PTM Engines 120F User manual

Gasoline Engine

Owner’s Manual

120F ●160F ●200F

240F ●270F ●340F ●390F●420F

Keep this owner's manual handy, so you can refer to it at any time.

This owner's manual is considered a permanent part of the engine and should remain with

the engine if resold.

The information and specifications included in this publication were in effect at the time of

approval for printing.

Only the D Type is equipped for both electric and manual starting.

RE D THIS OWNER’S M NU L C REFULLY. Pay special attention to these symbols

and any instructions that follow:

Indicates serious injury or deat will result if instructions are not followed.

Indicates

a

strong

possibility

t at

serious

injury

or

deat

could

result

if

instructions

are

not

followed.

Indicates

a

possibility

t at

minor

injury

or

an

result

if

instructions

are

not

followed.

Indicates t at equipment or property damage can result if

instructions

are

not

followed.

NOTE: Gives helpful information.

If a problem should arise, or if you have any questions about your engine, consult your

engine dealer.

CONTENTS

CONTENTS

2

1. ENGINE S FETY.............................. ........................... .............. ....... .......... 2

2. COMPONENTS & CONTROL LOC TIONS……………................................................3

3. CONTROLS................................. .................................... .......................... 4

4. CHECK BEFORE OPER TION .............................................................................. 6

5. OPER TION............................................................................................ 7

6. M INTEN NCE ……………………….......................................................................11

7. STOR GE/TR NSPORTING ...................................................................................23

8. TROUBLESHOOTING………………………………………………................................26

9. TECHNIC L & CONSUMER INFORM TION ……..……………………………………27

10. SPECIFIC TIONS .......................... ....... .................... ........................ ...... 33

11. WIRING DI GR MS ..................... ............................ ............... .......... .....36

12. OPTION L P RTS.................................................................................... 38

B TTERY................................................................................................. 38

ENGINE S FETY

3

1. ENGINE SAFETY

IMPORTANT SAFETY INFORMATION

Most accidents with engines can be prevented if you follow all instructions in this manual

and on the engine. Some of the most common hazards are discussed below, along with

the best way to protect yourself and others.

Owner Responsibilities

The

engines

are

designed

to

give

safe

and

dependable

service

if

operated

according

to instructions. Read and understand this owner’s manual before operating the engine.

Failure to do so could result in personal injury or equipment damage.

Know

how

to

stop

the

engine

quickly,

and

understand

the

operation

of

all

controls.

Never permit anyone to operate the engine without proper instructions.

Do not allow children to operate the engine. Keep children and pets away from the

area of operation.

Refuel Wit Care

Gasoline is extremely flammable, and gasoline vapor can explode. Refuel outdoors, in a

well-ventilated area, with the engine stopped. Never smoke near gasoline, and keep other

flames and sparks away. lways store gasoline in an approved container. If any fuel is

spilled, make sure the area is dry before starting the engine.

Hot Ex aust

The muffler becomes very hot during operation and remains hot for a while after

stopping the engine. Be careful not to touch the muffler while it is hot. Let the engine

cool before storing it indoors.

To

prevent

fire

hazards

and

to

provide

adequate

ventilation

for

stationary

equipment

applications, keep the engine at least 3 feet (1 meter) away from building walls and

other equipment during operation. Do not place flammable objects close to the engine.

Carbon Monoxide Hazard

Exhaust gas contains poisonous carbon monoxide. void inhalation of exhaust gas. Never

run the engine in a closed garage or confined area.

Ot er Equipment

Review the instructions provided with the equipment powered by this engine for any

additional safety precautions that should be observed in conjunction with engine startup,

shutdown, operation, or protective apparel that may be needed to operate the equipment.

