factory customer service

representative.

Contact Information –International

customers should direct all inquiries to

their local distributor or sales office. A

complete list of distributors and offices

can be found at www.pcb.com.

Customers within the United States may

contact their local sales representative

or a factory customer service

representative. A complete list of sales

representatives can be found at

www.pcb.com. Toll-free telephone

numbers for a factory customer service

representative, in the division

responsible for this product, can be

found on the title page at the front of this

manual. Our ship to address and

general contact numbers are:

PCB Piezotronics, Inc.

3425 Walden Ave.

Depew, NY14043 USA

Toll-free: (800) 828-8840

24-hour SensorLineSM: (716) 684-0001

Website: www.pcb.com

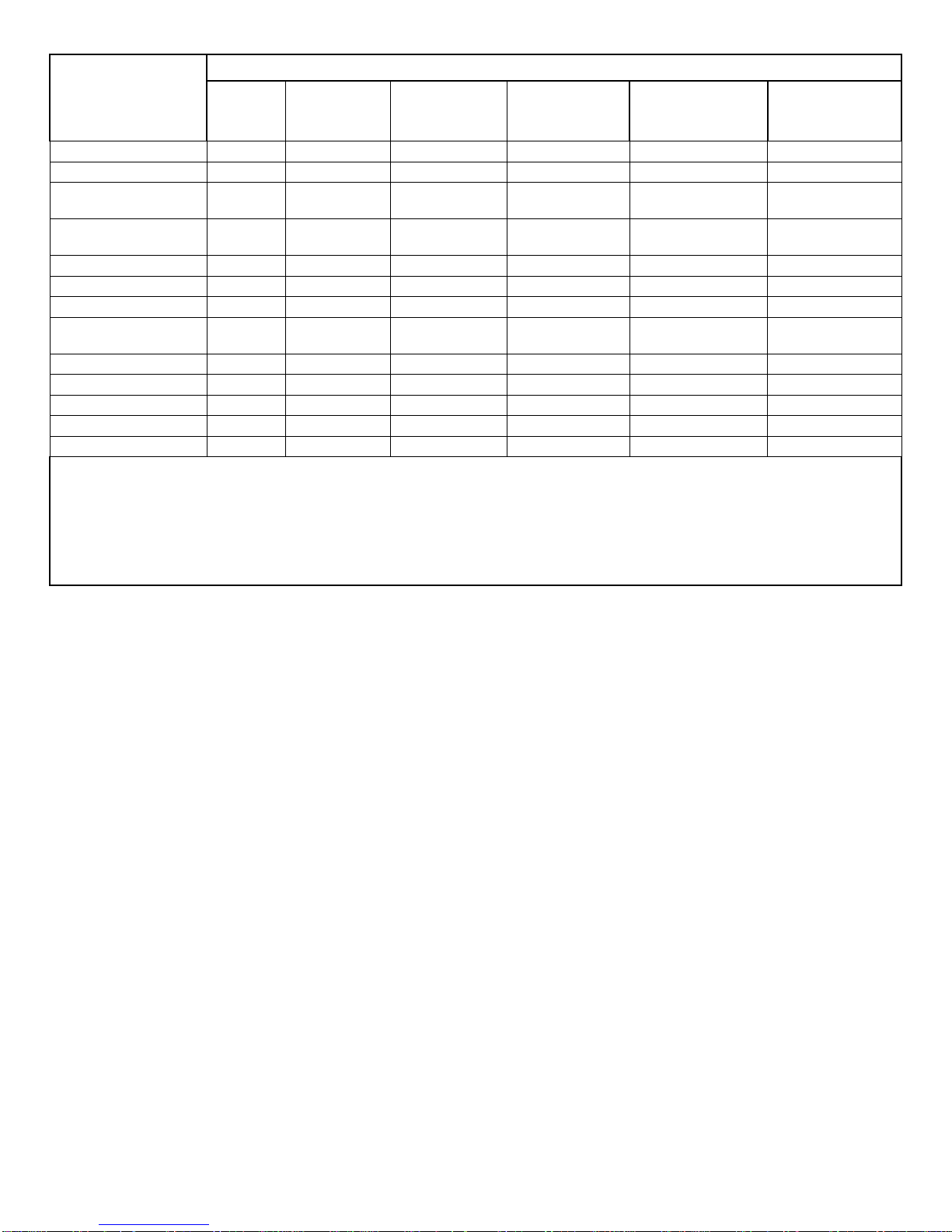

PCB工业监视和测量设备 - 中国RoHS2公布表

PCB Industrial Monitoring and Measuring Equipment - China RoHS 2 Disclosure Table

