PST MICHELL Instruments ADG400 User manual

ADG400

Advanced Dew-Point Generator

User Manual

99998 Issue 1

November 2022

Please ll out the form(s) below for each instrument that has been purchased.

Use this information when contacting Michell Instruments for service purposes.

Product Name

Order Code

Serial Number

Invoice Date

Installation Location

Tag Number

Product Name

Order Code

Serial Number

Invoice Date

Installation Location

Tag Number

Product Name

Order Code

Serial Number

Invoice Date

Installation Location

Tag Number

© 2022 Michell Instruments

This document is the property of Michell Instruments Ltd and may not be copied or

otherwise reproduced, communicated in any way to third parties, nor stored in any Data

Processing System without the express written authorization of Michell Instruments Ltd.

For Michell Instruments' contact information please go to

www.michell.com

ADG400

ADG400 User Manual

iv 99998 Issue 1, November 2022

1 INTRODUCTION ................................................................................................1

1.1 Features ............................................................................................................ 1

1.2 Theory of Operation ........................................................................................... 2

2 INSTALLATION ..................................................................................................3

2.1 Unpacking the Instrument ................................................................................... 3

2.2 Power Supply ..................................................................................................... 3

2.3 USB Connection.................................................................................................. 3

2.4 Dry Gas Supply .................................................................................................. 3

2.5 Gas Connections ................................................................................................. 4

2.6 Typical Setup ..................................................................................................... 4

3 OPERATION ......................................................................................................5

3.1 First-time Operation ............................................................................................ 5

3.2 Typical Calibration Run ....................................................................................... 5

3.3 HMI ................................................................................................................... 6

3.4 Screensaver ....................................................................................................... 6

3.5 Main Screen ....................................................................................................... 7

3.6 Modes of Operation ............................................................................................ 8

3.6.1 Manual Mode ................................................................................................ 8

3.6.1.1 Set Point Picker ....................................................................................... 9

3.6.2 Prole Mode ................................................................................................. 9

3.6.3 Remote Mode ............................................................................................. 10

3.6.3.1 Remote Mode Commands ...................................................................... 11

3.6.4 Remote Access ........................................................................................... 12

3.6.5 Installing and Using the Remote Access Software .......................................... 12

3.6.6 Status Page ................................................................................................ 13

3.6.6.1 Transition Delay .................................................................................... 14

3.6.7 Settings Menu ............................................................................................. 14

3.6.8 Set Point Editor ........................................................................................... 15

3.6.8.1 Converting MFC Values to ml/min Flow Rates .......................................... 16

3.6.8.2 Adjusting Set Points .............................................................................. 16

3.6.9 Prole Editor ............................................................................................... 17

3.6.10 Saturator Filling Mode ................................................................................. 18

3.6.10.1 Saturator Filling Instructions .................................................................. 19

4 MAINTENANCE ................................................................................................20

4.1 Inlet Particulate Filter ....................................................................................... 20

4.2 Fuses .............................................................................................................. 20

4.3 General Troubleshooting ................................................................................... 21

4.4 Emptying the Saturators for Transport ................................................................ 22

Contents

Safety ................................................................................................................................vi

Electrical Safety ..........................................................................................................vii

Pressure Safety ...........................................................................................................vii

Hazardous Materials (WEEE, RoHS3 & REACH) ..............................................................vii

Safe Handling .............................................................................................................vii

Repair and Maintenance ..............................................................................................vii

Safety Conformity .......................................................................................................vii

Abbreviations .................................................................................................................... viii

ADG400 User Manual

Michell Instruments v

Tables

Table 1 Minimum Stabilization Times ........................................................................6

Table 3 Read Command Response Explanation ........................................................11

Table 2 Supported Serial Commands ......................................................................11

Table 4 Span of Installed MFCs ..............................................................................16

Figures

Figure 1 Typical Setup Diagram ................................................................................4

Figure 2 Manual Mode .............................................................................................7

Figure 3 Prole Mode ...............................................................................................7

Figure 4 Main Screen in Manual Mode .......................................................................8

Figure 5 Set Point Picker Screen ...............................................................................9

Figure 6 Main Screen in Prole Mode ........................................................................9

Figure 7 Prole Selection Screen .............................................................................10

Figure 8 Main Screen in Remote Mode ....................................................................10

Figure 9 Main Screen Shown on a PC via Remote Access Software ............................12

Figure 10 Status Page Screen ...................................................................................13

