PST Jets J600R User manual

J600R Miniature Turbojet

Instruction Manual

(Version 1.5.3.1/2005)

1111/1 Pattanakarn Road, Suanluang, Bangkok 10250, Thailand

Tel : Intl + 66 2318-6918: +66 2717-8645 Fax: Intl + 66 2318-6921

©Copyright 2004-2005 PST Jets Co., Ltd. All Rights Reserved

J600R Instruction Manual

Welcome Notes

Dear PST J600R owner,

Congratulations on the purchase of your new PST J600R miniature turbojet engine.

Let us greet you in our Thai tradition, “Sawasdee” which means welcome or greetings in

Thai. We are committed to producing and delivering quality products to our customers.

As avid Jet modelers we feel we have a good understanding of what other modelers

look for and need in a turbine engine.

The J600R is the result of significant R&D and manufacturing development undertaken

since 1997. In early 2003, we launched the J600R which is the successor to our original

popular J600. The J600R incorporates a PST designed modified diffuser, combustion

chamber, and tail cone resulting in higher thrust output. The engine controller unit,

TEMS, is a state-of-the-art device which is specifically manufactured/programmed for

the J600R. Your engine and support system have been factory tested and passed our

rigorous quality control standards. The appearance of the bluish tinge on the exhaust

cone is normal after factory testing of the engine prior to shipment. Factory test runs

also serve as the “break-in” and seating of bearings and internal components

procedure. All engines leave the factory with the confidence that they meet

specifications for performance and reliability that our customers expect.

Safety is our credo. Regardless of your turbine experience, it is necessary to carefully

read this manual in its entirety before attempting to operate the J600R. This manual has

important information that will ensure safe operation of the J600R.

Please read it !

We are dedicated to customer satisfaction. Technical support is available thru email 7

days a week. Replacement parts are always in stock for prompt service ensuring quick

turn-around time.

Thank you and enjoy.

PST Jets Co., Ltd.

1111/1 Pattanakarn Road

Suanluang, Bangkok 10250

Thailand

Web site: http://www.pstjets.com

Tel : Intl + 662 318-6918

Intl + 662 717-8645

Fax : Intl + 662 318-6921

Copyrights ©PST Jets Co., Ltd. - i- Version 1.5.3.1/2005

J600R Instruction Manual

Notices and Disclaimers

All contents copyright © PST JETS Co., Ltd., Bangkok, Thailand. All rights reserved.

No part of this manual may be reproduced, translated, transcribed or redistributed

without written permission from PST JETS Co., Ltd. All product information and

specifications are subject to change at any time without notice.

The “PST JETS” logo and “PST JETS with turbine wheel and passing jet” logo are

trademarks of PST JETS Co., Ltd., Bangkok Thailand.

Disclaimer:The turbine engine is a sophisticated piece of machinery. Modeling

experience, basic turbine knowledge, and technical common sense are required.

Always seek expert advice or experienced turbine operators before operating the

engine. If not operated properly, turbine engines are capable of causing property

damage and/or bodily harm to both the operator and other persons in proximity. PST

Jets assumes no liability for damage that may occur from the use/misuse of this product

in any form whatsoever. We recommend that you visit GTBA and read about turbine

safety and code of practice.

PST JETS assumes no responsibility for errors contained in this document and is not

liable for any damages resulting from such errors. This manual is not controlled by

revision. For latest version and updates, check our website www.pstjets.com or contact

Copyrights ©PST Jets Co., Ltd. - ii - Version 1.5.3.1/2005

J600R Instruction Manual

Warranty

PST JETS Co., Ltd. is hereinafter referred to as “PST”. The warranty period for the PST

J600 and J600R is 1 year from the original date of purchase or 120 run cycles,

whichever shall occur first. Warranty is valid for original owner only and non-transferable

upon resale. The warranty includes parts and labor and is limited to manufacturing and

material defects only. The limited warranty does not cover the electric starter motor,

batteries, or glow plug. Upon replacement of components from a warranty claim, the

replaced components and or engine servicing will be subject to the original warranty

coverage period.

Shipping costs (including insurance and applicable duty and taxes) to the local PST

representative or with authorization PST, for any warranty claim are the sole

responsibility of the customer. Return shipping is covered by PST in the same method

of receiving the shipment from the customer. Should any part of the product need to be

returned from the PST representative to PST headquarters (Bangkok, Thailand), this

shipment cost is covered by PST. Any additional costs are the responsibility of the

customer. PST assumes no liabilities for damage to products during shipping.

