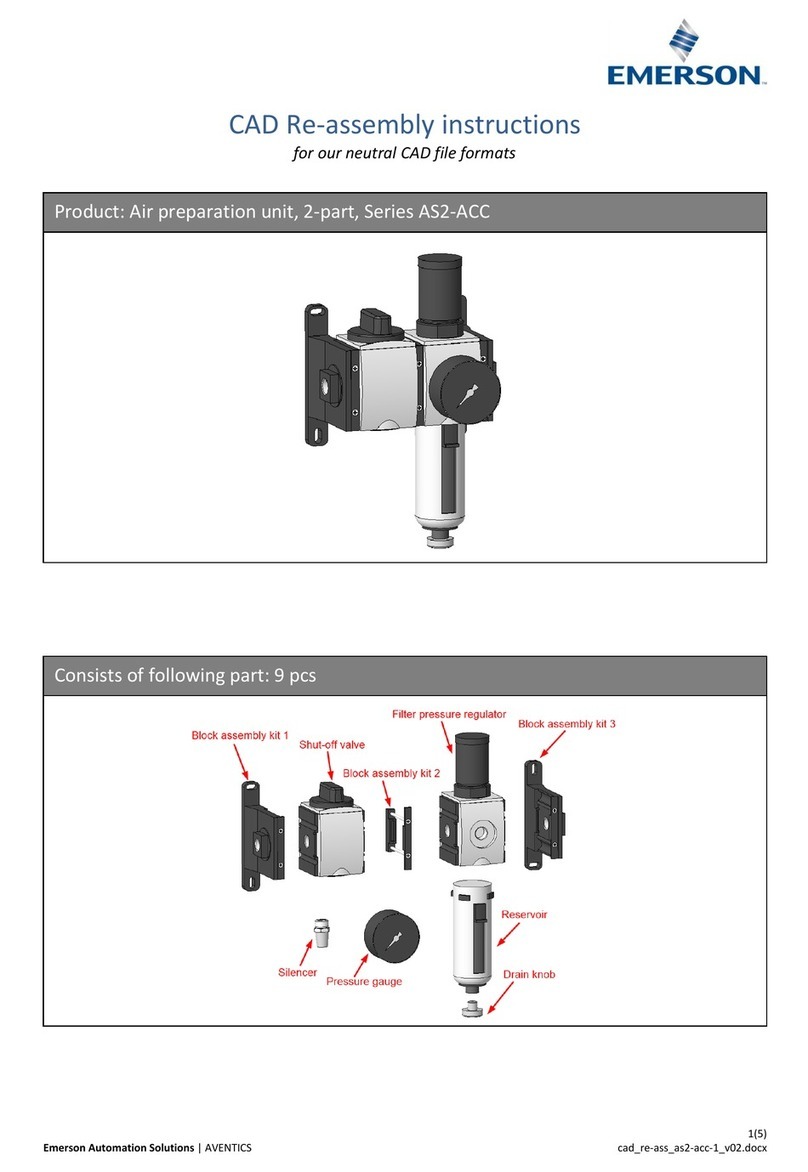

Jaw Capacity Chart

Jaw Style Gripping Dowel Gripping in Hole

Internal Diameter External Diameter

#1 Step Jaws 11/16" to 3-3/8" 0" to 1-7/8"

#2 Round Jaws 2" to 3-7/8" 1-1/2" to 3-3/8"

#3 Wide Jaws —— 3-1/8" to 5"