部件名称

有害物质

铅(Pb)

汞

(Hg)

镉

(Cd)

六价铬(Cr(VI))

多溴联苯 (PBB)

多溴二苯醚(PBDE)

住房

O

O

O

O

O

O

PCB板

X

O

O

O

O

O

电气连接器

O

O

O

O

O

O

压电晶体

X

O

O

O

O

O

环氧

O

O

O

O

O

O

铁氟龙

O

O

O

O

O

O

电子

O

O

O

O

O

O

厚膜基板

O

O

X

O

O

O

电线

O

O

O

O

O

O

电缆

X

O

O

O

O

O

塑料

O

O

O

O

O

O

焊接

X

O

O

O

O

O

铜合金/黄铜

X

O

O

O

O

O

本表格依据 SJ/T 11364 的规定编制。

O:表示该有害物质在该部件所有均质材料中的含量均在 GB/T 26572 规定的限量要求以下。

X:表示该有害物质至少在该部件的某一均质材料中的含量超出 GB/T 26572 规定的限量要求。

铅是欧洲RoHS指令2011/65/ EU附件三和附件四目前由于允许的豁免。

CHINA RoHS COMPLIANCE

DOCUMENT NUMBER: 21354

DOCUMENT REVISION: D

ECN: 46162

Component Name

Hazardous Substances

Lead

(Pb)

Mercury

(Hg)

Cadmium

(Cd)

Chromium VI

Compounds

(Cr(VI))

Polybrominated

Biphenyls

(PBB)

Polybrominated

Diphenyl

Ethers (PBDE)

Housing

O

O

O

O

O

O

PCB Board

X

O

O

O

O

O

Electrical

Connectors

O

O

O

O

O

O

Piezoelectric

Crystals

X

O

O

O

O

O

Epoxy

O

O

O

O

O

O

Teflon

O

O

O

O

O

O

Electronics

O

O

O

O

O

O

Thick Film

Substrate

O

O

X

O

O

O

Wires

O

O

O

O

O

O

Cables

X

O

O

O

O

O

Plastic

O

O

O

O

O

O

Solder

X

O

O

O

O

O

Copper Alloy/Brass

X

O

O

O

O

O

This table is prepared in accordance with the provisions of SJ/T 11364.

O: Indicates that said hazardous substance contained in all of the homogeneous materials for this part is below the limit

requirement of GB/T 26572.

X: Indicates that said hazardous substance contained in at least one of the homogeneous materials for this part is above

the limit requirement of GB/T 26572.

Lead is present due to allowed exemption in Annex III or Annex IV of the European RoHS Directive 2011/65/EU.

Manual Number: 43331

Manual Revision: B

3500/3600 Series Piezoresistive Shock Accelerometer Operating Guide

1

1.0 Introduction

This Operating Guide contains information that will

familiarize the user with the basic operation and installation of

the 3500/3600 Series Piezoresistive (PR) Shock

Accelerometers. However, it is not intended to cover all of the

specific measurement challenges that one may encounter while

using the device. Therefore, if you have detailed questions or

are unsure of how to properly operate the sensor after reading

this Operating Guide, please contact a PCB Application

Engineer using our 24-Hour SensorLineTM at 716-684-0001.

2.0 Principle of Operation

PR accelerometers are passive devices which require stable

external power, typically a regulated dc voltage such as 10V

(or more recently 5V or 3.3V), to operate with new

electronics. These full-bridge sensors include four, active,

silicon strain-sensing elements which change resistance

proportionally to an applied acceleration. In response to an

acceleration input, the resistance will increase for two of the

sensing elements and the resistance will decrease for the other

two elements, as shown in the Wheatstone-bridge circuit of

Figure 1. The sensitivity of the bridge is proportional to the

Excitation Voltage.

Figure 1 –Wheatstone Bridge Circuit

Terminology related to PR devices includes:

ZMO –Zero Measurand Output, also called bias or offset, is

the output when no input acceleration is applied.

TSS –Thermal Sensitivity Shift, the change of sensitivity due

to temperature. The sensors are uncompensated, so they

display a slight linear decrease in sensitivity as temperature

increases.

TZS –Thermal Zero Shift, the change in ZMO due to

temperature. This is less predictable, and from unit to unit may

have positive or negative slope, although it will be stable for

any one unit.

