PSI 8.8L LP User manual

Power Solutions International, Inc.

8.8L LP Engine Operation and Maintenance Manual

201 Mittel Dr.

Wood Dale, IL 60191

Power Solutions International, Inc.

US EPA & CARB HD-SI Certification

36100015 - Rev 4

May 2019

IMPORTANT

The information, specifications, and illustrations contained in this manual are based on data that was current at the time of

publication. Power Solutions International, Inc. reserves the right to make changes and/or improvements at any time

without notification, liability, or without applying those changes or improvements to vehicles previously manufactured and/or

sold.

NOTICE

Be

advised

that

this

motor

vehicle

may

be

equipped

with

computer

/

recording

devices.

Their

function

is

to

allow

an

authorized

individual

to

download

data

or

information

relating

to

the

operation

or

performance

of

this

vehicle.

The

stored

data

or

information

may

be

neither

downloaded

nor

retrieved

except

by

the

vehicle’s

registered

owner,

or,

in

the

alternative,

by

another

individual

or

entity

authorized

by

the

registered

owner,

(e.g.,

Certified

Service

Dealer)

who

may

need

this

data

or

information

to

properly

service

or

diagnose

this

vehicle

for

repair

or

following

an

accident.

Any

access

to

this

information

without

the

owner’s

consent

may

be

in

violation

of

law

and

may

subject

that

person

or

entity

to

criminal

penalties.