Pin Jaws 1" to 2-7/8" ——

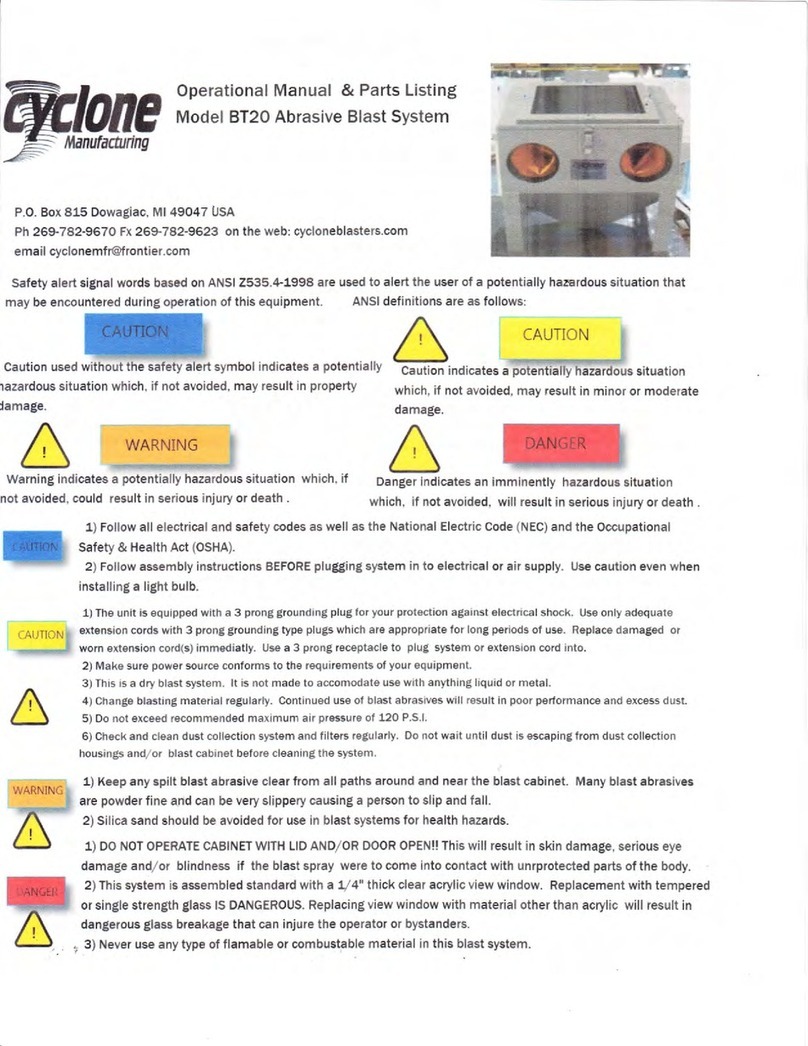

Chuck System Description

A. Main body: designed to hold all jaws as an assembly.

B. Carrier: to which the top jaws are each attached with one or two

hex screws.

C. Jaws: attached to the carrier, used for gripping the wood piece to be turned (#2

round jaws are shown in the photograph below).

D. Socket hex screws: attach jaws to chuck (2 per jaw).

E. Lever tightening holes: insert and turn tightening levers to secure grip

Installing the Jaws

Select the appropriate jaw for your project. Place the selected jaw on top of the

carrier, matching the number stamped on the main body to the number on each

individual jaw. Using the provided hex wrench and the hex set screws, firmly

tighten the jaw down onto the surface of the carrier. Repeat this step for for the

remaining three jaws.

Maintenance

Brushing is all that is needed to clean your chuck. If the chuck becomes sticky,

soak in varisol or mineral spirits with 10% oil added. Soak for thirty minutes and

blow dry.

Mounting the Adapter

1. Wipe the inside of the threads and the outside of the adapter to insure both

surfaces are clean.

2. Select the appropriate adapter for your lathe, 3/4" x 16tpi adapter or

1" x 8tpi adapter (pre-mounted).

3. Hold the chuck in your hand, screw and tighten the adapter into the bottom

threaded portion of the chuck.

Mounting the Chuck to Your Lathe

Screw the completed assembly onto your lathe. The chuck should go on

effortlessly with no binding. Screw the chuck all the way until the adapter face

contacts the shoulder of the lathe spindle. Lock the spindle, slightly unscrew the

chuck and give it a firm spin. This will snap the chuck firmly in place.