Figure 11 Settings Screen ........................................................................................14

Figure 12 Set Point Editor Screen .............................................................................15

Figure 13 Prole Editor Screen .................................................................................17

Figure 14 Saturator Filling Screen .............................................................................18

Figure 15 Saturator Fill Levels ..................................................................................18

Figure 16 ADG400 with Open Front Panel .................................................................19

Figure 17 ADG400 Internal View ..............................................................................22

Appendices

Appendix A Technical Specications .............................................................................. 24

A.1 Dimensions .................................................................................25

Appendix B Quality, Recycling, Compliance & Warranty Information ................................ 27

Appendix C Return Document & Decontamination Declaration ........................................ 29

ADG400 User Manual

vi 99998 Issue 1, November 2022

Safety

The instrument is designed to be completely safe when installed and operated correctly in accordance

with the information provided in this manual.

This manual contains all the required information to install, operate and maintain this product. Prior

to installation and use of this product, this entire manual should be read and understood. Installation

and operation of this product should be carried out by suitably competent personnel only. The

installation and operation of this product must be in accordance with the instructions provided and

according to the terms of any associated safety certicates. Incorrect installation and use of this

product other than those described in this manual and other than its intended purpose will render

all warranties void.

This product meets the essential protection requirements of the relevant EU & UK directives. Further

details of applied directives may be found in the product specication.

Electricity and pressurized gas can be dangerous. This product must be installed and operated only

by suitable trained personnel.

!

No user serviceable parts inside

!

Where this hazard warning symbol appears in the following

sections, it is used to indicate areas where potentially hazardous

operations need to be carried out and where particular attention to

personal and personnel safety must be observed.

Where this symbol appears in the following sections it is used to

indicate areas of potential risk of electric shock.

This product is intended for use only under the following conditions:

a. indoor use

b. altitude up to 2,000 m

c. temperature 5 °C...40 °C

(refer to Appendix A, Technical Specication, for Operating Temperature range)

d. maximum relative humidity 80 % for temperatures up to 31 °C decreasing

linearly to 50 %, relative humidity at 40 °C

e. MAINS supply voltage uctuations up to ±10 % of the nominal voltage

f. TRANSIENT OVERVOLTAGES up to the levels of OVERVOLTAGE CATEGORY ll

g. TEMPORARY OVERVOLTAGES occurring on the MAINS supply

h. applicable POLLUTION DEGREE 2 of the intended environment

ADG400 User Manual

Michell Instruments vii

Electrical Safety

Ensure electrical safety is complied with by following the directions provided here and observing all

local operation & installation requirements at the intended location of use.

This product is completely safe when using any options and accessories supplied by the manufacturer

of this product for use with it. Refer to Section 2 (Installation) of this manual for further details.

Pressure Safety

For this product to operate satisfactorily, pressurized gas must be connected to it. Observe all the

information contained within this manual and all local operation & installation requirements at the

intended location of use. Refer to Section 2 (Installation) of this manual for further details.

Hazardous Materials (WEEE, RoHS3 & REACH)

This product does not contain or release any prohibited chemicals listed on the SVHC (Substances

of Very High Concern) Candidate List. During the intended normal operation of this product it is not

possible for the user to come into contact with any hazardous materials. This product is designed to

be recyclable except where indicated.

Safe Handling

Appropriate lifting and handling techniques should be used when moving and installing the ADG400.

• The total weight of the product is 23 kg (51 lb).

• Before commencing any lifting or handling, ensure that the intended

location is suitable and is appropriately prepared.

• A clear path to the intended location should be made and appropriate

lifting aids used (e.g. a suitably rated trolley).

• Due to the bulky nature and weight of the product, it is recommended

that two people perform all handling operations.

• Be aware that saturators should be emptied of water before transporting

the ADG400. See Section 4.4 for instructions.

Repair and Maintenance

The instrument must be maintained either by the manufacturer or an accredited service agent. For

contact information, visit the website at www.michell.com.

Safety Conformity

This product meets the essential protection requirements of the relevant EU & UK directives. Further

details of applied standards may be found in Appendix B.