TABLE

OF

CONTENTS

FOREWORD 1

SAFETY INFORMATION 3

WARRANTY 9

EPA and CARB Emission System Warranty 9

Manufacturer's Warranty Coverage 9

Owner's Warranty Responsibilities 10

Warranty Exclusions 11

SECTION 1 – ENGINE SYSTEMS

Engine Serial Number 13

Engine Emission Label 14

Engine Accessories 14

Engine Specification 15

Engine Description 15

Engine Features 19

Engine Related Optional Features 20

Component Location – Top 23

Component Location – Front 24

Component Location – Left 25

Component Location – Right 26

Component Location – Rear 27

SECTION 2 – REQUIREMENTS FOR FUEL, ENGINE OIL, AND COOLANT

Fuel 29

Acceptable Fuel Blends 29

Unacceptable Fuel and Blends 29

Unsafe Practices 29

TABLE

OF

CONTENTS

Engine Oil

Engine Oil Quality and Service Categories

30

SAE Oil Viscosity Grade

30

30

Coolant

30

Coolant Mixtures

30

Contamination of Coolant

30

SECTION 3 – INSTRUMENTS, INDICATORS, AND SWITCHES

Instrument Panel Gauge Cluster

Warning Lamps 31

Wait to Start Lamp 31

Maintenance Lamp 31

31

Amber Warning Lamp (AWL) 31

RED Stop Lamp (RSL) 32

Malfunction Indicator Lamp (MIL) 32

Gauges

33

Typical Water Temperature Gauge 33

Oil Temperature Gauge 33

Oil Pressure Gauge 33

SECTION 4 – ENGINE OPERATION

Preoperation Checklist 35

Preparing the Fuel System 36

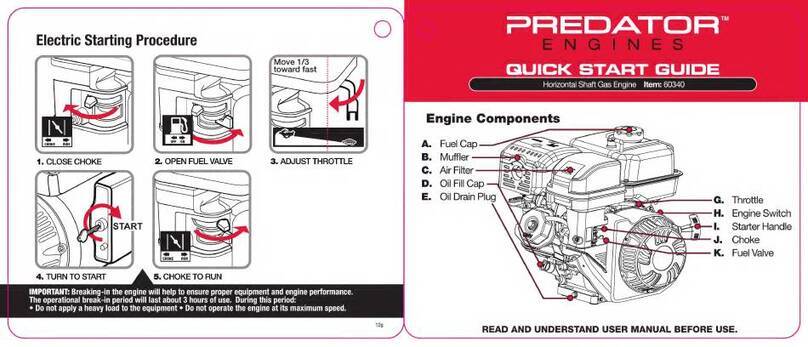

Starting the Engine 37

Emergency Starting 39

TABLE

OF

CONTENTS

Operation

40

Idle Speed 40

Cold Weather Operation 40

Hot Weather Operation 41

Engine Shutdown 41

Engine Warning Protection System (EWPS) 42

EMD Overview 43

Road Speed Governor (RSG) 43

Road Operation 43

SECTION 5 – MAINTENANCE SCHEDULE AND SERVICE PROCEDURES

Maintenance Schedule 45

Service Procedures 47

Oil Level 47

Coolant Level 48

External Leakage 49

Belt, Air Intake Piping and Clamps 50

Coolant Freeze Point 53

Engine Oil and Filter 53

Electrical System 55

SECTION 6 – LONG TERM STORAGE

General Information 57

SECTION 7 – SERVICE RECORDS

Maintenance Service Record 60

Daily Care and Report 61

APPENDIX 67

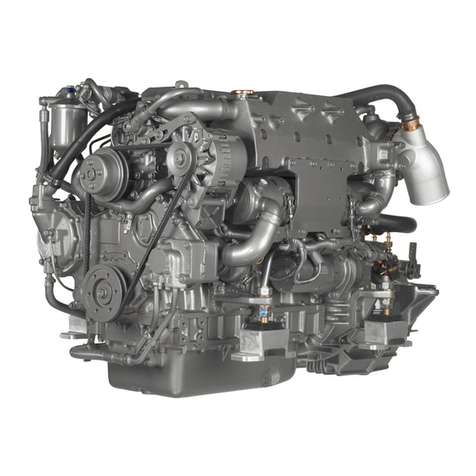

FOREWORD

FOREWORD

Page

1

Foreword

Power Solutions International, Inc. is committed to continuous

research and development to improve products and introduce

technological advances. Procedures, specifications, and

parts defined in published technical service literature may be

altered.

NOTE: Photo illustrations identify specific parts

or assemblies that support text and procedures; other

areas in a photo illustration may not be exact.

This manual includes necessary information and specifications

for operators to operate and maintain the PSI 8.8L LP engine.

Contact your dealer for more information.

Refer to the applicable technical service literature

Engine Service & Diagnostic Manual

Warranty Policy and Procedures Manual

Technical Service Literature is revised periodically. Use only

up-to-date service information.

To order technical service literature, contact your dealer.

All marks are trademarks of their respective owners.

About the Manual

This manual contains information needed to correctly operate

and maintain your engine as recommended by PSI.

Numerous

illustrations, symbols and feature descriptions are

used to aid in

understanding the meaning of the text. The

illustrations,

symbols or feature descriptions may not be

available for all

applications, please contact your dealer for

complete

information. Both metric and U.S. customary values

are listed

in this manual. The U.S. Customary value is listed

first,

followed by the metric value in brackets. For additional

service

literature refer to Service Literature noted in this

manual. This

manual does not cover vehicle or equipment

maintenance

procedures.

When referring to the left-hand or right-hand side of the

engine, this will be as viewed from the rear. (Looking at the

flywheel)

Consult the original vehicle or equipment manufacturer for

specific maintenance recommendations.

Page

2

SAFETY

INFORMATION

Page

3

SAFETY

INFORMATION

Safety Information

This manual provides general and specific

maintenance

procedures essential for reliable engine

operation and your

safety. Since many variations in

procedures, tools, and service

parts exist, advice for all

possible safety conditions and

hazards cannot be stated.

Read safety instructions before doing any service and test

procedures for the engine. See related manuals for more

information.

Obey Safety Instructions, Warnings, Cautions, and Notes in this

manual. Not following Warnings, Cautions, and Notes can lead

to injury, death, or damage to the engine or vehicle.

Safety Terminology

Three terms are used to stress your safety and safe operation of

the engine: Warning, Caution, and Note.

Warning: A warning describes actions necessary to prevent

or

eliminate conditions, hazards, and unsafe practices that can

cause personal injury or death.

Caution: A caution describes actions necessary to prevent or

eliminate conditions that can cause damage to the engine or

vehicle.

Note: A note describes actions necessary for correct, efficient

engine operation.

Safety Instructions

Work Area

•

Keep work area clean, dry, and organized.