This warranty is void if any one or more of the following conditions applies. Under such

conditions PST assumes no liability for personal damages, third party damages, loss of

models, or any other consequences arising from the purchase usage of operation of the

J600/J600R engine.

a. The serial number or identification information is defaced, modified, or removed.

b. The product is used for purposes other than that of radio-controlled model

airplanes without written authorization by PST.

c. The product has been damaged from a crash or otherwise accidental event,

ingestion of foreign materials, improper installation / configuration, improper

storage or environmental exposure, and any acts of god.

d. The product has been subject to any form of start-up or operation with any

incorrect fuel, oil, or fuel/oil mixture ratio.

e. Dirty or contaminated fuel is used.

f. Unauthorized maintenance or modifications have been performed on any part(s)

of the product.

g. The product has been abused, incorrectly maintained, or neglected.

h. The product has not followed the mandatory check-up procedure, whereby every

PST J600 should be inspected by a certified PST service representative or PST

after 120 starts.

Yearly inspection is highly recommended but not mandatory. Components required in

the inspection / warranty claim include the complete turbine as purchased, TEMS,

thermocouple, and fuel pump. Please contact your PST representative or PST for

further details.

Copyrights ©PST Jets Co., Ltd. - iii - Version 1.5.3.1/2005

J600R Instruction Manual

Warranty (cont)

All turbines will be partially disassembled, inspected, and shipped within 5 business

days of receiving. Damaged components that are deemed to be warranty covered are

replaced, tested, and returned at PST cost.

For crash damaged, depending on the extent of damage, the turbine may required more

than 5 days downtime, at which time the customer will be immediately contacted for a

consultation. Please verify all service details with PST representative before shipping.

Shipping cost and insurance is the sole responsibility of the customer in addition to the

repair/service costs.

Copyrights ©PST Jets Co., Ltd. - iv - Version 1.5.3.1/2005

When upgrade option becomes available and the original owner wishes to have the

engine upgraded, the newly installed components shall be given a 1-year warranty

(valid from the return shipment date). Other original parts/components remain under the

original warranty. Shipping cost and insurance is again the sole responsibility of the

customer and is not covered under the modification costs.

J600R Instruction Manual

PST Dealers/Representatives

USA/Canada

Dean Wichmann, HeliJet R/C International; [email protected]; www.helijet.ca

Kelly Williams, HeliJet R/C International; [email protected]; www.helijet.ca

Australia/New Zealand

Kevin Dodd (TMAC), Brisbane, QLD - very experienced flight instructor and certified

Phillip Collings, Brisbane - Service / Repair Center; E-mail: [email protected]

Rick Butnaro, Sydney, NSW - Tel: 0412-353-645; E-mail: [email protected]

Trim Aircraft, Melbourne, Victoria – Website: www.trimair.com.au

Rene Redmond,New Zealand - Galtech Models Ltd.; Tel:063555747;Fax:063594501;

Japan

Masashi Tahara, Osaka, JetSet; Email: [email protected] ; ma@jetsetj.com ;

www.jetsetj.com

South Africa

Bruce Rattray, GB Hobby Electronics

Website: http://www.gbhobby.com; Email: [email protected]

South Korea

JY Shim, Email: [email protected]

Taiwan

Anton Lin, RC ARF.com; Email: [email protected]

United Kingdom/Europe

Iain Nicol, Scotland - I.A.D. Model Designs, Tel +44(0)1236423448; Home of "Serpent"