ADG400 User Manual

viii 99998 Issue 1, November 2022

Abbreviations

The following abbreviations are used in this manual:

barg pressure unit (=100 kP or 0.987 atm) (bar gauge)

°C degrees Celsius

°F degrees Fahrenheit

DC direct current

g grams

in inch(es)

µm micrometer

m/sec meters per second

mA milliampere

mm millimetres

MPa megapascal

Nl/min normal liters per minute

Nm Newton meter

oz ounces

psig pounds per square inch

RH relative humidity

scfh standard cubic feet per hour

fps feet per second

T temperature

V Volts

Ω Ohms

ø diameter

ADG400 User Manual

Michell Instruments 1

INTRODUCTION

1 INTRODUCTION

The ADG400 is designed for use as part of a hygrometry calibration system. It is capable

of repeatable generation of dew points across a range of -80 °C...+20 °C, when used in

conjunction with the Michell Instruments PSD2 pressure swing dryer.

The generator is based on the volumetric mixing of dry and wet gases. It gives the

fastest response when changing between set points in comparison to other dew-point

generator technologies (such as two-temperature, two-pressure or a combination of

both).

The controller comes pre-programmed with a standard table of dew-point set points,

from -80 °C to +20 °C at 10 °C intervals. The table contains ow rates for each of the 5

MFCs, along with solenoid settings that determine if 1 or 2 stage mixing is used. A user

table is also provided allowing up to 13 user-dened setpoints to be stored.

There are 3 modes of operation: Manual mode for push-button selection of set-points,

Prole mode for automatic timed changing of set-points, and Remote mode for changing

of set-points via serial commands sent over the USB port for integration with customer

software. Further to this, the ADG HMI can be displayed and interacted with on a PC

connected via the USB interface.

The ADG400 is designed to be used in conjunction with a high accuracy reference

instrument such as a Michell Instruments S8000 RS.

1.1 Features

The key features of the ADG include:

• Full-color touch-screen HMI

• 11-point factory-programmed dew-point setpoint table from -80 to +20 °C

at 10 °C intervals

• 13-point user programmable dew-point setpoint table

• 3 programmable 13-point automatic calibration proles with customizable

timings

• Change set points using serial commands via built-in USB port

• Remote Access mode allows HMI to be operated using a connected PC

• Temperature-controlled enclosure to ensure output stability and repeatability

ADG400 User Manual

299998 Issue 1, November 2022

INTRODUCTION

1.2 Theory of Operation

Dried air is supplied to the ADG – some of this dry air is used as-is for mixing, and

some is diverted through the two saturators. Each saturator is lled with distilled or

demineralized water, and the dry air stream is bubbled through this water via a sintered

nozzle, which creates a stream of wet air that can be used for mixing. Each saturator

is followed by a water trap which is necessary to prevent water from escaping the

saturation system when it is pressurized/depressurized.

The rst mixing stage comprises 3 high-precision mass-ow controllers. One MFC

controls the dry air ow from the external dry air source. The other 2 MFCs give coarse

and ne control of the wet air from the saturators. This stage enables dew points from

+20 °C to -20 °C to be generated.

The second mixing stage comprises of 2 further MFCs. One MFC controls a ow of dry

air from the external dry air source. The second MFC controls the ow of air from the

rst stage. This second mixing stage enables dew points from -30 to -80 °C.

ADG400 User Manual

Michell Instruments 3

INSTALLATION

2 INSTALLATION

2.1 Unpacking the Instrument

On delivery, please check that all the following standard components are in the packing box:

• ADG400 Dew-Point Generator

• IEC Power Cable

• USB-B Cable

2.2 Power Supply

The ADG400 is tted with a switch-mode power supply that can accept mains power

90...264 V AC, 47...63 Hz via the IEC power connection.

The ADG400 is tted with a 10 A 20 x 5 mm (T) fuse located behind a fuse cover next

to the IEC power connection.

2.3 USB Connection

A USB type-B port is tted to the back of the instrument to enable remote access to the

HMI from a PC or changing set-points via serial commands.

Refer to

Section 3.6.3, Remote Mode

, and

Section 3.6.4, Remote Access

, for more

information.

2.4 Dry Gas Supply

The generator requires a supply of high-quality (oil free) dry gas with a moisture

content of <0.5 ppmV (<-80 °C atmospheric dew point) or compressed air to the same

specication as used during its setup/calibration. This enables the maximum range of

dew points to be generated.

A minimum ow of 7 Nl/min (14.8 scfh) is required, delivered at a pressure of 2.0 barg

(29.0 psig).