•

Keep tools and parts off the floor.

•

Make sure the work area is ventilated and well lit.

•

Make sure a First Aid Kit is available.

Safety Equipment

•

Use correct lifting devices.

•

Use safety blocks and stands.

Protective Measures

•

Wear protective safety glasses and shoes.

•

Wear correct hearing protection.

•

Wear cotton work clothing.

•

Wear sleeved heat protective gloves.

•

Do not wear rings, watches or other jewelry.

•

Restrain long hair.

Page

4

SAFETY

INFORMATION

Vehicle

•

Shift transmission to park or neutral, set parking brake, and

block wheels before doing diagnostic or service procedures.

•

Clear the area before starting the engine.

Engine

•

The engine should be operated or serviced only by

qualified individuals.

•

Provide necessary ventilation when operating engine in a

closed area.

•

Keep combustible material away from engine exhaust

system and exhaust manifolds.

•

Install all shields, guards, and access covers before

operating engine.

•

Do not run engine with unprotected air inlets or exhaust

openings. If unavoidable for service reasons, put protective

screens over all openings before servicing engine.

•

If an engine is not safe to operate, tag the engine and ignition

key.

Fire Prevention

•

Make sure charged fire extinguishers are in the work area.

NOTE: Check the classification of each fire extinguisher

to ensure the following fire types can be extinguished.

1.

Type A — Wood, paper, textiles, and rubbish

2.

Type B — Flammable liquids

3.

Type C — Electrical equipment

Batteries

•

Always disconnect the main negative battery cable first.

•

Always connect the main negative battery cable last.

•

Avoid leaning over batteries.

•

Protect your eyes.

•

Do not expose batteries to flame or sparks.

•

Do not smoke in workplace.

Compressed Air

•

Use an OSHA approved blow gun. Limit blow gun air

pressure to 30 psi (207 kPa).

•

Wear safety glasses or goggles.

•

Wear hearing protection.

•

Use shielding to protect others in the work area.

•

Do not direct compressed air at body or clothing.

Page

5

SAFETY

INFORMATION

Tools

•

Make sure all tools are in good condition.

•

Make sure all standard electrical tools are grounded.

•

Check for frayed power cords before using power tools.

Fluids Under Pressure

•

Use extreme caution when working on systems under

pressure. Pay close attention when working with the fuel

system.

•

Follow approved procedures only.

Fuel

•

Do not smoke in the work area.

•

Do not refuel the tank when the engine is running.

Removal of Tools, Parts, and Equipment

•

Reinstall all safety guards, shields, and covers after

servicing the engine.

•

Make sure all tools, parts, and service equipment are

removed from the engine and vehicle after all work is done.

Propane Safety Instructions

Warnings:

•

Never loosen fittings or vent any propane. Escaping propane

can cause frostbite and severe freeze burns. Wear insulated

PVC rubber gloves resistant to propane, goggles for

protection against accidental release of pressurized

products, and thermal protective clothing when handling

refrigerated liquids.

•

Do not remove any valves, bulkheads, or fittings from a tank

unless the tank has been drained completely. The pressure

inside a propane tank can push a loosened bulkhead or

valve out with enough force to cause injury or death.

•

Keep all sources of ignition away from propane vehicles

while the fuel system is being serviced. Even if the tank and

fuel lines are empty, there may still be flammable vapors

near the vehicle.

•

Do not disconnect any propane hoses unless they have

been completely drained using the proper procedure.

•

Do not vent or release propane indoors or near sewers, pits

or low lying areas. Propane can accumulate in low spots,

creating a fire hazard. Propane can also displace oxygen,

creating a suffocation hazard.

•

Always unplug the fuel control box or disconnect the battery

before you work on any part of the fuel system.

NOTE: It is recommended that you obtain and read the

NFPA (National Fire Protection Association) #58, Standard

for the Storage and Handling of Liquefied Petroleum

Gases.