3.0 Features

The 3500/3600 Series uses micro-electromechanical systems

(MEMS) technology, in which all structural and electronic

components are manufactured in silicon using electronic

microfabrication technologies. MEMS devices are preferred in

many high shock impact measurements over piezoelectric

elements, since these PR devices are inherently DC coupled,

exploit the strength of single crystal silicon (SCS) and display

minimal zero shift. However, an additional characteristic of

SCS is extremely low internal damping, which results in

susceptibility to overshoot and resonant excitation. Although

the stiffness of silicon can allow extremely high resonant

frequencies in some MEMS shock sensor designs, PCB

MEMS sensors take a different approach in which the resonant

frequency is intentionally lowered to reduce the response to

higher frequency energy present in shock events. The

relatively low resonance also creates displacements of the

seismic element sufficient to introduce squeeze film damping.

Air is used rather than a fluid so thermal effects on damping

are negligible.

Manufactured using recent advances in semiconductor

processing, the PCB MEMS design consists of a mildly under-

damped sensor with sufficient bandwidth to accurately track

rigid-body vehicle deceleration. Resonant amplification is

reduced by orders of magnitude, and survivability is increased.

Ruggedness is enhanced through the use of mechanical stops.

The sensors are manufactured as the sandwich of three wafers,

with the active core surrounded by the two outer wafers which

provide hermetic protection and restrict the travel of the proof

mass.

Because many such applications are coupled with battery

powered conditioning and data acquisition, PCB MEMS

sensors were designed with relatively high value resistors

(approximately 10 times that of other devices) to maximize

battery life.

4.0 Common Applications

The 3500/3600 Series PR Shock Accelerometers achieve true

DC response for measuring long duration shock. For this

reason, they are preferred for applications in which integration

from acceleration to velocity or displacement may be

or

Yellow

Manual Number: 43331

Manual Revision: B

3500/3600 Series Piezoresistive Shock Accelerometer Operating Guide

2

performed. These are violent events. Because of the critical

nature of these and similar test applications, PCB MEMS DC

Accelerometers have been designed and manufactured with the

following common characteristics:

Rugged, all-welded, titanium housing, or ceramic housing,

insures reliability and durability in demanding

applications and environments.

The MEMS sensor includes over-range stops set at

approximately twice the full range.

Gas damping attenuates unwanted high-frequency output.

5.0 Sensor Installation

The 3500/3600 Series DC Accelerometers are available in

various forms. Review Outline Drawings and/or Installation

Drawings provided with sensors for specific details and

requirements related to hardware, mounting, materials,

packaging, cabling, etc.

For certain applications not requiring a signal cable, surface

mount technology (SMT) style sensors are available upon

request. Contact PCB Application Engineers to discuss

specific application requirements.

When choosing a mounting method, it’s important to take

characteristics like location, temperature, environment, and

surface condition into consideration. The sensor must be

mounted on a clean, flat surface to avoid the potential for

misalignment and/or limited contact with the mounting surface

which may diminish the sensor’s performance. Mounting

surface flatness, finish & preparation requirements are

indicated on the provided Sensor Installation Drawing.

Mounting the sensor will require a clean contact surface to

avoid small particles or debris trapped between the mounting

surface and sensor that can preload the accelerometer case

with unwanted static strain, possibly resulting in zero-shift

during a shock measurement.

Prepare a smooth, flat mounting surface and, if applicable,

drill and tap mounting holes according to the Sensor

Installation Drawing.

Wipe clean the mounting surface and, as appropriate,

apply a thin film of couplant, such as machinist oil, to

enhance transmissibility by filling small voids in the

mounting surface and increasing mounting stiffness.

Hand-tighten the sensor (or mounting hardware, as

appropriate), then torque down per the Sensor Installation

Drawing. In extreme conditions it’s recommended to

check the mounting torque after each measurement. It’s

also recommended that a thread locking adhesive be

applied to any threads, if applicable.

Ceramic LCC (leadless chip carrier) packages available in this

series are designed to be installed on circuit boards with

conventional surface mounting techniques. An under-fill epoxy

is recommended to be used for additional mechanical strength.