If replacing an existing dew-point generator connected to a PSD2, the internal pressure

regulator of the PSD2 MUST be adjusted to 2.0 barg (29.0 psig), otherwise the

ADG400 will not function. Refer to the latest PSD2 manual from the PST website (www.

processsensing.com) for instructions on how to perform this adjustment.

The generator was set up/calibrated using either a Michell PSD2 Pressure Swing Dryer

or a specic compressed air supply. A warning label, stipulating what the air inlet

specication needs to comply with, appears on the rear panel of the generator.

WARNING!

COMPLY WITH AIR INLET SPECIFICATION

TO ENSURE ACCURATE OPERATION

Air Inlet Specication:

Pressure = 2.00 BarG (29 PsiG)

Dew Point = -85 °C @ 1.013 BarA

ADG400 User Manual

499998 Issue 1, November 2022

INSTALLATION

2.5 Gas Connections

The gas inlet and outlet connections are Swagelok® 6 mm stainless-steel bulkhead

union tube ttings, located on the rear panel of the unit marked GAS IN and GAS OUT.

2.6 Typical Setup

The ADG should be used in conjunction with a Michell Chilled Mirror Reference Instrument.

A complete system would usually include:

• Dry air source (Michell Instruments PSD2)

• ADG400 Generator

• Chilled Mirror Reference Instrument with ow control valve

• Manifold for units under test with ow control valve

• Bypass leg for venting excess ow with ow control valve

Figure 1

Typical Setup Diagram

ADG400 User Manual

Michell Instruments 5

OPERATION

3 OPERATION

It is recommended to familiarize yourself with the installation, operation and maintenance

sections of this manual before using the product for the rst time.

3.1 First-time Operation

Before using the instrument for the rst time, the following steps should be taken.

1. Install the electrical and gas connections as per the instructions in

Section

2, Installation

.

2. Power-on the instrument.

3. Fill the saturators using the saturator lling mode – full instructions are

given in

Section 3.6.10

.

4. It is recommended to leave the generator set to DRYER mode and run

overnight before rst use.

Note: The generator is designed to be operated continuously and does not need to be

powered o. When not using the generator, it should be set to DRYER mode.

3.2 Typical Calibration Run

Dew-point calibrations should always run from the driest point to the wettest, with an

adequate purge being carried out at the beginning to reduce the moisture level of the

system, and all the units under test, to below the lowest point to be calibrated.

Prior to beginning a calibration, the following checks should be carried out:

1. Power-on the reference hygrometer.

2. Ensure all units under test are installed into calibration manifold and all

unused manifold ports are blanked o.

3. Check the saturator level and top up, if required, by initiating the saturator

lling mode.

ADG400 User Manual

699998 Issue 1, November 2022

OPERATION

A typical calibration to -80 °Cfp, for the Michell Instruments Easidew, would use the

following timings:

Set Point

(°C Dew/Frost Point) Minimum Stabilization Time

DRYER 48 hours

-80 12 hours

-70 8 hours

-60 4 hours

-50 2 hours

-40 1 hour

-30 1 hour

-20 1 hour

-10 1 hour

0 1 hour

+10 1 hour

+20 1 hour

Table 1

Minimum Stabilization Times

3.3 HMI

The ADG uses a 3.5" full-color touch-screen controller.

3.4 Screensaver

When idle for 10 minutes, the display of the ADG will be set to screensaver mode, which

dims the display. This helps to maintain the brightness of the backlight as the unit is

constantly powered on.

The length of time before the screensaver is active is congurable in the settings menu.

ADG400 User Manual

Michell Instruments 7

OPERATION

3.5 Main Screen

Figure 2

Manual Mode

Figure 3

Prole Mode

Item Description

Set Point

Indicates currently selected set point in all modes.

The indicator to the far right shows if the selected set point is from:

SStandard Table

UUser Table

Pressing the button will bring up the Set Point selection screen in

Manual mode.

Enclosure

Temperature

Displays the current enclosure temperature, which should be at 35 °C

±0.1 °C

? (Status

Button)

Displays the status screen.

Note: Entering the status screen will pause a running prole, until un-

paused by the user.

Mode Only available in Manual mode; allows the mode of operation to be set

to Prole or Remote.

Remaining

Shows the remaining time for the current prole set point in hh:mm:ss

format. Press the time button to pause/un-pause the prole.

Far-right indicator:

Green Prole running

Yellow Prole paused

Red Prole complete

Lock Only shown in Manual mode; locks the display with the xed passcode.

Stop Shown in Prole and Remote modes when a passcode is not set.