Page

6

SAFETY

INFORMATION

First Respondent and Operator Warning

Material ID Number: 1075

Guide Number: 115

NOTE: Please refer to Cautions and Warnings in the

PHMSA

Emergency Response Guidebook. (Pipeline and

Hazardous

Material Safety Administration)

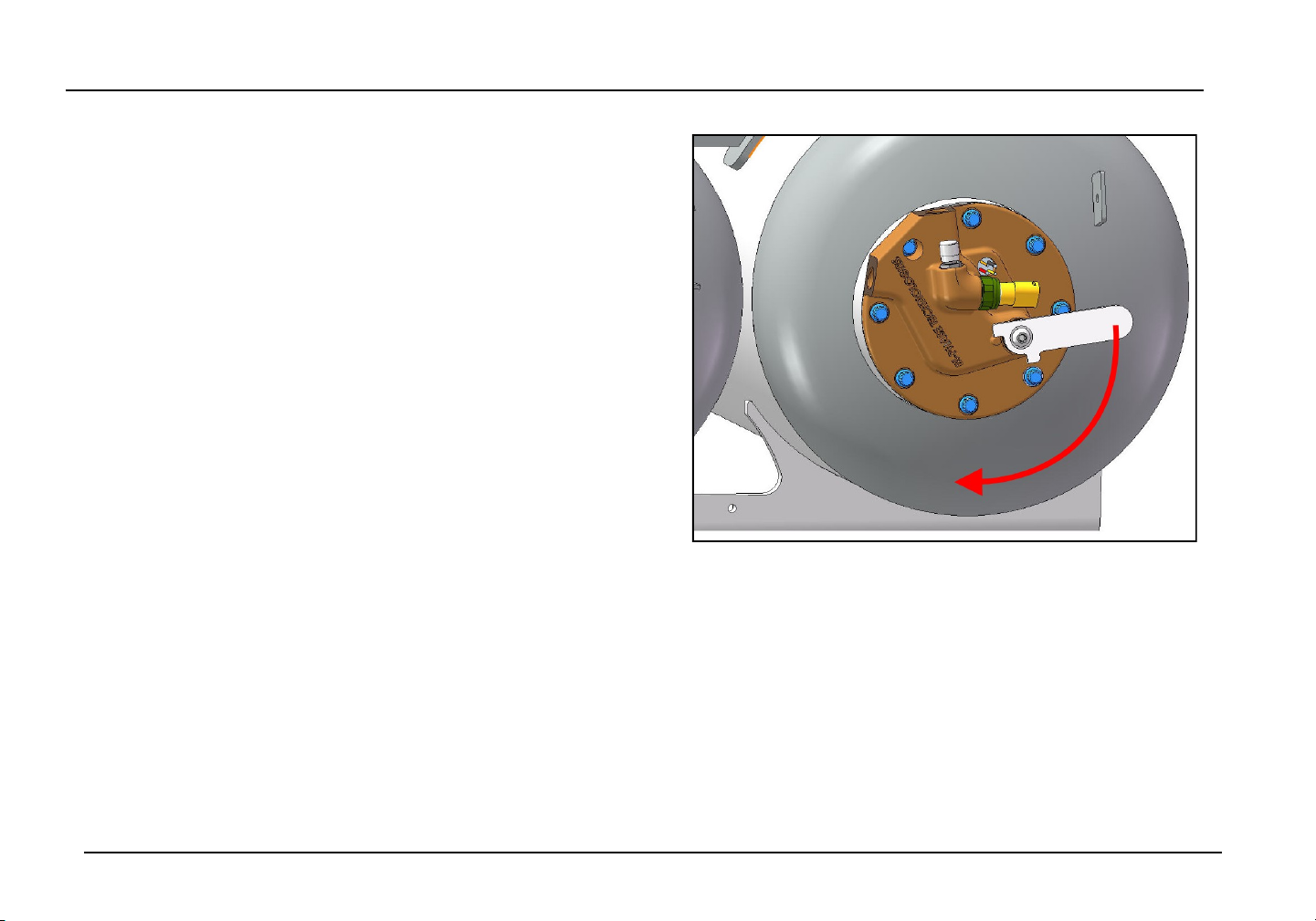

1/4 Turn Safety Shut-Off Valve

The fuel system utilizes a manual shut-off valve to be used in

the case of an emergency.