COMPONENTS & CONTROL LOC TIONS

4

2. COMPONENTS & CONTROL LOCATIONS

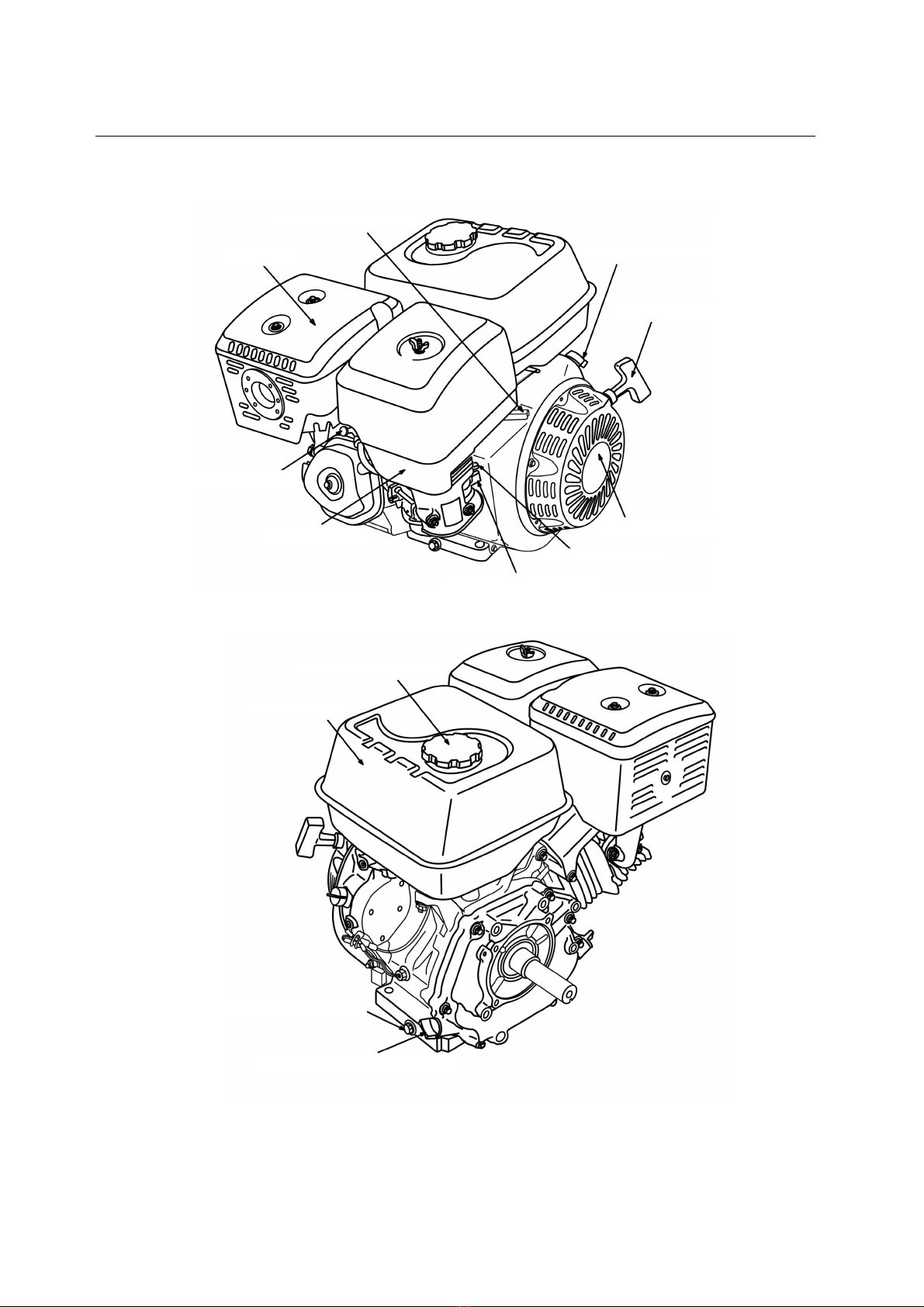

THROTTLE LEVER

MUFFLER

SP RK PLUG

IR CLE NER

FUEL V LVE LEVER

CHOKE LEVER

RECOIL ST RTER

ST RTER GRIP

IGNITION SWITCH

FUEL FILLER C P

FUEL T NK

OIL DR IN PLUG

OIL FILLER C P/DIPSTICK

CONTROLS

5

3. CONTROLS

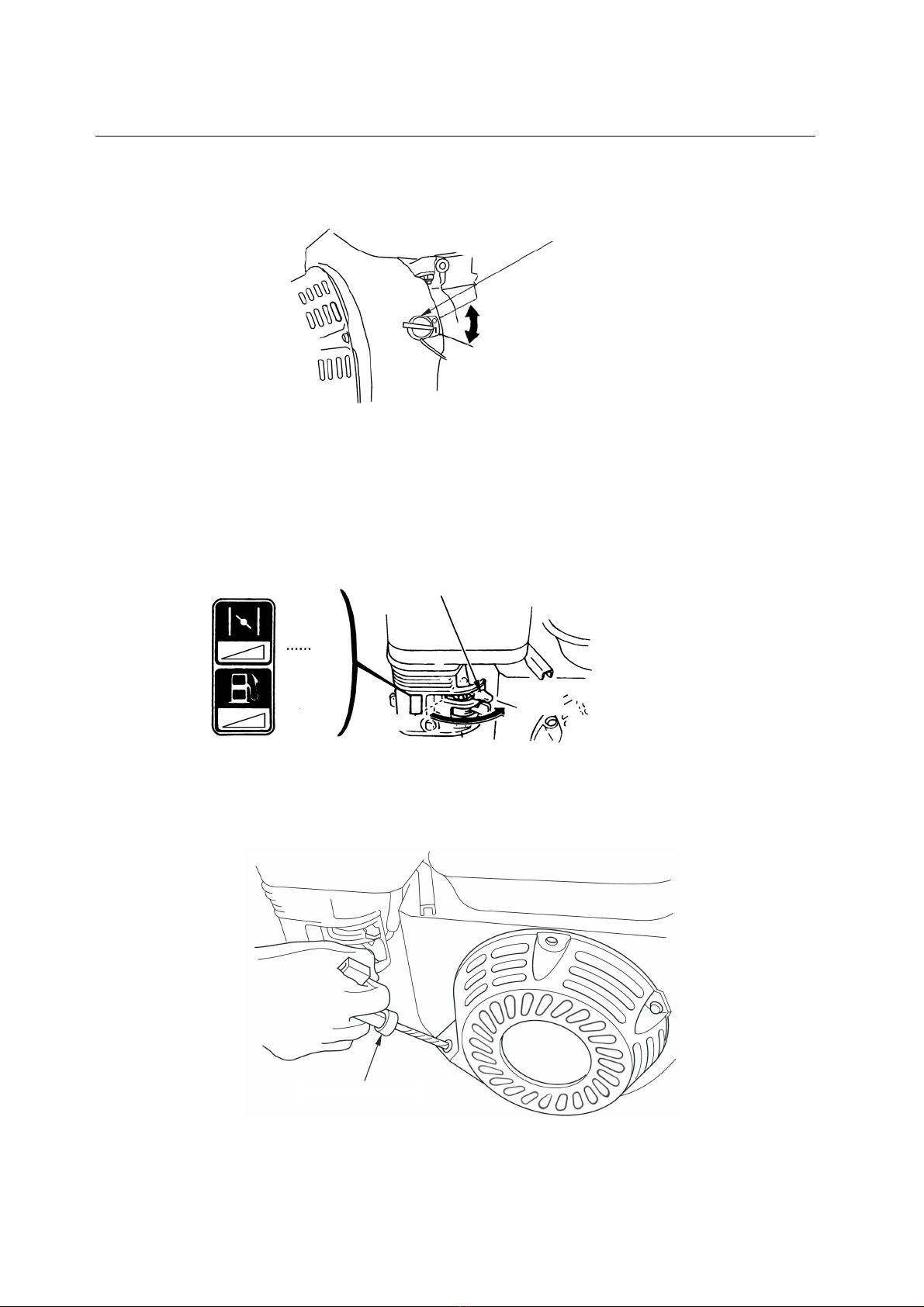

Fuel Valve Lever

The fuel valve opens and closes the passage between the fuel tank and the carburetor.

The fuel valve lever must be in the ON position for the engine to run.

When the engine is not in use, leave the fuel valve lever in the OFF position to prevent

carburetor flooding and to reduce the possibility of fuel leakage.