Martin Forrest, England –

U.A.E

Kajoor Power Models, Dubai – Website: www.kajoorpower.com

Copyrights ©PST Jets Co., Ltd. - v- Version 1.5.3.1/2005

** For more updated information, please visit our website at www.pstjets.com **

J600R Instruction Manual

Table of Contents

WelcomeNotes i

Legal & Disclaimer ii

Warranty iii

PST Dealers/Representatives v

Table of Contents vi

Introduction to turbine 1

PackingLists 3

Safety Tips and Notes 4

Fuel System

A.FuelTanks 6

B.FuelPump 7

C.Fuel&Oil 7

Gas System

A. Internal Gas Canister 8

B. External Gas Tank 9

C.One-wayValve 9

D. Quick Disconnect Valve 9

Accessories

A.Battery 10

B.Fuel&GasFilters 10

C.GlowPlug 10

D.Chargers 11

E. Battery Checker 11

PST TEMS -Turbine Engine Management System

A. System Components 12

B. Features of TEMS 13

C.SoftwareVersion 13

D.InstallationofTEMS 13

E. GDT (Ground Display Terminal) 15

F. Programming Features 16

G. GDT Diagnostics Display Interpretation 18

H. TEMS Trouble Shooting 19

I. Auto Start Sequences 20

J. Calibrating MIN and MAX rpm 21

Copyrights ©PST Jets Co., Ltd. - vi - Version 1.5.3.1/2005

J600R Instruction Manual

Copyrights ©PST Jets Co., Ltd. - vii - Version 1.5.3.1/2005

Table of Contents (cont)

Mounting & Installation 22

BeforeStart 23

Starting 24

Maintenance 25

J600R Trouble Shooting 26

J600R Specifications 28

Diagrams

A. Fuel & Gas Canister/Cartridge Setup 29

B. Internal Gas Canister/Cartridge 29

C. Main & Header Tanks Setup 30

D. J600R Sectional View & Parts list 31

FAQ 33

J600R Log Sheet 35

J600R Instruction Manual

Introduction to turbines

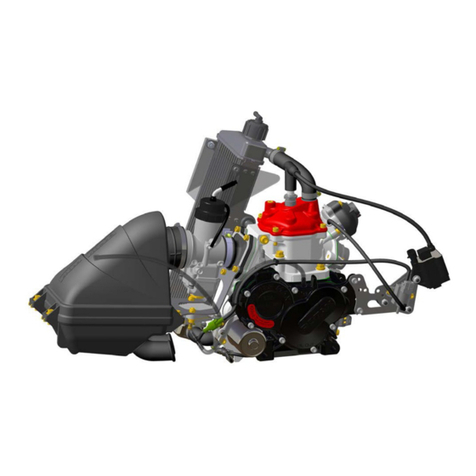

The first phase of turbine operation is intake and compression. In large-scale jet

engines, the compression phase may involve several stages of axial and radial

compression. For simplicity only a single centrifugal (radial) stage will be discussed in

this manual. Axial compression is rarely seen in model turbines and is more reliant on

having a clean air intake, similar to a ducted fan configuration. Centrifugal compressors

rely far less on ram air effects, clean intakes, and Reynolds number effects, making

them much more predictable at speed and much more suitable for use in model jets.

After the air leaves the radial compressor, it flows outward through a set of primary and

secondary diffuser vanes which harness the high velocity radial flow and transform it to

high pressure axial flow into the pressure chamber. Diffuser design is critical due to the

amount of losses induced in the transformation; the less energy lost in the compression

process, the less energy needed to drive the compressor for the same overall mass flow

and thrust output. Poorly designed diffusers can be susceptible to elevated temperature

at the engine’s front end and compressor surge / stall at different atmospheric

situations. The turbine outer diameter size is also a contributing factor to the efficiency

of the diffuser design. As the outside diameter increases, the airflow though the diffuser

is smoother and has lower velocity gradients. Our PST J600R is an excellent example

of a balancing act between performance vs. size and design complexity.

Copyrights ©PST Jets Co., Ltd. - 1- Version 1.5.3/2005

Next is the combustion phase. The combustion chamber is basically just a container

that houses a continuous and very intense explosion. High temperature materials such

as stainless steel Inconel and titanium are commonly used in large-scale turbines, but

thin stainless steel / Inconel sheet is usually the more cost effective material of choice

for models. The annular style chambers used in models have holes strategically located

in the inner and outer walls for feeding the combustion flame and for cooling the

exhaust gasses as they exit. Some holes are dimpled inward to produce higher velocity

mixing jets. Fuel is added from the rear end of the chamber, sprayed forward through a

number of vaporizer tubes that heat the fluid to produce a combustion ready air-fuel

mixture. Combustion occurs in the front section of the chamber and only persists for a

short distance rearward. After combustion, the optimized holes mix cool air (relatively

cool…+100°C approx.) with the exhaust gasses to bring them down to a more suitable

level in the exhaust turbine. (Absolute design maximum: 800° C in this case)

J600R Instruction Manual

Copyrights ©PST Jets Co., Ltd. - 2- Version 1.5.3/2005

Introduction to turbines (cont)