Operating the Chuck

Your chuck has two movable discs. Each disc has 4 holes to accommodate the

tightening levers. Insert a tightening lever into one of the holes on each level.

Rotate the tightening levers away or toward each other to close or open the chuck.

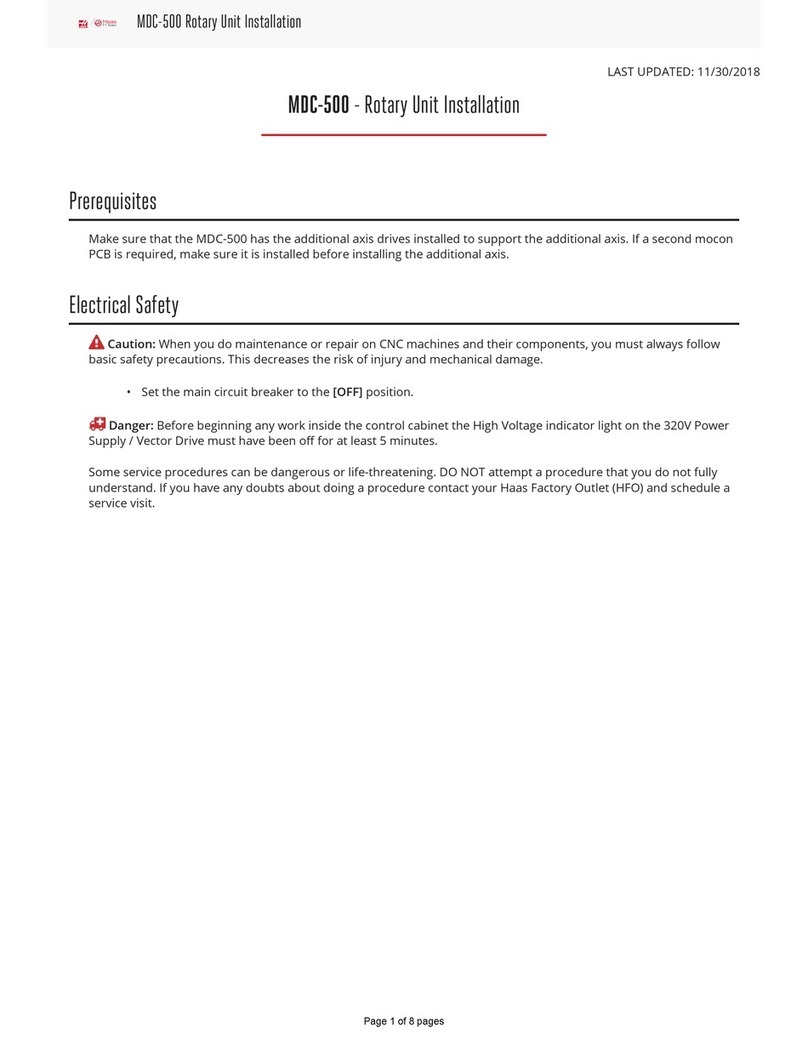

Chuck Gripping Depth

When turning a bowl, for safety reasons, allow a minimum amount of wood for

the chuck to grab while turning.

1. Cavity base (inside grip) – for a 2" diameter base,

minimum hole depth is 3/16".

2. Spigot base (outside grip) – for a 2" diameter base

minimum grip is 3/16".

Lathe Speeds

Turning: 500-1500 RPM

Sanding & Polishing: 1500-2500 RPM

Make sure your wood is properly aligned and balanced

when mounted or re-mounted.

Use slower speeds for larger work.

PSI Woodworking Products CSC2000C Barracuda Chuck

A

B

C

3/16”

©2005PSI Woodworking Products 9900 Global Rd., Philadelphia, PA 19115

D

E

12

(Shown with two #2 round jaws installed)

Spigot base

Cavity base 3/16”

INDSUPCSC2000C-V2