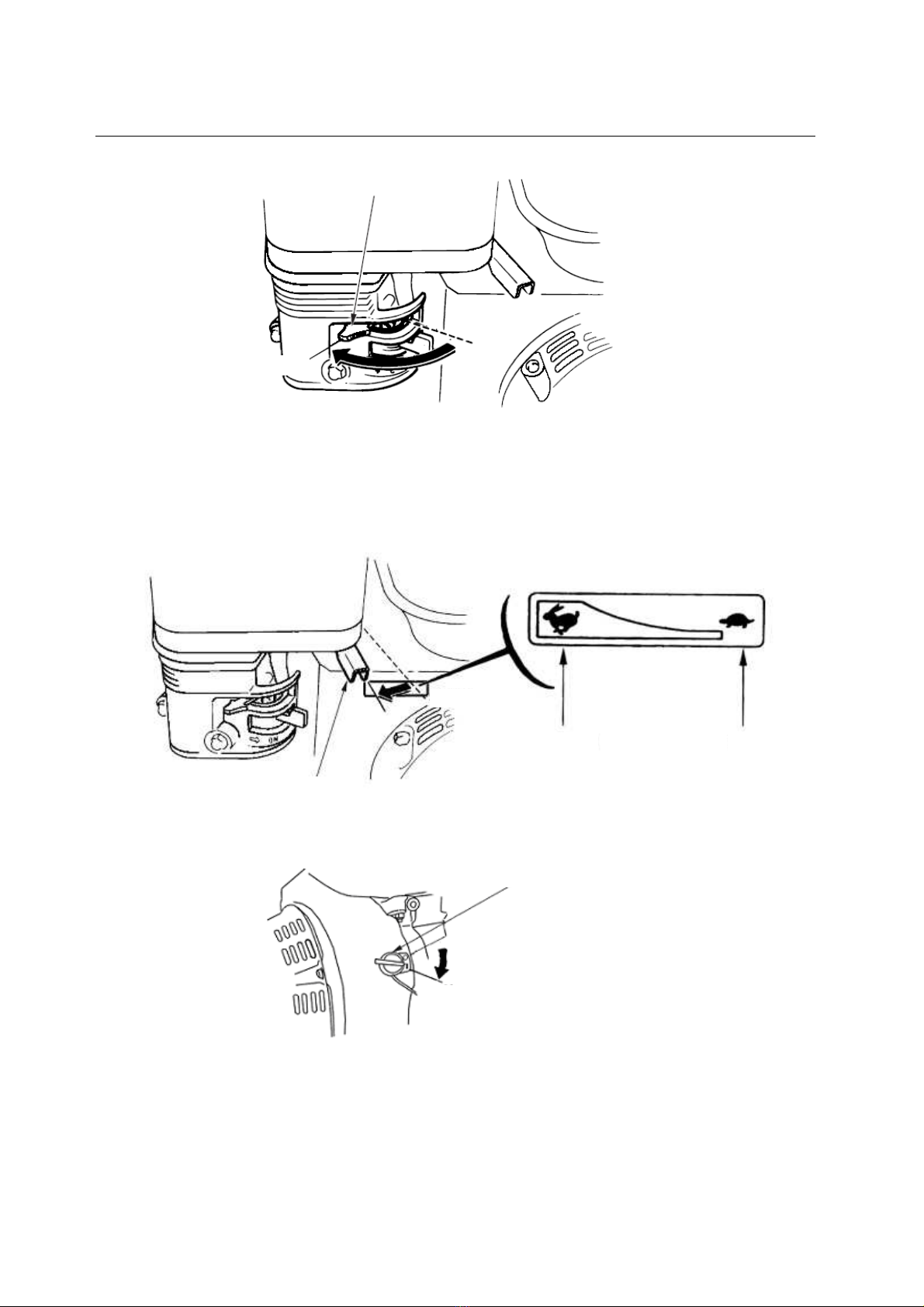

T rottle Lever

The throttle lever controls engine THROTTLE LEVER speed.

Moving the throttle lever in the directions shown makes the engine run faster or slower.