6.0 Power

Normally PR devices are powered with regulated excitation,

since the sensitivity is proportional to input voltage. PCB

MEMS sensors generally exhibit good proportionality (due to

minimal self-heating of the comparatively high-resistance

elements). Still, it is generally recommended to obtain the

calibrated sensitivity using the intended excitation voltage. In

integrated applications, in which the data acquisition is

powered by the same voltage that supplies the bridge, it is

possible to reduce the effect of variations in excitation on

overall system sensitivity by using the excitation voltage as the

reference for the data acquisition.

7.0 Typical Measurement System

The output from the sensor is typically routed to a bridge

conditioner then an oscilloscope or various data acquisition

instruments. Consult PCB Application Engineering for

additional signal conditioning options. To take advantage of

the DC response of the accelerometer, the readout device must

be in a DC coupled state. Consult the appropriate manufacturer

or product manual for your readout device for details.

8.0 Sensor Verification

Generally the ZMO of a PR transducer is a good measure of

the health of the transducer. Input Resistance (from Red to

Black) or Output Resistance (from Green or Yellow to White),

is less commonly used to check the condition, since resistance

changes with temperature. A thorough check of the health

(suggested both before and after an expensive test) must

include calibration of the sensitivity.

In some laboratories which use piezoresistive transducers, it is

customary to check the continuity and gain of the conditioning

and data acquisition system using a technique called “Shunt

Calibration”. By temporarily unbalancing the bridge with a

shunt resistor placed in parallel with a leg of the bridge

(usually between the “+ Sig” wire and either the “+ Exc” or “–

Exc”), dc shifts of the offset are created. Whereas the process

does not calibrate the transducer, it is a check of system gain,

with accuracy of the resultant dc shift in output dependent on

the degree that the resistances of both the leg of the bridge and

Manual Number: 43331

Manual Revision: B

3500/3600 Series Piezoresistive Shock Accelerometer Operating Guide

3

the shunt resistor are accurately known. Among other sources

of variability, temperature can change the value of the

resistors, and therefore the Shunt Calibration output. The user

should be aware that because the sensors are full bridge

transducers, all legs are active and will have temperature

coefficients typical of piezoresistive sensors (approximately

+0.1%/degree C).

9.0 Sensor Calibration

For shock accelerometers, the most appropriate, accurate and

reliable calibration is with a comparison shock using a back-

to-back reference and pneumatic exciter, as described in ISO

16063-22, “Methods for the calibration of vibration and shock

transducers —Part 22: Shock calibration by comparison to a

reference transducer.” PCB offers this calibration as a service.

10.0 Maintenance and Repair

Because of the sophisticated nature of PCB instrumentation,

field repair of the equipment is not recommended. Most PCB

sensors are of modular construction and are factory repairable.

A repair or replacement quotation is available at no charge.

Before returning equipment for repair, it is recommended that

the user confer with a factory application engineer (or inter-

national representative) to first troubleshoot the problem.

11.0 Return Procedure

To expedite the repair process, contact a factory application

engineer to obtain a Return Material Authorization (RMA)

number prior to sending equipment to the factory. Please have

information, such as model number, serial number and

description of the problem, available.

Customers outside the U.S. should consult their local PCB

distributor for information on returning equipment. For

exceptions to this guideline, please contact the International

Sales department to request shipping instructions and an RMA.

For further assistance, please call (716) 684-0001 or fax us at

(716) 684-0987. You may also receive assistance via e-mail at

12.0 Customer Service / Warranty

The employees of PCB strive to provide superior, unmatched

customer service. Should you at any time find yourself

dissatisfied with any PCB product for any reason, consult a

factory Application Engineer or local representative/distributor

to discuss repair, refund, or exchange procedures.

When unexpected measurement problems arise, call our 24-

hour Sensor LineTM at (716) 684-0001 to discuss your

immediate dynamic instrumentation needs with a Factory

Representative.

Model Number

3503A1160KG TRIAXIAL HIGH AMPLITUDE MEMS SHOCK ACCELEROMETER Revision: NR

ECN #: 46383

Performanc

e

ENGLISH S

I

Sensitivity(± 50 %)(at 10 VDC excitation) 0.003 mV/g 0.0003 mV/(m/s²) [1]

Sensitivity 0.0003 mV/V/g 0.00003 mV/V/(m/s²) [7]

Measurement Range ± 60 kg ± 588,400 m/s² pk

Frequency Range(± 1 dB) 0 to 10,000 Hz 0 to 10,000 Hz

Resonant Frequency ≥120 kHz ≥120 kHz

Damping Ratio 2 % Critical 2 % Critical [5]