Returns to Manual mode, retaining the current set point.

Unlock Requires a passcode to unlock the display.

Returns to Manual mode, retaining the current set point.

Settings Only enabled in Manual mode; navigates to the Settings menu.

For information about locking the display with a passcode, refer to

Section 3.6.7,

Settings Menu

.

ADG400 User Manual

899998 Issue 1, November 2022

OPERATION

3.6 Modes of Operation

The modes of operations are:

• Manual mode: change set points by button press

• Prole mode: set points change automatically after a predetermined time

• Remote mode: set points are changed by serial command from a PC (for

software integration)

• Remote Access: the ADG is controlled from a PC using the HMI

When in Manual mode, the mode can be changed by pressing the Mode button.

When in Prole or Remote mode, the Stop button must be pressed to return to Manual

mode. The Stop button will be replaced with an Unlock button if passcode protection

is enabled.

3.6.1 Manual Mode

Pressing the Set Point button takes you to the set-point picker, enabling a new set point

to be selected.

Figure 4

Main Screen in Manual Mode

ADG400 User Manual

Michell Instruments 9

OPERATION

3.6.1.1 Set Point Picker

This is used to change the set point in Manual mode.

Item Description

Arrow Buttons < > Change the desired set point.

Standard Table /

User Table Button

Select a new set point from the displayed table. This is only

visible if the user-dened set points have been created.

Apply Apply the selected set point and return to the Main screen.

Back Return to the Main screen without changing the set point.

Figure 5

Set Point Picker Screen

3.6.2 Prole Mode

Prole mode runs one of three proles which contain a list of set points, each with an

associated duration. This allows unattended operation.

Figure 6

Main Screen in Prole Mode

To enter Prole mode, the Mode button is pressed from the Main screen. This takes you

to the Prole select screen, which allows one of the three prole presets to be loaded.

ADG400 User Manual

10 99998 Issue 1, November 2022

OPERATION

Figure 7

Prole Selection Screen

Selecting one of the prole presets will start the prole and return to the Main screen.

Pressing the Back button will lead back to the Main screen, leaving the ADG in Manual

mode.

Refer to

Section 3.6.9, Prole Editor

, for details on how to dene calibration proles.

3.6.3 Remote Mode

When connecting the ADG400 to a PC using the USB connection, it will appear as a

virtual serial port.

In Remote mode, set points can be changed via a serial command. This mode is designed

for integration with customer software. For remote control of the generator from a

PC, please see also

Section 3.6.4, Remote Access

, which may be more appropriate,

depending on the intended result.

In Remote mode, controls are disabled, including the Read MFCs button on the status

page, which is disabled to ensure a remote set-point change event cannot be interrupted.

The MFC Set Point and Measure values on the status page can only be updated using

the appropriate serial command.

Note: This cannot be used in conjunction with Remote Access, which relies on the same

serial port connection.

Figure 8

Main Screen in Remote Mode

ADG400 User Manual

Michell Instruments 11

OPERATION

3.6.3.1 Remote Mode Commands

The following commands are supported:

Command Description

SPxx<cr> Activate Set Point Index xx, where xx is a number from 00 to 13.

Set point is loaded from the standard set point table.

UPxx<cr> Activate Set Point Index xx, where xx is a number from 00 to 13.

Set point is loaded from the user set point table.

READ<cr> Returns the data string shown in the example below:

Table 2

Supported Serial Commands

READ command returned string:

I,5,S,0010,U,STD,SP,+06400+28800+00000+00000+00000,SP&MSR,+12801+12800+00000+00000+040

00+04000+30720+30720+10559+10560,H,+350,EOM

Component Description

I

5 Set Point Index

S

0010 Dew/Frost Point of Set Point (+10 °C)

U

STD Set Point Source Table (USR or STD)

SP

+06400+28800+00000+00000+00000 Target MFC Values

(S1Dry+S1Wet(C)+S1Wet(F)+S2Dry+S2Wet)

SP&MSR

+12801+12800+00000+00000+04000

+04000+30720+30720+10559+10560

Measured then Set Point Value for each MFC

12801 = S1Dry Measured

12800 = S1Dry Set-Point etc.

H

+350 Enclosure Temperature * 10 (35 °C)

EOM

Table 3

Read Command Response Explanation

Commands must be sent as a complete string and cannot by typed in letter by letter

using a terminal program.

Please contact your PST representative for an example software project, showing how

to implement the communications protocol.