The valve is located on the front of the left-hand side fuel tank

(driver's side). To operate the valve, grab firmly and pull the

valve down a 1/4 of a full turn (90°) until the tab on the lever

bottoms out on the dowel. This will manually stop fuel flow from

the tanks.

Refer to figure 1 to the right.

Figure 1 - 1/4 Turn Safety Shut-Off Valve

Page

7

SAFETY

INFORMATION

Propane Safety Specifications

Specification Item

Unit

Initial Boiling Point @ 14.7 psi

Weight per 1gal of liquid @ 60°F.

Ignition Temperature in Air

Air/Fuel Ratio by Volume

Air/Fuel Ratio by Weight

-44° (-42.2°)

4.24 (7.28)

920°-1,120° (493.3°-604.4°)

15.6:1

24:1

°F (°C)

lbs/gal (kg/L)

°F (°C)

Chemical Formula: C3H8

Page

8

WARRANTY

Page

9

WARRANTY

Warranty

EPA and CARB Emission System Warranty

WARRANTY PERIOD

Government agencies including the United States

Environmental Protection Agency (EPA) and the California Air

Resources Board (CARB) require Power Solutions International,

Inc. to provide emissions warranty to end users. PSI must

warrant the engine is designed, built and equipped so as to

conform at the time of sale with applicable regulations and be

free from defects in materials and workmanship for a defined

period of years or miles, whichever occurs first (Emissions

Warranty). PSI will provide emissions warranty coverage as

required by the EPA and CARB regulatory agencies. Emissions

Warranty does not cover, remanufactured, dealer rebuilt or

dealer exchange engines.

•

5 years

• 50,000 miles (80,467 km)

•

Or if covered by any basic or extended warranty (if greater

than above)

Your 8.8L LP engine conforms to U.S. Environmental

Protection Agency (EPA) regulations for emission systems.

The California Air Resources Board, United States

Environmental Protection Agency and Power Solutions

International, Inc. are pleased to explain the emission control

system warranty on your PSI 8.8L LP engine. In California, new

motor vehicles must be designated, built and equipped to meet

the State's stringent anti-smog standards. Power Solutions

International, Inc. warrants the emission control system on your

engine for the periods of time listed, provided there has been

no abuse, neglect or improper maintenance of your vehicle.

Your emission control system includes parts such as the LPG

fuel-injection system, the ignition system, catalytic converter,

and

engine computer. Also included may be hoses, belts,

connectors

and other emission-related assemblies.

Where a warrantable condition exists, Power Solutions

International, Inc. will repair your truck at no cost to you

including

diagnosis, parts and labor.

Manufacturer's Warranty Coverage

5 years or 50,000 miles (whichever first occurs):

1)

If your truck fails a Smog Check inspection, all necessary

repairs and adjustments will be made by Power Solutions

International, Inc. to ensure that your emission control system is

working properly. This is your Emission Control System

PERFORMANCE WARRANTY.

2)

If any emission-related part on your truck is defective, the

part will be repaired or replaced by Power Solutions

International, Inc. This is your short-term emission control

system DEFECTS WARRANTY.

Page

10

WARRANTY

Federal Emission System Warranty (cont.)

Owner's Warranty Responsibilities

As the truck owner, you are responsible for the performance of

the required maintenance listed in your Operation and

Maintenance manual. Power Solutions International, Inc.

recommends that you retain all receipts covering maintenance

on your truck, but Power Solutions International, Inc. cannot

deny warranty solely for the lack of receipts or for your failure to

ensure the performance of all scheduled maintenance.

You are responsible for presenting your truck to a certified

dealer

as soon as a problem exists. The warranty repairs should

be

completed in a reasonable amount of time, not to exceed 30

days.

As the truck owner, you should also be aware that Power

Solutions International, Inc. may deny you warranty coverage if

your truck or a part has failed due to abuse, neglect, improper

maintenance or unapproved modifications.

In the case of emergency when a warranted part or warranty

station is not reasonably available to you, repairs may be

performed at any available service establishment, or by you,

using any replacement part. Power Solutions International, Inc.

will reimburse you for your expenses including diagnostic

charges for such an emergency repair or replacement, which

cannot exceed Power Solutions International, Inc's suggested

retail price for all warranted parts replaced and labor charges

based on Power Solutions International, Inc's recommended

time

allowance for the warranty repair and the geographically

appropriate hourly labor rate.

