frEmffffitrtng

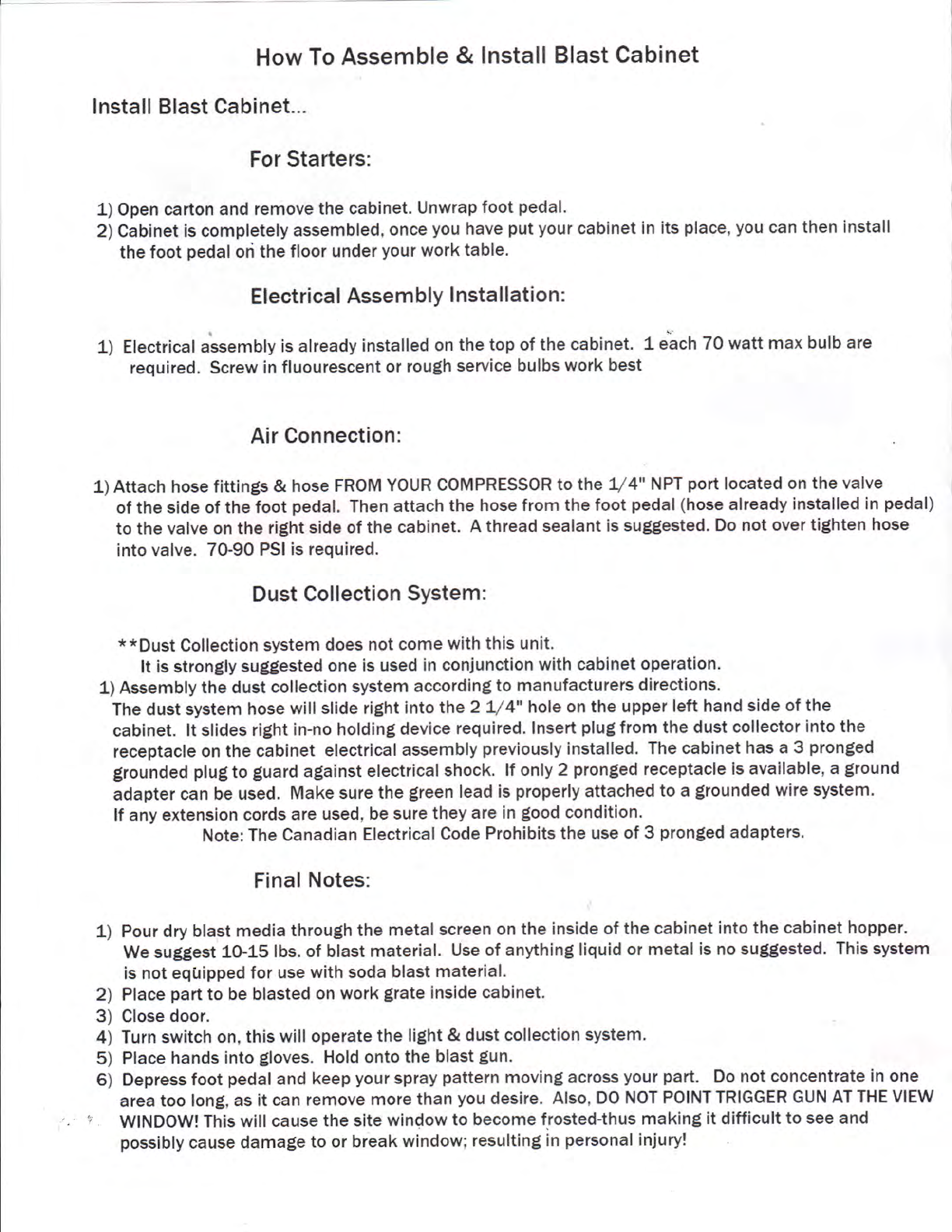

Operational Manual & Parts Listing

Model BT2O Abrasive Blast System

P.O. Box 815 Dowatiac. Ml 49047 USA

Ph 26S,782-967O Fx 26$782-9623 on the web: cycloneblasters.com

ema il cyclonemf r@f rontier.com

Safety alert siEnal words based on ANSI 2535.+1998 are used to

may be encountered during operation of this equipment. ANSI

Caution used alert symbol indicates a potentially

razardous situation which. if not avoided, may result in property which, if not avoided, may result in minor or moderate

!amage.

Adamage.

A

Warning indicates a potentiafly hazardous situation which, if

not avoided. could result in seriouE injury or death .

Danger indicates an imminently hazardous situation

which, if not avoided, will result in seriouE injury or death .

- ,]fi,t;;::*-JflIflffi.safety codes as wellas the NationalElectric code (NEC) and the occupationar

w 2) Follow assembly inetructions BEFORE plugging system in to electrical or air supply. Use caution even when

installint a light bulb.

1) The unit is equipped with a 3 prong Elroundang plug for your protection egainst alectrical shock. Use only adequate

CATJT]ON* ext€nsion cords with 3 prong grounding type plugs which ate appropriate for long periods ot use. Replace damaged or

"etilr#asF worn extension cord(s) irnmediatly. Use a 3 prong receptacle lo plug systern or ertension cord intc.

2) Make sure power source conforms to the requirernents of your equipment,

3) This is a dry blast system. lt is not msde to accomodate use wlth anything liquid or metal.

4) Chandr blasting material regularly. Contanued use of blast abrasives will result in poor performance and oxcess dust.

5) Do not exceed recommended maximurn eil prsssure of 120 P"S.l.

6) Check and clean dust collsction system and filters regularly. Do not wait until du$t is escaping from dust collaction

housings andlor blast cabinet before cleaning the system.

1) Keep any spilt blast abraeive clear from all paths around and near the bla6t cabinet" Many blast abrasives

are pawder fine and can be very slippery eausing a person to slip and fall.

2)silica sand should be avoided for use in blast systems for health hazards.

1) DO NOT OPIRATE CAEINEf WITH LID ANDIOR DOOH OPEN!!This will result in skin damage, serious eye

damag* andlor blindness if the blaet spray wele to come lnto contact with unrproteeted parts of the body.

2) This system is assembled standard with a 1r4" thick clear acrylic view window. Replacement with tempered

or single strength glass lS DANGEROUS. Replacin$ view window with material other than acrylic will result in

dangerous gla6s breakage that can lnjure the operator or bystanders.

., 3) Never use any type of flamable or combustable material in this blast system.

CAUTION