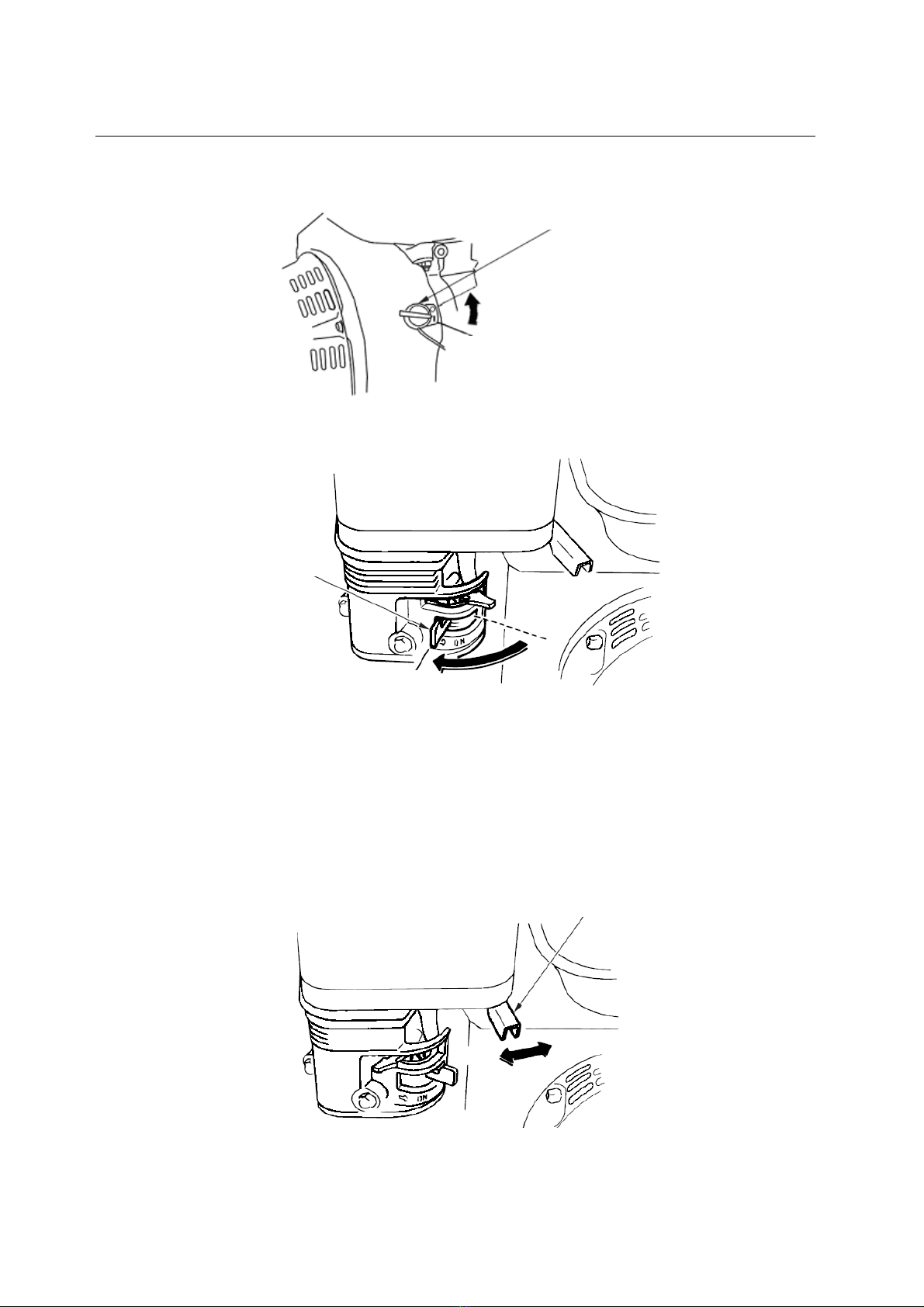

Engine Switc

The engine switch enables and disables the ignition system.

The engine switch must be in the ON position for the engine to run.

Turning the engine switch to the OFF position stops the engine.

OFF

FUEL

V LVE

LEVER

OFF

ON

THROTTLE

LEVER

F ST

SLOW

CONTROLS

6

C oke

Lever

The choke lever opens and closes the choke valve in the carburetor.

The CLOSE position enriches the fuel mixture for starting a cold engine.

The OPEN position provides the correct fuel mixture for operation after starting, and for

restarting a warm engine.

Some engine applications use a remotely-mounted choke control rather than the

engine-mounted choke lever shown here.

Recoil Starter Grip

Pulling the starter grip operates the recoil starter to crank the engine.

LL ENGINE EXCEPT D TYPE

ENGINE SWITCH

OFF

ON

CHOKE

LEVER

OPEN

O

PEN

CLOSE

ST RTER GRIP

CHECK BEFORE OPER TION

7

4. CHECK BEFORE OPERATION

IS YOUR ENGINE READY TO GO?

For your safety, and to maximize the service life of your equipment, it is very important to

take a few moments before you operate the engine to check its condition. Be sure to take

care of any problem you find, or have your servicing dealer correct it, before you operate

the engine.

Improperly maintaining t is engine,

or failing to correct a problem

before operation, could cause a

malfunction in w ic you could be

seriously injured.

Always perform a preoperation

inspection before eac operation,

and correct any problem.

Before beginning your preoperation checks, be sure the engine is level and the engine

switch is in the OFF position.

C eck t e General Condition of t e Engine

Look around and underneath the engine for signs of oil or gasoline leaks.

Remove any excessive dirt or debris, especially around the muffler and recoil starter.

Look for signs of damage.

Check that all shields and covers are in place, and all nuts, bolts, and screws are

tightened.

C eck t e Engine

Check the engine oil level. Running the engine with a low oil level can cause engine

damage.

The Oil lert system (applicable engine types) will automatically stop the engine before the

oil level falls below safe limits. However, to avoid the inconvenience of an unexpected

shutdown, always check the engine oil level before startup.

Check the air filter. dirty air filter will restrict air flow to the carburetor, reducing engine

performance.

Check the fuel level. Starting with a full tank will help to eliminate or reduce operating

interruptions for refueling.

C eck t e Equipment Powered by T is Engine

Review the instructions provided with the equipment powered by this engine for any

precautions and procedures that should be followed before engine startup.

OPER TION

8

5. OPERATION

SAFE OPERATING PRECAUTIONS

Before operating the engine for the first time, please review the IMPORTANT SAFETY

INFORMATION and the chapter titled BEFORE OPERATION.

Carbon monoxide gas is toxic.

Breathing it can cause

unconsciousness and even kill you.

void any areas or actions that

expose you to carbon monoxide.

Review the instructions provided with the equipment powered by this engine for any safety

precautions that should be observed in conjunction with engine startup, shutdown, or

operation.

STARTING THE ENGINE

1. Move the fuel valve lever to the ON position.

2. To start a cold engine, move the choke lever to the CLOSE position.

To restart a warm engine, leave the choke lever in the OPEN position.

Some engine applications use a remotely-mounted choke control rather than the

engine-mounted choke lever shown here.

FUEL V LVE

LEVER

ON

OPER TION

9

3. Move the throttle lever away from the SLOW position, about 1/3 of the way toward the

F ST position.

Some engine applications use a remotely-mounted throttle control rather than the

engine-mounted throttle lever shown here.

4. Turn the engine switch to the ON position.

5. Operate the starter.

RECOIL ST RTER (all engine types):

Pull the starter grip lightly until you feel resistance, then pull briskly.

CHOKE

LEVER

CLOSE

O

PEN

HIGH

SLOW

LOW

THROTTLE LEVER

ENGINE SWITCH

OFF

ON

OPER TION

10

Return

the

starter

grip

gently.

6. If the choke lever has been moved to the CLOSE position to start the engine, gradually

move it to the OPEN position as the engine warms up.