The turbine stage can also be radial or axial and involves multiple stages. For simplicity,

a single stage is discussed here. As the exhaust exits the combustion chamber, it

enters the nozzle guide vanes (NGV) which convert axial velocity to axial flow with a

large radial component. The swirl induced in the NGV is optimized for interaction with

the blade profile on the turbine wheel. The turbine wheel then harnesses a great deal of

energy from the exhaust gas flow’s radial component, leaving axial flow behind. The

energy is transferred through the shaft and used to drive the compressor while the

energy remaining in the exhaust flow after the turbine stage is converted directly into

thrust. Miniature turbines today are equipped with hi tech ceramic bearing to support the

shaft with the rotor assembly turning at more than 160,000 rpm. The J600/R uses two

GRW angular contact, cageless ceramic bearings which are rated up to 220,000 rpm.

That’s probably enough of an introduction on turbine theory. You bought this engine to

fly. We have done most of the difficult parts of turbine design/building and have

simplified operation procedures so that an average modeler can enjoy the world of jet

flying. Fasten your seat belt…let’s begin the exploration of the miniature turbine world

and see what we have in store for you.

J600R Instruction Manual

Packing List

Please check that all components listed below were shipped with your J600/R turbine.

Contact your dealer or ourselves if any items below are missing or appear to have been

damaged in shipment.

E-mail: [email protected]

SN600AC or SN600RAC – Auto start complete package:

1 PST J600/R Turbojet Engine with electric starter

1 PST TEMS

1 GDT (Ground Display Terminal)

1 Fuel Pump

1 Gas solenoid valve

1 Festo ball valve (Fuel Shutoff valve)

1 EGT probe

1 Glow plug (mounted on engine)

1 ECU switch with protective 15A Slow-Blow fuse

1 Battery pack (Ni-Cad 7.2V 1700SCR)

1 Charging cable with battery male-connector

1 set of engine mounting brackets

1 set of quick disconnect fittings

1 set of 4mm gas/fuel tubing (tubing for fuel tanks installation not included)

1 Gas Canister with 3-way connector and 1-way valve

Copyrights ©PST Jets Co., Ltd. - 3- Version 1.5.3.1/2005

1 PST J600/R Instruction Manual

J600R Instruction Manual

Safety & Notes

I M P O R T A N T !!!

Safety:A model turbine engine is a highly sophisticated and potentially dangerous

device if used improperly. Your turbine should be treated with care and the application

of prudent safety standards. The following safety guidelines must be adhered to ensure

your safety, the safety of others and your enjoyment of your engine.

Fire Extinguishers Eyes & Ears Protection

a. Always have a good fire extinguisher ready when starting turbine engines (Halon

1211 or BF2000 type recommended). Chemical fire extinguishers can be used but in

this event the engine must be returned to PST Jets for cleaning and inspection.

b. Always protect your eyes and ears during startup or when in close proximity to the

starting of a turbine.

c. Always start the turbine outdoors with good ventilation.

d. Always handle Jet A1, Kerosene, and propane/butane gas in well-ventilated areas

away from any open flame or heat sources. These substances are highly flammable.

e. Do not stand in high risk areas of the turbine such as on the side and in the area of

hot air behind it; and the immediate area in front of the compressor wheel. Again we

emphasize never allow anyone to stand behind the turbine when it is started.

f. Do not touch the engine while it is running. Turbines rotate at very high rpm and the

engine casing can reach very high temperatures. Severe burns or body injuries can

occur if you come into contact with the casing and/or exhaust nozzle.

g. Do seek expert advice for installing the turbine and support system to the airframe.

h. Abort start or any flight attempts if excessive vibration or abnormal noise is evident.

i. Keep unauthorized persons, especially children, away from starting area. We

recommend at least 30 feet away.

Copyrights ©PST Jets Co., Ltd. - 4- Version 1.5.3/2005

J600R Instruction Manual

Safety & Notes (cont)

Notes:

a. The recommended and default settings programmed into the ECU should not be

altered unless absolutely necessary. The engine has been tested and operates to its

designed performance specifications under these parameters. We cannot guarantee

proper operation of the J600/R if the parameters are altered or different fuel pumps

and accessories are used. E-mail us for technical help if you have any questions.

b. Use good chargers to charge both ECU and Rx batteries. Limit the ECU battery

(7.2V Nickel Cadmium with at least 1700mAh capacity) to two flights for one full

charge. The fuel pump drains lots of current at high rpm and no flight should be

made without recharging the ECU battery after approximately 25 minutes of engine

run time.

c. Make certain that all wiring and plumbing is done correctly in accordance with the

information contained in this manual.

d. Use filtered and moisture free Jet A1, Jet A, or kerosene fuel only.

e. Use turbojet oil, we recommend Exxon 2380, Aero Shell 500, or Mobil Jet Oil II).

