Carefree of Colorado FREEDOM TUBULAR MOTOR REPLACEMENT

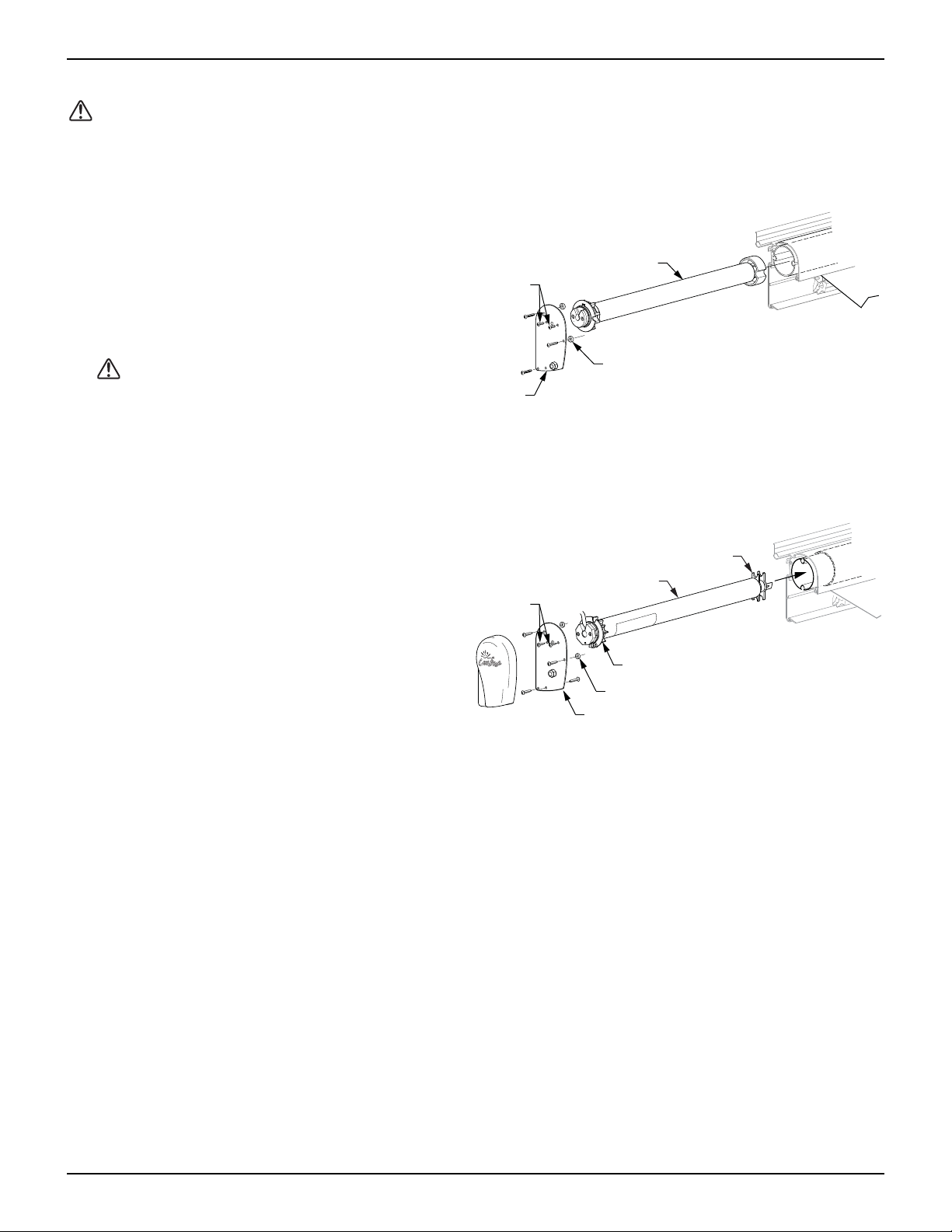

REMOVING THE MOTOR

CAUTION WHEN PULLING THE MOTOR OUT OF THE CASE,THE SERVICING TECHNICIAN MUST USE CARE TO NOT BREAK

OR DAMAGE THE MOTOR CABLES.

WHEN PULLING THE MOTOR,DO NOT LET THE ROLLBAR COME OUT MORE THAN 1"; OTHERWISE THE ROLLBAR IDLER WILL DISENGAGE

FROM THE OPPOSITE END PLATE.IF THIS OCCURS,REINSERT THE IDLER ONTO THE ENDPLATE BEFORE CONTINUING.

FIII047

Motor

Motor Screws

(qty: 2)

Spacer

(qty: 3)

End Plate

Figure 3. Removing the Old Motor.

1. Pull the end plate and motor partially out from the

awning case.

2. Disconnect the motor wires from inside the

coach and pull out or clip the motor wires. If

cutting the motor wires be sure to leave

enough wire that can be stripped and spliced.

3. Pull the motor, crown, roller bearing and drive hub

out of the roll bar.

CAUTION IF THE AWNING IS CLOSED WHEN

THE MOTOR IS REMOVED THE SPRING ARMS WILL TRY

TO OPEN.SUPPORT THE ROLL BAR AND ALLOW THE

AWNING TO OPEN SLOWLY THEN SECURE THE ARMS

BY TYING THE ELBOWS TOGETHER AS DESCRIBED

PREVIOUSLY.