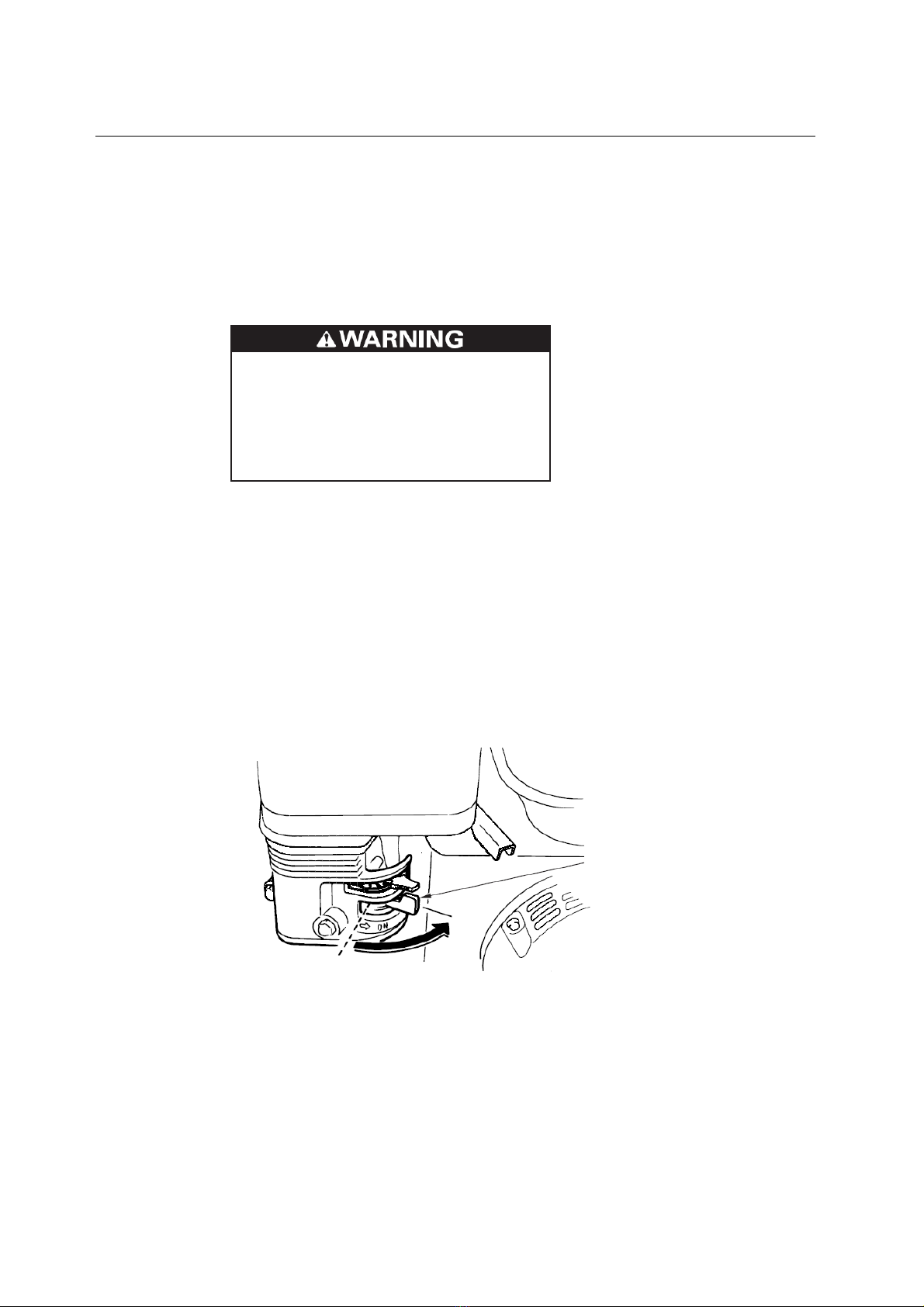

STOPPING THE ENGINE

To stop the engine in an emergency, simply turn the engine switch to the OFF position.

Under normal conditions, use the following procedure.

1. Move the throttle lever to the SLOW position.

Some engine applications use a remotely-mounted throttle control rather than the

engine-mounted throttle lever shown here.

CHOKE

LEVER

OPEN

THROTTLE

LEVER

SLOW

ST RTER GRIP

OPER TION

11

2. Turn the engine switch to the OFF position.

3. Turn the fuel valve lever to the OFF position.

SETTING ENGINE SPEED

Position the throttle lever for the desired engine speed.

Some engine applications use a remotely-mounted throttle control rather than the

engine-mounted throttle lever shown here.

For engine speed recommendations, refer to the instructions provided with the equipment

powered by this engine.

ENGINE SWITCH

OFF

ON

FUEL V LVE

LEVER

OFF

THROTTLE

LEVER

SLOW

F ST

M INTEN NCE

12

6. MAINTENANCE

THE IMPORTANCE OF MAINTENANCE

Good maintenance is essential for safe, economical, and trouble-free operation. It will also

help reduce air pollution.

Improperly maintaining this engine,

or failure to correct a problem

before operation, can cause a

malfunction in which you can be

seriously hurt or killed.

lways follow the inspection and

maintenance recommendations and

schedules in this owner’s manual.

To help you properly care for your engine, the following pages include a maintenance

schedule, routine inspection procedures, and simple maintenance procedures using basic

hand tools. Other service tasks that are more difficult, or require special tools, are best

handled by professionals and are normally performed by a technician or other qualified

mechanic.

The maintenance schedule applies to normal operating conditions. If you operate your

engine under unusual conditions, such as sustained high-load or high-temperature

operation, or use in unusually wet or dusty conditions, consult your servicing dealer for

recommendations applicable to your individual needs and use.

MAINTENANCE SAFETY

Some of the most important safety precautions are as follows: However, we cannot warn

you of every conceivable hazard that can arise in performing maintenance. Only you can

decide whether or not you should perform a given task.

Failure to properly follow

maintenance instructions and

precautions can cause you to be

seriously hurt or killed.

lways follow the procedures and

precautions in the owner’s manual.

Safety Precautions

Make sure the engine is off before you begin any maintenance or repairs. This will

M INTEN NCE

13

eliminate several potential hazards:

Carbon

monoxide

poisoning

from

engine

ex aust.

Be sure there is adequate ventilation whenever you operate the engine.