2-stroke oil is not allowed and will cause damage to the engine thus voiding the

warranty.

f. Fuel/Oil mixture of 5% should be used (See Fuel section for more details).

g. Extra fuel and gas filters are highly recommended to avoid clogging up of the “last

chance filters” located inside the front cover. The Kavan filter as shown in this

manual is a suitable filter type. Avoid cheap motorcycle or automobile plastic filters,

they may be used in the refueling system but not in the main system.

h. Bubble-elimination devices should be used in or as the header tanks for bubble-free

fuel. Seek expert advice if you are not experienced.

i. For manual or emergency shutdown, a fuel shut-off valve (Festo Ball Valve) is

included and should be installed between header tank and turbine fuel inlet.

j. LPG or camping gas with a maximum 70/30 Propane/Butane mix can be used. Use

a one-way valve for filling the gas canister. High pressure propane/butane can

freeze up the solenoid valve thus locking the valve in the closed position.

k. The fitting valves and connectors supplied are of a very high quality although other

similar products may be used.

l. When new devices or accessories are adopted, it is wise to test them on the bench

prior to installation into the airframe.

Copyrights ©PST Jets Co., Ltd. - 5- Version 1.5.3/2005

J600R Instruction Manual

Fuel System

A. Fuel Tanks

Fuel tank & Filter & Clunk Venting the tank Vent plug for storage

Fuel tube connection Main and header tanks Setup configuration

1. Use a sturdy polyurethane plastic bottle(s) or specially made Kevlar tank(s) with a

total capacity of at least 1.5 liter (2 liters recommended). This may vary upwards

depending on the requirements of your model including items such as size, weight,

wing loading and flight time requirements.

2. Use bubble-free filtered clunks for header tanks. We recommend the OS Super Filter

(size to suit tank size) as shown in the picture above. These filters are inexpensive

and do the job well. Similar bubble-elimination device may be used as well.

3. Use the clear 4mm tubing provided for the fuel line. Silicone gasoline/benzene

(Tygon) fuel line can also be used if preferred. If you want to connect Tygon fuel line

with the 4mm fuel line, insert at least ½ “ inch of the 4mm line into the Tygon line to

ensure a leak free connection

4. Vent the fuel system to avoid the creation of a vacuum. See pictures above and

diagram A. Important: Make sure the vent line is large enough, as insufficient venting

will cause a vacuum overcoming the fuel pump suction capability resulting in

flameout or the breakage of your fuel tank.

5. During startup we recommend that you run fuel lines from the main tank vent to an

external fuel tank outside of the airframe. The external fuel tank can serve as both

an overflow and ground start / supplementary fuel source. The airframe vent tube

should be at least ¾“ in length and cut 45 deg facing forward to avoid boundary air

effects. This takes up any fuel that flows out during filling, it also reduces

consumption of onboard fuel during startup which in turn allows you longer flight

times.

6. If multiple tanks are used, make sure that the tanks are of same size/shape and fuel

lines connecting the tanks are of equal length and that vent line is provided. See

diagram C for more details. Seek experienced or expert help if you are uncertain.

Copyrights ©PST Jets Co., Ltd. - 6- Version 1.5.3/2005

J600R Instruction Manual

Fuel System (cont)

7. Fueling is accomplished through the header tank into the main tank. Make sure that

air bubbles are removed from the header tank. Air inside the fuel line will cause a

flameout. Do not use flex tube or a clunk inside the header tank. The feed line

should be geometrically centered in the header tank. See diagram C for more detail.

8. After the header tank is filled you can then fuel directly into the main tank for faster

fueling. Your tanking system must be fitted with a fill tube to the main tank.

9. Ensure that you have safely wired and joined all line connections to prevent them

from coming loose during operation.

B. Fuel Pump

Pump in direction Festo Ball Valve Use good filter

1. Observe the pump fueling direction. Fuel goes in on the side marked by a small

indention and out on the other side.

2. Use the clear 4mm tubing provided for fuel line connections.

3. Install ball valve between header tank and engine, either between the header tank

and the pump (on suction side), or between the pump and engine (on pressure

side).