Non-Linearity(per 10,000 g (98,100 m/s²)) ± 1 % ± 1 %

Transverse Sensitivity ≤3 % ≤3 %

Environmental

Overload Limit(Shock) ± 80,000 g pk ± 784,532 m/s² pk [4]

Overload Limit(Mechanical Stops) ≥80 kg ≥782,534 m/s² pk

Temperature Range(Storage) -65 to 250 °F -54 to 121 °C

Temperature Range(Operating) -65 to 250 °F -54 to 121 °C

Temperature Coefficient of Sensitivity -0.11 %/°F -0.20 %/°C [5]

Zero g Offset Temperature Shift ± 10 mV ± 10 mV [6]

Base Strain Sensitivity 0.3 g/µε2.94 (m/s²)/µε[5]

Electrica

l

Excitation Voltage(Maximum) 15.0 VDC 15.0 VDC

Current Consumption <12 mA <12 mA

Input Resistance(± 700 Ohm) 2000 Ohm 2000 Ohm [1]

Output Resistance(± 2000 Ohm) 6000 Ohm 6000 Ohm [1]

Offset Voltage -40 to +40 mVDC -40 to +40 mVDC [1]

Settling Time 0.01 sec 0.01 sec [2]

Electrical Isolation(Case) ≥107Ohm ≥107Ohm [3]

Physica

l

Sensing Element Piezoresistive MEMS Piezoresistive MEMS

Sensing Geometry Full Active Full Active

Housing Material Titanium Titanium

Sealing Epoxy Epoxy

Size (Height x Length x Width) 0.25 in x 0.47 in x 0.47 in 6.35 mm x 11.81 mm x 11.81 mm

Weight(without cable) 0.1 oz 2.83 gm [5]

Electrical Connector Integral Cable Integral Cable

Electrical Connection Position Side Side

Cable Type 8-Cond., shielded, silcone jacket 8-Cond., shielded, silcone jacket

Cable Termination Pigtail Ends Pigtail Ends

Cable Length 10 ft 3.05 m

Mounting Through Holes (2) Through Holes (2)

Mounting Torque 6 to 8 in-lb 68 to 90 N-cm

All specifications are at room temperature unless otherwise specified.

In the interest of constant product improvement, we reserve the right to change specifications without notice.

ICP®is a registered trademark of PCB Group, Inc.

OPTIONAL VERSIONS

Optional versions have identical specifications and accessories as listed for the standard model

except where noted below. More than one option may be used.

NOTES

:

[1] Verified with test data provided on supplied calibration certificate.

[2] Settling Time is the maximum time after powe

r

-up for the Offset Voltage to be within +/-2% o

f

Measurement Range output of the final offset value. Mounting surface must be at thermal

equilibrium.

[3] Individually tested to ensure compliance with specified value.

[

4

]

Hal

f

-sine

p

ulse duration, ≥20

µ

sec

.

[5] Typical.

[6] -65 to +250 °F, ref. 75 °F (-54 to +121 °C, ref. 24 °C)

[7] Sensitivity is proportional to excitation voltage, and at other excitation values, sensitivity can

be predicted from the 10VDC calibrated value with a small

(

<~.5%

)

increase in uncertaint

y.

SUPPLIED ACCESSORIES:

Model 081A114 MOUNTING SCREW AND WASHER(4-40 x 3/8" SHCS) (2)

Model ACS-62T CALIBRATION OF HIGH G PR ACCCELEROMETER (1)

Entered: LK Engineer: GD Sales: MFG Approved: BAM Spec Number:

Date: 1/17/2017 Date: 1/17/2017 Date: 1/17/2017 Date: 1/17/2017 66350

3425 Walden Avenue, Depew, NY 14043

Phone: 716-684-0001

Fax: 716-684-0987

E-Mail: [email protected]

1

1

2

2

3

3

4

4

A A

B B

C C

D D

CODE

IDENT. NO.

52681

DWG. NO.

SCALE: SHEET

DRAWN CHECKED ENGINEER

TITLE

UNLESS OTHERWISE SPECIFIED TOLERANCES ARE:

DIMENSIONS IN MILLIMETERS

[ IN BRACKETS ]

XX ±0.13

ANGLES 2 DEGREES

3425 WALDEN AVE. DEPEW, NY 14043

DIMENSIONS IN INCHES

DECIMALS XX ±.01

ANGLES 2 DEGREES

FILLETS AND RADII

.003 - .005

DECIMALS X ± 0.3

FILLETS AND RADII

0.07 - 0.13

INSTALLATION DRAWING

66373

1 OF 26X

TRIAXIAL MEMS SHOCK

ACCELEROMETER

XXX ±.005

KRM 1/16/17 ECB 1/16/17 GCD 1/16/17

XZ

Y

Y

X

Y

XZ

Z

X

Z

Y

66373

PCB Piezotronics Inc. claims proprietary rights in

the information disclosed hereon. Neither it nor any

reproduction thereof will be disclosed to others

without the written consent of PCB Piezotronics Inc.