Burns

from

ot

parts.

Let the engine and exhaust system cool before touching.

Injury

from

moving

parts.

Do not run the engine unless instructed to do so.

Read the instructions before you begin, and make sure you have the tools and skills

required.

To

reduce

the

possibility

of

fire

or

explosion,

be

careful

when

working

around

gasoline.

Use only a nonflammable solvent, not gasoline, to clean parts. Keep cigarettes, sparks

and flames away from all fuel-related parts.

Remember that your servicing dealer knows your engine best and is fully equipped to

maintain and repair it.

To ensure the best quality and reliability, use only new, genuine parts or their equivalents

for repair and replacement.

MAINTENANCE SCHEDULE

Emission-related

items.

☆Replace the paper element type only.

(1)Service more frequently when used in dusty areas.

REGUL R SERVICE PERIOD

Performed at every indicated month or

operating hour interval, whichever comes

first.

Each

use

First

month or

20 Hrs.

Every 3

months or

50 Hrs.

Every 6

months or

100 Hrs.

Every

year or

300 Hrs.

ITEM

●

●●

●Engine oil Check level ○

Change ○ ○

●

●●

●ir cleaner

Check ○

Clean ○(1)

Replace ○☆

●

●●

●Sediment Cup Clean ○

●

●●

●Spark plug Check-Clean ○

Replace ○

Spark arrester

(optional parts) Clean ○

●

●●

●Idle speed Check- djust ○(2)

●

●●

●Valve clearance Check- djust ○(2)

●

●●

●Fuel tank and strainer Clean ○(2)

●

●●

●Combustion chamber Clean fter every 300 Hrs. (2)

●

●●

●Fuel line Check Every 2 years (Replace if necessary) (2)

M INTEN NCE

14

(2)These items should be serviced by your servicing dealer unless you have the proper

tools and are mechanically proficient. Refer to manual for service procedures.

REFUELING

Fuel tank capacities

120F: 2.5 L

160F(D), 160F(D)-B, 160F(D)-C: 3.6 L

200F(D), 200F(D)-B, 200F(D)-C: 3.6 L

240F(D), 240F(D)-B, 240F(D)-C: 6.0 L

270F(D), 270F(D)-B, 270F(D)-C: 6.0 L

340F(D), 340F(D)-D, 390F(D), 390F(D)-D: 6.5 L

With the engine stopped, remove the fuel tank cap and check the fuel level. Refill the tank

if the fuel level is low.

Gasoline is highly flammable and

explosive. You can be burned or

seriously injured when handling fuel.

Stop

the

engine

and

keep

heat,

sparks, and flame away.

Handle

fuel

only

outdoors.

Wipe

up

spills

immediately.

Refuel in a well-ventilated area before starting the engine. If the engine has been running,

allow it to cool. Refuel carefully to avoid spilling fuel. Do not fill above the fuel strainer

shoulder. fter refueling, tighten the fuel tank cap securely.

Never refuel the engine inside a building where gasoline fumes may reach flames or

sparks. Keep gasoline away from appliance pilot lights, barbecues, electric appliances,

power tools, etc.

Spilled fuel is not only a fire hazard, it causes environmental damage. Wipe up spills

immediately.

M XIMUM FUEL LEVEL

M INTEN NCE

15

Fuel

can

damage

paint

and

plastic.

Be

careful

not

to

spill

fuel

w en

filling

your

fuel

tank.

Damage

caused

by

spilled

fuel

is

not

covered

under warranty.

FUEL RECOMMENDATIONS

Use unleaded gasoline wit a pump octane rating of 86 or ig er.

These engines are certified to operate on unleaded gasoline. Unleaded gasoline produces

fewer engine and spark plug deposits and extends exhaust system life.

Never use stale or contaminated gasoline or an oil/gasoline mixture. void getting dirt or

water in the fuel tank.

Occasionally you may hear a light ‘‘spark knock’’ or ‘‘pinging’’ (metallic rapping noise) while

operating under heavy loads. This is no cause for concern.

If spark knock or pinging occurs at a steady engine speed, under normal load, change

brands of gasoline. If spark knock or pinging persists, see an authorized servicing dealer.

Running t e engine wit persistent spark knock or pinging can cause engine

damage.

Running t e engine wit persistent spark knock or pinging is considered misuse,

and t e Distributor’s Limited Warranty does not cover parts damaged by misuse.