4. Use a good gasoline filter between the fuel pump and the engine. It is better to have

the filter behind the pump to avoid bubbles caused by suction/cavitations.

5. Ensure that all wires and line connections are properly joined and attached to

prevent them from coming loose during operation.

C. Fuel and Oil

Use clean & filtered fuel Turbo Oil Use clean fuel tank

1. Use Jet A, Jet A1, or kerosene. Make sure that the fuel is clean and free from

moisture and other forms of contamination. Water is heavier than fuel and will settle

at the bottom of the container.

Copyrights ©PST Jets Co., Ltd. - 7- Version 1.5.3/2005

J600R Instruction Manual

Fuel System (cont)

2. The fuel tank must be free from foreign particles.

3. Use good quality turbo oil such as those in the picture above. 2-stroke oil will cause

serious damage to the engine and void your warranty.

4. The fuel must be mixed with 5 percent turbo oil. For simplicity, mix five parts of oil to

100 parts of kerosene. The J600 will tolerate mixture imperfections between 4-6%.

Too little oil will shorten the bearings life due to higher temperature. Too much oil will

reduce the engines performance due to unnecessary stress on the bearings.

5. We recommend that the fuel be mixed in gallon scales, as the mixing will be more

accurate. Example: mix 1 quart of oil to 5 gallons (19 liters) of kerosene. Most turbo

oil comes in quart cans, so mixing with 5 gallons of kerosene is simple.

Gas System

A. Internal Gas Canister

Gas Canister/Solenoid Valve & New Gas cartridge Filling the canister

1.

2.

3.

4.

5.

6.

7.

8.

A custom machined internal gas canister is provided with a quick connector

attached.

Use the blue 4mm tubing provided for gas connections.

The two-way quick connect is connected to the gas solenoid valve and the one-way

valve.

The direction of the one-way valve is marked on the valve itself. "IN" direction is from

the end with silver tape. The valve must be connected with the "IN" direction facing

away from the canister to allow proper filling. In the pictures above the "IN" direction

is plugged with an orange stopper.

The tube ends should be pushed all the way into the connector/valve to avoid

leakage.

Fill the canister by connecting an external gas source (Propane/butane 70/30 mix) to

the one-way valve "IN" direction. Point the external gas-filling tank (GAS CAN) down

to let the liquid flow into the canister.

Stop filling when the canister is 1/4 to 1/2 full. Since there is no visual indication, just

approximate the filling amount. Very little is actually required for one successful auto

start. The canister supplied is larger than required. From our tests, we can obtain

more than 5 starts with one fill (3 starts with a new gas cartridge).

Copyrights ©PST Jets Co., Ltd. - 8- Version 1.5.3/2005

Disconnect the filling line carefully, as high pressure propane is present in the line

and will be forced out briefly. Safety: Use towels or rags to cover the valve and keep

your face and eyes away during disconnection. Do not smoke any where near your

turbine at any time.

J600R Instruction Manual

Gas System (Cont)

9.

10.

Make sure that the canister/cartridge stands upright in the airframe to avoid liquid

gas entering the engine. During start, excessive flame and engine surge will result if

the liquid gas is allowed to enter the engine. (This is known as a hot start) This is not

healthy for the combustion chamber or your model.

For safety purposes, the onboard gas canister/cartridge should be emptied after

flying sessions prior to storage. Simply disconnect the line to the solenoid valve or

the one-way valve. Safety: Use towels or rags to cover the valve and keep your face

and eyes protected during the disconnection.

B. External Gas Tank

1. External gas tanks may be used to replace the internal canister/cartridge.

2. Use a similar manual valve connection as shown in the picture above (the valve is

not included but available as an option from PST).

3. Connect the external gas line to the solenoid valve via a quick disconnect connector.

4. Do not by-pass the gas solenoid valve during start. Incorrect manual metering of the

gas may cause internal damage and flame coming out of tail cone.

5. Before start, open the external gas tank valve.

6. After start, close the valve and disconnect the external gas tank. Take care that the

disconnection is done far from the exhaust cone as there could be excess gas

escaping during disconnection. Remember that this gas is highly flammable.

C. One-way Valve

One-way valve "IN" direction is from the silver shaded side.

Use this valve for filling the gas canister.

D. Quick Disconnect Connector

This can be used for both kerosene and gas. It allows easy

connection and disconnection of tubing extension.

