Daily coolant level check and replenishing shall be done only at the sub-tank. Usually do not open the

radiator cap to check or replenish.

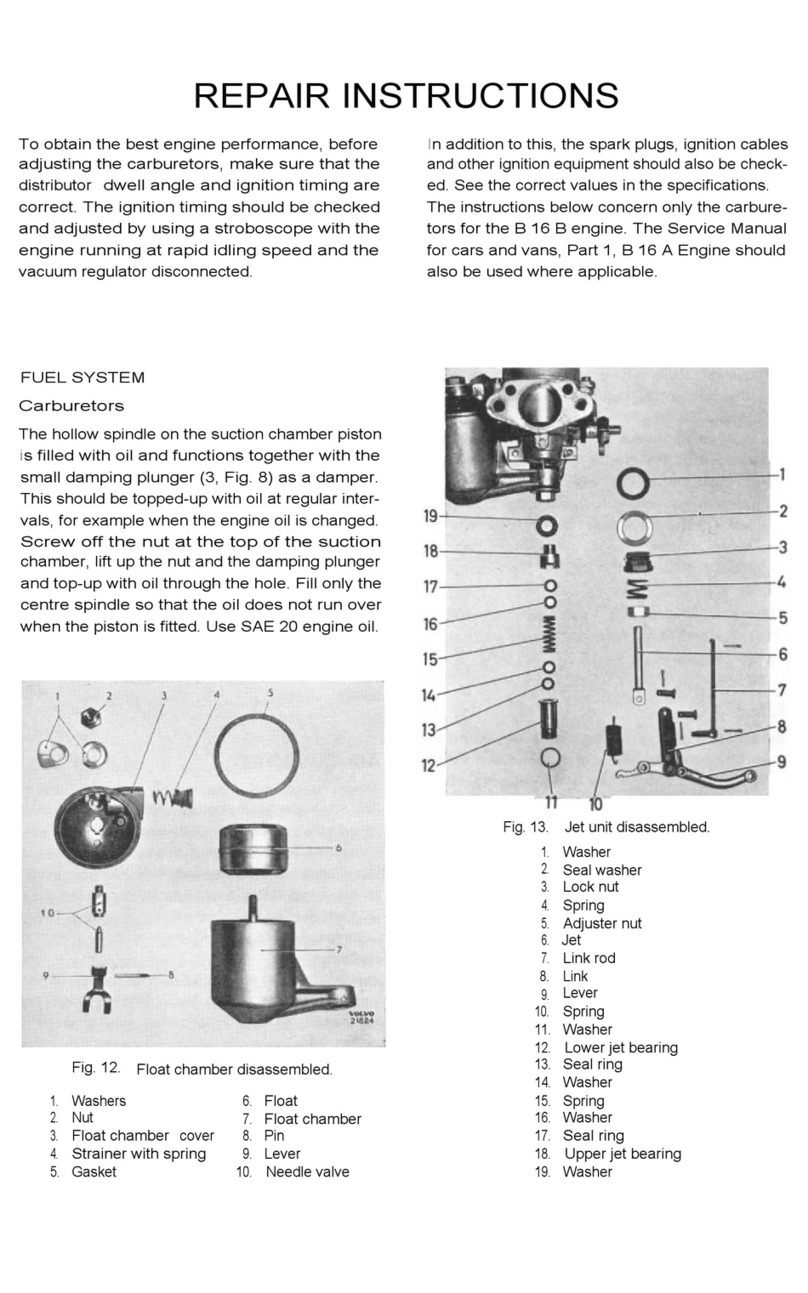

Figure 3

Replenishment, coolant

A.

B.

C.

Tighten

Loosen

Radiator cap

NOTE!

If the coolant runs short quickly or when the radiator runs short of coolant with the sub-tank level unchanged, coolant may

be leaking or the air tightness may be lost. Increase in the sub-tank level during operation is not abnormal. The increased

coolant in the sub-tank returns to the radiator when the engine is cooled down. If the level is normal in the sub-tank but low

in the radiator, check for loosened clamping of the rubber hose between the radiator and sub-tank or a tear in the hose.

Engine: The radiator shall be filled up.

Coolant capacity, unit: liter (gal)

Coolant volume in the engine

0.9 (0.23)

Fuel pipe and cooling water pipe inspection and maintenance

Check the rubber hoses for fuel and cooling water pipes cracked. If the cracked hose is found, replace it with new one. Check

the loosened clamp. If found, tighten it.

Warning lamp & instruments function check

Before and after starting the engine, check to see that the alarm function normally. Failure of alarm cannot warn the lack of

the engine oil or the cooling water. Make it a rule to check the alarm operation before and after starting engine every day.

Checking accelerator operation

Make sure the accelerator of the machine unit can be operated smoothly before starting the engine. If it feels heavy to

manipulate, lubricate the accelerator cable joints and pivots. Adjust the accelerator cable if there is a dislocation or excessive

play between the accelerator and the governor lever.

Inspection after initial 50 hours operation

WARNING

Hot oil and hot engine coolant can cause severe burns!

NOTE!

Replace engine oil after the engine oil becomes warm. It is most effective to drain the engine oil while the engine is still

warm.

In early period of use, the engine oil gets dirty rapidly because of the initial wear of internal parts. Replace the engine oil

earlier. Engine oil filter should also be replaced when the engine oil is replaced. Engine oil and engine oil filter replacing

procedures are as follows. Remove the oil filler cap to drain easily while draining the engine oil.

Drain engine oil

Prepare a waste oil container collecting waste oil.

Remove the drain plug using a wrench to drain the engine oil.

Securely tighten the drain plug after draining the engine oil.