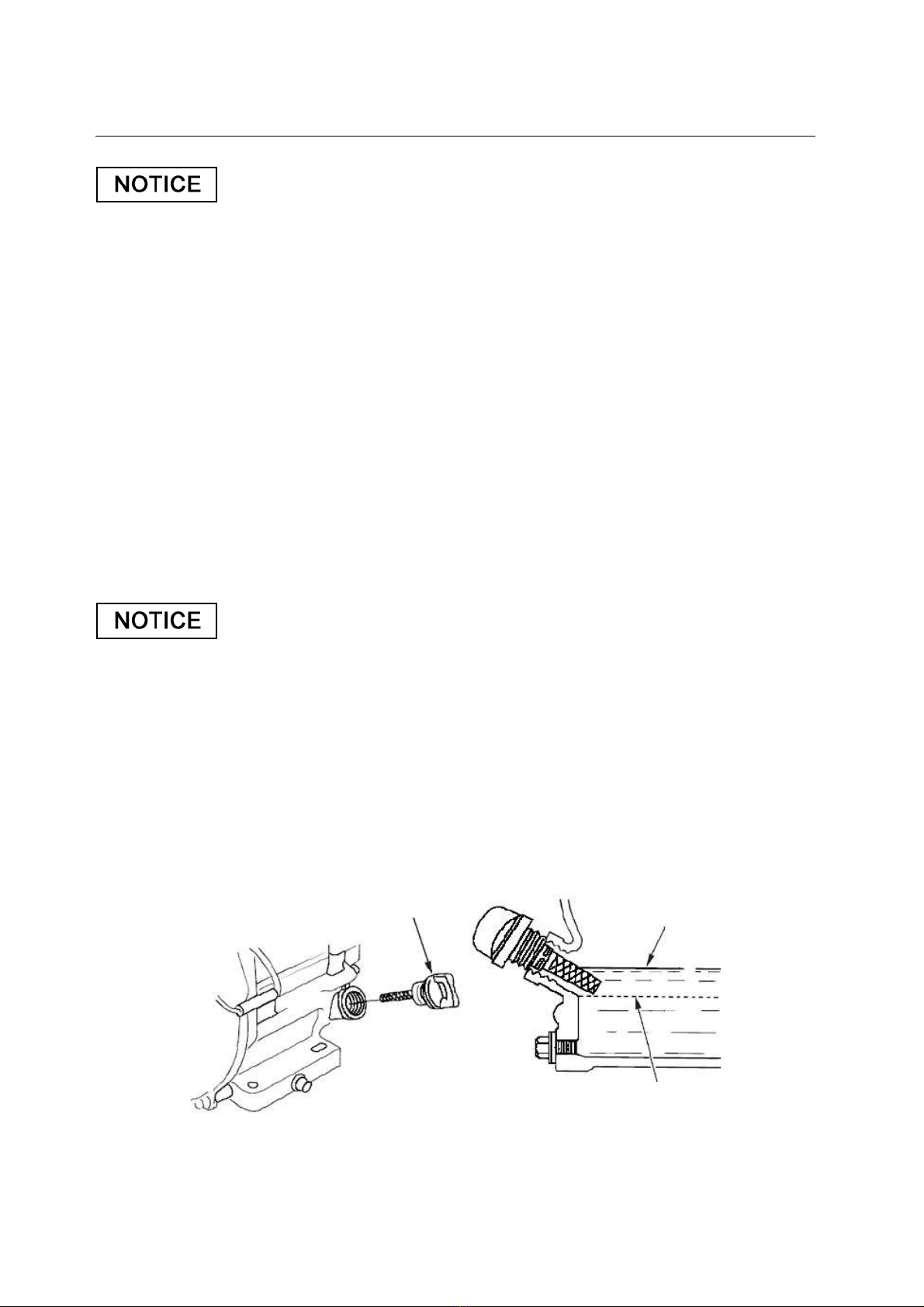

ENGINE OIL LEVEL CHECK

Check the engine oil level with the engine stopped and in a level position.

1. Remove the filler cap/dipstick and wipe it clean.

FILLER C P/DIPSTICK UPPER LIMIT

LOWER LIMIT

M INTEN NCE

16

2. Insert and remove the dipstick without screwing it into the filler neck. Check the oil level

shown on the dipstick.

3. If the oil level is low, fill to the edge of the oil filler hole with the recommended oil.

4. Screw in the filler cap/dipstick securely.

Running

the

engine

with

a

low

oil

level

can

cause

engine

damage.

The Oil lert system (applicable engine types) will automatically stop the engine before the

oil level falls below safe limit. However, to avoid the inconvenience of an unexpected

shutdown, always check the engine oil level before startup.

ENGINE OIL CHANGE

Drain the used oil while the engine is warm. Warm oil drains quickly and completely.

1. Place a suitable container below the engine to catch the used oil, and then remove the

filler cap/dipstick and the drain plug.

2. llow the used oil to drain completely, and then reinstall the drain plug, and tighten it

securely.

Please dispose of used motor oil in a manner that is compatible with the environment.

We suggest you take used oil in a sealed container to your local recycling center or

service station for reclamation. Do not throw it in the trash; pour it on the ground; or

down a drain.

3. With the engine in a level position, fill to the outer edge of the oil filler hole with the

recommended oil.

Engine oil capacities:

120F: 0.63 US qt ( 0. 6 L)

160/200F(D), 160/200F(D)-B, 160/200F(D)-C: 0.63 US qt ( 0.60 L)

240/270/340/390F(D), 240/270F(D)-B: 1.2 US qt ( 1.1 L)

240/270 F(D)-C, 340/390F(D)-D: 1.2 US qt ( 1.1 L)

Running the engine with a low oil level can cause engine damage.

The Oil lert system (applicable engine types) will automatically stop the engine before

the oil level falls below the safe limit.

However, to avoid the inconvenience of an unexpected shutdown, fill to the upper limit,

and check the oil level regularly.