Copyrights ©PST Jets Co., Ltd. - 9- Version 1.5.3/2005

J600R Instruction Manual

Accessories

A. Battery

1. Use a good 6-cells 7.2V Ni-Cad or 7.4V Lithium Polymer

battery pack for the ECU

2. Use at least 1700mAh capacity battery

3. The supplied battery pack is Sanyo 1700SCR mAh

B. Fuel & Gas Filters

Gas and Kerosene “last chance” filters are

already fitted inside the front cover

Extra protection is recommended with

additional external filters

C. Glow Plug

Glow Plug & Needle Pull Out the coil Coil pulled out 2mm Glow Plug Cap

1. Use an OS glow plug or similar threaded plug. Higher resistance or colder glow

plugs may require higher glow voltage and this is programmable via the GDT. (see

TEMS section)

2. The coil needs to be pulled out. We recommend using a needle for this job. Be

careful when pulling out the coil so as not to break the filament. For a new glow plug,

heating the filament prior to pulling out the coil will greatly reduce the chance of

breakage.

3. The coil must be pulled out about 2mm.

4. Replace the glow plug carefully and tighten firmly. Just firmly, do not over tighten.

5. The red glow plug cap goes over the plug. Pull the red spring-loaded wire and place

the cap over the glow plug, then release to engage the glow plug head.

6. Make sure that the cap fits firmly and will not come loose during operation. Tie down

the wiring to prevent any possibility of the cap entering the turbine if it inadvertently

comes loose.

Copyrights ©PST Jets Co., Ltd. - 10 - Version 1.5.3.1/2005

J600R Instruction Manual

Copyrights ©PST Jets Co., Ltd. - 11 - Version 1.5.3/2005

Accessories (Cont)

D. Chargers

Sample of charger used Sample of charger used

1. Use a high quality Ni-Cad/Li-Polymer charger that has good charging, discharging,

and conditioning cycle features. The supplied Ni-Cad battery can be quick or slow

charged.

2. Automatic charging is highly recommended.

3. Connect the appropriate charger connectors to the supplied charging cable taking

care that the polarity is correct.

E. Battery Checker

1. Use a good battery checker to check Rx battery

condition.

2. Rx battery’s health is important since the TEMS needs a

good radio signal to function properly.

3. ECU battery voltage can be monitored via the GDT.

J600R Instruction Manual

PST TEMS - Turbine Engine Management System

The PST TEMS is a highly sophisticated electronic turbine controller that is simple to

operate. It incorporates coding and circuitry designed and written specifically for the

J600/R. Your J600/R will perform at optimum levels under the control of the PST TEMS.

Do not, under any circumstances, attempt to use the J600/R with an ECU system other

than the one provided. Such operations can cause the turbine to operate outside its

proper parameters which is dangerous and will void the warranty.

A. System Components

Your system consists of the following:

1. GDT (Ground Display Terminal) – handheld terminal for programming, operating,

and monitoring the TEMS.

2. TEMS – engine controller unit which gather data from connected sensors and

manipulate them for optimum commanded performance.

3. Fuel Pump – supply pressured fuel to the engine as directed by the TEMS.

4. Gas Solenoid Valve (SMC) – automatically turn on and off starting gas as

directed by the TEMS during auto start sequence.

5. Internal Gas Canister – self-contained remote starting gas.

6. Fuel Shutoff (Ball) Valve – manually shut down the engine and provide fuel cutoff

to the engine during fueling.

7. EGT Probe – K-type temperature sensor

8. Hall Effect Speed Sensor – located in the engine front cover to pick up revolution

information.

9. Battery – main power for the TEMS and electric starter, 7.2V, 6-cells, 1700-

1900mAh Ni-Cad (Current supply - Sanyo 1700SCR)

10.ECU Power Switch with 15A Slow Blow fuse in case.

Copyrights ©PST Jets Co., Ltd. - 12 - Version 1.5.3.1/2005

Table of contents

Popular Engine manuals by other brands

Chris-Craft

Chris-Craft 307-Q owner's manual

PleasureCraft Engine Group

PleasureCraft Engine Group 5.0L Diagnostic manual

Predator Engines

Predator Engines 69727 Owner's manual & safety instructions

Rotax

Rotax 912 i series Maintenance manual

Regal

Regal Century VGreen 085 user manual

Lexus

Lexus 2VZ - FE Service Procedures