RECOMMENDED MOUNTING SURFACE SHOULD BE FLAT TO WITHIN .0003(.008)

TIR OVER .650[16.51] WITH A 32 [.08] FINISH FOR BEST RESULTS

RECOMMENDED MOUNTING TORQUE ON CAP SCREW, 6-8 IN LBS[68-90 N-CM]

DIRECTIONS SHOWN DEPICT ACCELERATIONS CAUSING POSITIVE OUTPUT

12345678

XYZ

9

#CONNECTION COLOR

1 + EXCITATION RED

2 - EXCITATION BLACK

3 -X-AXIS BLUE

4 + X-AXIS YELLOW

5 - Y-AXIS BROWN

6 + Y-AXIS ORANGE

7 - Z-AXIS WHITE

8 + Z-AXIS GREEN

9 SHIELD N/A

REVISIONS

REV DESCRIPTION DIN

NR RELEASED TO DRAFTING 46383

1

2

3

.233 [5.92]2X

.050 [1.27]

.125 [3.18]2X

.200 [5.08]

.465 [11.81]

.365 [9.27]

.050 [1.27]

.233 [5.92]2X

.100 [2.54]

.100 [2.54]

.365 [9.27]

.465 [11.81]

45°

1

1

1

SCREW ASSEMBLY

(2 SUPPLIED)

2

3.375 [9.53]

MOUNTING HOLE PREPARATION

Ø.089 [2.26] .230 [5.84]

4-40 UNC-2B .187 [4.75]

.250 [6.35]

1

1

2

2

3

3

4

4

A A

B B

CODE

IDENT. NO.

52681

DWG. NO.

SCALE: SHEET

DRAWN CHECKED ENGINEER

TITLE

UNLESS OTHERWISE SPECIFIED TOLERANCES ARE:

DIMENSIONS IN MILLIMETERS

[ IN BRACKETS ]

XX ±0.13

ANGLES 2 DEGREES

3425 WALDEN AVE. DEPEW, NY 14043

DIMENSIONS IN INCHES

DECIMALS XX ±.01

ANGLES 2 DEGREES

FILLETS AND RADII

.003 - .005

DECIMALS X ± 0.3

FILLETS AND RADII

0.07 - 0.13

INSTALLATION DRAWING

66373

2 OF 23X

TRIAXIAL MEMS SHOCK

ACCELEROMETER

XXX ±.005

KRM 1/16/17 ECB 1/16/17 GCD 1/16/17

4FASTEN CABLE TO TEST STRUCTURE TYPICALLY WITHIN 2-3[51-76] OF SENSOR. THEN FASTEN AGAIN WITHIN 3-4[76-101] OF

PREVIOUS ATTACHMENT. BETWEEN THE TEST STRUCTURE AND A FIXED STRUCTURE, ALLOW A SERVICE LOOP LARGE

ENOUGH TO PREVENT PULLING OF THE CABLE WHEN SHAKING. MORE ATTACHMENT POINTS WILL PROVIDE LESS NOISE

IN THE RESULTING DATA. LOOSE CABLES OR PARTS ELSEWHERE ON THE TEST STRUCTURE CAN ALSO GENERATE "NOISE"

ON THE SIGNAL RECEIVED FROM THE SENSOR

REVISIONS

REV DESCRIPTION DIN

-SEE SHEET ONE-

66373

PCB Piezotronics Inc. claims proprietary rights in

the information disclosed hereon. Neither it nor any

reproduction thereof will be disclosed to others

without the written consent of PCB Piezotronics Inc.

2 - 3[51-76] 3 -4[76 - 102]4 4

"SERVICE LOOP"

TO ALLOW MOTION

WITHOUT PULLING

CABLE

TEST STRUCTURE

TAPE

OR EQUIVALENT

(TYPICAL) INTEGRAL CABLE TO

PIGTAIL END

Table of contents

Other PSB Measuring Instrument manuals