M INTEN NCE

17

4. Screw in the filler cap/dipstick securely.

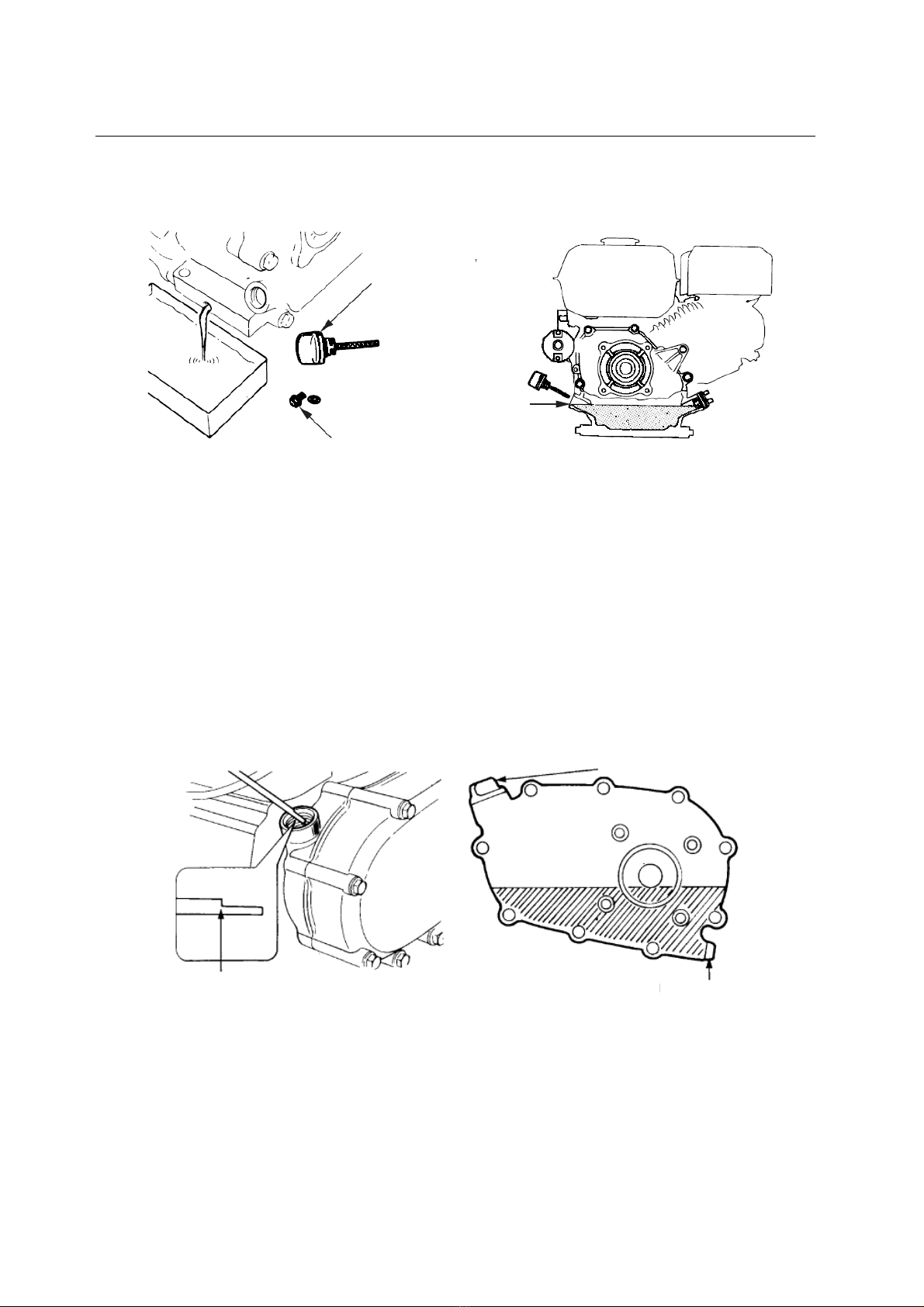

REDUCTION GEAR OIL (Only on equipped model)

<1/2 reduction with automatic centrifugal clutch>

1.

Remove

the

oil

filler

cap

and

wipe

the

dipstick

clean.

2.

Insert

the

dipstick

into

the

filler

neck

but

do

not

screw

it

in.

3.

If

the

level

is

low,

fill

to

the

upper

level

mark

with

the

same

oil

recommended

for

the

engine.

Oil capacity of 160/200/240/270F(D)-B: 500 cc

SERVICING YOUR ENGINE

ENGINE OIL RECOMMENDATIONS

Oil is a major factor affecting performance and service life. Use 4-stroke automotive

detergent oil.

FILLER C P/

DIPSTICK

DR IN BOLT

OIL LEVEL

DIPSTICK/FILLER

C P

UPPER LEVEL DR IN BOLT

M INTEN NCE

18

S E 10W-30 is recommended for general use. Other viscosities shown in the chart may

be used when the average temperature in your area is within the recommended range.

S E Viscosity Grades

MBIENT TEMPER TURE

The S E oil viscosity and service classification are in the PI label on the oil container. We

recommend that you use PI SERVICE Category SE or SF oil.

AIR FILTER INSPECTION

Remove the air cleaner cover and inspect the filter. Clean or replace dirty filter elements.

lways replace damaged filter elements. If equipped with an oil-bath air cleaner, also

check the oil level.

AIR

CLEANER

SERVICE

dirty air filter will restrict air flow to the carburetor, reducing engine performance.

P PER

FILTER

ELEMENT

FO M

FILTER

ELEMENT

FILTER

M INTEN NCE

19

If you operate the engine in very dusty areas, clean the air filter more often than specified

in the M INTEN NCE SCHEDULE.

Operating the engine without an air filter, or with a damaged air filter, will allow dirt to enter

the engine, causing rapid engine wear. This type of damage is not covered by the

Distributor’s Limited Warranty.

Dual-Filter-Element Types

1. Remove the wing nut from the air cleaner

cover,

and remove the air cleaner cover.

2.

Remove

the

wing

nut

from

the

air

filter,

and

remove

the

filter.

3.

Remove

the

foam

filter

from

the

paper

filter.

4.

Inspect

both

air

filter

elements,

and

replace

them

if

they

are

damaged.

lways

replace

the

paper

air

filter

element

at

the

scheduled

interval.

5.

Clean

the

air

filter

elements

if

they

are

to

be

reused.

Paper air filter element: Tap the filter element several times on a hard surface to

remove dirt, or blow compressed air [not exceeding 30 psi (207 kPa)] through the filter

element from the inside. Never try to brush off dirt; brushing will force dirt into the

fibers.

Foam air filter element: Clean in warm soapy water, rinse, and allow drying thoroughly.

Or clean in nonflammable solvent and allow drying. Dip the filter element in clean

engine oil, and then squeeze out all excess oil. The engine will smoke when started if

too much oil is left in the foam.

6.

Wipe

dirt

from

the

inside

of

the

air

cleaner

base

and

cover,

using

a

moist

rag.

Be

careful to prevent dirt from entering the air duct that leads to the carburetor.

7. Place the foam air filter element over the paper element, and reinstall the assembled

air filter. Be sure the gasket is in place beneath the air filter. Tighten the air filter wing

nut securely.

8.

Install

the

air

cleaner

cover,

and

tighten

the

cover

wing

nut

securely.

P PER

FILTER

ELEMENT

IR

CLE NER

COVER

FO M

FILTER

ELEMENT

G SKET

This manual suits for next models

7

Table of contents

Other PTM Engines Engine manuals

Popular Engine manuals by other brands

BECKER-Antriebe

BECKER-Antriebe P3/30C PS(+)SMI Assembly and operating instructions

Kohler

Kohler Courage XT-6 Service manual

Master

Master Apro instructions

Lutz

Lutz UNIVERSALMOTOR MA II Translation of the original instructions

Tecumseh

Tecumseh AH520 - Handbook

Kohler

Kohler Command PRO CH270 owner's manual