4. If still attached, remove the end cap from the end plate then remove the attaching screws holding the motor to the end

plate. Make note of the motor orientation on the end plate.

052985-106r1 2

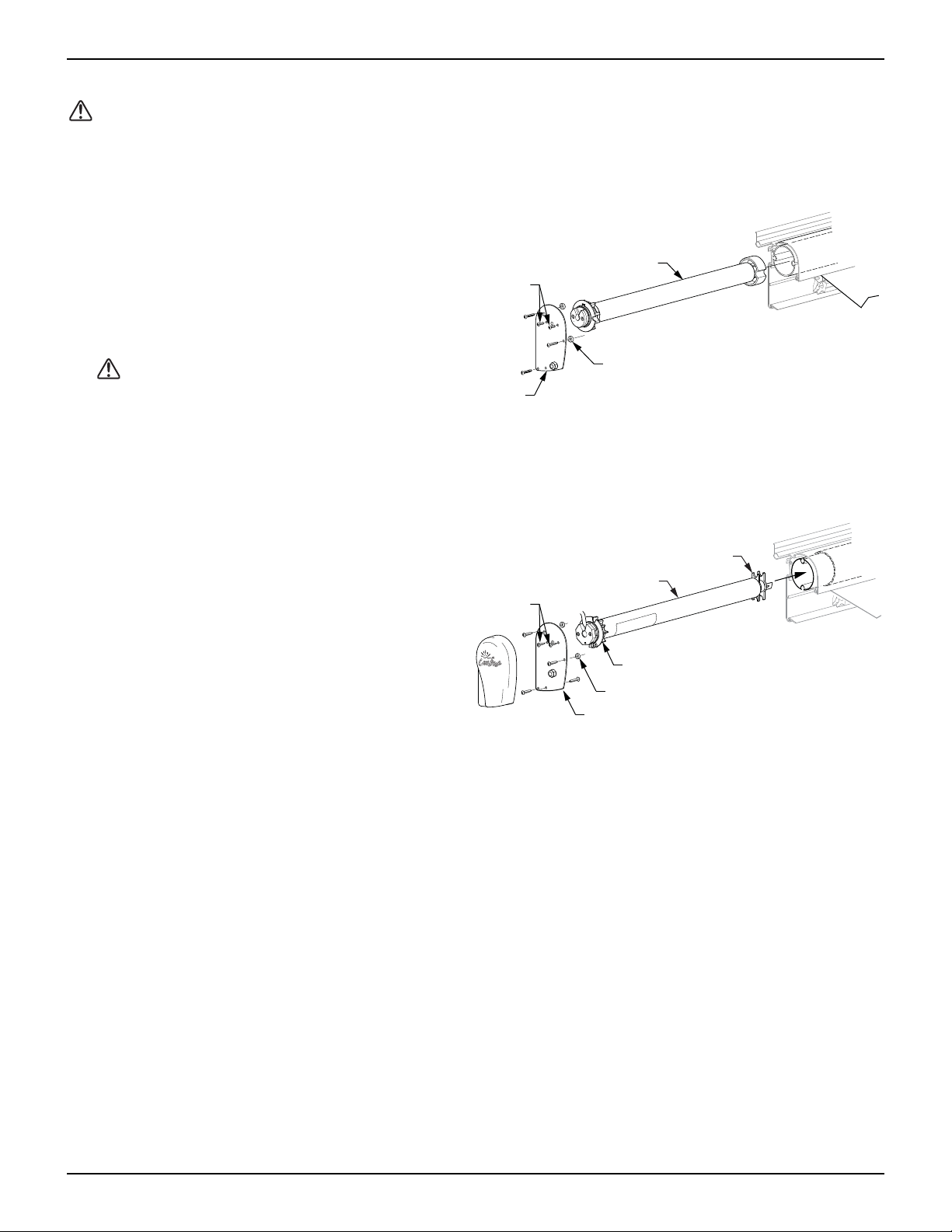

5. Attach the new motor to the end plate paying

attention to match the orientation from the old

motor.

6. Partially slide the new motor assembly into the

roll bar. Ensure that the drive and bearing are

properly aligned inside the roll bar.

7. Route the new motor wire into the coach and

attach or if the wires were cut, splice the new

wires to the existing wires. Ensure that the

wire colors match (Blue to Blue and Brown to

Brown). Use a quality silicone sealant to seal

the wire hole into the coach.

NOTE: If splicing the wires, allow enough lead wire from the motor so that the completed splices can be

pushed into the wall before sealing. There is not clearance room in the case for the wires and

splices.

FIII048

Motor Screws

(qty: 2)

Spacer (qty: 3)

End Plate

Motor

Bearing (ref)

Drive (ref)

Figure 4. Installing the New Motor.

8. Attach the end plate to the case.

9. While holding the lead rail, carefully remove any roller tube supports and arm ties. Allow the lead rail to extend

until the fabric is taunt.

10. To test, restore power then extend and retract the awning.

11. After replacing the motor, it will be necessary to adjust the motor limits (page 3).

12. After testing and adjusting the motor limits, attach the end cap.