All receipts and failed parts must be kept in order to receive

compensation for warranted repairs reimbursable due to an

emergency.

If you have any questions regarding your warranty rights and

responsibilities, you should contact Power Solutions

International, Inc. at 888-331-5764 or the California Air

Resource Board at 9528 Telstar Avenue, El Monte, CA 91731.

Page

11

WARRANTY

Federal Emission System Warranty (cont.)

WARRANTY EXCLUSIONS

The following items are not reimbursable under the PSI warranty

terms.

•

Any repair on an engine that has exceeded the hour or time

limitation of the stated warranty.

•

PSI may deny any claims that in their sole discretion are the

result of misapplication of the engine or part.

•

Units that are under development (i.e. prototype projects,

engineering projects).

•

Any repair on an engine where the hours of operation or in-

service date has been misrepresented.

•

Any repair on an engine if the hour meter has been altered

so that the true hours on the engine cannot be determined.

•

Any repair on an engine where the date of service has been

misrepresented to place an out-of-warranty engine inside the

warranty period.

•

Engines damaged by an Act of God or force majeure.

•

Routine maintenance repairs.

•

Repairs required due to improper storage precautions.

•

Adjustments made to improve performance beyond PSI

estimated normal standards.

•

Use of other than genuine OEM parts, unless in an

emergency situation.

•

Any failure that is a result of the application and not a defect

in the materials or workmanship from PSI as deemed by PSI.

•

Repairs to parts that, upon analysis, are found not to

be defective.

•

Repairs to engines used for re-powering on-road vehicles.

•

All consequential expenses, including, but not limited to,

those

resulting from equipment failure such as lodging, food,

downtime or replacement equipment rental.

•

Any misapplication or misuse of the product as deemed

by PSI.

•

Towing or transportation expense for moving an engine or

engine-powered equipment from the customer location to the

repair location.

•

Repairs caused by damage due to poor workmanship.

For additional warranty information please refer to the "Power

Solutions International Warranty Policy and Procedures

Manual".

Page

12

SECTION

1

–

ENGINE

SYSTEMS

Page

13

SECTION

1

–

ENGINE

SYSTEMS

Engine Serial Number

The engine serial number can be found in two locations.

The serial number label will be located on the right-hand side

valve cover as shown in figure 3.

The number will also be stamped on the left-hand side of the

engine, near the flywheel as shown in figure 4.

Engine Serial Number Examples

8.8L12345

Engine Serial Number Codes

8.8L - Engine Displacement

12345 - Engine Serial Number

Figure 2 - Serial Number Label Example

Figure 3 - Serial Number Label Location

Figure 4 - Stamped Location of Serial Number

Page

14

SECTION

1

–

ENGINE

SYSTEMS

Engine Emission Label

The U.S. Environmental Protection Agency (EPA) exhaust

emission label is attached to the plate on top of the intake

manifold as shown in figure 6. The EPA label typically includes

the following:

•

Model year

•

Engine family and displacement

•

Advertised horsepower rating

•

Emission family and control systems

Figure 5 - Emission Label Example

Engine Spec Label

There will also be an Engine Spec Label that contains the spec

description, spec number, and an engine spec barcode. This

will be located on the plate mounted to the top of the intake

manifold as shown in figure 6.

Engine Accessories

The following engine parts may have manufacturer's labels or

identification plates:

•

Alternator

•

Compressor

•

Engine Control Module

Figure 6 - Engine Spec Label

Table of contents

Other PSI Engine manuals

Popular Engine manuals by other brands

Perkins

Perkins 4016-61 TRG Operation and maintenance manual

Yanmar

Yanmar 4LHA-HTP Operation manual

Kohler

Kohler KD225 owner's manual

Nice

Nice Neomat A Series Instructions and warnings for the fitter

Detroit Diesel

Detroit Diesel 8 V 4000 M60 R operating instructions

Kohler

Kohler Aegis 05810334 Service manual