ADG400 User Manual

12 99998 Issue 1, November 2022

OPERATION

3.6.4 Remote Access

The ADG can be controlled from a PC, providing full access to the user interface in

a desktop window, as shown below. Note: this cannot be used in conjunction with

Remote mode, which relies on the same serial port over USB connection.

Figure 9

Main Screen Shown on a PC via Remote Access Software

3.6.5 Installing and Using the Remote Access Software

1. Navigate to the Michell Instruments software download page:

http://www.michell.com/uk/support/sware-downloads.php

2. Download and install the ADG400 Remote Access package.

3. Restart the PC – this is essential, otherwise the software will not launch.

4. Launch the Remote Access software from the Start menu. It must be

"Run as Administrator".

Note: You should rst change the compatibility options for the shortcut to always "Run

as Administrator": rst, right click on the shortcut and select Properties, then navigate

to the Compatibility tab.

5. Set the OPLC model to the Samba 35 through the conguration menu.

6. From the same menu, select Communication – PC Settings and change

the "PC Port" to the appropriate COM port number for the ADG. This can

be found in Device Manager, under Ports.

7. Click the OnLine button to connect to the ADG.

Table of contents

Popular Portable Generator manuals by other brands

Generac Mobile

Generac Mobile MDE570 owner's manual

Honeywell

Honeywell 0061520 owner's manual

Kohler

Kohler OnCue Plus quick start guide

Champion Global Power Equipment

Champion Global Power Equipment 201228 quick start

Clarke

Clarke PG3800A Operation & maintenance instructions

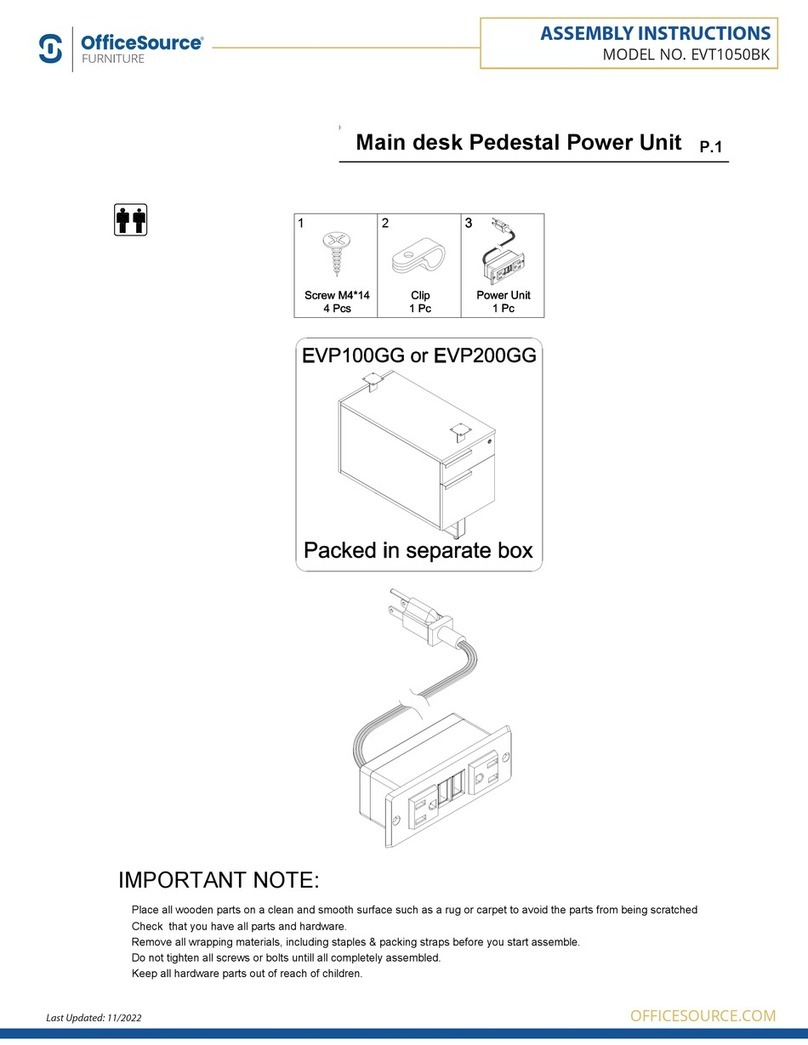

OfficeSource

OfficeSource EVT1050BK Assembly instructions